What Does Wood Glue Not Stick to: Unveiling the Surprising Grip Secrets

Wood glue does not stick to oily or greasy surfaces due to its inability to penetrate and bond properly. Wood glue is a common adhesive used for woodworking projects, but there are some surfaces it does not stick to.

One such surface is oily or greasy wood, as the glue is unable to penetrate and establish a strong bond. This is because oil or grease creates a barrier between the wood and glue, preventing them from properly joining together.

As a result, attempting to glue oily or greasy wood may lead to weak or failed bonds. It is important to thoroughly clean and remove any oil or grease from the wood surface before applying wood glue to ensure a successful bond.

Understanding The Chemistry Behind Wood Glue

Wood glue is a versatile adhesive that bonds wood surfaces effectively. However, it may not stick well to certain materials like metals, plastics, and glass due to differences in their chemistry. Understanding these limitations can help ensure successful woodworking projects.

How Wood Glue Bonds Materials Together

Wood glue is a versatile adhesive that is commonly used to bond wood pieces together. It works by creating a strong bond between the surfaces of the materials, essentially fusing them together. Understanding the chemistry behind wood glue can help us comprehend its bonding capabilities and limitations.

Factors Affecting The Bonding Strength Of Wood Glue

Wood glue may not stick to certain materials due to various factors that affect its bonding strength. These factors include:

- Surface Preparation: Proper surface preparation is crucial for the success of wood glue bonding. The materials being glued should be clean, dry, and free from any contaminants or oils that might hinder the adhesive’s effectiveness.

- Moisture Content: Wood glue relies on moisture to cure and establish a strong bond. However, excessive moisture can dilute the glue, affecting its ability to adhere properly. On the other hand, extremely dry wood can absorb the glue, resulting in a weaker bond.

- Wood Type: Different types of wood have varying porosity and density, which can impact the bonding strength of wood glue. Gluing porous and softwoods like pine or cedar may provide better adhesion compared to dense hardwoods like oak or maple.

- Temperature and Humidity: Temperature and humidity levels in the environment can influence the curing process of wood glue. Extreme temperatures or humidity can affect the glue’s drying time, consistency, and bonding strength.

- Joint Design: The design of the joint plays a vital role in the strength of the bond. Factors such as joint type, surface area, and the amount of glue applied must be taken into consideration to achieve optimal bonding strength.

- Adhesive Type: Different types of wood glues, such as PVA (polyvinyl acetate) and epoxy, have varying properties and strengths. Understanding the characteristics of the particular adhesive being used is essential for achieving desired results.

By considering these factors, woodworkers and do-it-yourself enthusiasts can ensure successful bonding with wood glue. It’s important to note that while wood glue is effective in most cases, it may not adhere to certain materials due to their composition or surface properties.

In such instances, alternative adhesives or mechanical fasteners might be more suitable for the task at hand.

Exploring Wood Types That Pose Challenges For Wood Glue

Wood glue may not adhere well to certain wood types, such as oily woods like teak or exotic hardwoods like rosewood. Additionally, plywood and fiberboard can present challenges due to their inconsistent surfaces. It is crucial to select the right glue and properly prepare the wood’s surface for a strong bond.

Wood glue is an essential adhesive used in woodworking projects to ensure a secure and durable bond between pieces of wood. However, there are certain wood types that can present challenges when it comes to using wood glue effectively. In this section, we will explore two categories of wood that may not adhere well to wood glue: highly resinous woods and treated woods.

Highly Resinous Woods And Their Non-Stick Nature

Some wood species contain a high concentration of resin or sap, which can interfere with the bonding properties of wood glue. These highly resinous woods have a natural non-stick nature that makes it difficult for the glue to adhere properly.

Here are some examples of highly resinous woods:

- Cedar: Known for its aromatic scent and natural resistance to decay, cedar contains high levels of resin that can impede the adhesive properties of wood glue.

- Pine: As a widely available softwood, pine also contains resin that can hinder the bonding process. The knots in pine wood, in particular, are known to be resin-rich areas that can be challenging for wood glue.

Although wood glue can still be used on highly resinous woods, it’s important to take extra precautions to ensure a strong bond. Here are some tips to improve the adhesion between wood glue and highly resinous woods:

- Clean the wood surface: Remove any excess resin or sap from the wood by sanding it thoroughly before applying the glue.

- Use a resin-blocking primer: Applying a resin-blocking primer to the wood surface can create a barrier that prevents the resin from interfering with the adhesive properties of the glue.

- Consider alternative adhesives: In cases where wood glue struggles to bond with highly resinous woods, using epoxy or polyurethane adhesives may be a more effective solution.

Treated Woods: An Unexpected Hindrance For Wood Glue

Another type of wood that may not adhere well to wood glue is treated wood. Treated wood refers to wood that has undergone a preservative treatment process, commonly used to protect against decay, insects, and other environmental factors. The chemical treatment can create a surface that is less receptive to wood glue.

Here are some examples of treated woods:

- Pressure-treated wood: This type of wood is commonly used in outdoor applications, such as decking and fencing. The treatment process involves injecting chemicals into the wood, which can create challenges for bonding with wood glue.

- Wood treated with fire retardants: Fire-retardant treatments are often applied to wood used in construction to reduce the risk of fire damage. These treatments can affect the adhesive properties of wood glue.

If you need to bond treated wood, here are some recommendations to enhance the adhesion between wood glue and treated woods:

- Sand the surface: Sanding the treated wood can help to remove any residue or chemicals that may hinder the bonding process.

- Use an adhesive compatible with treated wood: In some cases, using specific adhesives designed for treated wood, such as construction adhesives or polyurethane-based adhesives, can provide a stronger bond.

Understanding the challenges that highly resinous woods and treated woods present for wood glue can help you make more informed decisions when choosing the appropriate adhesive for your woodworking projects. By following the recommended tips and techniques, you can overcome these challenges and ensure a strong and durable bond between wood pieces.

Unveiling Substances That Resist The Adhesive Grip Of Wood Glue

Discover the untold secrets of wood glue’s limitations as researchers unveil substances that defy its adhesive properties. Explore what wood glue struggles to stick to, offering new insights into its bonding capabilities.

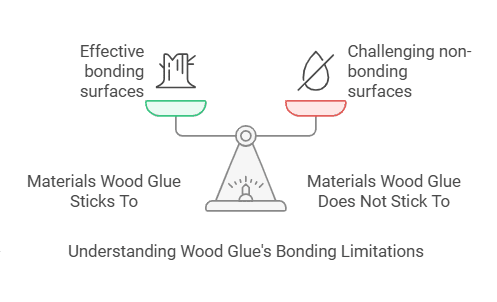

Wood glue is a versatile adhesive that provides secure bonds between wooden surfaces. However, not all materials adhere well to wood glue. In this blog post, we will uncover the substances that resist the adhesive grip of wood glue. Metal surfaces, plastic and glass, and non-porous surfaces pose unique challenges when it comes to bonding with wood glue.

Let’s explore each of these materials in detail.

Metal Surfaces: The Metallic Challenge

- Wood glue struggles to grip metal surfaces due to their smooth and non-porous nature.

- The absence of porosity prevents the glue from seeping into the surface and forming a strong bond.

- Rust, oils, and other contaminants on the metal surface can also interfere with the adhesive’s effectiveness.

- However, there are specific types of wood glue formulated to bond metal and wood, such as epoxy-based adhesives.

- These specialized glues contain additives that enhance their ability to bond with metal surfaces.

Plastic And Glass: Troublesome Materials For Wood Glue

- Plastic and glass materials are generally non-absorbent, making it difficult for wood glue to penetrate and create a strong bond.

- The smooth and shiny surfaces of plastic and glass do not provide enough texture for wood glue to adhere properly.

- The flexibility of plastic can also prevent a secure bond from forming, as the adhesive may not be able to withstand the material’s movements and stresses.

- For plastic and glass bonding, it is best to use adhesives specifically designed for these materials, such as cyanoacrylate (super glue) or epoxy adhesives.

Non-Porous Surfaces And The Struggle With Wood Glue Bonding

- Non-porous surfaces, including metals, plastics, and glass, create a challenging environment for wood glue bonding.

- The lack of absorption prevents the glue from penetrating the surface, resulting in weak adhesion.

- Dust, grease, or other contaminants on non-porous surfaces can further compromise the effectiveness of wood glue.

- In such cases, surface preparation becomes crucial to enhance the bonding capability of wood glue.

- Sanding the surface lightly or using a suitable primer can improve the adhesion of wood glue on non-porous surfaces.

While wood glue is an excellent adhesive for wood, it may not adhere effectively to certain materials. Metal surfaces, plastic and glass, and non-porous surfaces present challenges due to their smooth and non-absorbent nature. However, specialized adhesives can be used to overcome these limitations and ensure strong bonds.

Frequently Asked Questions On What Does Wood Glue Not Stick To

What Does Wood Glue Not Adhere To?

Wood glue does not adhere to surfaces that are oily, greasy, dirty, or covered in wax.

What Materials Will Glue Not Stick To?

Glue does not stick to certain materials, such as Teflon, silicone, and plastic.

How Do You Keep Glue From Sticking To Wood?

To prevent glue from sticking to wood, follow these steps:

1. Apply a thin layer of wax or petroleum jelly to the wood surface.

2. Use masking tape or painter’s tape to cover the areas where you don’t want glue to stick.

3. Clean the wood surface thoroughly before applying any adhesive.

4. Work quickly and wipe off excess glue before it dries.

What Tape Does Wood Glue Not Stick To?

Wood glue does not stick to masking tape effectively.

Conclusion

Understanding what wood glue does not stick to is crucial to ensure successful woodworking projects. While wood glue is known for its strong adhesive properties, there are certain materials that it may not bond effectively with. These include oily or greasy surfaces, plastics, metals, and materials with low porosity.

It is important to be aware of these limitations in order to choose the right adhesive for specific applications. Additionally, proper surface preparation is essential for improving the bonding strength of wood glue. By ensuring that the surfaces are clean, dry, and free from contaminants, woodworkers can achieve optimal results.

Experimenting with different types of wood glue and conducting tests beforehand can also help determine the most suitable adhesive for a particular project. Choosing the right glue and using it in the recommended manner will guarantee durable and reliable bonds in woodworking projects.