The cost of a wood beam can be determined using a wood beam cost calculator. Calculators consider factors such as dimensions, type of wood, and quantity needed to estimate the cost accurately.

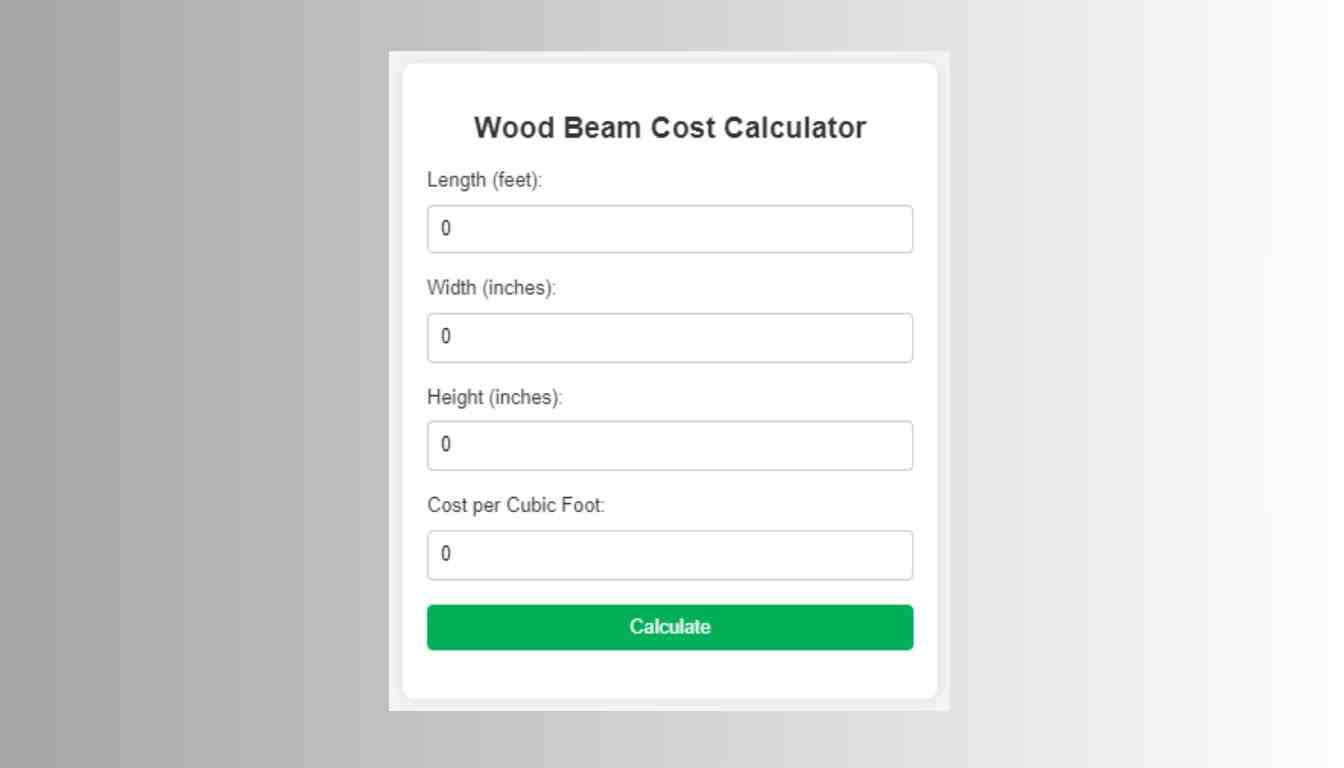

Wood Beam Cost Calculator

When planning a construction or renovation project that requires wood beams, it is essential to have an estimate of the cost. This helps in budgeting and ensures that the project remains within financial constraints. To determine the cost of a wood beam, a wood beam cost calculator can be used.

These calculators take into account factors such as the dimensions of the beam, the type of wood used, and the quantity required. By inputting these details, the calculator can provide an accurate estimate of the cost, enabling better planning and decision-making.

Credit: homeguide.com

Importance Of Wood Beams

Wood beams play a crucial role in construction, offering structural support and aesthetic appeal. Evaluating wood beam costs is essential for budgeting and planning. A wood beam cost calculator helps in estimating expenses accurately, ensuring cost-effective and efficient project management.

Wood beams play a crucial role in both residential and commercial construction projects. Not only do they provide structural support, but they also enhance the overall aesthetics of a space. From durability to natural beauty, there are several reasons why wood beams are widely favored in architectural designs.

Durability Of Wood Beams

Wood beams are known for their exceptional durability. When properly treated and maintained, they can withstand the test of time, providing long-lasting support to structures. The natural strength of wood combined with the appropriate treatments, such as pressure treatment or wood preservatives, enhances its resistance to decay, insects, and rot. As a result, wood beams offer stability and structural integrity, ensuring the safety of your building for years to come.

Aesthetics Of Wood Beams

In addition to their durability, wood beams are valued for their unmatched beauty and warmth. The natural grains, textures, and colors of wood add a distinctive charm and character to any space. Whether you prefer the rustic appeal of rough-sawn beams or the sleek and polished look of milled beams, wood offers a wide range of options to suit various architectural styles. Its versatility allows integration into both traditional and contemporary designs, making wood beams a versatile choice for interior and exterior applications.

When used in exposed applications, such as cathedral ceilings, open-plan living areas, or as stand-out architectural features, wood beams create a captivating focal point. The interplay of light and shadow on the wood’s surface adds depth and creates a cozy and inviting atmosphere. Whether you are striving for a cozy cabin vibe or a sophisticated modern look, wood beams can effortlessly transform a space, elevating its overall visual appeal.

Wood beams are also well-regarded for their eco-friendly attributes. As a renewable resource, wood is more sustainable compared to other building materials. Proper forest management and responsible harvesting ensure the replenishment of wood resources while minimizing the environmental impact. When you choose wood beams for your project, you contribute to the conservation of our forests and reduce the carbon footprint associated with construction.

Overall, the durability and aesthetics of wood beams make them an excellent investment for any construction project. Their natural beauty, warmth, and eco-friendliness make them an appealing choice for architects, designers, and homeowners alike. Whether you prioritize structural integrity, timeless appeal, or sustainable building practices, wood beams are sure to meet your requirements and enhance the overall quality and value of your space.

Factors Affecting Wood Beam Costs

Wood beam costs are influenced by factors such as the type of wood, dimensions, and finish. Other considerations include labor, transportation, and any additional treatments. A wood beam cost calculator can help estimate expenses and optimize project budgets.

When planning a construction or renovation project that requires wood beams, it is essential to consider various factors that affect wood beam costs. Understanding these factors will help you evaluate your budget and make informed decisions. Here are three key aspects that determine the cost of wood beams.

Wood Type

The type of wood selected plays a significant role in determining the cost of wood beams. Different wood species come with varying price tags due to their availability, durability, and aesthetics. For instance, hardwoods such as oak, walnut, and mahogany tend to be more expensive than softwoods like pine or fir. To assess the overall cost, it is crucial to consider the specific wood type that suits your project requirements.

Beam Size And Dimensions

The size and dimensions of wood beams directly affect their cost. Larger beams with wider cross-sections typically come at a higher price due to the increased amount of wood required for their construction. While determining the beam’s size, it’s necessary to consider the span it needs to cover and the load it will bear. Accurately assessing these factors in consultation with a structural engineer will help you choose the right beam size while staying within your budget.

Finish And Treatment

The finish and treatment options you choose for your wood beams can impact their cost. Treating the wood with chemicals like preservatives or fire retardants can enhance its longevity and protection against rot, insects, or fire hazards. However, these treatments often add to the overall cost. Additionally, the finish applied to the wood, such as staining or painting, can influence the price. It is essential to prioritize your project requirements and consider the long-term benefits when deciding on the finish and treatment options for your wood beams.

In conclusion, various factors contribute to the overall cost of wood beams. Considering the wood type, beam size and dimensions, as well as finish and treatment options, will help you determine an accurate budget for your project. By understanding these factors, you can make informed decisions and ensure the success and durability of your construction or renovation endeavor.

Calculating Wood Beam Costs

Explore the Wood Beam Cost Calculator to swiftly determine the expenses for your project. Easily estimate wood beam costs accurately for your construction needs. Get precise calculations with just a few simple inputs.

Cost Per Linear Foot

Wood beam costs vary depending on the size and type of wood.

Total Project Cost Estimation

To estimate the total project cost, multiply the cost per linear foot by the length needed.

For example:

| Wood Type | Cost per Linear Foot |

|---|---|

| Pine | $4 |

| Oak | $8 |

| Maple | $6 |

- Calculate total cost for desired wood type using cost per linear foot.

- Measure length needed for project.

- Multiply length by cost per linear foot for total project cost estimation.

Credit: www.weyerhaeuser.com

Comparison With Other Materials

When considering the cost of wood beams, it’s essential to compare them with other material options. This comparison can provide valuable insights into their suitability for different construction projects and overall value for money.

Wood Beams Vs. Steel Beams

Wood beams and steel beams are two commonly used materials for structural support in construction projects. Steel beams are known for their strength and durability, making them suitable for larger commercial structures. On the other hand, wood beams offer a natural aesthetic appeal and are often preferred for residential and smaller commercial buildings. The choice between the two materials depends on factors such as load-bearing requirements, design preferences, and budget constraints.

Wood Beams Vs. Engineered Beams

Wood beams and engineered beams have distinct differences in their composition and manufacturing processes. While wood beams are primarily made from natural lumber, engineered beams are constructed using composite materials such as laminated veneer lumber (LVL) or glued-laminated timber (glulam). Engineered beams are engineered to provide specific load-bearing capacities and dimensional stability, making them suitable for longer spans and heavier loads. However, wood beams offer a timeless charm and are often chosen for their aesthetic appeal and versatility in various architectural styles.

Cost-saving Tips

When considering the cost of wood beams for your project, it’s important to explore cost-saving techniques. By sourcing affordable wood and determining the feasibility of DIY vs. professional installation, you can effectively manage your expenses while achieving a stunning result.

Sourcing Affordable Wood

When it comes to sourcing wood beams at a budget-friendly cost, there are several considerations to keep in mind.

- Comparison Shopping: Research and compare prices from different suppliers to find the most cost-effective option.

- Local Sawmills: Consider purchasing wood directly from local sawmills, which can often offer competitive prices and personalized service.

- Reclaimed Wood: Explore the possibility of using reclaimed wood, which not only adds character to your project but also tends to be more cost-efficient than newly produced wood.

Diy Vs. Professional Installation

Determining whether to undertake a DIY installation or hire a professional can significantly impact the overall cost of your wood beam project.

| DIY Installation | Professional Installation |

|---|---|

|

|

Case Studies

Delve into real-life examples to understand how the Wood Beam Cost Calculator can benefit your projects.

Residential Wood Beam Project

- Renovating a farmhouse with wooden beams

- Easy-to-use calculator for accurate cost estimation

- Enhanced structural support with cost-effective beams

Commercial Wood Beam Project

- Constructing a modern office space with wood beams

- Efficient cost calculation for budget planning

- Sustainable choice for environmentally conscious projects

Maintenance And Longevity

When it comes to investing in wood beams for your construction project, it’s important to consider the maintenance required as well as the expected lifespan of the beams. Proper maintenance techniques and an understanding of their longevity can help you make an informed decision. Let’s explore the preservation techniques and expected lifespan of wood beams in detail.

Preservation Techniques

Preserving wood beams is crucial to extend their lifespan and maintain their structural integrity. By implementing the following preservation techniques, you can ensure that your wood beams remain sturdy and durable:

- Regular inspections: To identify any signs of damage or decay, inspecting wood beams regularly is essential. This allows you to take prompt action when necessary, preventing further deterioration.

- Sealing: Coating the wood beams with a moisture-resistant sealant helps protect them from water damage and excessive humidity. This prevents rot and prolongs their lifespan.

- Termite treatment: Since termites pose a significant threat to wood beams, treating them with appropriate insecticides is vital. This prevents termites from infesting and weakening the beams over time.

- Proper ventilation: Ensuring proper ventilation around the wood beams helps reduce moisture build-up, preventing the growth of mold and fungi. Adequate ventilation promotes their longevity.

- Regular cleaning: Removing dirt, debris, and other contaminants from the surface of the wood beams is crucial to prevent degradation. Use a mild detergent solution and a soft brush for safe and effective cleaning.

Expected Lifespan Of Wood Beams

The expected lifespan of wood beams varies depending on several factors, including the type of wood used, environmental conditions, and maintenance practices. On average, well-maintained wood beams can last for several decades. Below are some estimated lifespans for commonly used wood beams:

| Wood Type | Expected Lifespan |

|---|---|

| Pressure-treated Pine | 20-30 years |

| Oak | 30-50 years |

| Cedar | 25-40 years |

| Douglas Fir | 30-40 years |

These estimated lifespans may vary depending on the aforementioned factors and the quality of the wood used. Proper maintenance and regular inspections can significantly extend the lifespan of wood beams.

Credit: homeguide.com

Future Trends In Wood Beam Costs

As the construction industry continues to evolve, so does the cost of wood beams, a crucial component in building structures. Understanding the future trends in wood beam costs can help contractors, architects, and homeowners make informed decisions about their projects. In this section, we will explore key factors that will shape wood beam costs in the coming years. From innovative construction techniques to sustainable practices, these trends will not only influence cost but also contribute to a greener and more efficient construction industry.

Innovations In Wood Beam Construction

The construction industry has been witnessing significant advancements in wood beam construction techniques. These innovations aim to improve the structural integrity, durability, and overall performance of wood beams. One notable innovation is the use of engineered wood products that are stronger and more dimensionally stable than traditional solid wood beams.

These engineered wood beams, such as laminated veneer lumber (LVL) and glulam beams, offer a cost-effective alternative to solid wood beams without compromising strength. Moreover, the advent of computer-aided design (CAD) and computer numerical control (CNC) technology has made it easier to create customized wood beams with intricate designs, resulting in greater versatility and aesthetic appeal.

Sustainability And Cost Trends

In recent years, there has been a growing emphasis on sustainable construction practices. Wood beams, being a renewable and environmentally friendly material, are at the forefront of this trend. As more buildings strive for green certifications and energy efficiency, the demand for sustainably sourced wood beams continues to rise. This increased demand can have a positive impact on cost, as builders and suppliers invest in sustainable forestry practices and certifications. Additionally, advancements in wood treatment technologies have extended the lifespan of wood beams, making them a durable and cost-efficient option compared to other construction materials. The adoption of sustainable practices not only benefits the environment but also contributes to the long-term cost savings for construction projects.

Overall, the future of wood beam costs is shaped by innovations in construction techniques and the growing importance of sustainability. By embracing these trends, the construction industry can benefit from cost-effective, structurally sound, and environmentally friendly wood beams. Whether it’s utilizing engineered wood products or sourcing sustainable materials, staying informed and adaptable to these future trends will be essential for successful and cost-conscious construction projects.

Frequently Asked Questions On Wood Beam Cost Calculator

How Do I Calculate The Cost Of Wood Beams For A Project?

To calculate the cost of wood beams, measure the length, width, and height of the project area. Determine the type and quality of wood beams needed, then multiply these measurements by the current cost per linear foot. Add in any additional expenses such as delivery or installation for a comprehensive estimate.

What Factors Influence The Cost Of Wood Beams?

Several factors influence the cost of wood beams, including the type and quality of wood, the length and dimensions required, as well as the supplier’s pricing and delivery fees. Additionally, market demand and availability can impact the final cost of wood beams for your project.

How Can I Save Money When Buying Wood Beams?

You can save money when buying wood beams by purchasing directly from a wholesaler or manufacturer, comparing prices from different suppliers, and considering alternative wood options that offer similar strength and aesthetics. Additionally, buying in bulk or during off-peak seasons can often result in cost savings.

Conclusion

Calculating wood beam costs is crucial for accurate budgeting. Use our simple calculator for efficient planning. Stay informed, stay ahead in your construction projects. Make informed decisions effortlessly. Let numbers guide your next wood beam selection. Simplify your budgeting process starting today.

Ready, set, calculate!