Oil finishes penetrate the wood’s fibers and cannot be built up to a thick coating like polyurethane or varnish. They are easy to apply but offer less protection and are susceptible to wear.

Oil finishes are a popular choice among woodworkers for their ease of application and natural appearance. These finishes penetrate the wood fibers, enhancing the wood’s natural beauty while providing protection. Unlike polyurethane or varnish, oil finishes cannot be built up to a thick coating due to their penetrative properties.

This makes them less durable and more susceptible to wear than other finishes. However, their natural appearance and ease of application make them a great choice for projects that require a subtle finish. We will discuss the types of oil finishes available, their advantages, disadvantages, and how to apply them.

Benefits Of Oil Finish

Oil finish is a preferred choice in woodworking as it allows the wood to retain its natural beauty and texture. Unlike varnish and polyurethane, oils penetrate into the wood, enhancing its durability, easy to apply and repair.

If you are looking for an easy and natural way to finish your woodworking project, then oil finish might be the perfect choice for you. There are several benefits of using oil finish on wood, such as enhanced wood grain appearance, natural look and feel, and easy application. Let’s take a closer look at each of these benefits.

Easy Application

One of the biggest advantages of using oil finish on wood is the easy application process. Unlike varnish or polyurethane, which require multiple coats and extensive drying time, oil finish can be applied in a single coat. Furthermore, since oil is absorbed into the wood, there is no need for sanding between coats, making the process quicker and more straightforward. This ease of application makes oil finish an excellent option for beginners or those looking to save time on their project.

Enhanced Wood Grain

Another benefit of using oil finish is the way it enhances the natural beauty of the wood’s grain. When applied on wood, oil penetrates the fibers, giving them a deep and rich appearance. This enhancement of the wood grain’s natural beauty makes oil finish a popular choice for projects where the wood’s texture and pattern are essential.

Natural Appearance

Oil finish provides a natural and warm look to wood projects. Unlike varnish or polyurethane, which leave a plastic-like finish, oil finish penetrates the wood’s pores, making it look and feel natural. With oil finish, you can preserve the natural color of the wood, making it an excellent choice for projects where you want to show off the wood’s natural look.

In conclusion, if you’re looking for a versatile and straightforward way to finish your woodworking projects while preserving the wood’s natural beauty, oil finish is an excellent option. With its easy application, enhanced wood grain, and natural appearance, you can create beautiful, long-lasting, and elegant pieces that you’ll be proud to show off.

Types Of Oil Finish

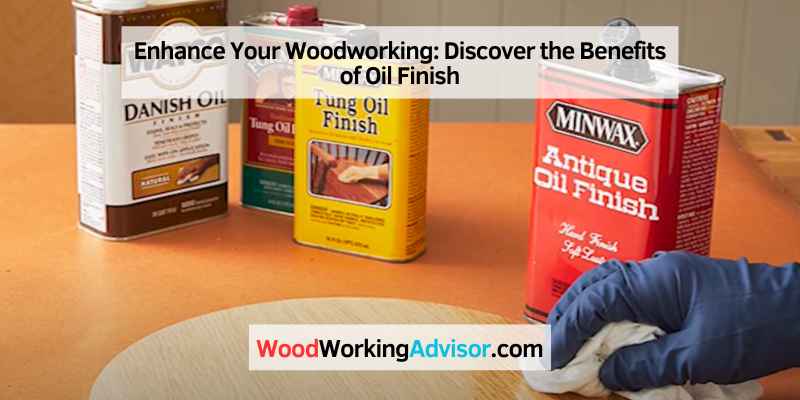

There are various types of oil finishes available for woodworking, including tung oil, Danish oil, and finishing oil. Oil finishes penetrate the wood’s fibers, offering less protection than polyurethane or varnish but are the easiest to apply. Different types of oils have their own benefits and disadvantages and are dependent on the intended use of the wood.

When it comes to finishing your woodworking project, oil finishes can be an excellent choice. Unlike other finishes that form a hard, protective layer on top of the wood, oil finishes penetrate deep into the wood fibers, providing a rich, natural look that highlights the wood grain. There are several types of oil finish to choose from, including tung oil, Danish oil, and linseed oil.

Tung Oil

Tung oil is a popular oil finish derived from the nut of the tung tree. This oil finish is known for its durability, water resistance, and ability to highlight the natural beauty of the wood. Tung oil is easy to apply and can create a glossy or satin finish depending on how many coats are applied. However, if you have a nut allergy, tung oil should be avoided.

Danish Oil

Danish oil is a mixture of tung oil and varnish, along with mineral spirits to thin the mixture. It is a popular choice among woodworkers due to its ease of application and quick drying time. Danish oil can create both a natural or glossy finish depending on how many coats are applied, and it is also water-resistant.

Linseed Oil

Linseed oil is derived from the seeds of the flax plant. It is a popular choice for woodworkers because it is affordable and readily available. Linseed oil provides a natural-looking finish that highlights the wood grain. It does take longer to dry compared to tung oil and Danish oil, but it is highly water-resistant and dries to a glossy finish.

In conclusion, oil finishes are an excellent choice for woodworking projects. Each type of oil finish has its own unique properties and can provide a natural-looking finish that protects the wood from moisture and wear. When choosing an oil finish, consider the properties of each type and how they will work with your project to achieve the desired results.

When To Use An Oil Finish

Woodworking oil finish is ideal for wood that needs frequent wetting and has a natural wood look. Oil finishes penetrate deeply into the wood’s fibers, seeping in to offer protection. However, oil finishes cannot build up to a thick coat like polyurethane or varnish finishes.

When it comes to finishing your woodworking projects, there are many options available. However, oil finishes have remained a popular choice over the years, as they offer a natural and durable finish to your wooden pieces. One of the key benefits of using an oil finish is that it can penetrate deep into the wood, protecting it from within. In this article, we’ll discuss when to use an oil finish for exterior wood, furniture, and woodworking projects.

Exterior Wood

If you’re looking to protect your exterior woodwork, such as decks, fences, and outdoor furniture, then an oil finish can be the ideal solution. Since oil finishes penetrate deeply into the wood, they are able to protect and preserve it against harsh weather conditions, UV rays, and other damaging elements. Traditional oil finishes, like linseed oil and tung oil, can be effective on exterior wood, but they do require regular maintenance to ensure that the wood remains protected.

Furniture

Oil finishes can also be a great choice for wooden furniture. They offer a natural matte or satin finish, which enhances the natural beauty of the wood grain, making it a popular choice for pieces that require a subtle look, such as antique furniture or bespoke wooden pieces. However, it’s important to note that oil finishes provide less protection against water, scratches, and stains compared to varnish or polyurethane finishes, so it may not be a suitable option for furniture that will be exposed to heavy use or contact with liquids.

Woodworking Projects

Oil finishes can be an ideal coating for woodworking projects that require a more natural, organic look, such as cutting boards, wooden toys, and decorative pieces. Since oil finishes do not form a thick layer on top of the wood, it allows the wood to breathe and allows you to feel the warmth and texture of the wood. Moreover, oil finishes can be applied easily and quickly, as it just needs to be wiped on with a lint-free cloth.

In conclusion, if you’re looking for a natural, durable, and easy-to-use finish for your woodworking project, then an oil finish may be the perfect solution. Just remember to choose the right oil finish for your specific needs, apply it according to the manufacturer’s instructions, and ensure that the wood remains well-maintained to keep it looking great for years to come.

Disadvantages Of Oil Finish

Oil finishes for woodworking have a few disadvantages. They cannot be built up into a thick coat like polyurethane or varnish because they seep into the wood and penetrate its fibers. Additionally, they offer less protection and are susceptible to wear.

When it comes to finishing woodwork, oil finishes have their fair share of advantages and disadvantages. While oil finishes are easy to apply and enhance the natural beauty of the wood, they also have some drawbacks. Let’s take a closer look at the disadvantages of oil finishes.

Less Protection

Oil finishes seep into the wood and penetrate its fibers, which means that they cannot be built up to a thick coat like polyurethane or varnish can. As a result, oil finishes offer less protection against scratches, dings, and other wear and tear. If you are looking for a finish that provides a high degree of protection, oil may not be your best bet.

Cannot Create Thick Coat

As mentioned earlier, because oil finishes penetrate the wood, it is not possible to build up a thick coat with this type of finish. Therefore, if you want a glossy or shiny look, oil may not be the right choice for your project. Instead, you might consider using a polyurethane or varnish.

Despite their disadvantages, oil finishes remain a popular choice for many woodworkers due to the ease of application and their ability to enhance the natural beauty of the wood. However, it’s important to keep in mind their limitations, particularly when it comes to protection and creating a thick coat. As with any other finish, it’s essential to choose the right one for your project based on your needs and preferences.

Choosing The Right Oil

Choosing the right oil for a woodworking project is crucial in achieving the desired outcome. Oil finishes such as tung oil, Danish oil, and finishing oil offer a natural look and feel to the wood surface, although they offer less protection compared to varnish or polyurethane.

Choosing the right oil finish is crucial for your woodworking project. There are various factors to consider when selecting an oil finish, including the type of wood you are working with, the intended use of the finished product, and the level of maintenance required. Let’s look at some factors to consider when choosing the right oil finish.

Factors to Consider

When selecting an oil finish, there are several factors to consider to ensure that you choose the right product. These factors include:

1. Wood Type – Different wood types absorb oil finishes differently. Softwoods, like pine, tend to absorb oil finishes more readily than hardwoods, like oak.

2. Intended Use – Consider the intended use of the finished product. Is it for indoor or outdoor use? Is it for a high traffic area? This will determine the level of protection required and the type of oil finish to use.

3. Maintenance – Some oil finishes require minimal maintenance, while others need regular upkeep. If you require a low maintenance finish, choose a product that requires reapplication less frequently.

Comparison of Popular Brands

There are many popular oil finish brands to choose from, each with its unique benefits and drawbacks. Let’s take a look at some of the popular brands and their features.

| Brand | Price | Type of Oil | Drying Time | Level of Protection | Maintenance |

| — | — | — | — | — | — |

| Watco Danish Oil | $13.98 | Danish Oil | 6-8 hours | Medium | Low |

| Minwax Tung Oil Finish | $13.98 | Tung Oil | 24 hours | Medium | Low |

| Talas, 3+ | $23.08 | Boiled Linseed Oil | 2-4 days | Low | Medium |

| Osmo Polyx Oil | $17.59 | Hardwax Oil | 24 hours | High | Low |

| Furniture Clinic | $14.95 | Teak Oil | 24 hours | Medium | Low |

| General Finishes Hard Wax Oil | $37.49 | Hardwax Oil | 12 hours | High | Low |

| Liberon Finishing Oil | $16.95 | Tung Oil | 24 hours | Medium | Low |

In conclusion, choosing the right oil finish is essential for achieving a polished look and ensuring durability. Consider the factors mentioned above and compare different brands to find the best option for your woodworking project.

Application Techniques

When it comes to woodworking oil finishes, it’s essential to apply the oil properly to achieve a beautiful and durable finish. There are different techniques you can use, such as brushing, wiping, or flooding, depending on the wood’s type and condition.

Using the right application technique can make a significant difference in the final result of your project.

The application technique you use when finishing your woodwork can largely influence the outcome of the finished product. Whether you are using oil finishes for the first time or are a seasoned expert, knowing the right technique can make all the difference. Here are three popular application techniques for using woodworking oil finishes:

Flooding Method

The flooding method involves applying the oil finish in excess until the wood can no longer absorb it. This allows the oil to penetrate deep into the wood pores, providing maximum protection. However, using too much oil can also cause problems such as prolonged drying time, resulting in curing issues and poor water resistance.

Brush-On Polyurethane

Brush-on polyurethane is one of the most popular finishing methods, primarily due to its durability and resistance to scratches. It is applied using a brush and often requires multiple coats for maximum protection. Polyurethane finishes create a clear and hard protective surface on the wood, making it ideal for high-traffic areas.

Armour Seal

Armour Seal is a unique oil finish that offers excellent water resistance and durability. It’s easy to apply and requires only one coat. Unlike polyurethane finishes, Armour Seal doesn’t leave a shiny film on the wood, giving it a natural appearance. It is particularly suited for use on outdoor furniture and surfaces exposed to moisture.

When it comes to applying woodworking oil finishes, finding the right technique can be overwhelming. However, choosing the correct technique for your project can ensure a perfect finish that is durable and long-lasting. By following these techniques, you can achieve an attractive and protective finish that will enhance the beauty of any woodwork project.

Frequently Asked Questions Of Woodworking Oil Finish

What Are The Disadvantages Of Oil Finishes On Wood?

Oil finishes cannot be built up to a thick coat like polyurethane or varnish. They offer less protection and are susceptible to wear since they seep into the wood and penetrate the fibers. However, they are easy to apply, ideal for wood that gets wet frequently, and can enhance the wood’s beauty.

Which Is Better Tung Oil Or Danish Oil?

Both tung oil and Danish oil are popular wood oils with their own unique features. Tung oil provides a natural and clear finish with better water-resistant properties, while Danish oil dries faster and offers better durability against wear and tear.

Ultimately, the choice depends on personal preferences and the project’s specific requirements.

What Is The Difference Between Oil And Varnish Finish?

Oil finishes penetrate into the wood fibers while varnish creates a protective layer on the surface. Oil finishes cannot build up a thick coat and offer less protection than varnish. However, oil finishes are easy to apply and ideal for wood that gets wet frequently.

Varnish protects the wood by forming a layer on top.

Is Wax Or Oil Better For Wood?

Both wax and oil have their own benefits for wood. Wax acts as a barrier to prevent wood from graying and doesn’t penetrate the wood. On the other hand, oil penetrates the wood, enhances its beauty, and offers protection. However, oil finishes are susceptible to wear and cannot be built up to a thick coat.

Ultimately, your choice depends on your goal for your wood project.

Conclusion

When it comes to choosing a wood finish, oil finishes provide a natural and simple option that can bring out the beauty of the wood. They are easy to apply and allow the wood to breathe while providing adequate protection.

However, they are not as durable as polyurethane or varnish finishes and can wear off over time. Ultimately, the choice of a finish depends on individual preferences and requirements. With the right application techniques, woodworkers can achieve the desired results with oil finishes and enjoy the natural beauty of wood for years to come.