The Strong-Drive SDWC Truss screw is a versatile fastener used for securing trusses and rafters to top plates while also providing a stud-to-bottom plate connection. With a mushroom-shaped head and a full-threaded shank that engages the entire length of the fastener, the SDWC Truss screw provides a secure and reliable connection.

Additionally, it comes in various types like Wood Coarse SAE, Wood Torx Coarse, Wood Hex Coarse, and Wood Torx SAE, with different count options. A quick search on Google yields several suppliers of these screws, including Lowe’s, Home Depot, and Amazon.

It is important to determine which type and count of SDWC Truss screws are best suited for your construction needs.

What Are Rafter Screws?

Rafter screws are a type of screw designed for use in wood framing, particularly for fastening rafters to the top plates. They have a full-threaded shank that engages the entire length of the fastener, providing a secure connection and are a popular alternative to traditional hurricane clips.

Definition of Rafter Screws

Rafter screws are self-tapping screws used in the construction of roofs to connect rafters to the top plate. These screws have a special design that allows them to easily penetrate wood without causing any splitting. Rafter screws are available in various sizes, thread types, and lengths to suit different applications and building codes.

How Rafter Screws Work

Rafter screws are engineered to create a strong connection between the top plate and the rafter. The screw’s unique design allows it to easily penetrate the wood without causing any splitting. The threads on the screw are spaced apart wider than on other screws, to increase the screw’s pull out strength.

When installing rafter screws, you must ensure that you are using the right screw size, length, and thread type. The most commonly used rafter screw types are the Strong-Drive® SDWC Truss Screw and the Timberlok FastenMaster Wood Screw, both of which provide a secure connection between the top plates and rafters.

Rafters come in different sizes and shapes, and it’s important to choose a rafter screw that will not only penetrate the wood but also hold it securely. The rafter screw’s full-threaded shank, for example, engages the entire length of the fastener, providing a secure connection.

In conclusion, rafter screws are an essential element in roof construction, providing a secure and strong connection between the top plate and rafters. Proper installation of rafter screws is crucial to ensure the roof structure can withstand the weight of the roof and is safe to use.

Benefits Of Using Rafter Screws

Rafter screws provide a strong and secure connection between the truss or rafter and the top plate. With their full-threaded shank, they offer a reliable solution for fastening rafters to top plates. Rafter screws are an essential component in building structures that meet building code requirements and provide maximum safety.

Increased Stability

Using rafter screws can significantly increase the stability of your structure. This is because rafter screws have a full-threaded shank that engages the entire length of the fastener, providing a secure connection. Strong-Drive® Interior Wood Screws are an excellent example of quality screws that can be used to stabilize your rafters. These screws can provide a stud-to-bottom plate or stud-to-top plate connection, fastening trusses and rafters to top plates, and ensuring structural stability.

Ease Of Installation

Rafter screws are easy and quick to install, making them a popular choice among DIYers, contractors, and builders. One advantage of using rafter screws is that they do not require pre-drilling, unlike other types of screws. This saves time, effort, and makes the installation process more convenient. Moreover, rafter screws are available in various sizes and styles to fit different types of rafters and structures.

Cost-effective

Rafter screws are cost-effective, making them an economical choice for builders and contractors. They come in different quantities and are available at affordable prices, which can help reduce the total cost of construction. Additionally, since rafter screws do not require pre-drilling, you save money on labor costs, which can be expensive in larger construction projects.

In summary, by using rafter screws, you can achieve increased stability, ease of installation, and cost-effectiveness. They are an excellent option for builders and contractors looking to save time, effort, and money while ensuring structural stability and integrity in their constructions.

Types Of Rafter Screws

Rafter screws come in different types such as the Wood Coarse SAE, Wood Torx Coarse, Wood Hex Coarse, and Wood Torx SAE, among others. These screws allow secure connections between trusses and rafters, as well as fastening top plates. Installation involves fully threading the shank of the screw for a sturdy hold.

Types of Rafter Screws

Rafter screws, also known as structural wood screws, are an efficient and easy-to-use fastener solution for joining wood beams, rafters, trusses and other carpentry applications. Rafter screws are specifically designed to provide a reliable and stable source of support for frameworks in buildings and can be used in various types of wood. There are several types of rafter screws, and in this section, we will explore the most popular ones.

Wood Coarse SAE

A popular type of rafter screw is Wood Coarse SAE. These screws have a coarse thread and sharp point, making them ideal for use in softwoods or hardwoods. Wood Coarse SAE screws have a flat head which can be countersunk into the wood, making them useful for fastening floor joists, framing walls, and other carpentry projects. These screws are available in a pack of 50 and can be bought from popular hardware stores like Lowe’s and Home Depot.

Wood Torx Coarse

Wood Torx Coarse screws are another type of rafter screw that are suitable for use in wood applications. These screws feature a coarse thread with high torque, making them easy to install and remove. Wood Torx Coarse screws have a Torx drive system, which provides better grip, less slippage, and reduces damage to the screw head. These screws come in a pack of 50 and can be found at Home Depot and Amazon.com.

Wood Hex Coarse

Wood Hex Coarse screws are an excellent option if you’re looking for a larger pack size. These screws come in a pack of 250 and are suitable for use in softwoods and hardwoods. As the name suggests, these rafter screws have a hex head, which provides greater control during the installation process. With a coarse thread and a sharp point, these screws are perfect for fastening large wood beams or rafters. Wood Hex Coarse screws can be purchased from Lowe’s.

Wood Torx SAE

Wood Torx SAE screws are designed to work with hardwoods, treated lumber, and dense materials like engineered wood products. These rafter screws have a Torx drive system, which makes them easy to drive in, reducing slippage, and increasing torque. With a flat head, these screws can be countersunk into the wood, providing a flush finish. Wood Torx SAE screws are available in a pack of 40 and can be found at leading hardware stores like Home Depot.

In conclusion, choosing the right rafter screw for your project is crucial to provide a secure framework. It’s essential to select a screw that matches the specifications of your wood project. With the help of this guide, you can easily evaluate the different types of rafter screws available and make an informed decision about which type to use.

Choosing The Right Rafter Screws

Choosing the right rafter screws is crucial to ensure a secure attachment of your roof trusses, as well as resistance against uplift forces and wind loads. The Strong-Drive® SDWC Truss Screw is a popular choice, with a full-threaded shank providing a secure connection between the stud and top or bottom plate.

Rafter screws are essential components of any roof truss assembly, providing stability and contributing to the structural integrity of the roof. The right screws can make all the difference, ensuring that the rafters don’t loosen over time or fail under heavy loads or severe weather conditions. However, not all rafter screws are created equal, and choosing the right ones can be a challenge. Here are some key factors you should consider when selecting rafter screws:

Length And Diameter

The length and diameter of the rafter screws are essential parameters that affect their holding power and load-carrying capacity. If the screws are too short, they won’t penetrate the framing members sufficiently to provide a strong connection. Conversely, if the screws are too long, they may split the wood, weaken the rafter, or protrude through the roof sheathing. Similarly, the diameter of the screws should match the thickness of the members they’re fastening. Typically, 1/4-inch or 5/16-inch screws are adequate for most truss assemblies, but thicker and longer screws may be needed for larger or heavier roofs.

Material

The material of the rafter screws is another critical factor that affects their performance and longevity. Stainless steel, for instance, is highly resistant to corrosion caused by exposure to moisture, UV rays, and chemicals, making it ideal for outdoor applications. However, stainless steel screws are also more expensive than other materials. Galvanized steel is another option that provides some degree of corrosion resistance and affordability but may not be as durable in harsh environments. Other materials, such as brass, copper, or aluminum, may be suitable for specific applications but are less common in truss assemblies.

Load Capacity

The load capacity of the rafter screws is the maximum amount of weight they can support without failing or compromising the assembly’s stability. The load capacity depends on several factors, such as the screw’s diameter, length, thread pattern, and material, as well as the type and orientation of the truss members, the spacing of the screws, and the overall design of the roof. Therefore, it’s essential to consult the manufacturer’s specifications or a structural engineer’s recommendations to ensure that the rafter screws can handle the expected loads.

Weather Resistance

The weather resistance of the rafter screws is vital to prevent corrosion, rust, or decay over time, especially in humid or rainy climates. Screws that are not weather-resistant may weaken or break under the effects of temperature changes, moisture, or chemical reactions, compromising the roof’s integrity. Therefore, it’s crucial to choose screws that are rated for outdoor use and have a protective coating or plating that can resist weathering. Some screws may also have a special thread design that helps to optimize their grip and prevent leaks or water damage.

In conclusion, choosing the right rafter screws for your roof truss assembly requires careful consideration of several factors, including the length and diameter, material, load capacity, and weather resistance. By choosing high-quality, durable, and well-designed screws, you can ensure that your roof will provide reliable and long-lasting protection for your home or business.

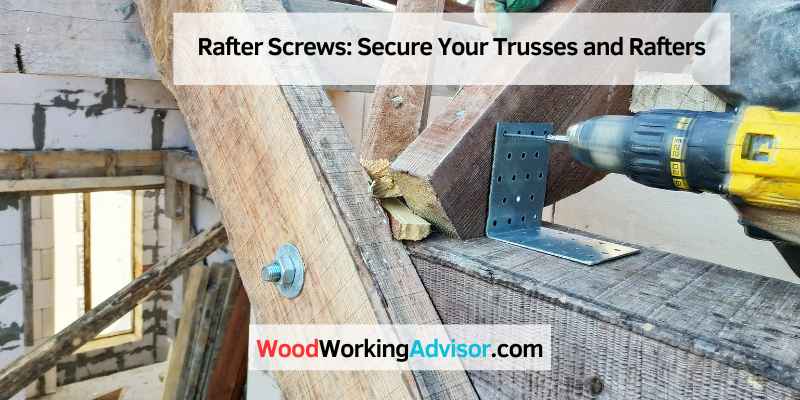

Installation Of Rafter Screws

Installation of rafter screws is an essential part of framing a roof. Strong-Drive SDWC Truss screws are an excellent option for fastening trusses and rafters to top plates and for stud-to-top plate connections. These screws have a full-threaded shank that engages the entire length of the fastener, providing a secure and code-compliant connection.

Preparation

Before you begin the installation of rafter screws, it’s important to gather all the necessary tools and materials. Here’s what you’ll need:

- Rafter screws

- Drill

- Drill bits

- Tape measure

- Level

- Safety goggles

Make sure you have the correct size and type of rafter screws for your project. It’s recommended to consult with a professional or refer to the manufacturer’s instructions to ensure you choose the right screws.

Step-by-step Guide

Now that you’ve gathered all the necessary tools and materials, let’s dive into the step-by-step guide for installing rafter screws:

- Start by measuring and marking the location of the rafter screws along the rafter and top plate. Use a tape measure and pencil to make accurate marks.

- Put on your safety goggles to protect your eyes from any debris or particles that may be released during the installation.

- Using a drill bit that matches the size of the rafter screws, begin drilling pilot holes at the marked locations. Make sure the pilot holes are slightly smaller than the diameter of the screws to ensure a secure fit.

- Insert the rafter screws into the pilot holes and use a drill to drive them all the way in. Make sure they are flush with the surface and provide a secure connection.

- Once all the rafter screws are installed, use a level to ensure that the rafters are properly aligned and perpendicular to the top plate.

It’s important to follow these steps carefully to ensure a professional and secure installation of rafter screws. Remember to consult with a professional or refer to the manufacturer’s instructions for any specific guidelines or recommendations.

The installation of rafter screws is a crucial step in ensuring the stability and strength of your roofing structure. By following the proper techniques and using the right tools, you can confidently complete this installation and prevent any potential issues in the future.

Code Compliance Of Rafter Screws

The Strong-Drive SDWC Truss screw is a reliable option for code-compliant rafter connection. With full threading engaged throughout the fastener, this screw provides a secure connection between studs and top or bottom plates, as well as trusses and rafters. Truss head screws are also an option for securing rafters, but they do not sit flush with the workpiece like pan head screws.

Meeting Building Codes

As a construction professional, ensuring code compliance is crucial. Rafter screws have increasingly become a popular choice among contractors and DIYers alike. But before using them, it’s essential to understand if they meet code requirements in your area. The Strong-Drive SDWC Truss screw is one such example of a rafter screw that complies with various codes, including the International Residential Code and International Building Code. Its specially designed full-threaded shank provides a secure connection between the rafter and the top plate, making it suitable for use in even high-wind and seismic zones.

Replacing Hurricane Ties With Rafter Screws

Hurricane straps or ties are a crucial component of roofs in high-wind-prone regions. They’re responsible for creating a secure connection between the rafter and the top plate to prevent uplift. However, traditional hurricane ties are time-consuming to install and often require specialized tools. On the other hand, rafter screws like the SDWC Truss screw provide a faster and more efficient alternative for securing roof framing. It replaces the need for hurricane ties by creating a strong truss-to-top-plate connection and reducing uplift. Not only does this save time and effort, but it also ensures code compliance.

What Screws For Rafters?

When choosing screws for rafters, it’s important to consider their load-carrying capacity, material, and size in relation to the rafter’s thickness. Rafter screws like the SDWC Truss screw come with multiple load-carrying and thread options, including wood coarse, wood torx, and wood hex, allowing you to tailor the screw to meet your specific needs. Additionally, they’re available in different sizes, with 50-250 count packs available for various project sizes. By selecting the right screw for the job, you can ensure a secure connection between the rafter and the top plate, meeting building code regulations.

Comparison Of Rafter Screws With Hurricane Straps

Rafter screws are a cost-effective and efficient way to secure rafters directly to the top plate. Compared to hurricane straps, the Strong-Drive® SDWC Truss screw offers a simpler and faster installation process while providing a secure stud-to-top plate or stud-to-bottom plate connection.

The full-threaded shank creates a stronger hold and meets code requirements.

Uplift Resistance

When it comes to preventing uplift, rafter screws are much more efficient than hurricane straps. The Strong-Drive SDWC Truss Screw provides an excellent solution in this regard. The full-threaded shank runs the entire length of the fastener, providing a secure and reliable connection between the trusses and the top plates. This helps to resist the uplift force generated during hurricanes and other severe weather events, which could otherwise cause significant damage to the roof structure.

Cost Comparison

While hurricane straps are generally less expensive than rafter screws, they don’t offer the same level of security and stability. The Simpson Strong-Tie Strong-Drive SDWC Truss Screw costs more than a hurricane strap, but the additional investment pays off in terms of better uplift resistance. When it comes to using rafter screws, the product’s quality and quantity significantly impact the price, making it difficult to predict an exact cost. However, it’s wise to compare different options available online and in physical stores before making a decision on which one to purchase.

If you choose to use rafter screws, you need to ensure that the screws meet code requirements in your area. A reputable solution like the Strong-Drive Interior Wood Screws ensures code-compliance, further adding to the overall cost of the installation.

In conclusion, while hurricane straps offer some resistance to uplift, rafter screws are much more efficient in preventing damage to the roof structure during severe weather conditions. Although rafter screws are relatively more expensive, the extra investment ensures a better connection between the trusses and top plates, providing added protection against uplift forces.

Where To Get Rafter Screws?

There are several options to get rafter screws, including Lowe’s, Home Depot, and Amazon. Strong-Drive® Interior Wood Screws and SDWC Truss Screws are some of the recommended options for securing rafters and trusses to plates. Make sure to choose the appropriate type of screw for the job and follow installation instructions carefully.

When it comes to constructing or repairing a roof, it’s important to ensure that you’re using the right materials and tools for the job. Rafter screws are a commonly used type of hardware for fastening rafters and trusses to wood members, providing a secure and reliable connection. If you’re in need of rafter screws for your roofing project, you may be wondering where to get them. In this post, we’ll explore some of the options available for purchasing rafter screws, including hardware stores and online retailers.

Hardware Stores

If you prefer to do your shopping in person, visiting a hardware store can be a convenient option for purchasing rafter screws. Many chain hardware stores like Lowe’s and Home Depot offer a wide variety of rafter screws in different sizes, materials and types. For example, Home Depot offers 50-count wood coarse SAE rafter screws for $38.98 and 50-count wood torx coarse rafter screws for $41.97. Meanwhile, Lowe’s offers 50-count wood coarse SAE rafter screws for $46.98 and 250-count wood hex coarse rafter screws for $1.98. Checking with your local hardware store may also be a good option if you need quick access to rafter screws.

Online Retailers

Online shopping has become increasingly popular in recent years, and for good reason. It offers the convenience of shopping from anywhere and the ability to read customer reviews and compare prices from different sellers. Online retailers like Amazon, WhiteCap.com, and McCoy’s Building Supply offer a wide selection of rafter screws in different sizes and quantities. For instance, Amazon.com offers 250-count wood hex coarse rafter screws for $136.81 with free shipping and a FastenMaster FlatLok Structural Wood Screw for $266.59.

WhiteCap.com offers Timberlok FastenMaster Wood Screws for $2.28 per screw and Timberlok Wood Screws for $7.74 per screw. McCoy’s Building Supply offers 50-count wood torx SAE rafter screws for $51.99. Before making a purchase online, be sure to check the seller’s ratings and reviews to ensure that you’re getting a quality product.

In conclusion, whether you prefer the convenience of online shopping or the hands-on approach of visiting a hardware store, there are many options available for purchasing rafter screws. By taking the time to research and compare prices and reviews, you can find a reliable and affordable solution that meets your needs.

Frequently Asked Questions On Rafter Screws

What Screws For Rafters?

The Strong-Drive SDWC Truss screw is recommended for providing secure connections for trusses and rafters to top plates. It has a full-threaded shank that engages the entire length of the fastener, ensuring a strong connection. Other recommended options for rafter screws are the Timberlok wood screws, FastenMaster Headlok screws, and FastenMaster FlatLok structural wood screws.

Truss head screws are also an option but they have a mushroom-shaped head and won’t sit flush with workpieces.

Do Truss Screws Meet Code?

The Strong-Drive SDWC Truss screw meets code requirements for fastening trusses and rafters to top plates and providing a secure connection for stud-to-bottom or stud-to-top plate. It has a full-threaded shank that engages the entire length of the fastener, providing a secure connection.

Truss screws can replace hurricane ties.

What Are Truss Screws?

Truss screws are fasteners with a mushroom-shaped head used for securing trusses and rafters to top plates. The Strong-Drive SDWC Truss screw’s full-threaded shank ensures a secure connection while meeting code standards. It is a popular replacement for hurricane ties and ideal for stud-to-bottom or stud-to-top plate connections.

Installing truss screws is easy with the Quik Stik tool.

How Do You Install Rafter Screws?

To install rafter screws, use the Strong-Drive SDWC Truss screw or Wood Coarse SAE/Torx screws to fasten trusses and rafters to top plates. Make sure to engage the full-threaded shank and provide a secure connection. Follow the installation guidelines provided by the manufacturer for the specific screw type you choose.

Conclusion

Choosing the right rafter screw is crucial to ensure a secure connection between the trusses and rafters to top plates. The Strong-Drive SDWC screws are popular options that meet code requirements and offer strong and stable connections. It’s essential to follow proper installation guidelines to ensure the rafter screws deliver optimum performance.

With the above guidelines and information, you can make an informed decision when purchasing and installing rafter screws for your roofing project.