How to Laminate Curved Wood: Expert Tips & Tricks

To laminate curved wood, use thin veneer layers and apply heat and pressure. A vacuum bag or form can help maintain the curve while laminating.

Laminating curved wood adds strength and aesthetic appeal to projects. This technique is widely used in furniture, cabinetry, and boat building. Proper preparation and the right materials are essential for success. Begin by selecting high-quality veneer that can bend without breaking.

Use adhesives designed for wood laminating to ensure a strong bond. Heat and pressure are critical in this process, allowing the layers to conform to the desired shape. Understanding these steps can lead to impressive results in your woodworking projects. Curved laminated wood not only enhances durability but also showcases beautiful grain patterns.

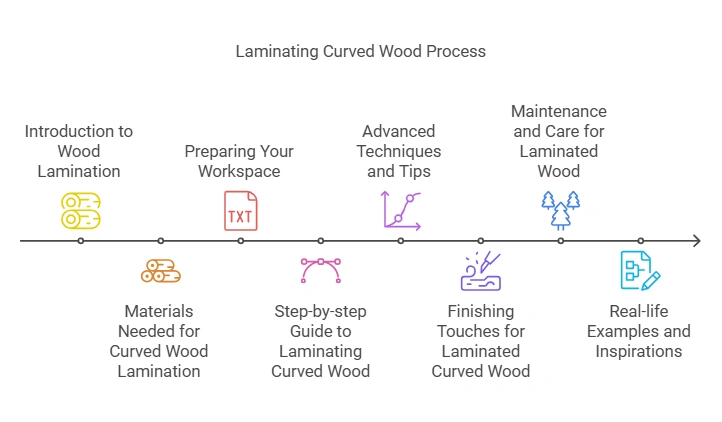

Introduction To Wood Lamination

Laminating curved wood is an exciting way to create beautiful shapes. Lamination involves layering thin sheets of wood. This process allows for flexibility and strength.

Curved wood has a unique appeal. It can be used for furniture, decor, and architectural elements. Choosing curved wood adds style and elegance to any project.

Benefits of using laminated curved wood include:

- Increased strength: Laminated wood is less likely to warp.

- Design flexibility: Easily shape wood into various curves.

- Aesthetic appeal: Offers a smooth and polished finish.

Materials Needed For Curved Wood Lamination

Choosing the right wood is essential for curved wood lamination. Use flexible woods like bent laminates or thin veneers. These types bend well without breaking. Avoid hardwoods that do not bend easily.

For the adhesives, select a strong glue like PVA or epoxy. These glues provide a solid bond for laminated layers. Ensure the adhesive is suitable for wood. It helps prevent future damage.

Gather essential tools such as a clamp, saw, and sanding block. A clamp keeps the layers in place while drying. A saw helps cut the wood to desired shapes. Sanding blocks smooth the edges for a neat finish.

Preparing Your Workspace

Preparing your workspace is very important for laminating curved wood. Start by gathering protective gear. Use safety glasses to protect your eyes. A dust mask will help keep you safe from fumes.

Wear gloves to protect your hands from chemicals. Hearing protection can be useful if you use loud tools. Make sure your workspace is clean and organized.

Clear away any clutter to avoid accidents. Good lighting helps you see your work clearly. Always keep a first aid kit nearby, just in case.

By following these steps, you ensure a safe and effective workspace for your project.

Step-by-step Guide To Laminating Curved Wood

Start by cutting the wood into the desired shape. Use a bandsaw or a jigsaw for curves. Sand the edges to make them smooth. This helps the adhesive bond well.

Next, apply a thin layer of adhesive evenly on both surfaces. Use a brush or a roller for even distribution. Ensure the adhesive covers all areas to prevent gaps.

After applying the adhesive, clamp the wood pieces together tightly. Use clamps or a band clamp to hold the shape. Allow the wood to cure for the time specified by the adhesive manufacturer.

Advanced Techniques And Tips

Working with curved wood can be tricky. Use steam to soften the wood. This makes it easier to shape. Apply laminate carefully to avoid bubbles. Start from one end and work your way across.

For complex curves, use templates. Cut a piece of cardboard to match the curve. This helps in cutting the laminate accurately. Always measure twice before cutting.

Avoid common mistakes like rushing the process. Take your time to ensure a good fit. Check the edges for any gaps or misalignments. Using a roller can help smooth out any imperfections.

Finishing Touches For Laminated Curved Wood

Start by sanding the laminated curved wood. Use fine-grit sandpaper for a smooth finish. Sand along the grain to avoid scratches. Pay special attention to edges and corners.

Once sanding is complete, apply finishes to enhance the wood. Choose a suitable wood stain or sealant for protection. Use a brush or cloth to spread the finish evenly. Allow time for drying between coats. Multiple coats can increase durability.

Ensure the final layer is smooth and shiny. This adds to the beauty of the wood. Regular maintenance keeps the finish looking fresh.

Maintenance And Care For Laminated Wood

To keep laminated wood looking great, regular cleaning is essential. Use a soft cloth or sponge. Avoid harsh chemicals that can damage the surface. A mix of water and mild soap works well for cleaning.

For protection, always use coasters under drinks. Place mats under hot items to prevent burns. Avoid direct sunlight to reduce fading over time.

In case of damages, small scratches can be fixed easily. Use a wood repair marker that matches the color. For deeper scratches, consider wood filler for a smooth finish.

Always let repairs dry completely before using the surface again. This ensures lasting results and keeps your laminated wood looking its best.

Real-life Examples And Inspirations

Explore some amazing projects that use laminated curved wood. These examples can inspire your creativity.

| Project | Description |

|---|---|

| Curved Shelves | Stylish shelves that add elegance to any room. |

| Wooden Chairs | Comfortable chairs with a unique curved design. |

| Artistic Tables | Tables that showcase beautiful, flowing lines. |

| Decorative Frames | Frames that highlight photos with a soft touch. |

Try creating your own laminated curves. Use different wood types for unique effects. Experiment with colors and finishes. Let your imagination run wild!

Frequently Asked Questions

How Can I Laminate Curved Wood Effectively?

To laminate curved wood effectively, start by selecting the right veneer. Use thin layers for better flexibility. Apply an even layer of adhesive, and then carefully shape the wood around a form. Clamp it securely and allow adequate drying time.

This ensures a smooth, even finish.

What Materials Do I Need For Laminating Wood?

You will need wood veneer, adhesive, clamps, and a form. A roller or brush helps apply adhesive evenly. Select high-quality clamps to hold the wood in place. Additionally, having a utility knife for trimming edges can be beneficial. This setup ensures a successful laminating process.

Can I Laminate Any Type Of Wood?

Most woods can be laminated, but softer woods work best. Hardwoods may require more pressure and adhesive. Ensure the wood is clean and free of imperfections. Thin sheets of veneer also make the process easier. Always consider the final application when choosing your wood type.

How Long Does It Take To Laminate Wood?

The laminating process can take several hours to a day. Drying time depends on the adhesive used and environmental conditions. Typically, allow at least 24 hours for optimal results. Always refer to the manufacturer’s instructions for specific drying times. Patience is key for a quality finish.

Conclusion

Laminating curved wood opens up exciting possibilities for your projects. With the right techniques and materials, you can achieve beautiful, durable results. Remember to take your time and follow each step carefully. Embrace your creativity, and enjoy the process of transforming wood into stunning, curved designs.

Happy laminating!