Is MDF Strong? Unveiling the Truth About Its Durability

MDF (Medium Density Fiberboard) is strong, but not as strong as solid wood or plywood. It’s suitable for many indoor applications.

MDF is a popular choice in furniture and cabinet making. Made from wood fibers and resin, it offers a smooth surface ideal for painting. Its consistent density and lack of grain make cutting and shaping easy. MDF is cost-effective compared to solid wood and plywood.

However, it is susceptible to moisture and not recommended for outdoor use. It is also heavier and can sag under heavy loads. MDF works well for shelves, doors, and decorative projects. For optimal results, seal the edges to prevent moisture absorption. Overall, MDF is a versatile and economical option for many indoor projects.

The Composition Of MDF

Understanding the composition of MDF helps us know its strength. MDF stands for Medium Density Fiberboard. It is a popular material in furniture and construction.

Materials Used In MDF

MDF is made from wood fibers, wax, and resin. These materials are combined to form a strong board.

| Material | Purpose |

|---|---|

| Wood Fibers | Provide the main structure |

| Wax | Offers moisture resistance |

| Resin | Binds the fibers together |

Manufacturing Process

The manufacturing process of MDF involves several steps:

- Wood fibers are collected and refined.

- Wax and resin are added to the fibers.

- The mixture is formed into a sheet.

- The sheet is compressed and heated.

- The board is cooled and cut to size.

This process ensures that MDF is dense and uniform. The result is a material that is strong and reliable for various uses.

Comparing Mdf With Other Wood Products

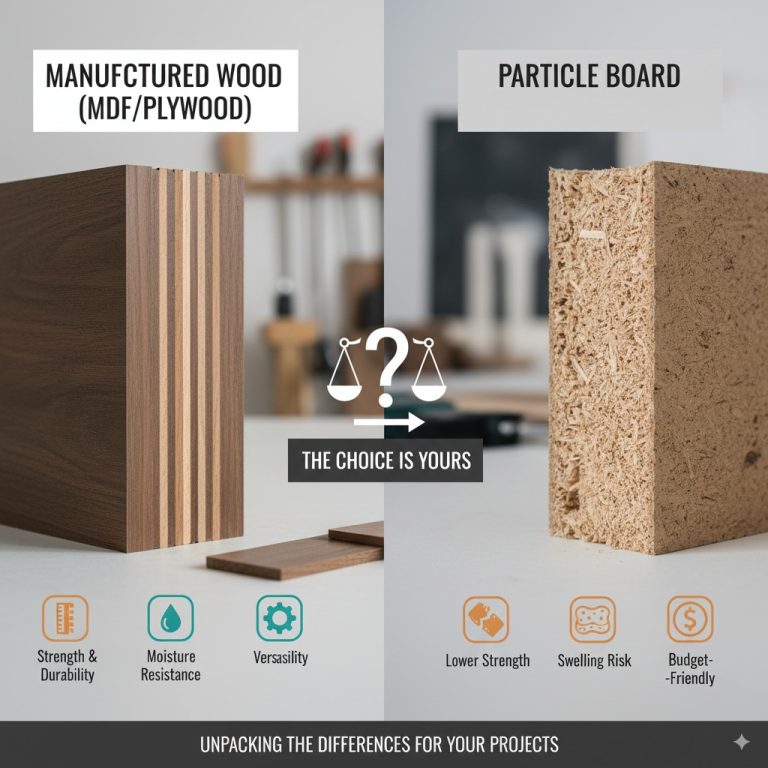

MDF (Medium-Density Fiberboard) is a popular choice for many wood projects. To understand its strength, compare it with other wood products like plywood and solid wood.

MDF Vs. Plywood

Plywood is made by gluing thin layers of wood veneers together. MDF is made from wood fibers glued under heat and pressure. Both have their strengths and weaknesses.

| Feature | MDF | Plywood |

|---|---|---|

| Strength | Medium | High |

| Weight | Heavier | Lighter |

| Cost | Less expensive | More expensive |

| Moisture Resistance | Low | High |

- Plywood is stronger and more durable.

- MDF is cheaper and smoother.

MDF Vs. Solid Wood

Solid wood is natural and strong. MDF is engineered and uniform. Each has unique qualities.

| Feature | MDF | Solid Wood |

|---|---|---|

| Strength | Medium | Very High |

| Appearance | Uniform | Natural grain |

| Cost | Less expensive | More expensive |

| Workability | Easy to cut | Harder to cut |

- Solid wood is strong and beautiful.

- MDF is smooth and easy to paint.

MDF offers a smooth surface, making it great for painting. Solid wood provides unmatched strength and natural beauty.

Physical Properties Of MDF

Medium Density Fiberboard (MDF) is a popular material in woodworking. Understanding its physical properties is crucial for making informed decisions. MDF is known for its uniformity and smooth surface.

Density And Strength

MDF has a high density compared to other wood products. It typically ranges between 600 to 800 kg/m³. This high density gives MDF its strength.

Strength is an essential factor for any material. MDF can support considerable weight without bending. It is less likely to warp or crack under pressure.

| Property | Value |

|---|---|

| Density | 600-800 kg/m³ |

| Flexural Strength | 30-50 MPa |

These values make MDF suitable for furniture and cabinetry. It is also used in flooring and shelving. The high density provides a smooth surface for painting and veneering.

Moisture Resistance

MDF is not naturally moisture-resistant. Moisture can cause swelling and damage to the material. Special types of MDF are treated to be moisture-resistant.

- Standard MDF: Not moisture-resistant

- Moisture-Resistant MDF: Treated with resin or wax

Moisture-resistant MDF is suitable for bathrooms and kitchens. It offers better performance in humid conditions. Always check the type of MDF you are using for specific projects.

Proper sealing and finishing can improve MDF’s moisture resistance. Applying a sealant or paint can protect the material. This step is crucial to extend the lifespan of MDF.

The Durability Factor

Understanding the durability of MDF (Medium Density Fiberboard) is essential. MDF is a popular material in many households. Its strength and durability often come into question. This section will delve into the durability aspects of MDF.

Life Expectancy Of MDF

MDF has a long life expectancy. If well-maintained, it can last for many years. It’s commonly used in furniture, cabinetry, and shelving. These items often remain in good condition for a decade or more.

Several factors affect MDF’s lifespan. Proper sealing and finishing can extend its durability. Keeping it away from moisture also helps. Placing MDF in dry areas ensures it stays strong for longer periods.

Wear And Tear Resistance

MDF is resistant to wear and tear. It’s more resistant than particleboard. MDF does not easily chip or crack. This makes it suitable for high-traffic areas.

Even though MDF is durable, it can still get damaged. Surface scratches and dents can occur. Using protective coatings can minimize this. Regular maintenance can also help preserve its appearance.

| Factor | Impact on Durability |

|---|---|

| Moisture Exposure | Reduces lifespan and strength |

| Proper Sealing | Increases durability |

| Heavy Use | May lead to surface damage |

| Regular Maintenance | Preserves appearance and strength |

- High Density: MDF has a high density, making it durable.

- Consistent Structure: Its uniform structure enhances strength.

- Easy Maintenance: Simple maintenance practices can extend its life.

Applications Of MDF

MDF, or Medium Density Fiberboard, is a versatile material used in various applications. It is known for its smooth surface and uniform density. This makes it a popular choice in several industries.

Ideal Uses For MDF

MDF is perfect for furniture making. Its smooth surface allows for easy painting and finishing. You can use MDF for cabinets, shelves, and drawers.

In the construction industry, MDF is used for interior paneling. It is also ideal for molding and trim work. This is because MDF can be cut into intricate shapes.

Crafts and DIY projects also benefit from MDF. Its uniform density ensures clean cuts and precise shapes. This makes it an excellent material for hobbyists and artists.

Here is a table showing common uses for MDF:

| Application | Benefit |

|---|---|

| Furniture | Easy to paint and finish |

| Interior Paneling | Smooth surface |

| Molding and Trim | Can be cut into intricate shapes |

| Crafts and DIY | Uniform density |

Limitations In Use

While MDF is versatile, it has some limitations. MDF is not water-resistant. Moisture can cause it to swell and warp.

MDF is also heavy. This can make it difficult to handle and transport. It is not as strong as plywood. So, it is not ideal for structural applications.

MDF produces fine dust when cut. This can be a health hazard. Always use proper safety equipment when working with MDF.

Here are some limitations of MDF:

- Not water-resistant

- Heavy and difficult to transport

- Not suitable for structural use

- Produces fine dust

Improving Mdf’s Strength

Medium Density Fiberboard (MDF) is a versatile material. It is used in many DIY and professional projects. But, it lacks the natural strength of solid wood. To make it stronger, you can use several techniques and finishes. These methods will enhance the durability of MDF.

Reinforcement Techniques

Reinforcing MDF is essential for heavy-duty applications. Below are some effective techniques:

- Edge Banding: Apply edge banding to protect the edges from chipping. It also adds strength to the board.

- Adding Braces: Use wooden braces on the corners. This prevents the MDF from bending.

- Using Screws and Dowels: Screws and dowels increase the holding power. They make the joints more robust.

- Metal Inserts: Place metal inserts in high-stress areas. This boosts the load-bearing capacity.

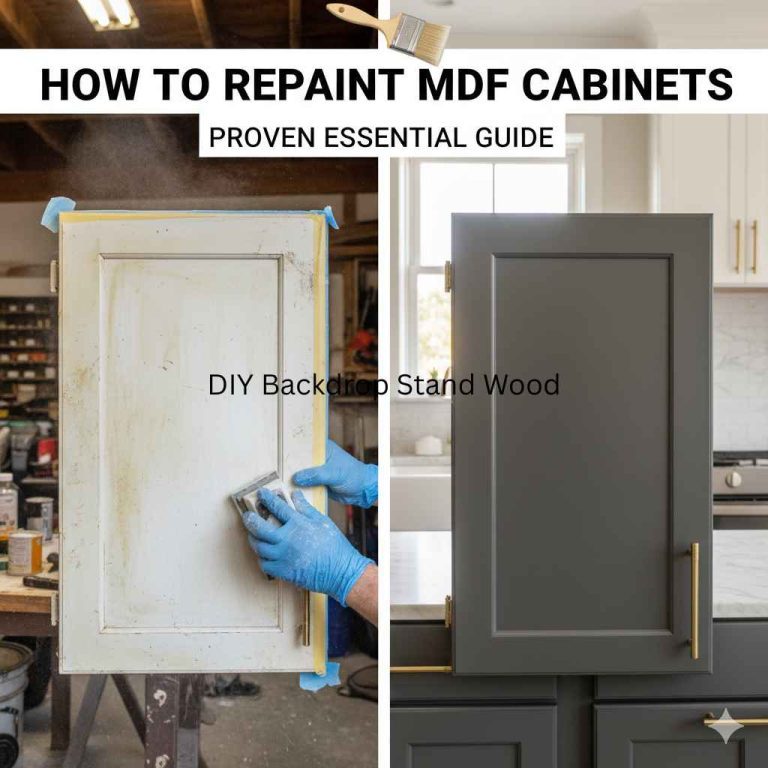

Protective Finishes

Applying protective finishes can significantly increase MDF’s lifespan. Here are some finishes you can use:

- Sealants: Sealants prevent moisture from seeping into the MDF. They keep the board from swelling and warping.

- Paint: High-quality paint adds a layer of protection. It also gives a smooth and attractive finish.

- Varnish: Varnish creates a hard, durable surface. It protects against scratches and dents.

- Laminates: Laminate sheets add a tough outer layer. They are resistant to water and wear.

Incorporating these techniques will improve MDF’s strength and durability. The choice of method depends on your specific needs and project requirements.

Maintenance And Care

Maintaining and caring for MDF (Medium-Density Fiberboard) is essential to extend its lifespan and preserve its appearance. Proper cleaning practices and timely repair and restoration can keep your MDF strong and looking new. Follow these guidelines to ensure your MDF remains in top condition.

Cleaning Practices

Regular cleaning is vital to keep MDF looking its best. Use a soft, damp cloth to wipe away dust and dirt. Avoid soaking the MDF, as excessive moisture can damage the material.

For tough stains, use a mild soap solution. Apply it gently with a sponge. Ensure the surface is dried completely after cleaning to prevent moisture damage.

Never use harsh chemicals or abrasive cleaners. These can scratch or weaken the MDF. Stick to gentle, non-abrasive solutions for the best results.

Repair And Restoration

Minor damages to MDF can be easily fixed. For small scratches or dents, use wood filler or putty. Apply it smoothly and let it dry before sanding it down to a smooth finish.

For larger damages, such as cracks or deep gouges, consider using a stronger wood filler. After applying the filler, sand the area and repaint or re-laminate if necessary.

If the MDF gets water damaged, act quickly. Dry the area thoroughly and assess the damage. Replace any sections that are severely swollen or compromised.

Regular inspection and timely repair can greatly extend the life of your MDF furniture or fixtures. Keeping it in good condition will ensure it remains strong and functional for years.

Environmental Considerations

Medium-density fiberboard (MDF) is a popular choice for many wood projects. It is important to understand its environmental impact. This section dives into the environmental considerations of MDF.

Sustainability Of Mdf

MDF is made from wood fibers that are often by-products of sawmills. This means less waste from wood processing. Using wood waste helps in reducing the need for fresh timber. MDF production can help in saving forests. It allows for efficient use of resources.

Additionally, some manufacturers source wood from sustainably managed forests. These forests follow strict guidelines. They ensure that tree cutting does not harm the ecosystem. This practice makes MDF a more sustainable option.

Recycling And Disposal

Recycling MDF can be challenging. The resins and adhesives used in MDF complicate the process. MDF can’t be recycled in the same way as natural wood. Special facilities are needed for its recycling.

For disposal, burning MDF is not recommended. Burning releases harmful chemicals into the air. Instead, it is better to take MDF to special disposal facilities. These facilities handle it in an environmentally safe manner.

Below is a table that shows the key environmental considerations for MDF:

| Aspect | Details |

|---|---|

| Material Source | Wood fibers from sawmills |

| Sustainability | Often sourced from managed forests |

| Recycling | Requires special facilities |

| Disposal | Should not be burned; special disposal needed |

When choosing MDF, keep these environmental factors in mind. This will help in making a more informed and eco-friendly decision.

Frequently Asked Questions

Does Mdf Break Easily?

MDF can break under heavy pressure or impact. It’s less durable than solid wood but suitable for light to moderate use.

Can Mdf Hold A Lot Of Weight?

Yes, MDF can hold a lot of weight if properly supported. Use additional reinforcements to increase its load-bearing capacity.

Is Mdf Stronger Than Wood?

MDF is not stronger than solid wood. Wood offers more strength and durability. MDF is denser and smoother, ideal for certain applications.

Does Mdf Crack Easily?

MDF does not crack easily. It is dense, stable, and resistant to warping. Proper handling prevents damage.

Conclusion

MDF offers a balance of strength and affordability. It’s versatile for various projects and easy to work with. Although not as strong as solid wood, it performs well for many applications. Consider MDF for your next project if you need cost-effective and durable material.

Its benefits make it a popular choice.