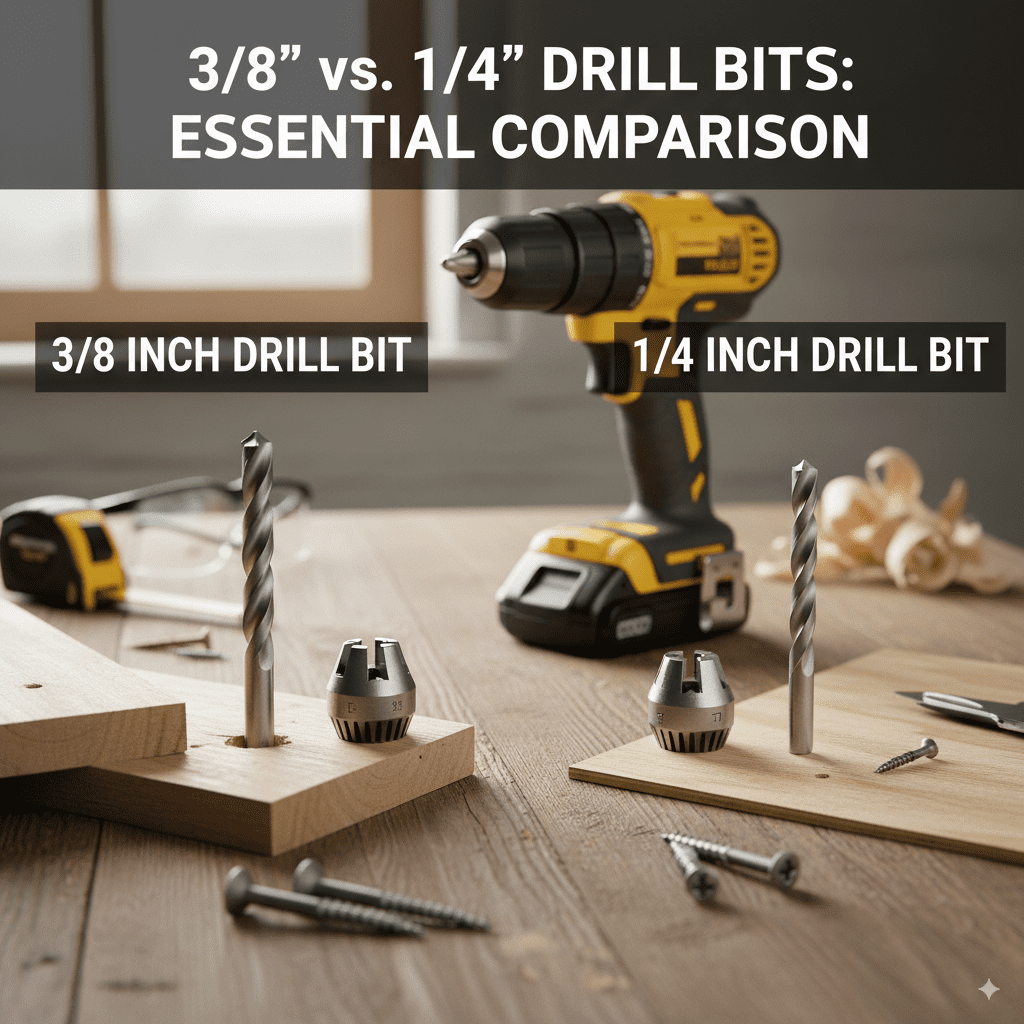

3 8 Drill Bit vs 1 4: Essential Comparison

Choosing between a 3/8″ and 1/4″ drill bit comes down to hole size and material strength. 1/4″ is great for lighter tasks like pilot holes for screws or small fasteners, while 3/8″ is for larger holes, heavier-duty screws, or when more material needs to be removed quickly for things like dowels or larger bolts.

Hey there, fellow DIYers and aspiring woodworkers! Md Meraj here, ready to demystify another common workshop question that can sometimes feel a bit puzzling: the difference between a 3/8 drill bit and a 1/4 drill bit. It’s easy to look at them and think, “They’re both just drill bits, right?” But in the world of making things, those small differences in size truly matter. Picking the right bit ensures your project goes smoothly, your fasteners hold tight, and you don’t end up with a hole that’s too big or too small. Don’t worry if this feels a little confusing; we’re going to break it down step-by-step so you can make the best choice for your next project, every time. Let’s get drilling!

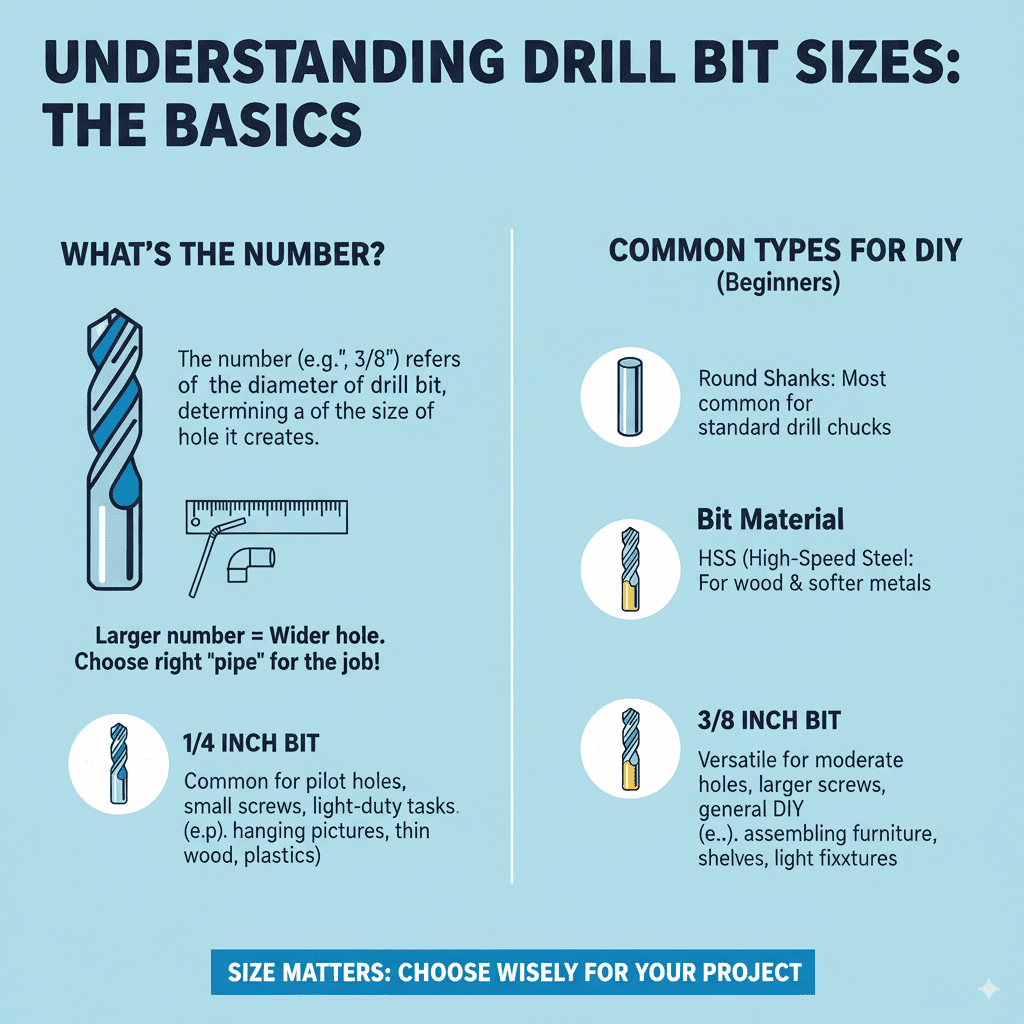

Understanding Drill Bit Sizes: The Basics

Drill bits come in countless sizes, measured in inches or millimeters, and understanding how these measurements affect your work is foundational to successful DIY projects. For beginners, focusing on the most common Imperial sizes, like 1/4 inch and 3/8 inch, is a fantastic starting point. These two sizes are workhorses in any home workshop, used for a wide range of common tasks.

The number refers to the diameter of the drill bit – essentially, how wide the hole it creates will be. A larger number means a wider bit and thus a wider hole. Think of it like choosing the right size pipe for water; you wouldn’t use a tiny straw for a whole sink, would you? The same principle applies to drilling. The material you’re drilling into and what you plan to do with the hole afterwards dictates the bit size you should reach for.

It’s also worth noting that drill bits have different shank styles (the part that goes into the drill chuck), but for the most common twist drill bits used by beginners, you’ll likely encounter round shanks that fit right into your standard drill chuck. The material of the bit itself also matters – high-speed steel (HSS) is common for wood and softer metals, while carbide-tipped bits are for tougher materials. For our comparison today, we’ll assume standard HSS twist drill bits, which are perfect for general woodworking and DIY.

The 1/4 Inch Drill Bit: Your Everyday Workhorse

The 1/4 inch drill bit is often the first “larger” bit many DIYers acquire after the very smallest sizes. It’s incredibly versatile and finds a home in a multitude of common household and workshop tasks. Its moderate size makes it ideal for creating pilot holes, which are essential before driving screws, especially into hardwoods. Pilot holes prevent the wood from splitting and make driving screws much easier, even by hand. Have you ever had a screw just refuse to go in straight, or worse, split a beautiful piece of wood? Using the right size pilot hole with a 1/4″ bit can save you a lot of frustration.

Beyond pilot holes, a 1/4″ bit is perfect for drilling clearance holes for certain types of bolts or threaded rods. It’s also commonly used for installing hardware like drawer pulls, light fixtures, or small hinges where the screw or mounting bolt is around 1/4 inch in diameter. Think about assembling a bookshelf, mounting a bracket, or even putting up a picture frame with heavier-duty hardware – the 1/4″ bit is often the go-to.

When to Use a 1/4″ Drill Bit:

- Drilling pilot holes for screws (especially in hardwoods).

- Creating clearance holes for bolts and threaded rods up to approximately 1/4 inch.

- Installing common hardware such as drawer knobs, light fixtures, and basic hinges.

- Making holes for small dowels or wooden pegs.

- Working with materials like standard lumber, plywood, MDF, and some plastics.

- General-purpose drilling tasks where a precise, but not overly large, hole is needed.

The 1/4″ bit offers a good balance: it’s wide enough to be effective for its intended purposes without being so large that it’s difficult to control or removes excessive material. It’s the kind of bit you’ll find yourself reaching for project after project. It’s a staple for a reason!

The 3/8 Inch Drill Bit: For Bigger Jobs

Now, let’s talk about the 3/8 inch drill bit. As you can see, it’s noticeably wider than the 1/4 inch bit. This increased diameter means it’s designed for tasks where you need a larger hole. The most significant advantage of a 3/8″ bit is its ability to create holes for larger fasteners, such as 3/8″ bolts, lag screws, or when you need to drill a hole for a larger dowel rod. When you’re building something sturdy, like a workbench, a garden planter box, or framing a structure, you’ll often encounter hardware that requires a hole of this size or larger.

Another key use for a 3/8″ bit is when you need to drill a hole that’s slightly larger than the fastener itself, providing ample clearance. This is crucial for components that need to move freely or for situations where precise alignment might be a challenge. For example, if you’re attaching two large pieces of wood and need to pass a bolt through both, a 3/8″ bit might be what you need to accommodate a 5/16″ or 3/8″ bolt with some wiggle room.

Using a 3/8″ bit requires a drill with sufficient power and torque. While most modern cordless drills can handle it, especially in softer woods, trying to force a larger bit through dense material with an underpowered drill can strain the tool and lead to poor results. It’s important to match your drill’s capability to the size of the bit and the material you’re working with. For a more in-depth look at drill power and types, you might find resources from organizations like the Toolocity blog on drill bit types helpful for understanding material compatibility.

When to Use a 3/8″ Drill Bit:

- Drilling holes for 3/8″ bolts, lag screws, or other large fasteners.

- Creating clearance holes for larger dowels or wooden joinery.

- When a larger diameter hole is specifically required for a project component.

- Drilling through thicker materials where a larger hole speeds up the process.

- Applications requiring more substantial structural connections.

- Creating larger anchor points for heavy-duty items.

The 3/8″ bit is your go-to for applications where strength and substantial connections are key. It allows for bigger bolts, wooden joinery, and generally more robust construction compared to its smaller counterpart.

Direct Comparison: 3/8″ vs. 1/4″ Drill Bit

Here’s a direct look at how these two popular drill bit sizes stack up against each other. Understanding these differences will help you pick the right tool for the job instantly.

| Feature | 1/4 Inch (1/4″) Drill Bit | 3/8 Inch (3/8″) Drill Bit |

|---|---|---|

| Diameter | 0.25 inches (approximately 6.35 mm) | 0.375 inches (approximately 9.53 mm) |

| Hole Size Created | Smaller, precise holes | Larger, more substantial holes |

| Primary Uses | Pilot holes for screws, hardware installation (knobs, hinges), small bolts, general DIY. | Larger bolts, lag screws, substantial dowels, clearance holes for larger fasteners, heavier construction. |

| Material Removal Rate | Lower: Removes less material, slower for larger holes. | Higher: Removes more material, faster for creating larger openings. |

| Drill Power Requirement | Generally manageable for most drills, including lighter cordless models. | Requires a drill with adequate power and torque, especially for denser materials. |

| Effect on Wood | Less likely to cause splitting when used as a pilot hole for appropriate screws. | Can cause significant splitting if used as a pilot hole for small screws; primarily for larger holes. |

| Common Fastener Size Accommodated | Screws up to about #10 or #12, bolts up to 1/4″. | Bolts and lag screws up to 3/8″, larger dowels. |

As you can see from the table, the primary distinction is diameter, which directly impacts the size of the hole you can create and the types of fasteners you can accommodate. Think of the 1/4″ bit as your everyday screwdriver helper, and the 3/8″ bit as your heavy-duty construction buddy.

Why Choosing the Right Size Matters: Avoiding Common Pitfalls

It might seem like a small detail, but using the wrong drill bit size can lead to several frustrating problems. Let’s walk through a couple of common scenarios:

Scenario 1: Using a 3/8″ bit for a pilot hole where a 1/4″ would suffice.

If you’re driving a standard wood screw (say, a #8 or #10 screw) and you drill a 3/8″ pilot hole, you’ve created a hole much larger than the screw shank. When you drive the screw, there won’t be enough wood for the threads to grip effectively. This means the screw could be loose, wobbly, or simply won’t hold anything securely. In some cases, you might even strip the threads of the screw itself. For smaller screws, a 1/4″ bit is usually too large for a pilot hole anyway; you’d typically use bits in the range of 3/32″ to 7/32″ depending on the screw size and wood type.

Scenario 2: Trying to use a 1/4″ bit for a 3/8″ bolt.

If you need to pass a 3/8″ bolt through two pieces of wood, a 1/4″ drill bit simply won’t be big enough. You’ll either be unable to get the bolt started, or you’ll have to force it, potentially damaging the wood or the bolt. Even if you could somehow force it, there would be no clearance, making alignment very difficult. This is where the 3/8″ bit shines – it creates the necessary space for that larger fastener to pass through cleanly.

Always consult your fastener’s packaging or a reliable guide if you’re unsure about pilot hole or clearance hole sizes. The Popular Mechanics guide on using a drill offers excellent foundational advice for beginners.

The key takeaway is that each bit size is designed for a specific purpose. Using the correct one ensures strength, stability, and a professional finish to your work.

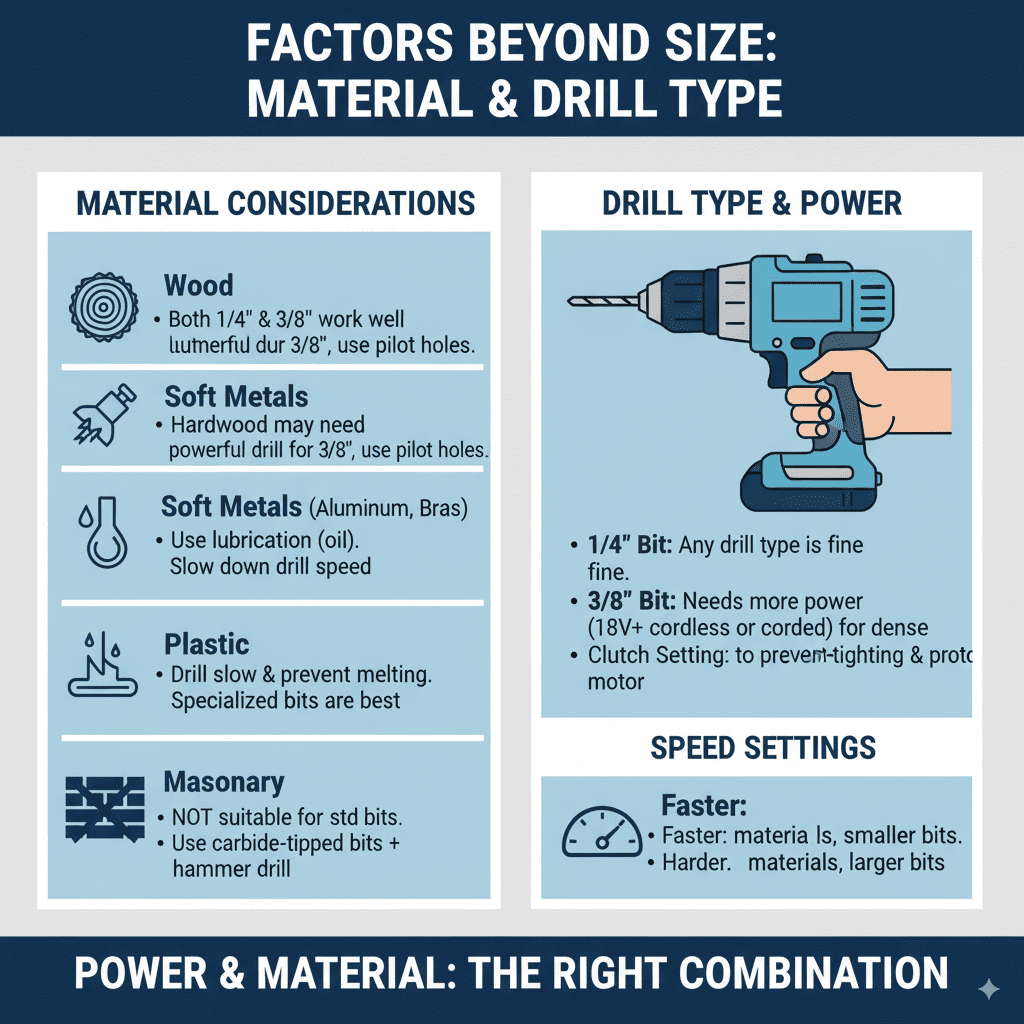

Factors Beyond Size: Material and Drill Type

While size is your primary consideration when comparing 1/4″ and 3/8″ drill bits, don’t forget about the material you’re drilling and the type of drill you’re using. These factors play a crucial role in achieving successful results.

Material Considerations:

- Wood: Both 1/4″ and 3/8″ bits work well in most woods. However, very hard woods might require a more powerful drill for the 3/8″ bit, and pilot holes are almost always recommended for hardwoods for any screw size to prevent splitting.

- Plywood/MDF: These engineered wood products are generally easier to drill. The main concern might be tear-out on the exit side, so using a backing board is a good practice.

- Soft Metals (e.g., Aluminum, Brass): Both bit sizes can be used, but it’s crucial to use lubrication (like cutting oil or WD-40) to prevent the bit from overheating and to ensure a clean cut. Slow down your drill speed.

- Plastic: Plastics can melt if you drill too fast. Use a slower drill speed and consider a specialized plastic drill bit if available, though standard bits work with care.

- Masonry (Brick, Concrete – requires special bits): Standard steel bits like the 1/4″ and 3/8″ discussed here are NOT suitable for masonry. You’ll need carbide-tipped masonry bits and often a hammer drill.

Drill Type and Power:

Your drill is the engine behind the drill bit. For a 1/4″ bit, almost any drill, from a basic corded model to a compact cordless drill, will handle the job with ease. For a 3/8″ bit, especially when drilling into denser materials or for extended periods, a drill with more power (higher voltage for cordless drills, typically 18V or higher) and torque is beneficial. Cordless drills often have a clutch setting that you can adjust to prevent over-tightening screws and to protect the drill motor from strain.

Understanding your tools and materials is just as important as selecting the right drill bit. Always make sure your drill is set to the appropriate speed – faster for softer materials and smaller bits, slower for harder materials and larger bits. For more detailed explanations on drill settings and safety, the OSHA standard (1926.302) for power tools, while geared towards construction, offers excellent safety principles applicable to all DIYers.

Safety First: Essential Tips for Drilling

As your woodworking mentor, safety is always my top priority. Drilling is generally safe, but a few simple precautions will prevent injuries and mistakes:

- Wear Safety Glasses: Always protect your eyes from flying debris. This is non-negotiable.

- Secure Your Workpiece: Clamp down the material you are drilling. This stops it from spinning and prevents injuries. Never try to hold small pieces by hand while drilling.

- Use the Right Bit for the Job: We’ve covered this extensively! Using the correct size and type of bit for the material is crucial for safety and efficiency.

- Ensure Proper Drill Bit Installation: Make sure the drill bit is securely tightened in the drill chuck. A loose bit can wobble, break, or even fly out.

- Maintain a Stable Stance: Stand comfortably with good balance. This helps you control the drill, especially when it bites into the material.

- Be Aware of What’s Behind Your Material: Before drilling, know what’s on the other side so you don’t drill into pipes, wires, or other important things.

- Start Slow: Begin drilling at a slower speed to create a divot, then increase speed as needed. This gives you better control and a cleaner start.

- Let the Drill Do the Work: Don’t force the drill. Apply steady, even pressure. Forcing can damage the bit, the drill, or the workpiece, and can lead to loss of control.

By following these simple safety guidelines, you can approach your drilling tasks with confidence and keep yourself injury-free. Remember, a safe workshop is a happy workshop!

Frequently Asked Questions (FAQ)

Q1: Can I use a 3/8″ drill bit to screw in a 1/4″ bolt?

A1: Yes, you can use a 3/8″ drill bit to create a clearance hole for a 1/4″ bolt. This creates a larger hole than necessary, allowing the bolt to pass through easily with plenty of room. This is often done when you need to assemble parts that might not align perfectly or require some play.

Q2: What’s the difference in hole size between 3/8″ and 1/4″ in millimeters?

A2: A 1/4 inch drill bit creates a hole of approximately 6.35 millimeters. A 3/8 inch drill bit creates a hole of approximately 9.53 millimeters. So, the 3/8″ bit creates a hole that’s about 3 millimeters wider.