Wheels for a Table Saw: Enhance Mobility and Efficiency

Wheels for a table saw can make your woodworking projects easier. They add mobility and convenience to a heavy, stationary tool.

Imagine moving your table saw with ease, without straining your back. Wheels are a game-changer for woodworkers who need flexibility in their workspace. Whether you have a small garage or a large workshop, adding wheels to your table saw can save time and effort.

It’s not just about convenience; it’s about maximizing your efficiency and safety. In this blog post, we’ll explore the benefits of using wheels for your table saw and how they can enhance your woodworking experience. Stay tuned to learn more about this practical upgrade for your workshop.

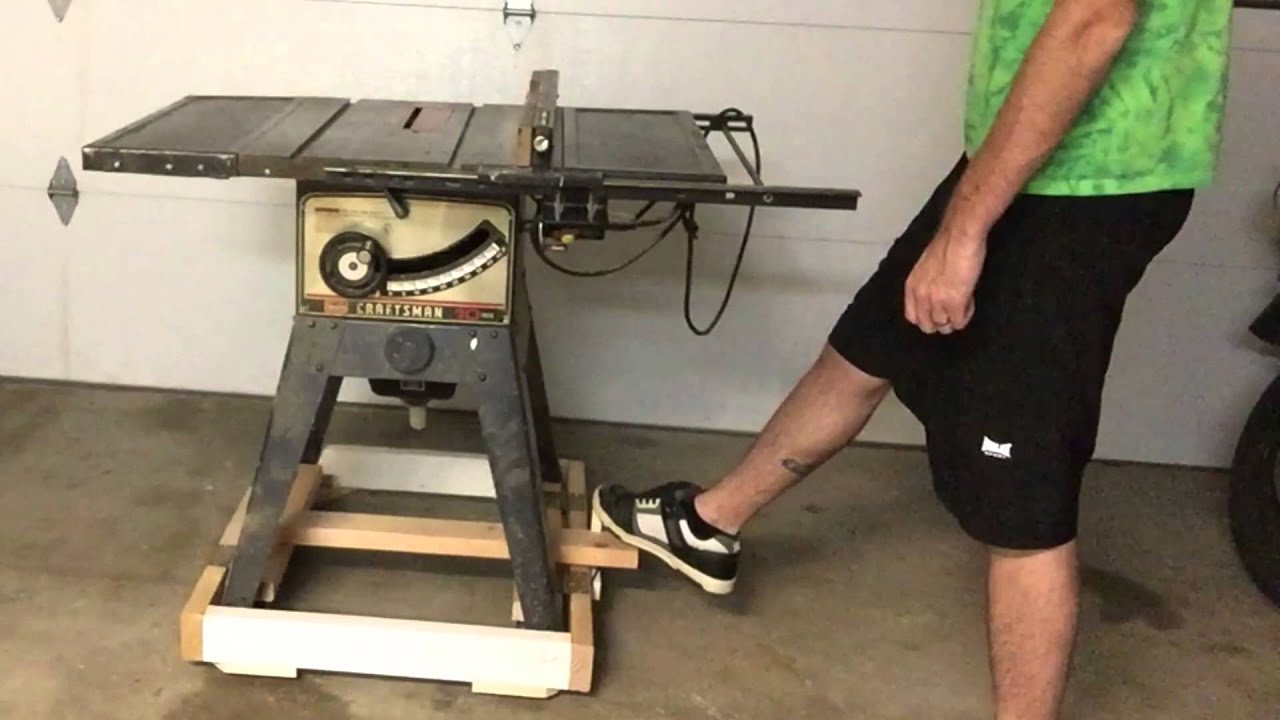

Credit: www.youtube.com

Introduction To Table Saw Wheels

Table saw wheels give your saw the power to move easily. This makes your work area more flexible. You can quickly move the saw where you need it. This saves time and effort. It also helps in keeping the workspace clean. You can push the saw aside to sweep up sawdust.

Using wheels on a table saw can make your work faster. You don’t have to lift the saw anymore. This means you can start your projects sooner. It also reduces the chance of getting hurt by lifting heavy tools. This makes your tasks safer and more enjoyable.

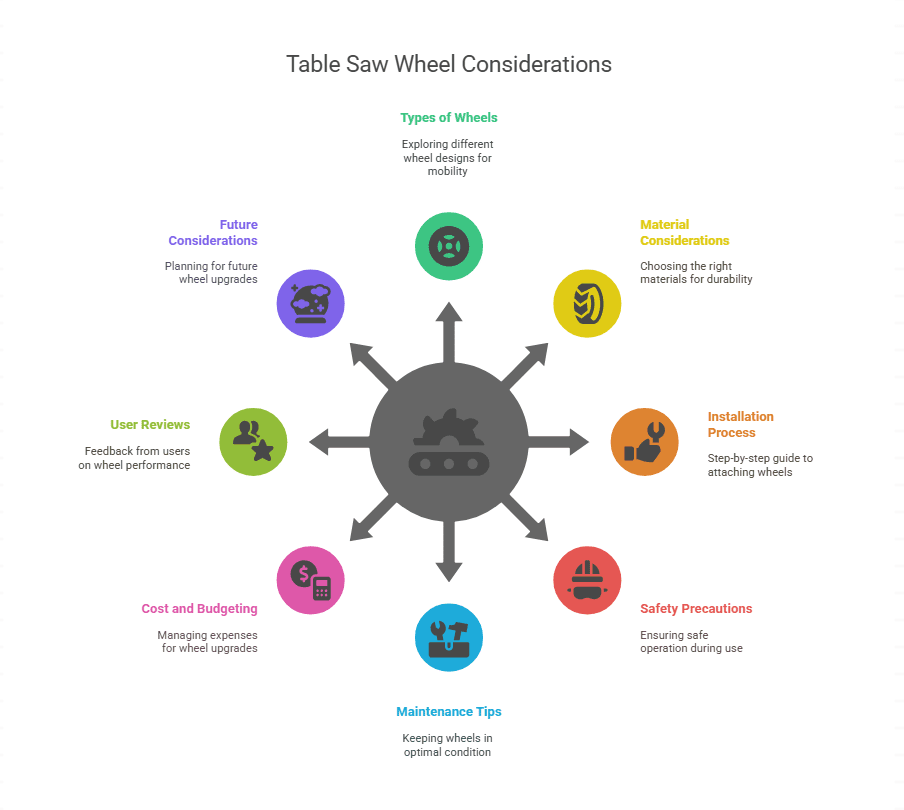

Types Of Table Saw Wheels

Fixed wheels do not rotate. They only move in a straight line. This makes them stable. Fixed wheels help in moving the saw in a fixed direction. They are ideal for straight movements. Fixed wheels do not turn, so they are less flexible. They are good for heavy table saws. Fixed wheels offer stability and control.

Swivel wheels can rotate in any direction. This makes them very flexible. They can move the saw in any direction you want. Swivel wheels are great for tight spaces. They allow for easy turning. These wheels make it easy to maneuver the table saw. Flexibility is their main advantage.

Material Considerations

Durability is key for table saw wheels. They must handle heavy loads. Strong materials like steel or reinforced plastic work best. These materials resist wear and tear. They last longer. Weak materials can break easily. This can cause accidents.

Weight capacity is very important. Choose wheels that support the table saw’s weight. Overloading wheels can be dangerous. Always check the weight rating. Ensure it matches your table saw. Higher capacity wheels are safer. They provide better stability. This prevents wobbling and accidents.

Installation Process

The tools needed are simple. You will need a wrench. Also, a screwdriver is needed. Get a drill if possible. Grab some bolts and nuts. Don’t forget the wheels. Make sure you have safety gloves. Always wear safety glasses. A measuring tape is useful. These tools will help you.

First, measure the base of the table saw. Mark where the wheels will go. Next, use the drill to make holes. Put the bolts through the holes. Attach the wheels to the bolts. Tighten the nuts with the wrench. Make sure the wheels are secure. Test the movement of the table saw.

Safety Precautions

Always use both hands to move the table saw. This keeps it steady. Wear gloves to protect your hands from sharp edges. Keep your work area clean to avoid tripping over things. Do not rush. Take your time to move the saw carefully.

Lock the wheels when the saw is in place. This prevents it from moving. Check the brakes to ensure they work well. Place the saw on a flat surface. This keeps it from tipping over. Use clamps if necessary to hold the saw in place.

Maintenance Tips

Check your table saw wheels often. Look for any wear or damage. Make sure bolts and screws are tight. Loose parts can cause problems. Worn wheels can affect cuts. Replace them if needed. Regular checks keep your saw in good shape.

Keep the wheels well lubricated. Use the right lubricant for your saw. Lubrication helps wheels move smoothly. It also reduces wear. Apply lubricant to the wheel bearings. Do this regularly. It ensures the saw works well.

Cost And Budgeting

Table saw wheels come in many prices. Some are cheap, around $20. Others can cost $100 or more. The cost depends on the brand and quality. Think about how often you will use the wheels. Buying the best wheels might save you money long term.

Good wheels last longer. They are safer and make your work easier. Spending more now can mean fewer problems later. Cheap wheels may break faster. You might end up spending more to replace them. Quality wheels give you better value for your money.

User Reviews And Recommendations

Many users recommend DeWalt wheels for table saws. Bosch is another popular choice. Both brands have high ratings. Users love their durability and easy installation. Craftsman wheels also receive praise for their smooth movement.

Most reviews highlight the importance of sturdy wheels. Customers prefer wheels that lock securely. Safety is a big concern. Easy maneuverability is another key feature. Many users appreciate wheels that roll smoothly on different surfaces.

Conclusion And Final Thoughts

Adding wheels to your table saw enhances its mobility and efficiency. Easy to move, it boosts productivity and safety. Make your woodworking projects smoother and more enjoyable.

Summary Of Benefits

Wheels for a table saw make it easy to move. You can clean the workshop quickly. The table saw becomes more versatile. You can work in different areas. It saves time and effort. You will avoid back pain. Moving heavy tools is safe. Wheels are a great addition. They enhance productivity.

Future Considerations

Check wheel quality before buying. Ensure they can hold the saw’s weight. Look for locking wheels for stability. Consider wheel size for smooth movement. Regularly inspect wheels for damage. Replace worn-out wheels. Maintenance is key for long-lasting use. Think about upgrading other parts. Better tools improve work quality.

Credit: www.youtube.com

Frequently Asked Questions

How Much Weight Can Castor Wheels Take?

Castor wheels can carry weights ranging from 50 to 10,000 pounds, depending on size and material. Always check manufacturer specifications.

What Are Table Wheels Called?

Table wheels are called casters.

What Is The Most Common Accident Caused By Table Saws?

The most common accident caused by table saws is kickback. Kickback occurs when wood is thrown back at the operator. It can lead to serious injuries.

Can You Put A Sawstop On Any Table Saw?

No, you cannot install a SawStop on any table saw. SawStop technology is built into specific SawStop table saws.

Conclusion

Adding wheels to your table saw enhances its mobility. This makes your workspace more flexible. Moving your saw becomes easier and less stressful. You can quickly reposition it for various tasks. Safety improves when you can secure the saw in place.

Wheels also help in managing limited space effectively. Choose durable wheels for long-term use. Easy installation boosts convenience. With these benefits, wheels become a valuable addition to your table saw. Enjoy a more efficient and versatile workshop.