Auger vs Spade Bit: Which Drill Bit Is Better?

Choosing the right drill bit can sometimes feel tricky, especially when you’re just starting out with DIY projects. You might wonder about things like Auger vs Spade Bit Which Drill Bit Is Better?. It’s a common question because both are useful, but for different jobs.

Don’t worry, we’ll make it super simple. We’ll walk through what each bit does and help you pick the perfect one for your next task. Get ready to learn the easy way!

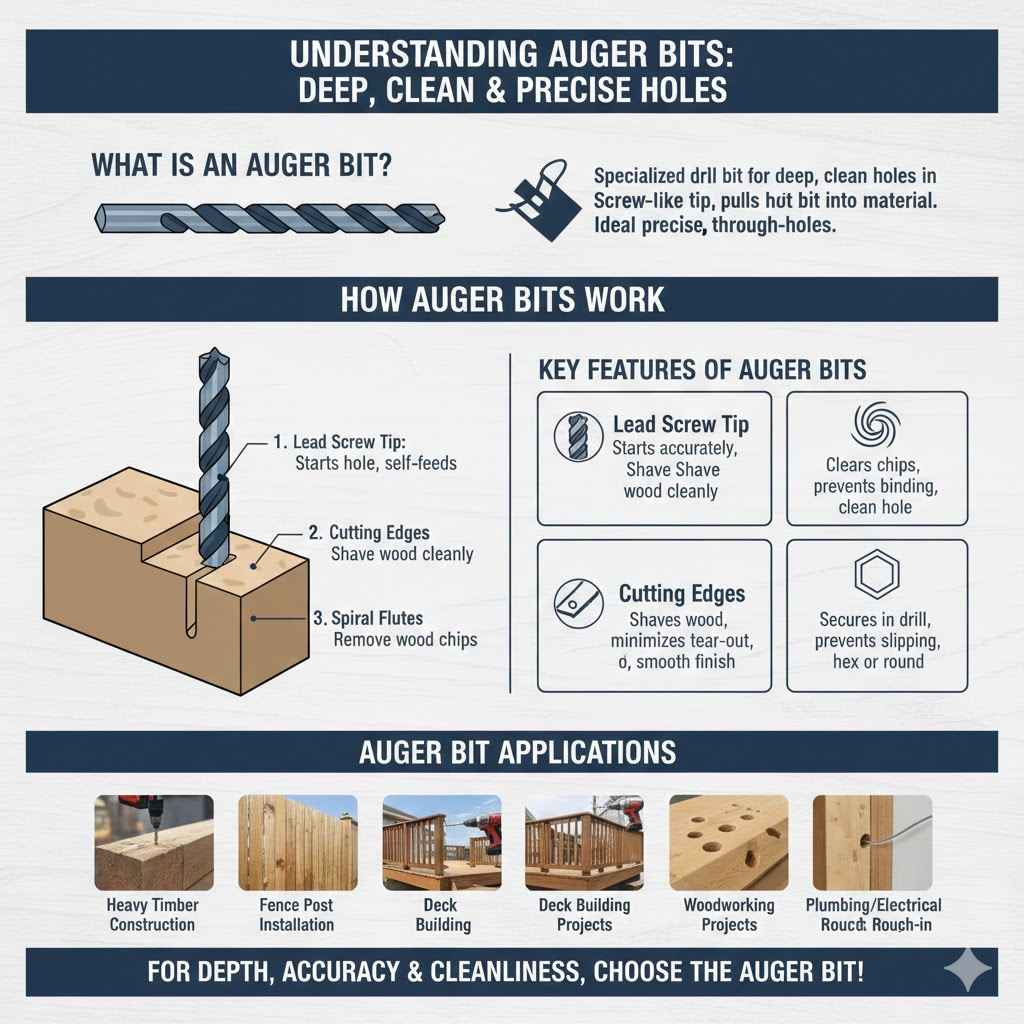

Understanding Auger Bits

Auger bits are specialized drill bits designed for making deep, clean holes, especially in wood. They look a bit like a screw with a cutting tip. This screw-like design helps pull the bit into the material, making it easier to drill deeper.

Auger bits are great for tasks where you need a precise and clean hole that goes all the way through. They are commonly used in construction, carpentry, and for installing things like fence posts or deck supports. The sharp lead screw on the tip starts the hole quickly and accurately.

How Auger Bits Work

The main feature of an auger bit is its lead screw. This screw is a pointed tip that bites into the wood. As you drill, the screw pulls the bit further into the material.

The spiral flutes on the side of the bit then clear out the wood chips. This is why they make such clean holes, even deep ones. The deeper you go, the more effective the flutes are at removing debris.

This prevents the bit from getting stuck.

The cutting edges at the tip are designed to shave the wood cleanly. This is different from how some other bits might tear the wood. Because of this, auger bits are ideal when the appearance of the hole matters, or when you need a very straight and precise entry point.

They require a bit more torque from your drill than a standard bit. This is because they are actively pulling themselves in and removing material efficiently.

Key Features of Auger Bits

- Lead Screw TipThe lead screw is the pointed tip that looks like a screw. It’s the first part of the bit to touch the material. Its job is to start the hole accurately and to pull the bit into the wood as you drill.

This means less pushing is needed from you, making deep holes easier to create. The screw’s sharpness ensures a quick start without slipping.

- Spiral FlutesThese are the twisty channels that run along the body of the bit. They are very important for removing the wood chips created during drilling. The deeper the hole, the more the flutes help to keep the cutting area clear.

This prevents the bit from binding or getting stuck. Good chip removal also leads to a cleaner hole.

- Cutting EdgesLocated just behind the lead screw, these sharp edges shave the wood. They work with the screw to create a smooth, clean-cut hole. They are angled to efficiently cut through wood fibers.

This design minimizes tear-out, especially when the bit is exiting the material. This is crucial for projects where a smooth finish is desired.

- ShankThis is the part of the bit that goes into your drill’s chuck. Auger bits often have a hex shank or a round shank with flats. The hex shank provides a secure grip and prevents slipping.

The shank size must match your drill’s chuck capacity. A good grip ensures efficient power transfer from the drill motor to the bit.

When to Use Auger Bits

Auger bits shine when you need to drill deep, accurate holes. Think about building a deck and needing to drill through thick beams. Or maybe you’re setting fence posts and need to go deep into the ground.

They are also perfect for furniture making or any project where precise, clean holes are a must. If you are drilling through multiple pieces of wood stacked together, an auger bit’s ability to pull itself through can be a big help.

One common use is for drilling holes for lag bolts or through-bolts in heavy timber construction. Another is for creating pilot holes for large screws. When you need to drill a hole that must be perfectly straight and not widen at the exit, an auger bit is a great choice.

They are often made from hardened steel for durability.

Auger Bit Applications

- Heavy Timber Construction: Drilling through large wooden beams for structural connections. This requires bits that can handle dense wood and go deep.

- Fence Post Installation: Creating deep, clean holes in the ground for fence posts to stand firm. Sometimes these holes are in soil mixed with roots.

- Deck Building: Drilling through deck joists and beams for railing supports or structural screws. Accuracy is key for a safe and stable deck.

- Woodworking Projects: Making precise holes for dowels, tenons, or complex joinery where a clean entry and exit are important.

- Plumbing and Electrical Rough-in: Drilling through studs for running pipes or wires, especially when a straight pass-through is needed.

Exploring Spade Bits

Spade bits, also known as paddle bits, are designed for drilling larger diameter holes quickly. They have a flat, paddle-like shape with sharp cutting edges at the tip. Unlike auger bits, they don’t have a lead screw.

Instead, they rely on aggressive cutting edges to bore through wood. They are often used for general woodworking tasks where speed and a larger hole size are more important than extreme precision or depth.

Spade bits are very common because they are relatively inexpensive and can create holes from about 1/4 inch up to several inches in diameter. They are a good choice for rougher work or when you need to drill a large hole for something like a pipe or electrical conduit. Because they don’t have a lead screw, they can be a bit more prone to wandering or splintering the wood if not used carefully.

They require a strong drill to power through the wood.

How Spade Bits Work

A spade bit has a center spur at the very tip. This spur helps to locate the drill point and start the hole. It scores the wood fibers to prevent the bit from wandering.

The two sharp cutting edges on the sides of the bit then slice through the wood. As the bit rotates, these edges remove material. The flat shape of the bit means it removes a lot of wood quickly.

The lack of a deep screw thread means spade bits don’t pull themselves into the wood. You need to apply steady pressure to keep the bit drilling. This also means they are less likely to get stuck deep inside a piece of wood compared to an auger bit.

However, this also means they can create more dust and larger chips. The exit of the hole can sometimes be rougher if you’re not careful.

Key Features of Spade Bits

Center Spur

This is a small, sharp point in the center of the bit’s tip. Its primary function is to mark the exact spot where you want to drill. It also scores the wood fibers before the main cutting edges start to work.

This helps to keep the bit from slipping and guides it accurately into the material.

Cutting Edges

These are the two flat, sharp blades that flank the center spur. They are designed to cut through wood efficiently. They slice the wood fibers as the bit rotates.

The sharpness and angle of these edges determine how cleanly the bit cuts. They are responsible for removing the bulk of the material to create the hole.

Flat Paddle Shape

The distinctive flat, wide shape of the bit is what gives it its name. This design allows it to remove a large volume of wood quickly. It’s ideal for making large diameter holes without needing a more expensive or specialized bit.

The flat sides also help to create a relatively flat-bottomed hole.

Shank

Like other drill bits, spade bits have a shank that fits into the drill chuck. This is usually a hex shank to prevent slipping. Spade bits often have a shorter overall length compared to auger bits.

The shank needs to be securely gripped by the drill chuck for effective drilling.

When to Use Spade Bits

Spade bits are excellent for general-purpose drilling of larger holes in wood. They are perfect when you need to drill holes for doorknobs, light switches, or running pipes and wires through studs. If you’re building simple projects like birdhouses or shelving, a spade bit is often all you need.

They are also good for creating larger holes for ventilation or access.

They are a cost-effective option for larger hole sizes. If you only need to drill a few large holes, buying a set of spade bits is usually more economical than buying a single large auger bit. Just be prepared for more cleanup of wood dust and chips.

Spade Bit Applications

- Installing Door Hardware: Drilling large holes for doorknobs, deadbolts, and hinges.

- Running Utilities: Creating holes through studs and joists for electrical wires, plumbing pipes, or HVAC ducts.

- General Woodworking: Making holes for dowels, pegs, or decorative elements in furniture and crafts.

- Cabinetry: Drilling clearance holes for hinges or mounting brackets.

- DIY Projects: Cutting holes for various purposes in home improvement and creative projects.

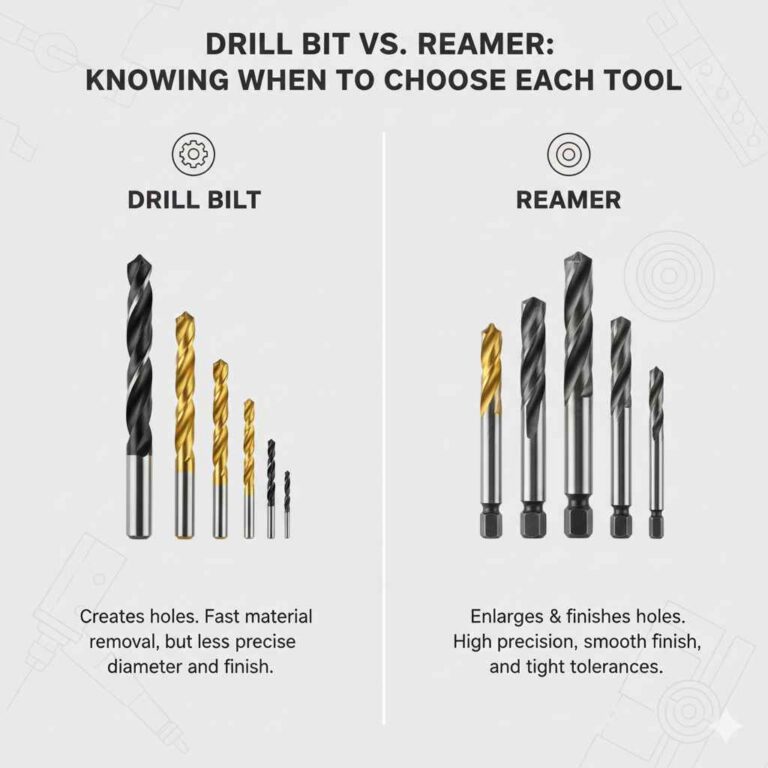

Auger vs Spade Bit Which Drill Bit Is Better? The Key Differences

The main difference between auger bits and spade bits lies in their design and how they cut. Auger bits are built for depth and precision, using a lead screw to pull them in and flutes to clear chips efficiently. They make clean, deep holes and are good for structural work or fine woodworking.

Spade bits, on the other hand, are designed for speed and larger hole sizes. They use aggressive cutting edges and a spur to bore through wood, making them ideal for general carpentry and utility work.

Let’s break down some of the most important distinctions side-by-side. This will make it easier to see when each bit is the right tool for the job.

| Feature | Auger Bit | Spade Bit |

|---|---|---|

| Primary Use | Deep, precise holes; structural work | Large diameter holes; general carpentry |

| Cutting Mechanism | Lead screw, sharp cutting edges, spiral flutes | Center spur, aggressive cutting edges |

| Depth Capability | Excellent for deep holes | More suited for through-holes or medium depth |

| Hole Quality | Very clean, smooth | Can be rougher at exit, more chip production |

| Speed | Moderate, efficient chip removal | Fast, aggressive material removal |

| Price | Can be more expensive for larger sizes | Generally more affordable |

| Material Removal | Efficient and controlled | Aggressive and high volume |

Precision and Depth

When you absolutely need a hole to be perfectly straight and go deep into a piece of wood, an auger bit is your go-to. The lead screw is the hero here, guiding the bit and pulling it forward with minimal effort. This is critical for structural integrity in construction.

For instance, imagine building a large timber frame house. You need to drill long, accurate holes for massive wooden pegs or bolts. An auger bit ensures these holes are precise and go through several inches of dense hardwood without deviating.

This level of control is hard to achieve with a spade bit.

Hole Size and Speed

If you’re just trying to make a quick, large hole for a pipe or a cable to pass through, a spade bit is usually faster. Its wide cutting edges chew through wood rapidly. It’s a workhorse for making larger openings where the exact finish isn’t the top priority.

Consider running a 2-inch drainpipe through a wall of 2×4 studs. A spade bit of the same diameter will bore through each stud much faster than an auger bit. You might need to do a little sanding on the edges, but the time saved is significant for such general tasks.

Material Removal and Chip Ejection

Auger bits have those spiral flutes for a reason. They are designed to actively pull wood chips away from the cutting face. This is vital when drilling deep holes, as it prevents the bit from becoming packed with debris and jamming.

The controlled removal makes for a cleaner hole.

Spade bits, with their flat design, tend to produce more dust and larger chips. While some spade bits have chip ejection features, they are generally not as efficient as the flutes on an auger bit. You’ll often find yourself needing to pause and clear debris more frequently when using spade bits for deeper holes.

Cost and Availability

Spade bits are generally more affordable and widely available in a variety of common sizes. This makes them a popular choice for DIYers and for general workshop use. You can easily find sets of spade bits that cover a range of popular diameters for a reasonable price.

Auger bits, especially larger ones or those made of premium materials, can be more expensive. Their specialized design for deep, precise holes means they are often a more considered purchase. However, for specific applications where their performance is essential, the cost is justified.

Example Scenario 1 Deck Building

- Project: Building a sturdy wooden deck.

- Task: Drilling pilot holes through thick deck joists for lag bolts that will secure the frame. These holes need to be deep and perfectly straight.

- Bit Choice: Auger Bit.

- Reasoning: The auger bit’s lead screw will accurately start the hole and pull the bit through the dense joist material. The flutes will clear sawdust, ensuring the bit doesn’t bind. The resulting hole will be clean and straight, providing a solid foundation for the lag bolt, which is crucial for the deck’s stability and safety.

Example Scenario 2 Running Electrical Wire

- Project: Running electrical cable through a wall.

- Task: Drilling a 1-inch hole through several wooden studs to pass a wire. Speed and ease of use are important.

- Bit Choice: Spade Bit.

- Reasoning: A 1-inch spade bit will quickly bore through the studs. The center spur will help locate the hole accurately on each stud. While the hole might not be as perfectly clean as one made by an auger bit, the speed and efficiency make it the better choice for this common utility task. The less aggressive pull means less chance of the drill binding.

Maintenance and Safety Considerations

Regardless of which bit you choose, proper maintenance and safety practices are essential for a good outcome. Keeping your bits sharp ensures they cut effectively and with less effort. This also reduces the risk of the bit binding or breaking.

Always wear safety glasses to protect your eyes from flying debris.

Ensure your drill’s chuck is tight around the bit shank to prevent it from slipping. If a bit gets stuck, don’t force it. Reverse the drill gently to back it out.

For deeper holes, especially with auger bits, it’s wise to pause periodically to clear chips and let the drill cool.

Sharpening Your Bits

Over time, the cutting edges of both auger and spade bits will dull. Sharp bits make drilling easier, faster, and cleaner.

- For Auger Bits: You can sharpen the cutting edges and the lead screw with a metal file or a grinding wheel. Be careful not to overheat the metal, as this can temper it and make it brittle. Focus on maintaining the original angles of the cutting surfaces.

- For Spade Bits: Sharpen the two main cutting edges with a file. The center spur can also be touched up. Aim for a sharp, clean edge that will slice through wood easily. Regular sharpening prevents the wood from being torn or compressed.

Safety First

Drilling can be hazardous if not done carefully. Always secure your workpiece with clamps. This prevents it from spinning when the drill bit engages.

- Eye Protection: Always wear safety glasses. Wood chips and dust can fly off at high speeds.

- Secure Workpiece: Never hold a small piece of wood by hand while drilling. Use a vise or clamps to secure it to your workbench.

- Proper Grip: Ensure your drill is held firmly with both hands, especially when using larger bits.

- Awareness: Be mindful of where the drill bit will exit the material. Don’t drill into yourself or other objects.

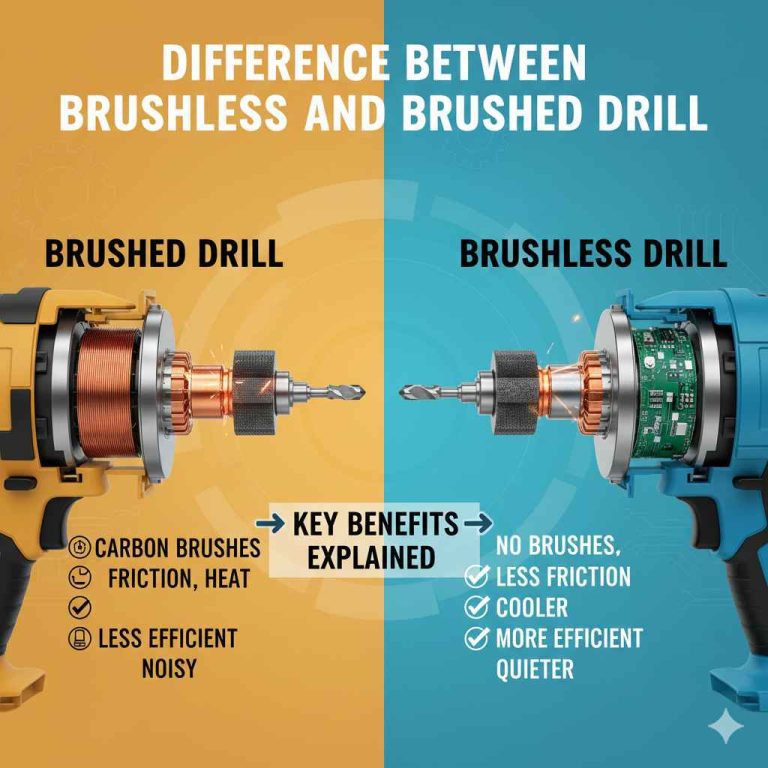

Drill Compatibility

The type of drill you use also matters. Larger bits, like many spade and auger bits, require a powerful drill. Corded drills often offer more sustained power than cordless ones, especially for tough jobs.

- Chuck Size: Make sure your drill’s chuck can accommodate the shank size of the bit you intend to use.

- Power: For spade bits and auger bits over 1 inch, a drill with a good amount of torque is recommended. A drill with a variable speed setting is also helpful, allowing you to start slowly and increase speed as needed.

- Auger Bit Torque: Because auger bits pull themselves in, they can generate significant torque on the drill. A drill with a side handle can provide better control.

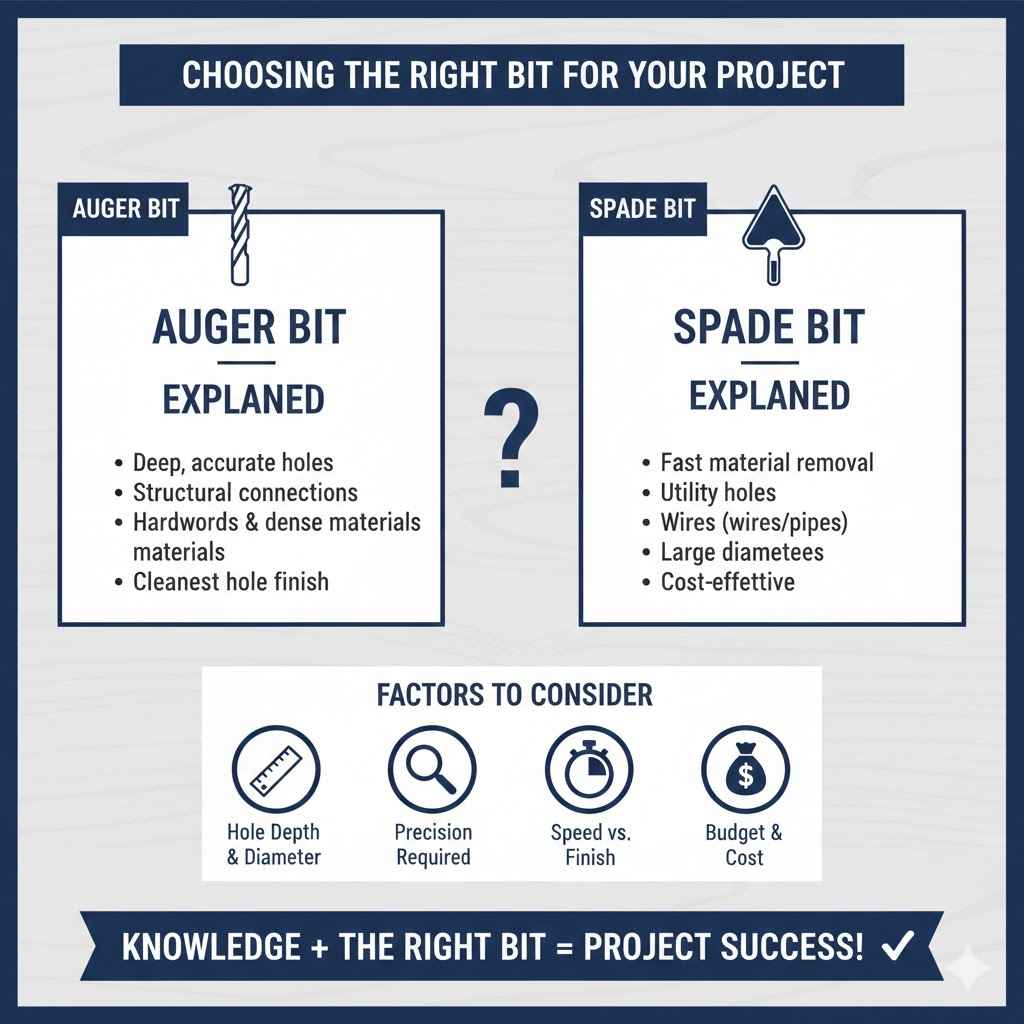

Choosing the Right Bit for Your Project

Deciding between an auger bit and a spade bit comes down to understanding the specific demands of your task. If your project requires deep, accurate holes in wood, like for structural connections or precise joinery, the auger bit is usually the superior choice. Its self-feeding mechanism and efficient chip ejection make it ideal for these applications.

However, if you need to make larger holes quickly for general purposes, such as running wires, pipes, or installing hardware, the spade bit is often the more practical and cost-effective option. It excels at removing material rapidly, even if the hole finish isn’t as refined.

Factors to Consider

To make the best choice, think about these key points:

- Hole Depth: How deep does the hole need to be? Auger bits are better for deep holes.

- Hole Diameter: What size hole do you need? Both bits come in various sizes, but spade bits are typically used for larger diameters.

- Material: Are you drilling into hardwood, softwood, or something else? Both bits work well in wood, but dense hardwoods might require more power.

- Precision Required: How important is a perfectly clean entry and exit point? Auger bits generally provide a cleaner result.

- Speed vs. Finish: Do you need to drill fast, or is a smooth finish more critical? Spade bits are faster, while auger bits offer a better finish.

- Budget: Consider the cost of the bits and how often you’ll use them.

When an Auger Bit Excels

You’ll reach for an auger bit when:

- You need to drill a hole that goes through several inches of wood.

- The hole must be perfectly straight and centered.

- You are working with hardwoods or dense materials.

- Chip removal is important to prevent binding.

- You are installing structural components or hardware that requires precise fitting.

When a Spade Bit Excels

A spade bit is the better choice when:

- You need to drill a large diameter hole quickly.

- The hole is for utility purposes like wires or pipes.

- The exact finish of the hole edge is not critical.

- You are on a tighter budget and need a common hole size.

- You want to make multiple large holes efficiently.

Frequently Asked Questions

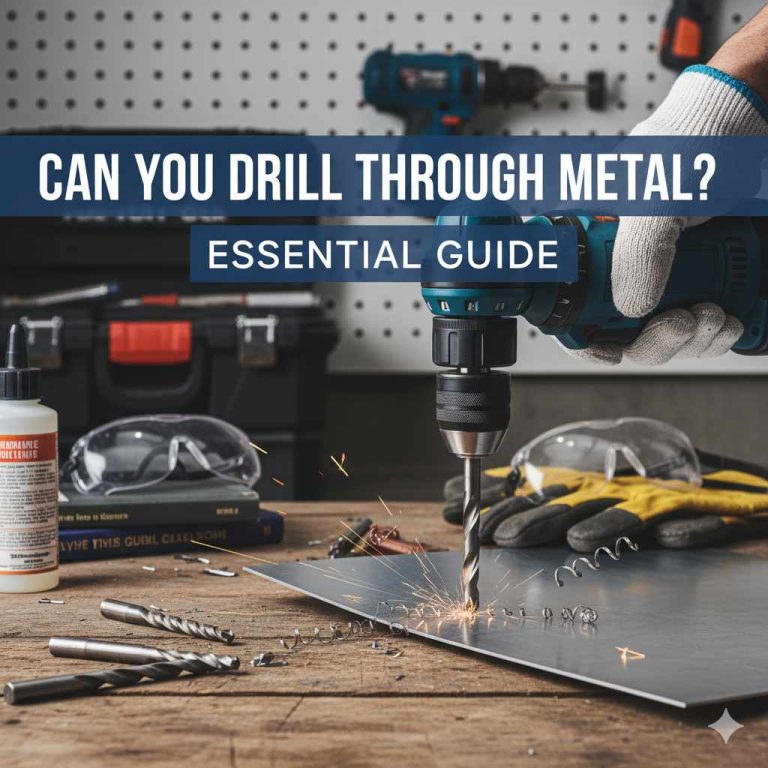

Question: Can I use an auger bit for drilling into metal or plastic?

Answer: Auger bits are primarily designed for wood. While they might be able to drill into some softer plastics with care, they are not suitable for metal. Specialized bits are needed for those materials.

Question: Will a spade bit work in treated lumber?

Answer: Yes, spade bits can drill into treated lumber. However, treated lumber can be harder and more abrasive, so keeping your spade bits sharp is important to prevent them from dulling quickly.

Question: Is it safe to use an auger bit with a handheld drill without a side handle?

Answer: It can be safe if you are careful, especially with smaller auger bits. However, for larger auger bits or when drilling deep holes, the torque can be significant. A drill with a side handle provides much better control and stability, reducing the risk of injury.

Question: Can I use a spade bit for creating pilot holes for screws?

Answer: Yes, you can use a spade bit for pilot holes, especially for larger screws or bolts where you need a wider opening. However, for smaller screws, a twist drill bit or brad-point bit is usually more appropriate as it creates a much smaller, more precise hole.

Question: Which type of drill bit is better for drilling into plywood?

Answer: Both auger bits and spade bits can be used for plywood. An auger bit will provide a cleaner entry and exit, reducing splintering. A spade bit will drill faster but may cause more tear-out on the exit side.

For clean holes, an auger bit is generally preferred for plywood.

Summary

Choosing between an auger and a spade bit depends on your project. Auger bits excel at deep, clean holes for structural work. Spade bits are faster for larger holes in general carpentry.

Both are useful tools, so pick the one that best fits your task for the best results.