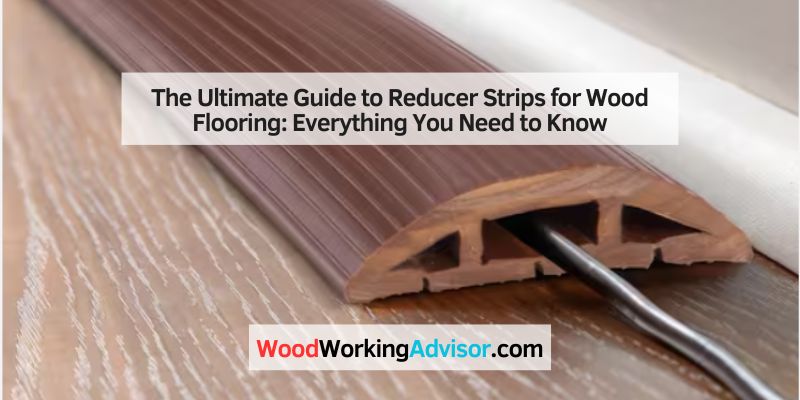

The Ultimate Guide to Reducer Strips for Wood Flooring: Everything You Need to Know

Hey there! If you’re diving into the world of wood flooring, you’ve probably come across the term reducer strip for wood flooring. Maybe you’re installing new hardwood floors or transitioning between rooms, and you’re wondering what these strips are and why they matter. I’ve been down this road myself, exploring every nook and cranny of woodworking projects, and let me tell you—reducer strips are a game-changer for creating seamless, polished floors. In this guide, I’m going to walk you through everything I’ve learned about reducer strips, from what they are to how to install them. Whether you’re a DIY newbie or a seasoned woodworker, I’ve got you covered with practical tips and insights. Let’s make your flooring project shine!

What Is a Reducer Strip for Wood Flooring?

When I first started working on my home’s flooring, I had no idea what a reducer strip was. Picture this: you’ve got a beautiful hardwood floor in your living room, but it meets a tile floor in the kitchen, and there’s a slight height difference. That’s where a reducer strip comes in. It’s a small but mighty piece of molding designed to bridge the gap between two floors of different heights. Think of it as a smooth ramp that makes the transition safe and visually appealing.

Reducer strips are typically made from wood, metal, or vinyl, and they come in various finishes to match your flooring. I’ve seen them in oak, walnut, and even sleek aluminum for a modern look. They’re not just about looks, though—they prevent tripping hazards and protect the edges of your floors from damage. In my experience, choosing the right reducer strip can make your floors look like they were installed by a pro.

Why Are Reducer Strips Important for Wood Flooring?

I remember installing my first hardwood floor and noticing how awkward the transition to my carpeted bedroom looked without a reducer strip. It wasn’t just ugly—it felt unsafe. Reducer strips are crucial for a few reasons. First, they create a smooth transition between floors of different heights, like from hardwood to tile or carpet. This reduces the risk of tripping, which is especially important if you have kids or elderly folks at home.

Second, they protect the edges of your wood flooring. Without a reducer, the exposed edges can chip or wear down over time. I learned this the hard way when my dog’s enthusiastic sprints left scratches on an unprotected edge. Finally, reducer strips add a polished, finished look to your floors. They’re like the cherry on top of a sundae—small but essential for that wow factor.

Types of Reducer Strips for Wood Flooring

When I started shopping for reducer strips, I was surprised by the variety available. Each type serves a specific purpose, so let’s break them down. Here’s a quick table to give you an overview:

| Type | Purpose | Best For |

|---|---|---|

| T-Molding | Joins two floors of the same height | Hardwood to hardwood or similar surfaces |

| Reducer Strip | Transitions between floors of different heights | Hardwood to tile, carpet, or vinyl |

| Threshold | Covers gaps at doorways or room entrances | Doorways between rooms |

| Overlap Reducer | Overlaps the higher floor for a seamless look | Floating floors like laminate |

| End Cap | Finishes edges at fireplaces or exterior doors | Edges not meeting another floor type |

- T-Molding: I used T-molding when I installed hardwood in two adjacent rooms that were the same height. It sits neatly between the floors, creating a clean line.

- Reducer Strip: This is the star of our show. It’s perfect for transitioning from a thicker hardwood floor to a thinner tile or carpet. I found it especially helpful in my kitchen-to-living-room transition.

- Threshold: These are great for doorways. I installed a threshold between my hallway and bathroom, where the height difference was minimal but noticeable.

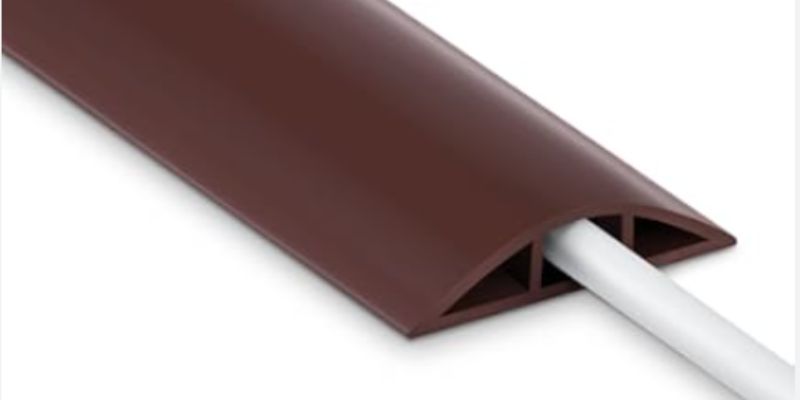

- Overlap Reducer: If you’re working with floating floors like laminate, an overlap reducer is your friend. It sits on top of the higher floor and slopes down to the lower one.

- End Cap: I used an end cap near my fireplace, where the hardwood ended without meeting another floor type. It gave the edge a clean, finished look.

Each type has its own charm, and choosing the right one depends on your project. I always recommend measuring the height difference between your floors before shopping to ensure a perfect fit.

Materials for Reducer Strips: Which One to Choose?

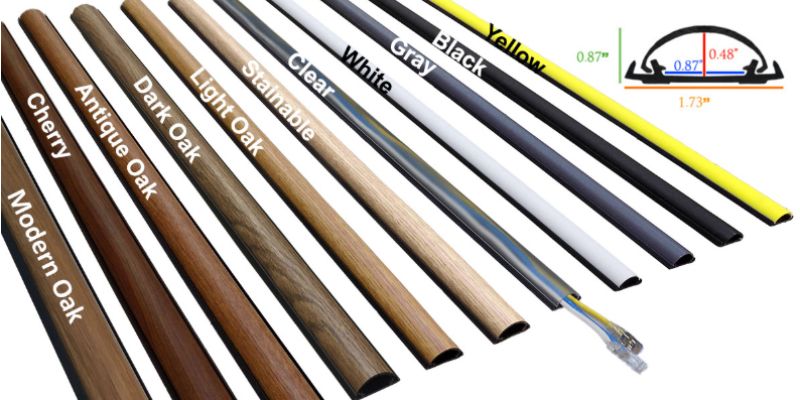

Picking the material for your reducer strip can feel overwhelming, but I’ve tried a few and can share what works. Here are the most common options:

- Wood: Wood reducer strips are my go-to for hardwood floors. They blend seamlessly with the floor, especially if you match the wood species and finish. I used an oak reducer to match my oak hardwood, and it looks like it was always part of the floor.

- Metal: For a modern vibe, metal reducers (like aluminum or brass) are fantastic. I installed an aluminum reducer in a friend’s home where hardwood met tile, and it added a sleek touch.

- Vinyl: Vinyl is budget-friendly and versatile. It’s great for areas with moisture, like bathrooms. I used a vinyl reducer in my laundry room, and it’s held up well against spills.

- MDF (Medium-Density Fiberboard): MDF reducers are affordable and can be painted or stained. I used one in a rental property to keep costs down, but they’re not as durable as solid wood.

When choosing a material, think about your floor’s style and the room’s function. For high-traffic areas, I lean toward wood or metal for durability. For budget projects, vinyl or MDF works fine.

How to Choose the Right Reducer Strip for Your Project

I’ll be honest—picking the right reducer strip took me a few tries to get right. Here’s what I’ve learned to make the process easier:

- Measure the Height Difference: Use a tape measure to check the height gap between your floors. For example, my hardwood was 3/4 inch thick, and my tile was 1/4 inch, so I needed a reducer to bridge that 1/2-inch gap.

- Match the Style: Your reducer should complement your floor’s color and finish. I brought a scrap piece of my hardwood to the store to find a matching oak reducer.

- Consider the Room’s Purpose: In high-moisture areas like kitchens, I avoid wood reducers unless they’re sealed well. Vinyl or metal is safer.

- Check Durability: For heavy foot traffic, like in my living room, I chose a solid wood reducer over MDF for longevity.

- Think About Installation: Some reducers snap into a track, while others need glue or nails. I found snap-in reducers easier for my DIY projects.

Pro tip: If you’re unsure, buy a small sample to test at home. I once bought a reducer that looked perfect in the store but clashed with my floor’s undertone in natural light.

How to Install a Reducer Strip for Wood Flooring

Installing a reducer strip isn’t as daunting as it seems. I’ve done it a few times, and with the right tools, it’s a manageable DIY project. Here’s my step-by-step guide:

- Gather Your Tools: You’ll need a tape measure, saw (miter or hand saw), adhesive or nails, a hammer or drill, and a level. I also keep a pencil and safety glasses handy.

- Measure and Cut: Measure the length of the transition area. I mark the reducer strip with a pencil and cut it to size using a miter saw for clean edges.

- Prepare the Area: Clean the floor where the reducer will go. I use a vacuum and damp cloth to remove dust and debris.

- Test the Fit: Place the reducer strip in position to ensure it fits snugly. I had to trim mine slightly to account for an uneven subfloor.

- Install the Reducer: For snap-in reducers, I attach the track to the subfloor with adhesive or screws, then snap the strip into place. For solid wood reducers, I use construction adhesive or nails. Make sure it’s level!

- Finish Up: If you’re using wood, you might need to sand or stain the reducer to match your floor. I sealed mine with polyurethane for extra protection.

One mistake I made early on was not checking the subfloor for levelness. An uneven subfloor can make your reducer wobble, so take the time to check and shim if needed.

Common Mistakes to Avoid When Using Reducer Strips

I’ve made my fair share of mistakes with reducer strips, so let me save you some trouble. Here are the pitfalls to watch out for:

- Ignoring the Height Difference: I once bought a reducer without measuring the height gap, and it was too short. Always measure first.

- Mismatching Colors: A reducer that doesn’t match your floor sticks out like a sore thumb. I learned to double-check finishes in natural light.

- Poor Installation: Rushing the installation can lead to loose or wobbly reducers. I take my time to ensure a secure fit.

- Skipping Maintenance: Wood reducers need sealing to resist moisture and wear. I forgot this once, and my reducer warped in a humid bathroom.

- Using the Wrong Type: Using a T-molding instead of a reducer for a height difference caused a tripping hazard in my first project. Know your transition type!

Where to Buy Reducer Strips for Wood Flooring

Finding the right reducer strip can be a bit of a treasure hunt. I’ve scoured stores and online retailers to find the best options. Here are my go-to places:

- Home Improvement Stores: Places like Home Depot and Lowe’s have a wide selection of wood, vinyl, and metal reducers. I found a great oak reducer at Lowe’s that matched my floor perfectly.

- Flooring Specialty Stores: Local flooring shops often carry custom or hard-to-find reducers. I got a unique walnut reducer from a nearby store.

- Online Retailers: Amazon and Wayfair offer tons of options, especially for vinyl and MDF reducers. I like browsing online for deals and variety.

- Manufacturer Websites: If your flooring is from a specific brand, check their website for matching reducers. I bought one directly from Bruce Flooring for a seamless match.

Prices vary widely—wood reducers can cost $20-$50 for a 6-foot piece, while vinyl is often under $15. I always compare prices and read reviews before buying.

Tips for Maintaining Reducer Strips

Once your reducer strip is installed, you want it to last. I’ve learned a few tricks to keep mine looking great:

- Clean Regularly: I sweep or vacuum my reducers weekly to prevent dirt buildup. A damp cloth works for stubborn spots.

- Seal Wood Reducers: For wood reducers, I apply a polyurethane sealant every couple of years to protect against moisture and scratches.

- Avoid Harsh Chemicals: I once used a strong cleaner that dulled my reducer’s finish. Stick to mild soap and water.

- Check for Wear: Over time, high-traffic areas can wear down. I inspect my reducers annually and replace them if they’re damaged.

- Protect from Furniture: I use felt pads under furniture legs to prevent scratches on my wood reducers.

Reducer Strips and Aesthetics: Making Your Floors Pop

One thing I love about reducer strips is how they can elevate your floor’s look. A well-chosen reducer doesn’t just function—it adds style. For example, in my dining room, I used a walnut reducer with a darker stain to create a subtle contrast with my light oak floors. It draws the eye and makes the transition feel intentional.

If you’re going for a modern look, try a metal reducer with clean lines. For a rustic vibe, a distressed wood reducer can add character. I’ve also seen creative folks paint or stain reducers for a custom look. Just make sure the finish is durable to withstand foot traffic.

Reducer Strips for Different Flooring Types

Not all flooring transitions are the same, and I’ve tackled a few in my projects. Here’s how reducer strips work with different flooring types:

- Hardwood to Tile: This is a common transition in kitchens. I used a wood reducer with a slight bevel to bridge the 1/2-inch height difference.

- Hardwood to Carpet: For my living room-to-bedroom transition, I chose a reducer that tucked under the carpet edge for a smooth look.

- Hardwood to Vinyl: Vinyl floors are often thinner, so a reducer is essential. I used a vinyl reducer here for moisture resistance.

- Hardwood to Laminate: If the laminate is floating, an overlap reducer works best. I installed one in my office, and it’s held up great.

Each transition has its quirks, so measure carefully and choose a reducer designed for the specific flooring types.

Conclusion

After diving deep into the world of reducer strips for wood flooring, I can say they’re one of the unsung heroes of a beautiful home. They’re not just functional—they’re a chance to add style, safety, and durability to your floors. Whether you’re transitioning from hardwood to tile, carpet, or vinyl, the right reducer strip can make all the difference. I’ve loved experimenting with different types, materials, and finishes to find what works best for my projects, and I hope this guide helps you do the same.

Take your time choosing the right reducer, measure carefully, and don’t skip the prep work. Trust me, a little effort upfront pays off in a seamless, professional-looking floor. So grab your tools, pick a reducer that matches your style, and get ready to transform your space. Your floors deserve it!

Frequently Asked Questions

What’s the Difference Between a Reducer Strip and T-Molding?

A reducer strip bridges floors of different heights, like hardwood to tile. T-molding is for floors of the same height, like hardwood to hardwood. I’ve used both, and the key is knowing your floor’s height difference.

Can I Install a Reducer Strip Myself?

Yes, it’s a DIY-friendly project! I’ve installed several with basic tools like a saw and adhesive. Just measure carefully and follow the steps I outlined earlier.

How Do I Match a Reducer Strip to My Wood Floor?

Bring a sample of your flooring to the store or check the manufacturer’s website. I once mismatched a reducer, and it was noticeable. Testing in natural light helps.

Are Reducer Strips Necessary?

They’re not always required, but they prevent tripping and protect floor edges. I skipped one once, and the edge of my hardwood got damaged fast.

How Long Do Reducer Strips Last?

With proper care, wood reducers can last decades. Vinyl and MDF may need replacing sooner. I check mine yearly for wear and tear.

Can I Paint or Stain a Reducer Strip?

Absolutely! I’ve stained wood reducers to match my floors. Just use a durable finish to protect against foot traffic.

Where Can I Find Custom Reducer Strips?

Flooring specialty stores or manufacturer websites often offer custom options. I got a custom walnut reducer from a local shop for a unique project.