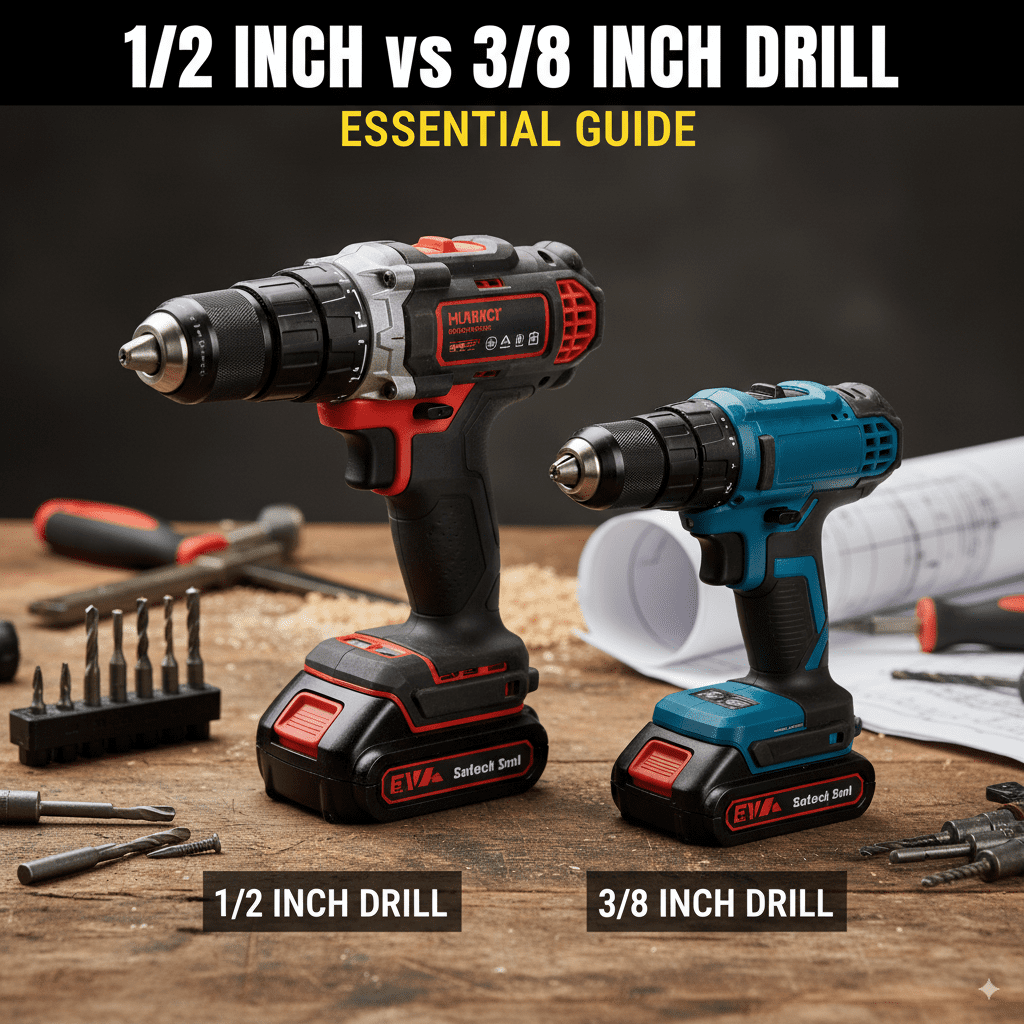

1 2 Inch vs 3 8 Inch Drill: Essential Guide

Choosing between a 1/2 inch and a 3/8 inch drill chuck size can seem confusing, but it’s simpler than you think! For most home DIY and basic woodworking, a 3/8 inch drill is perfectly adequate. However, if you tackle tougher jobs or need more power and versatility, a 1/2 inch drill is the better, more robust choice. This guide will clarify the differences and help you pick the right drill for your needs.

Hobbyists and homeowners often face a common dilemma when buying their first drill: what chuck size is best? It’s a small detail, but it can impact what you can do with your tool. You might look at a drill’s specs and see “3/8 inch” or “1/2 inch” and wonder, “Does this really matter for my projects?” Don’t worry, I’ve been there, and it’s a perfectly normal question to ask! This guide will break down the differences between 1/2 inch and 3/8 inch drills in a way that makes sense. We’ll explore what these sizes mean, why they matter, and which one you should choose to add to your toolbox.

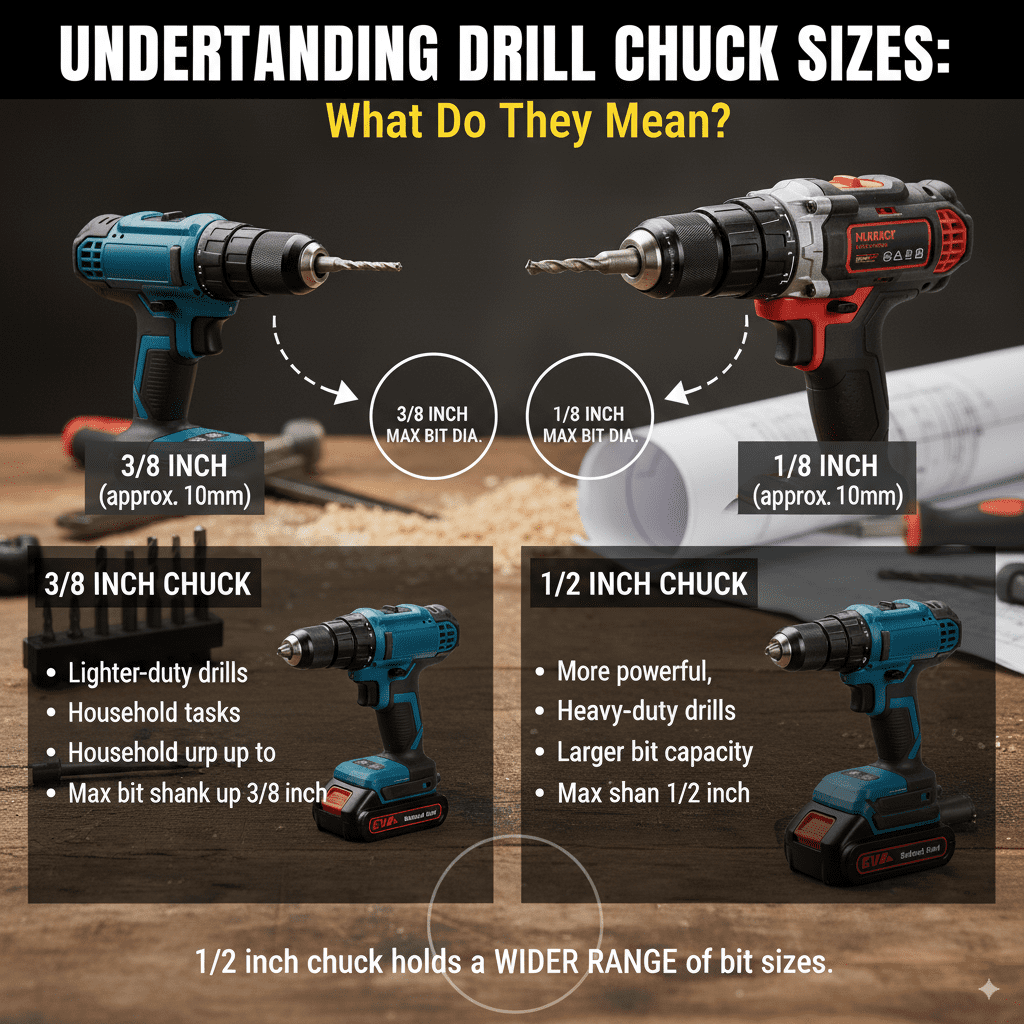

Understanding Drill Chuck Sizes: What Do They Mean?

The “chuck” is the part of the drill that holds the drill bit. Think of it like the drill’s hand – it grips the bit firmly so it can spin and make holes. The size mentioned for a drill, like 3/8 inch or 1/2 inch, refers to the maximum diameter of drill bit shank it can securely hold. This might seem small, but it’s a crucial factor in a drill’s capability.

Drill Chucks Explained

3/8 Inch (approx. 10mm): These are common for lighter-duty drills, often found in cordless models designed for household tasks. They can grip shanks of drill bits up to 3/8 of an inch in diameter.

1/2 Inch (approx. 13mm): These chucks are typically found on more powerful, heavier-duty drills. They can accommodate larger drill bit shanks, up to 1/2 inch in diameter.

Essentially, a 1/2 inch chuck can hold a wider range of drill bit sizes, including all the sizes a 3/8 inch chuck can hold, plus larger ones.

Key Differences: 1/2 Inch vs. 3/8 Inch Drills

The primary difference between these two drill sizes lies in their power, torque, and the types of jobs they are best suited for. It’s not just about the chuck size, but what that chuck size signifies about the drill’s overall build and capability.

Power and Torque

3/8 Inch Drills: Generally, drills with 3/8 inch chucks are designed for lighter tasks. They offer sufficient power for drilling into drywall, wood, and softer materials. Their torque (rotational force) is adequate for everyday home use.

1/2 Inch Drills: Drills with 1/2 inch chucks are typically more powerful. They are built to handle more demanding applications, such as drilling into harder woods, metals, masonry (with appropriate bits and settings), and larger diameter holes. They usually have higher torque ratings, making them better for tasks that require sustained power.

Drill Bit Capacity

This is where the chuck size directly impacts your work.

3/8 Inch Chuck: Can hold drill bits with shanks up to 3/8 inch. This covers a vast majority of common drill bits used for wood screws, general drilling, and small-to-medium holes.

1/2 Inch Chuck: Can hold drill bits with shanks up to 1/2 inch. This opens the door to using larger twist bits, spade bits, and hole saws that have thicker shanks, often needed for bigger holes or more robust materials.

Motor Size and Gearbox

Manufacturers usually pair larger chucks with more powerful motors and more robust gearboxes.

3/8 Inch Drills: Often come with smaller, more efficient motors, ideal for battery-powered drills where conserving energy is key. The gearing might be optimized for speed over raw power.

1/2 Inch Drills: Tend to have larger, beefier motors and stronger gear trains. This allows them to deliver more consistent power and withstand the stress of heavy-duty drilling.

Applications and Usage

The intended use case is a major deciding factor.

3/8 Inch Drills are great for:

Hanging pictures and shelves

Assembling furniture

Light repairs around the house

Drilling pilot holes for screws

Working with softer woods or plastic

1/2 Inch Drills are better for:

Drilling larger holes in wood (e.g., for dowels, large fasteners)

Working with denser hardwoods or even some metals

Using large hole saws for tasks like installing doorknobs or running pipes

Projects requiring high torque, like mixing paint with an attachment

Tasks that demand sustained power and durability

Size, Weight, and Ergonomics

A larger chuck often means a larger, heavier drill, but not always.

3/8 Inch Drills: Can be more compact and lightweight, making them easier to handle for extended periods or when working in tight spaces. This is a big plus for many DIYers who prioritize comfort.

1/2 Inch Drills: Can be bulkier and heavier, especially corded models. However, modern cordless 1/2 inch drills have made great strides in ergonomics, making them more comfortable to use than older models.

When to Choose a 3/8 Inch Drill

For many beginners and homeowners, a 3/8 inch drill is the perfect starting point. It’s the workhorse for most common tasks.

Pros of a 3/8 Inch Drill:

Cost-Effective: Generally less expensive than 1/2 inch models.

Lighter Weight: Easier to handle, especially for repetitive tasks or overhead work.

Compact Size: More maneuverable in tight spaces.

Wide Availability: Most entry-level and mid-range cordless drills come with 3/8 inch chucks.

Sufficient for Most DIY: Handles the majority of household drilling, assembly, and light woodworking needs.

Cons of a 3/8 Inch Drill:

Limited Capacity for Large Bits: Cannot accept the largest common drill bits (over 3/8 inch shank).

Less Torque: May struggle with very hard materials or large hole saws.

Less Versatile for Heavy Tasks: Not ideal for consistent, heavy-duty work.

When to Choose a 1/2 Inch Drill

If you plan to do more than just basic home maintenance, or if you’re looking for a tool that will grow with your skills, a 1/2 inch drill is often the better investment.

Pros of a 1/2 Inch Drill:

Greater Capacity: Accepts a much wider range of drill bits, including larger ones.

More Power and Torque: Handles tougher materials and larger holes with ease.

Increased Versatility: Suitable for a broader spectrum of DIY, woodworking, and even construction tasks.

Durability: Often built with more robust components for heavy-duty use.

Future-Proofing: Provides the capability for more advanced projects as your skills grow.

Cons of a 1/2 Inch Drill:

Higher Cost: Typically more expensive than 3/8 inch models.

Heavier and Bulkier: Can be more fatiguing to use for long periods, though ergonomics are improving.

Overkill for Simple Tasks: May be more than you need for very basic jobs.

Cordless vs. Corded Drills: Chuck Size Considerations

The choice between cordless and corded drills also plays a role.

Cordless Drills

Most cordless drills, especially those in the compact or standard sizes, come with 3/8 inch chucks. This is to balance power, battery life, and weight. However, higher-end, full-size cordless hammer drills or impact drivers often feature 1/2 inch chucks due to their increased power and intended applications. If you’re going cordless and aiming for versatility, look for a 1/2 inch chuck on a drill with a good amp-hour (Ah) battery rating.

Corded Drills

Corded drills, historically, were the standard for power and torque. Many corded drills, particularly those aimed at tradespeople or serious DIYers, come with 1/2 inch chucks. They offer unlimited power and are excellent for sustained, heavy-duty tasks. If you need maximum power and don’t mind being tethered to an outlet, a corded 1/2 inch drill is a fantastic option.

Understanding Drill Bit Shanks

To truly grasp the 1/2 inch vs. 3/8 inch drill decision, it’s helpful to know about drill bit shanks. The shank is the part of the drill bit that goes into the chuck. Most common twist bits have round shanks.

Round Shank: The most common type. For bits up to 3/8 inch, these fit snugly into either chuck. For bits larger than 3/8 inch but less than 1/2 inch, they will only fit in a 1/2 inch chuck.

Hex Shank: Often seen on driver bits and some specialized drill bits. These have a hexagonal shape for better grip, especially in impact drivers. A 1/4 inch hex shank will fit in any drill chuck, but larger hex shanks might require specific chuck types or adapters.

SDS Shank: Primarily found on hammer drills for masonry. These are not compatible with standard drill chucks.

The key takeaway here is that a 1/2 inch chuck offers more room for larger diameter round shanks, which are common on bigger drill bits and hole saws.

Choosing the Right Drill for Your Needs – A Table Guide

To make the decision easier, consider these common scenarios:

| Your Primary Use Case | Recommended Drill Size | Why? |

|---|---|---|

| Basic home repairs, hanging decor | 3/8 Inch | Light-duty, convenient, and cost-effective for tasks like pilot holes and small fasteners. |

| Furniture assembly, IKEA furniture | 3/8 Inch | Adequate power and speed for screws and small holes. Lighter weight is good for repetitive work. |

| Occasional woodworking (softwoods) | 3/8 Inch | Suitable for smaller holes and general shaping. |

| More advanced woodworking, hardwoods | 1/2 Inch | Needed for larger bits, more torque, and drilling through denser materials. |

| Using large hole saws (e.g., plumbing) | 1/2 Inch | Essential for securely holding and powering larger diameter bits like hole saws. |

| Drilling into metal or masonry (occasionally) | 1/2 Inch (Hammer Drill) | Higher torque and often hammer function (on hammer drills) are necessary for tough materials. |

| Expecting to grow into more advanced projects | 1/2 Inch | A 1/2 inch drill offers greater versatility and capability for future, more challenging endeavors. |

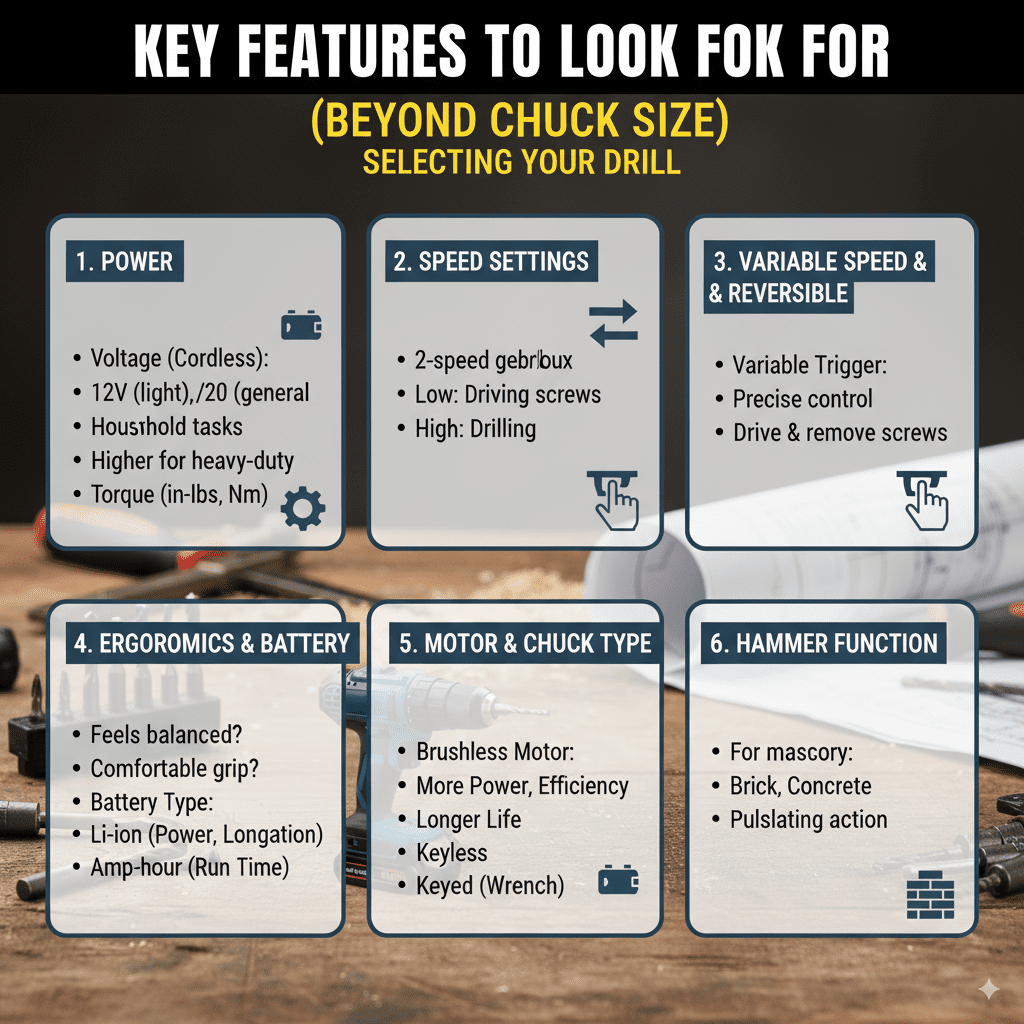

Key Features to Look For (Beyond Chuck Size)

When selecting your drill, don’t let the chuck size be the only deciding factor. Consider these other important features:

Power: Look at voltage for cordless (12V for light, 18V/20V for general use, higher for heavy-duty) and wattage for corded. For torque, check its rating (in-lbs or Nm).

Speed Settings: Most drills have 2-speed settings. Lower speed for driving screws, higher speed for drilling.

Variable Speed Trigger: Allows for precise control over speed.

Reversible: Essential for driving and removing screws.

Ergonomics: How does it feel in your hand? Is it well-balanced?

Battery Type (Cordless): Lithium-ion (Li-ion) is the standard, offering good power and longevity. Check amp-hour (Ah) for run time.

Brushless Motor (Cordless): Offers more power, efficiency, and longer tool life compared to brushed motors.

Chuck Type: Keyed chucks require a separate “key” to tighten the bit, while keyless chucks are tightened by hand. Keyless is more convenient for most users.

Hammer Function: If you plan to drill into brick or concrete regularly, a hammer drill function is beneficial.

Frequently Asked Questions (FAQs)

Q1: Can a 3/8 inch drill use 1/2 inch drill bits?

No, a 3/8 inch drill chuck can only securely hold drill bits with shanks up to 3/8 inch in diameter. Attempting to force a larger bit will not work and could damage the chuck.

Q2: Will a 1/2 inch drill accept smaller drill bits, like 1/4 inch or 3/8 inch?

Yes, absolutely! A 1/2 inch chuck is designed to grip a range of bit shank sizes, from very small up to 1/2 inch. So, all the bits you would use in a 3/8 inch drill will also work perfectly in a 1/2 inch drill.

Q3: Is a 1/2 inch drill too big or heavy for a beginner?

It can be, but it’s not always the case. Modern 1/2 inch cordless drills have excellent ergonomics. While they might be slightly heavier than their 3/8 inch counterparts, the added capability often outweighs the minor weight difference for many DIYers. It’s best to hold one in a store if possible.

Q4: When do I absolutely need a 1/2 inch drill?

You’ll definitely need a 1/2 inch drill when working with large hole saws (typically larger than 1.5 inches in diameter), spade bits over 1 inch, or when drilling repeatedly into dense hardwoods or metals where consistent torque is crucial.

Q5: What is the difference between a drill and a hammer drill?

A standard drill spins a bit to make holes. A hammer drill has an added “hammering” action that pounds the bit forward as it spins, making it much more effective for drilling into masonry like brick and concrete. Both can have either 3/8 inch or 1/2 inch chucks. For masonry work, a 1/2 inch hammer drill is usually recommended.

Q6: Are 1/2 inch chucks always “metal”?

While many higher-quality 1/2 inch chucks are indeed made of metal for durability, some are still made of robust composite materials. The material is important, but the overall build quality and the size of the chuck (1/2 inch) is usually a better indicator of whether it’s designed for heavier use.

Q7: If I’m just starting, what’s the safest bet?

For most homeowners just starting out with basic tasks, a good quality 18V (or 20V max) cordless drill with a 3/8 inch chuck is a fantastic and practical choice. If you know you’ll be tackling more robust projects soon, or want a tool that will last through more advanced skill-building, investing in a 1/2 inch cordless drill from the start is a wise decision.

Making Your Final Choice

Deciding between a 1/2 inch and a 3/8 inch drill boils down to understanding your project needs and your future DIY aspirations. For filling your toolbox with basic tools for everyday fixes and simple assemblies, a 3/8 inch drill will serve you well. It’s lighter, often more affordable, and handles the bulk of common household tasks with ease.

However, if you envision yourself tackling more ambitious woodworking projects, working with denser materials, or frequently using larger drill bits and hole saws, stepping up to a 1/2 inch drill is a smart move. It’s an investment in versatility and power that will empower you to take on a wider range of challenges. Remember to also consider the power source (corded vs. cordless), the motor type, and other features that enhance usability. Whichever you choose, knowing the differences will help you make an informed decision that sets you up for success in your crafting journey. Happy drilling!