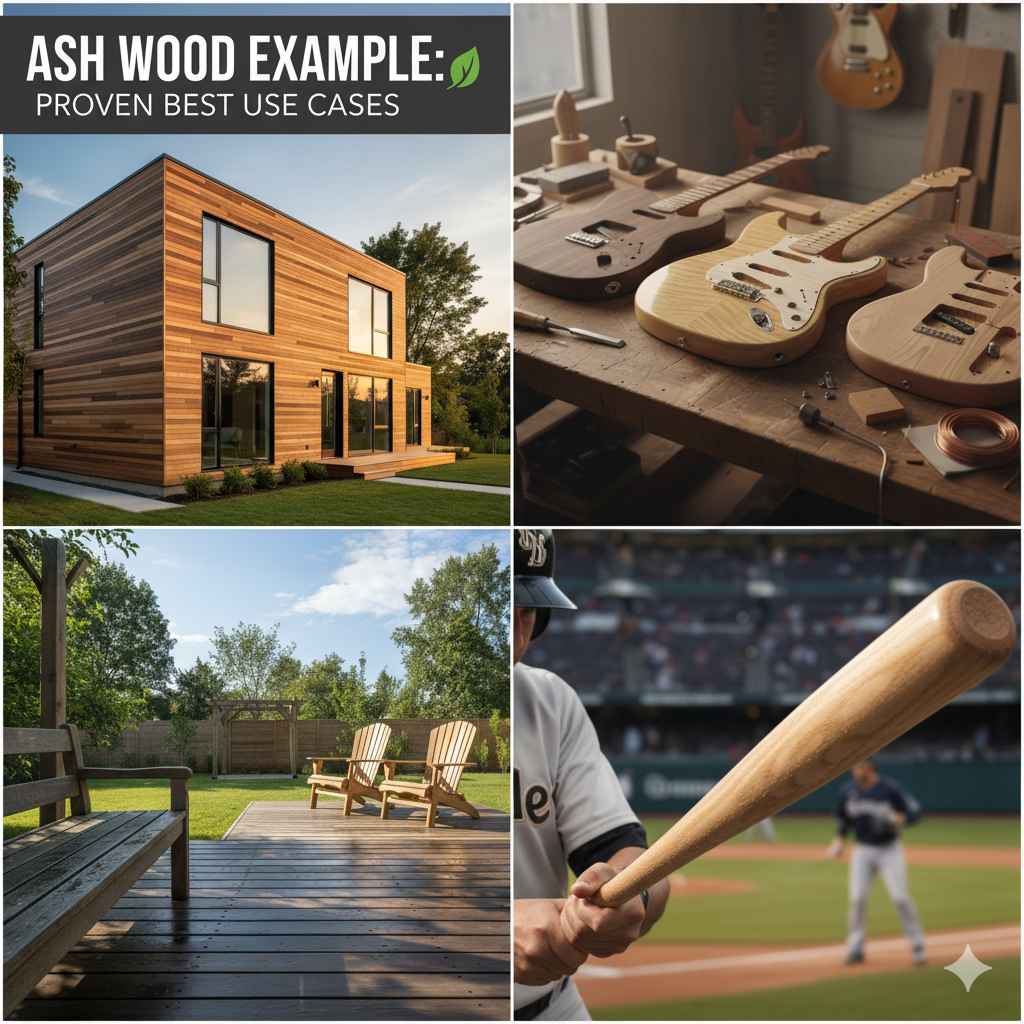

Ash Wood Example: Proven Best Use Cases

Ash wood is a versatile, strong, and attractive hardwood, ideally suited for furniture, tool handles, sports equipment, and flooring due to its excellent shock resistance and appealing grain patterns.

Woodworking can sometimes feel like deciphering a secret code! You’ve probably looked at different wood types and wondered, “What’s this one good for?” Or maybe you’ve picked up a piece of ash wood and thought, “This looks nice, but what can I actually make with it?” It’s a common feeling, and you’re not alone. Choosing the right wood is crucial for any project, big or small. Get it wrong, and your hard work might not last as long as you’d hoped. But don’t worry!

Today, we’re going to shine a bright light on ash wood, showing you exactly why it’s a fantastic choice for so many projects. We’ll break down its best uses with simple explanations, so you can confidently pick up ash for your next DIY adventure.

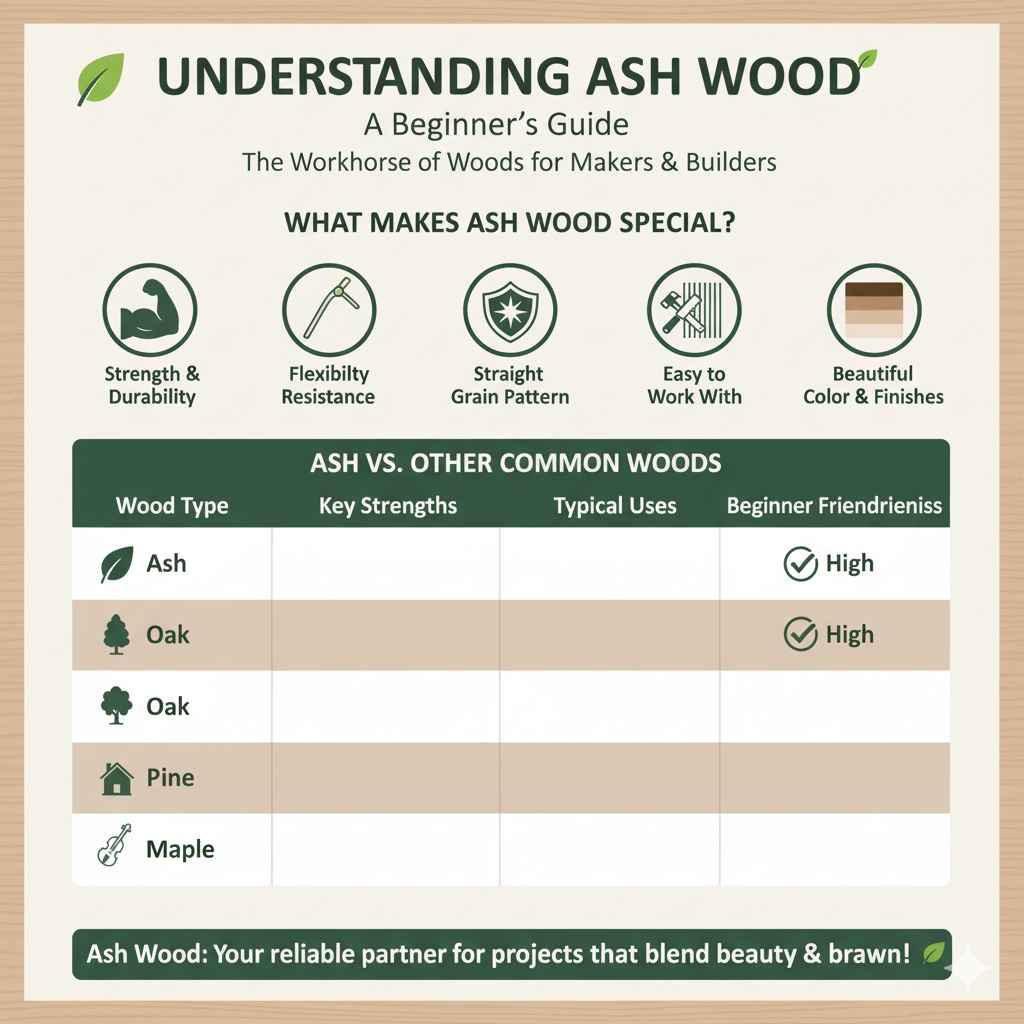

Understanding Ash Wood: A Beginner’s Guide

Ash wood comes from ash trees, and it’s a popular choice for crafters and builders alike. Why? Because it’s a real workhorse! It’s known for being tough, flexible, and looking great. When you’re starting out, understanding a wood’s strengths helps you make smart choices. Ash usually has a straight grain, which means it’s easier to work with, and it can be painted or stained beautifully to match your style.

What Makes Ash Wood Special?

Ash trees, like those in the Fraxinus genus, grow in many parts of the world. The wood from these trees shares some fantastic qualities that make it a favorite.

Strength and Durability: Ash is very strong for its weight. It can handle knocks and bumps really well.

Flexibility: This wood has a good amount of “give” to it, meaning it can bend without breaking easily.

Shock Resistance: Because it’s so tough and flexible, ash is brilliant at absorbing shock.

Grain Pattern: You’ll usually see a straight, often prominent grain, which looks lovely and is easy to work with.

Workability: Ash machines, bends, and finishes well. It holds screws and nails securely.

Color: Typically pale, ranging from creamy white to light brown, sometimes with darker streaks.

Ash vs. Other Common Woods

Thinking about how ash stacks up against other woods you might know can be helpful. Let’s look at a couple.

Here’s your clean table exactly as requested:

| Wood Type | Key Strengths | Typical Uses | Beginner Friendliness |

|---|---|---|---|

| Ash | Strong, flexible, shock-resistant, straight grain | Furniture, tool handles, sports equipment, flooring, cabinetry | High |

| Oak | Very strong, durable, good resistance to decay, prominent grain | Furniture, flooring, cabinetry, boat building, barrels | Medium (can be harder to work) |

| Pine | Lightweight, easy to work, affordable, widely available | Furniture (especially rustic), DIY projects, framing, shelving | Very High |

| Maple | Hard, dense, fine grain, smooth finish, durable | Furniture, flooring, cabinetry, musical instruments, butcher blocks | Medium (hard to plane) |

As you can see, ash strikes a great balance. It’s not as soft and easily dented as pine can be, and it’s often easier to work with than denser hardwoods like oak or maple, making it a sweet spot for many DIYers.

Proven Best Use Cases for Ash Wood

Now, let’s get to the exciting part: what can you make with ash wood? Its properties make it ideal for a surprising range of projects.

1. Furniture Making: The Classic Choice

Ash wood’s strength, durability, and attractive grain make it a star in furniture making. It can handle the daily wear and tear of chairs, tables, and cabinets.

Chairs and Stools: Its flexibility allows for comfortable, slightly curved designs that give a bit when you lean back. Think of classic shaker-style chairs – ash is often used for their strong, elegant frames.

Tables: From dining tables to coffee tables, ash holds up well. Its sturdy nature means legs and tabletops can be made reliably.

Shelving Units: For open shelving or bookcases, ash provides the necessary strength to support heavy books and decor without bowing over time.

Cabinetry: Kitchen cabinets and built-in wardrobes made from ash are strong, durable, and can be finished to look incredibly sophisticated or beautifully simple.

Why it’s great for beginners: Ash is forgiving. It glues well, takes finishes nicely, and if you accidentally make a small mistake, it’s often easy to sand out or conceal.

2. Tool Handles: Where Strength Meets Grip

This is one of ash’s most traditional and effective uses. Think about the handles on your hammers, axes, and shovels. Many of these are made from ash for a very good reason!

Shock Absorption: When you swing a hammer or chop with an axe, there’s a significant impact. Ash’s natural shock resistance helps absorb these vibrations, protecting your hands and wrists from jarring. You can learn more about the properties of woods used for tool handles on resources like those from the U.S. Forest Service, which highlight ash’s resilience.

Toughness: Tool handles take a beating. They’re dropped, twisted, and bashed. Ash’s durability means the handle won’t easily break or splinter.

Grip: The straight grain can provide a comfortable and secure grip, especially when the wood is shaped and finished properly.

3. Sports Equipment: Pouncing on Performance

The combination of strength, flexibility, and shock absorption makes ash a natural fit for various sporting goods.

Baseball Bats: For decades, ash was the go-to wood for professional baseball bats. It offered a good balance of power, flexibility, and energy transfer. While other woods and materials are now common, ash bats are still favored by many for their classic feel and performance.

Lacquered Hockey Sticks: Historically, ash was used for hockey sticks, especially for the blades and shafts. Its ability to withstand impacts and flex was invaluable.

Archery Bows: Some traditional archery bows are crafted from ash, leveraging its flexibility and strength to store and release energy efficiently.

4. Flooring and Architectural Elements: Lasting Beauty at Your Feet

Ash flooring is a popular choice for homes because it’s both beautiful and robust.

Hardwood Flooring: Ash offers a look similar to oak but is often more affordable. It’s resilient enough for high-traffic areas. Its lighter color can make rooms feel brighter and more spacious. Sources like the National Wood Flooring Association provide extensive data on wood species performance for flooring.

Stair Treads: Similar to flooring, stair treads need to be durable. Ash can stand up to the constant foot traffic.

Decorative Trim and Moldings: The straight grain and ability to take stains make ash ideal for decorative architectural details that add a touch of elegance.

5. Musical Instruments: Resonant Qualities

Less common for beginners but a significant use nonetheless, ash’s tonal properties make it valuable in instrument making.

Electric Guitar Bodies: Ash is a very popular wood for the bodies of electric guitars, particularly for Fender Stratocasters and Telecasters. It provides a bright, resonant tone that’s great for many music genres. Its weight can vary, affecting the sustain and overall sound.

Working with Ash Wood: Tips for Beginners

You’ve seen what ash is good for, but how do you actually work with it? Here are some simple tips to get you started.

Essential Tools

You don’t need a professional workshop to start. Here are some basics that will serve you well when working with ash:

Measuring Tape & Pencil: For accurate marking.

Saw: A handsaw (like a crosscut saw) or a jigsaw for straighter cuts. A circular saw can be very helpful for longer, straight cuts.

Clamps: Essential for holding pieces together while glue dries.

Sander: An orbital sander makes smoothing much faster and easier than sanding by hand. Sandpaper in various grits (e.g., 80, 120, 220) is a must.

Drill: For making holes and driving screws.

Screwdriver Bits: To match your screws.

Wood Glue: A good quality wood glue is crucial.

Safety Gear: Always wear safety glasses and consider hearing protection and a dust mask when sanding or sawing.

Step-by-Step: Preparing and Finishing Ash

Let’s say you have a piece of ash and want to make something simple, like a small shelf or a basic box.

1. Measure and Cut: Carefully measure your ash wood according to your project plan. Use your saw to make precise cuts. Remember, measure twice, cut once!

2. Sand Smooth: Start with a coarser grit sandpaper (like 80 or 100 grit) to remove any saw marks or rough spots. Then, move to a finer grit (150-220 grit) to get the wood super smooth to the touch. Always sand in the direction of the wood grain.

3. Joinery (if needed): For simple projects, screws and glue are often enough. Pre-drill pilot holes slightly smaller than your screws to prevent the ash from splitting. Apply wood glue to the edges that will be joined and clamp them tightly together until the glue dries completely.

4. Finishing: Ash takes finishes beautifully.

Staining: If you want to change the color, apply a wood stain evenly with a brush or cloth. Wipe off any excess stain after a few minutes, following the product’s instructions.

Sealing: After staining (or if you’re leaving the wood its natural color), apply a protective finish. Polyurethane, lacquer, or shellac are good options. Apply thin coats, letting each dry thoroughly. You may need to lightly sand with very fine grit sandpaper (320+) between coats for an extra-smooth finish.

Paint: Ash’s smooth surface is also excellent for painting. A good primer and a couple of topcoats will give you a durable, attractive painted finish.

Safety First!

Working with wood is fun, but safety is always number one.

Eye Protection: Always wear safety glasses to protect your eyes from sawdust and flying debris.

Dust Masks: Sawdust can be harmful to your lungs. Wear a dust mask, especially when sanding.

Sharp Tools: Keep your tools sharp; dull tools are more dangerous because they require more force and can slip.

Secure Your Work: Use clamps to hold your wood firmly while cutting or drilling.

Read Tool Manuals: If you’re using power tools, understand how they work and follow the manufacturer’s safety guidelines.

Ash Wood vs. Other Hardwoods: A Comparison Table

To help you decide when ash is the best choice, let’s look at how its key properties compare to other common hardwoods used in similar applications.

| Feature | Ash Wood | Red Oak | Maple Wood | Walnut Wood |

|---|---|---|---|---|

| Hardness | Medium-hard (Janka: ~1320) | Hard (Janka: ~1290) | Very Hard (Janka: ~1450) | Medium-hard (Janka: ~1010) |

| Strength | Very good | Excellent | Excellent | Good |

| Flexibility | Excellent | Fair | Fair | Fair |

| Shock Res. | Excellent | Good | Good | Good |

| Grain Look | Straight, distinct, can be coarse | Prominent, open, wavy or straight | Fine, uniform, often straight | Straight to wavy, attractive, smooth |

| Color | Creamy white to light brown, dark streaks | Pinkish-brown to light tan/gray | Creamy white to pale brown, sometimes reddish | Rich dark brown, often two-tone with sapwood |

| Workability | Good, easy to machine | Fair, can chip/split, open grain | Fair, hard on tools, needs sharp blades | Very good, machines and finishes beautifully |

| Cost | Moderate | Moderate | Moderate to High | High |

| Best For | Furniture, tool handles, sports equipment | Furniture, flooring, cabinetry | Furniture, flooring, cutting boards, cabinetry | Fine furniture, cabinetry, décor, gunstocks |

Note: Janka hardness is a measure of the force required to embed a steel ball halfway into a sample of wood. Higher numbers mean harder wood.

The table shows that ash offers a fantastic combination of strength, flexibility, and shock resistance, often making it easier to work with than oak or maple. While walnut offers a richer color and fine grain, it’s generally more expensive and less flexible. This makes ash a very practical and reliable choice for many DIY projects where durability and a good aesthetic are key.

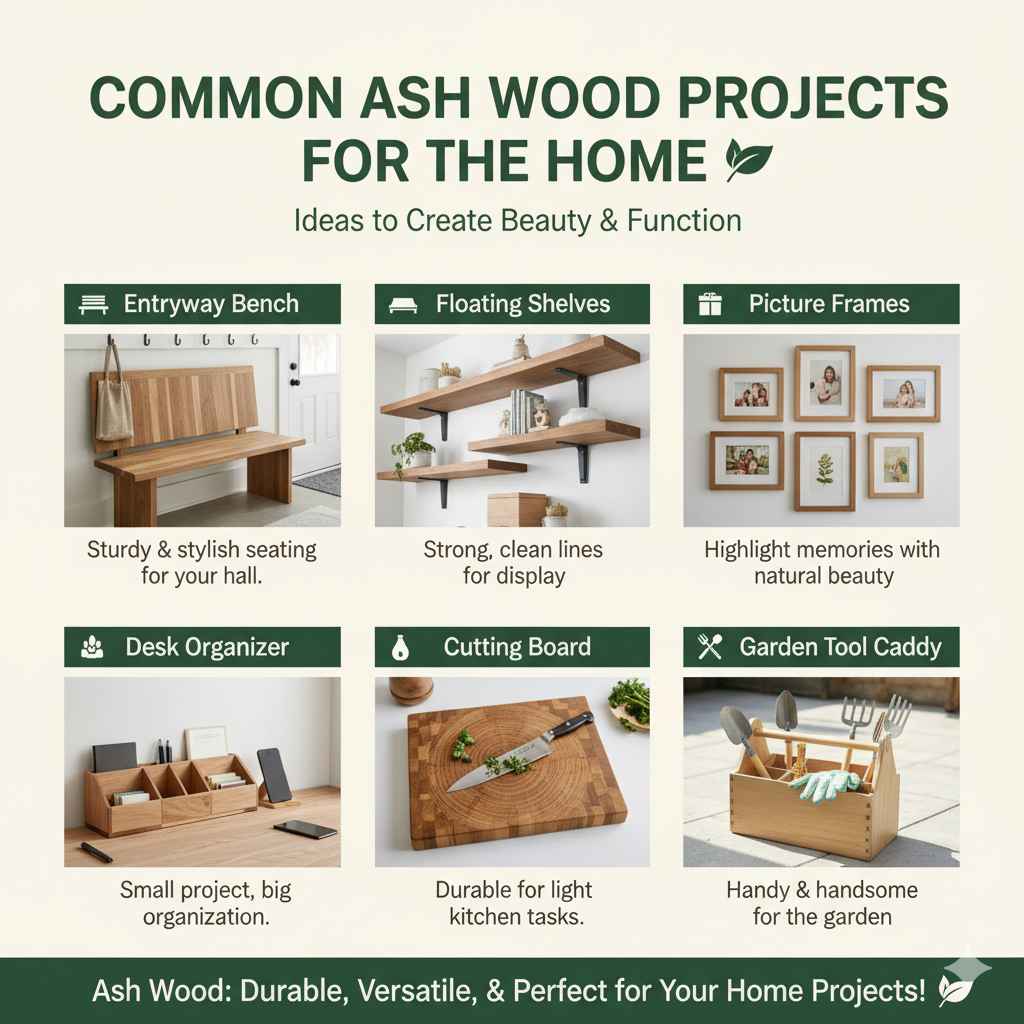

Common ash Wood Projects for the Home

Thinking about specific projects can really spark your creativity. Here are some beginner-friendly ideas using ash that you can tackle:

Entryway Bench: Strong enough to sit on and stylish enough for your hallway.

Floating Shelves: Ash’s strength means you can make them quite long without needing heavy brackets.

Picture Frames: The attractive grain looks great with a natural finish.

Desk Organizer: A small project to practice your joinery and finishing skills.

Cutting Board: While maple is king here, ash can be used for less demanding cutting tasks if sealed well, or combine it with other woods for a decorative effect.

Garden Tool Caddy: Imagine durable ash handles for trowels and a sturdy caddy to hold them – perfect for the garden!

Frequently Asked Questions About Ash Wood

Here are some common questions beginner woodworkers have about ash wood.

Is ash wood strong enough for outdoor use?

While ash is durable, it’s not naturally resistant to rot and decay like some other woods (like cedar or redwood) when exposed to the elements long-term. For outdoor furniture or structures that will be directly exposed to rain and sun, it’s essential to use a robust exterior-grade finish and apply it frequently. It’s better suited for covered patios or areas with less direct weather exposure.

Is ash wood hard to find?

Ash is generally quite available in lumberyards and well-stocked hardware stores. Its widespread growth means it’s a common hardwood. You should be able to find it in various thicknesses and lengths for most projects.

Should I seal ash wood before staining?

Typically, you stain ash wood directly, and then seal it with a protective coating like polyurethane or an oil finish. Staining onto bare wood allows the color to penetrate and become part of the wood’s surface. Applying a sealer before staining would prevent the stain from absorbing properly.

What is the difference between white ash and green ash?

White ash (Fraxinus americana) is generally considered superior for most woodworking uses. It’s often lighter in color, has a straighter grain, and is known for its excellent strength and shock resistance, making it ideal for furniture and tool handles. Green ash (Fraxinus pennsylvanica) is also usable but can sometimes be less dense and more prone to decay. In lumberyards, “ash” often refers to white ash unless specified otherwise.

Can I use ash for rough carpentry or framing?

Ash is usually too dense and too expensive for rough framing lumber, which is typically done with softwoods like pine or fir. Ash’s strength and attractive grain are best utilized in applications where these qualities are appreciated for aesthetics and performance, such as furniture, flooring, or tool handles.

How does ash wood compare to pine for furniture?

Pine is a softwood that is much easier to cut and shape, and it’s far less expensive. However, pine dents and scratches much more easily than ash. Ash is a hardwood – it’s significantly stronger, more durable, and more resistant to wear and tear. For furniture that needs to last and withstand regular use, ash is a much better long-term investment, though it will require a bit more effort to work with than pine.

What kind of finish is best for ash wood?

The best finish depends on the look you want. For a natural, durable finish, a clear polyurethane or a penetrating oil finish (like Danish oil or tung oil) works wonderfully, enhancing the wood’s natural grain and color. If you want to change the color, a good quality interior wood stain followed by a protective topcoat is ideal. For a smooth, painted finish, a good primer and paint will adhere well to ash.

Conclusion: Your Next Project with Ash Wood

So, there you have it! Ash wood is a fantastic choice for both beginners and experienced woodworkers. Its impressive blend of strength, flexibility, and shock resistance makes it ideal for everything from sturdy furniture and reliable tool handles to beautiful flooring. You’ve learned what makes ash special, seen some of its best uses, and picked up tips on working with it safely and effectively.

Don’t be intimidated! Ash is a forgiving wood that rewards your efforts with durable and attractive results. Whether you’re building a simple shelf, a custom tool handle, or dreaming of a new piece of furniture, ash wood is a reliable and rewarding material to use. Grab a piece, plan your project, and enjoy the process of creating something wonderful with your own hands. Happy woodworking!