Before applying paint, it is essential to thoroughly clean the metal surface with a metal cleaner to ensure proper adhesion and a smooth finish. By using a metal cleaner, you can remove dirt, grease, and other contaminants that may prevent the paint from adhering properly.

This step is crucial for achieving a professional-looking paint job that will last for a long time. When preparing to paint metal surfaces, using a metal cleaner before applying paint is a critical step that should not be overlooked. The cleaner will help remove any dirt, grease, or residue that could interfere with the paint’s adhesion, resulting in a smooth and long-lasting finish.

In the following paragraphs, we will explore the importance of using a metal cleaner, the types of cleaners available, and how to properly clean metal surfaces before painting.

Credit: vpracingfuels.com

The Importance Of Metal Cleaning

Metal cleaning before painting is crucial for achieving a successful and long-lasting finish. By removing contaminants and creating a clean surface, metal cleaning plays a vital role in the paint adhesion process.

Preventing Paint Failure

- Effective metal cleaning prevents paint failure due to poor adhesion.

- Contaminants like oil, grease, and rust can interfere with paint bonding.

- Proper cleaning ensures a smooth surface for the paint to adhere to.

Improving Adhesion

- Thorough metal cleaning improves paint adhesion and durability.

- Clean metal surfaces allow the paint to bond securely for long-lasting results.

- Enhanced adhesion reduces the risk of peeling, flaking, or chipping paint.

Types Of Metal Cleaners

Before painting metal surfaces, it is crucial to use the right type of metal cleaner to remove any dirt, grease, or rust. There are various types of metal cleaners available, including solvent-based cleaners, acid-based cleaners, and alkaline cleaners. It’s important to select the appropriate cleaner depending on the type of metal and the level of grime present.

Solvent-based Cleaners

Solvent-based cleaners are effective for removing oil and grease from metal surfaces.

Alkaline Cleaners

Alkaline cleaners are ideal for removing tough dirt and grime from metal surfaces.

Best Practices For Metal Cleaning

Metal surfaces must be properly cleaned before applying paint to ensure the best adhesion and longevity of the finish. Following the best practices for metal cleaning is essential to achieve a smooth and durable paint application. In this section, we will explore the key considerations for effectively preparing metal surfaces for painting.

Surface Preparation

Proper surface preparation is crucial for the success of any metal painting project. Before applying any cleaner or paint, it’s important to ensure that the metal surface is free from rust, corrosion, oil, grease, and any other contaminants. Start by thoroughly cleaning the surface using a suitable metal cleaner to remove all traces of dirt and grime.

Additionally, consider using a solvent or degreaser to eliminate any oil or grease residue. After cleaning, the surface should be thoroughly rinsed with clean water and dried completely using a lint-free cloth.

Proper Application Techniques

When applying metal cleaner before paint, it’s important to follow the manufacturer’s instructions for the specific product being used. Ensure that the cleaner is applied evenly and allowed to dwell for the recommended time to effectively loosen and remove any contaminants.

Using a soft-bristled brush or a sponge can aid in agitating the cleaner to remove stubborn stains or residues. After the cleaner has had sufficient time to work, thoroughly rinse the surface with clean water to remove all traces of the cleaner, and then pat the surface dry with a clean cloth to prevent the formation of water spots.

Credit: dicorproducts.com

Understanding Metal Pre-treatment

Metal pre-treatment involves using a metal cleaner before applying paint to ensure optimal adhesion. This process removes contaminants and prepares the surface for a lasting finish. Proper pre-treatment is essential for enhancing the durability and appearance of the painted metal surface.

Metal pre-treatment plays a crucial role in ensuring the longevity and durability of painted metal surfaces. Before applying a fresh coat of paint, it is essential to properly clean and prepare the metal to optimize adhesion and prevent any potential issues that may arise over time. One of the most commonly used methods for metal pre-treatment is conversion coatings. Another popular pre-treatment is phosphating. Let’s dive deeper into these two techniques and understand their significance in the metal pre-treatment process.

Conversion Coatings

Conversion coatings are chemical surface treatments that create a protective layer on the metal surface. These coatings convert the metal substrate into a more corrosion-resistant and paint-friendly surface. By immersing the metal in a solution containing specific chemicals, a chemical reaction takes place on the surface, which forms a thin film or layer. This layer enhances adhesion of the subsequent paint layer and acts as a barrier against water, chemicals, and other harmful substances.

The most commonly used conversion coatings include chromate, phosphate, and oxalate coatings. Chromate conversion coatings are widely used for aluminum surfaces due to their excellent corrosion resistance properties. On the other hand, phosphate conversion coatings are preferred for iron and steel surfaces, offering enhanced adhesion, corrosion resistance, and improved paint bonding.

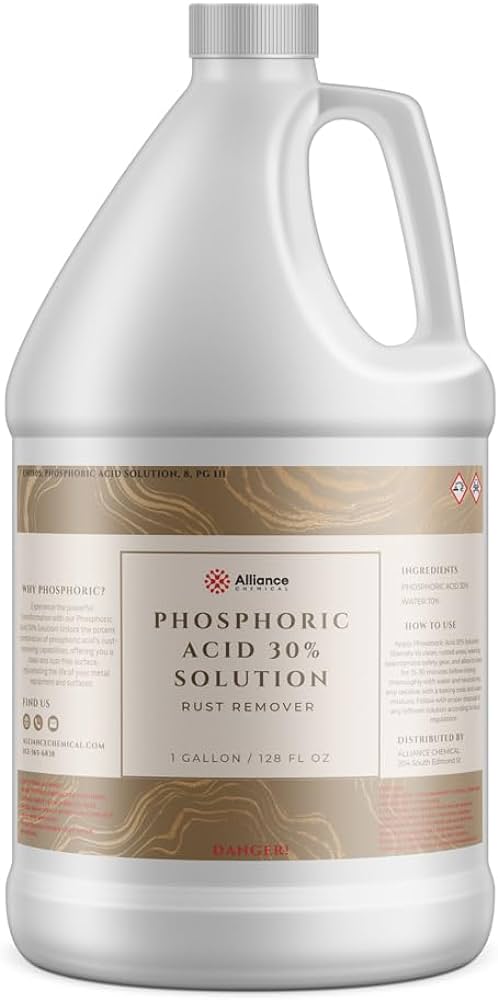

Phosphating

Phosphating is another popular metal pre-treatment process that involves the formation of a phosphate coating on the metal surface. This coating provides an ideal surface for paint adhesion and improves corrosion resistance. Phosphating is achieved by immersing the metal substrate in a phosphoric acid-based solution that also contains specific additives. The acid reacts with the metal surface, resulting in the formation of a closely adhering phosphate coating.

A commonly used phosphating process is zinc phosphate conversion coating, which is widely applied to ferrous surfaces. This coating not only increases paint adhesion but also provides excellent corrosion resistance. Additionally, zinc phosphate coatings act as a sacrificial barrier against rust formation, preventing the spread of corrosion under the paint layer.

In conclusion, understanding metal pre-treatment is crucial for achieving long-lasting and high-quality paint finishes on metal surfaces. Conversion coatings and phosphating are two effective methods used in this process. Conversion coatings create a protective layer on the metal surface, enhancing adhesion and providing corrosion resistance. Phosphating, on the other hand, forms a phosphate coating that improves paint adhesion and offers superior corrosion protection. By implementing these pre-treatment techniques, you can ensure optimal paint performance and extend the lifespan of your painted metal surfaces.

Choosing The Right Metal Cleaner

When it comes to choosing the right metal cleaner before paint, the first step is to consider the type of metal you will be working with. Different metals require different cleaning solutions, as each metal has its own unique properties and characteristics that can affect the adhesion and durability of the paint.

For example, steel and iron are prone to rusting, while aluminum can become oxidized. Copper, on the other hand, can develop a patina over time. Therefore, it is crucial to choose a metal cleaner that is specifically formulated to address the specific needs of the metal you are working with.

Environmental Impact

Another important factor to consider when choosing a metal cleaner is its environmental impact. Many traditional metal cleaners contain harsh chemicals, such as acids and solvents, that can be harmful to both the environment and the person using them.

Choosing an eco-friendly metal cleaner not only helps reduce the negative impact on the environment but also ensures the safety of the user. Look for metal cleaners that are biodegradable, non-toxic, and free from harmful fumes. These environmentally-friendly options not only clean effectively but also promote a healthier and greener work environment.

Moreover, if you are working on a project that requires the removal of lead-based paint, it is essential to choose a metal cleaner that is specifically designed for lead paint removal. This will help ensure the proper and safe removal of lead-containing substances, minimizing the risk of contamination and potential health hazards.

Frequently Asked Questions For Metal Cleaner Before Paint

What Is The Purpose Of Using A Metal Cleaner Before Painting?

Using a metal cleaner before painting helps remove dirt, grease, rust, and other contaminants from the surface of the metal. This ensures proper adhesion of the paint and helps prevent premature paint failure.

How Does A Metal Cleaner Work?

A metal cleaner typically contains solvents or detergents that break down and dissolve dirt, grease, and rust from the metal surface. It also promotes the removal of any oxidation or corrosion, leaving the surface clean and ready for painting.

Can I Skip Using A Metal Cleaner And Still Get Good Paint Adhesion?

While it is possible to skip using a metal cleaner, doing so may result in poor paint adhesion and premature paint failure. Metal cleaners help remove contaminants that can interfere with the paint’s ability to bond to the metal surface, ensuring a longer-lasting paint job.

What Type Of Metal Cleaner Should I Use?

The type of metal cleaner you should use depends on the specific needs of your project. There are various options available, including solvent-based cleaners, acidic cleaners, and water-based cleaners. Consult with a paint or hardware expert to determine the best cleaner for your particular situation.

Conclusion

Using a metal cleaner before painting is essential for achieving a smooth and flawless finish. By removing any dirt, grease, or rust, the cleaner primes the surface for a durable coat of paint. With the right product and technique, you can ensure a professional and long-lasting result for your metal surfaces.