Black Oxide Vs Titanium Drill Bits: Essential Comparison

For most home DIY and light woodworking, black oxide drill bits offer great value and performance. Titanium drill bits are best for harder materials, frequent heavy-duty use, or when you need maximum durability and heat resistance. Understanding the differences ensures you pick the perfect bit for smoother, faster, and more successful drilling.

Hey there, fellow DIYers and woodworking enthusiasts! Md Meraj here, ready to help you navigate the sometimes confusing world of drill bits. Ever stood in the hardware store, staring at rows of shiny drill bits, wondering which ones will actually get the job done without costing a fortune or breaking halfway through your project? You’re not alone! It’s a common sticking point for beginners, and choosing the wrong drill bit can lead to frustration, messy holes, and even damaged materials. Today, we’re going to shine a light on two of the most popular types: black oxide and titanium. By the end of this guide, you’ll know exactly which drill bit is your best friend for any task. Let’s get drilling!

Black Oxide Vs Titanium Drill Bits: An Essential Comparison

As a woodworker, I’ve learned that the right tool makes all the difference. Drill bits are no exception. When you’re starting a project, whether it’s hanging a shelf, building a birdhouse, or assembling furniture, you need to drill holes. But not all holes are created equal, and neither are the bits that make them. The two most common bits you’ll encounter are black oxide and titanium-coated drill bits. They look similar, but their coatings and intended uses are quite different. Understanding these differences will save you time, money, and a whole lot of sanding.

Let’s break down what makes each of these drill bits tick, their strengths, their weaknesses, and when to reach for one over the other. This isn’t about having the “best” bit in an absolute sense, but rather the best bit for your specific job.

What is Black Oxide Coating?

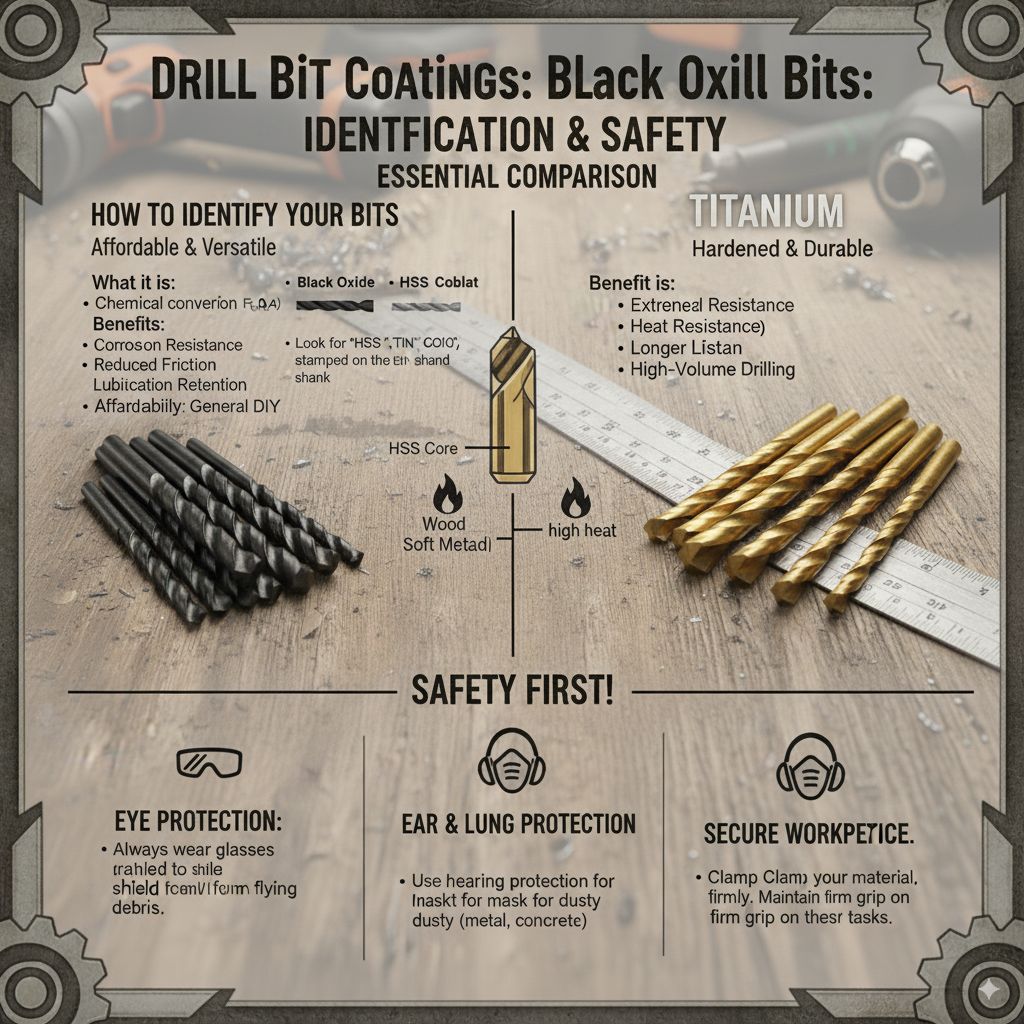

Black oxide is a chemical process that converts the surface of steel into magnetite, a black iron oxide. This isn’t a plating like titanium; it’s a conversion of the metal itself. Think of it as a very thin, integral layer that becomes part of the drill bit’s surface. This specialized coating offers several benefits.

Benefits of Black Oxide Coating:

- Corrosion Resistance: The black oxide layer provides decent protection against rust and corrosion, especially when compared to bare steel bits. This means your bits will last longer and perform better, even if they get a little damp.

- Reduced Friction: The smooth, dark surface helps reduce friction as the bit drills through material. This leads to cooler running temperatures, which in turn helps the bit maintain its sharpness and prolongs its life.

- Lubrication Retention: The porous nature of the black oxide coating allows it to hold lubricating oils better. This further aids in reducing friction and heat, making drilling smoother.

- Affordability: Black oxide drill bits are generally less expensive than their titanium-coated counterparts, making them a fantastic budget-friendly choice for general use.

When to Use Black Oxide Drill Bits:

Black oxide bits are your go-to for a variety of common tasks, especially around the house and in many woodworking applications. They excel when drilling into softer materials like:

- Wood: From softwoods like pine and cedar to hardwoods like oak and maple, black oxide bits will perform admirably.

- Softer Metals: They can handle drilling into aluminum, brass, and mild steel for lighter applications.

- Plastic: Most common plastics can be drilled with ease using black oxide bits.

They are perfect for general DIY projects, home repairs, and hobbyist woodworking. If you’re drilling a few holes in your garden fence or putting up shelves, a black oxide set will serve you wonderfully.

What is Titanium Coating?

Titanium drill bits, more accurately called titanium-coated drill bits, have a thin layer of titanium nitride (TiN) applied to their surface, usually through an industrial PVD (Physical Vapor Deposition) process. This coating is incredibly hard and durable. It’s a very thin, golden or bronze-colored layer that significantly enhances the performance of the underlying drill bit material, which is often high-speed steel (HSS).

Benefits of Titanium Coating:

- Extreme Hardness and Durability: Titanium nitride is one of the hardest materials known, second only to diamond. This makes titanium-coated bits significantly more durable and resistant to wear than black oxide or uncoated bits.

- Heat Resistance: The TiN coating is highly resistant to heat. Drilling generates friction, which creates heat. Titanium coating dissipates this heat more effectively, allowing the bit to stay sharper for much longer, especially when drilling harder materials or at higher speeds.

- Faster Drilling: Due to their hardness and ability to withstand heat, you can often drill faster with titanium bits, saving you time.

- Longer Lifespan: Their superior hardness and heat resistance mean titanium drill bits can last many times longer than standard bits, especially under demanding conditions.

- Less Lubrication Needed: While some lubrication is always good, titanium bits are less reliant on it to stay cool and sharp compared to less robust coatings.

When to Use Titanium Drill Bits:

Titanium-coated drill bits shine when you’re working with tougher materials or when you need a bit that will last through a lot of abuse. They are ideal for:

- Hardwoods: Excellent for dense woods like oak, maple, hickory, and exotic hardwoods.

- Hard Metals: They are the go-to for drilling through stainless steel, cast iron, tougher alloys, and thicker gauge metals.

- Abrasive Materials: Can handle materials that might quickly wear down other types of bits.

- High-Volume Drilling: If you’re drilling dozens or hundreds of holes, especially in tougher materials, titanium will pay for itself in longevity and performance.

- Variable Speed Drills: When you can control your drill speed, titanium bits allow you to utilize higher speeds for quicker material removal.

Think metal fabrication, building with steel components, or drilling through very dense, hard woods. They are an investment that offers significant returns in durability and efficiency for more demanding tasks.

Head-to-Head: Black Oxide vs. Titanium Drill Bits

Let’s put them side-by-side to see how they stack up in key areas:

| Feature | Black Oxide Drill Bits | Titanium Drill Bits |

|---|---|---|

| Coating Type | Chemical conversion (Magnetite/Iron Oxide) | Physical Vapor Deposition (Titanium Nitride – TiN) |

| Hardness | Good | Excellent (Significantly harder) |

| Durability | Good for general use | Excellent; resists wear and tear |

| Heat Resistance | Moderate | Very High |

| Corrosion Resistance | Good | Excellent (TiN is very resistant) |

| Ideal Materials | Wood, plastics, soft metals (aluminum, brass), mild steel | Hardwoods, tough metals (stainless steel, cast iron), abrasive materials |

| Drilling Speed | Moderate | Can drill faster, especially in harder materials |

| Lifespan | Good for intended use | Significantly longer, especially in demanding applications |

| Cost | $$ (More affordable) | $$$ (Higher initial cost) |

| Best For | Homeowners, DIYers, light woodworking, general repairs | Metalworking, demanding woodworking, frequent heavy-duty use, construction |

Understanding Drill Bit Materials

It’s important to remember that both black oxide and titanium are coatings. The underlying drill bit material is also crucial. Most common drill bits, including most black oxide and titanium-coated ones, are made from High-Speed Steel (HSS). HSS bits are excellent all-around performers. For extremely tough jobs, you might see Cobalt drill bits (often used for very hard metals), but for most DIYers, comparing HSS with different coatings is what you’ll be doing.

The black oxide coating enhances the properties of standard HSS, while the titanium coating provides a significant upgrade. Think of it like painting a car versus adding a protective clear coat or even a Rhino-lining. Each adds benefits, but to different degrees and for different purposes.

Tips for Maximizing Your Drill Bit Performance

No matter which type of drill bit you choose, a few best practices will make your drilling experience smoother and help your bits last longer:

- Use the Right Speed: Generally, you want a slower speed for larger bits and harder materials, and a faster speed for smaller bits and softer materials. Consult your drill’s manual or look up recommended speeds for the material you’re drilling. A good starting point for wood with a standard bit is around 1000-1500 RPM, but this varies. For metal, speeds are typically much lower.

- Apply Steady Pressure: Let the drill bit do the work! Don’t force it. Apply consistent, moderate pressure. Pushing too hard can overheat the bit, break it, or result in an oversized, sloppy hole.

- Drill Pilot Holes: For larger diameter holes, especially in hardwoods, drilling a smaller pilot hole first makes the job much easier for the main drill bit.

- Keep it Cool: Heat is the enemy of drill bits. For harder materials, metal, or prolonged drilling, use a cutting fluid or a suitable lubricant. For wood, the reduced friction from coatings helps, but sometimes a spritz of water can help if you notice the bit getting very hot.

- Clear Chips Regularly: Pull the drill bit out of the hole periodically to clear away sawdust or metal shavings. This prevents the hole from getting clogged, reduces heat build-up, and allows for more efficient drilling.

- Store Properly: Keep your drill bits clean and dry. Store them in their original case or a dedicated drill bit organizer to prevent damage and rust.

- Angle for Entry: For materials like sheet metal, start drilling at a slight angle (around 45 degrees) to create a starting point for the bit, then straighten up to drill vertically.

For more on drill bit best practices, especially in different materials, resources like Popular Mechanics often provide great foundational tips for DIYers.

When is it Worth Spending More on Titanium?

The price difference between black oxide and titanium drill bits can be noticeable, especially when buying a large set. So, when is that extra investment truly worthwhile?

- Frequent Metalworking: If you find yourself regularly drilling into steel, stainless steel, or other hard metals, titanium bits are arguably essential. They will cut cleaner, faster, and last infinitely longer than black oxide in these applications.

- Demanding Woodworking Projects: Working with very dense hardwoods like ebony, ironwood, or even compacted bamboo can quickly dull or even snap less robust bits. Titanium stands up to this abuse.

- Constant, High-Volume Use: Are you building a deck, putting up dozens of fence posts, or working on a construction project that involves extensive drilling? The longevity of titanium bits will save you money and time in the long run by reducing the need for frequent replacements.

- Accuracy and Cleanliness: For projects where a clean, precise hole is critical, the ability of titanium bits to cut cleanly and resist wandering can be a significant benefit.

- Professional or Semi-Professional Use: If you use your tools for side hustles or professional work, durability, speed, and longevity are key factors in your profitability and efficiency.

For the homeowner who drills one or two holes a month for a picture frame or to mount a light fixture, black oxide is perfectly adequate and much more cost-effective. But for serious hobbyists or tradespeople, titanium is often a no-brainer.

How to Identify Drill Bits

When you’re looking at drill bits, here’s how to tell them apart:

- Color: Black oxide bits are typically dark gray to black (the color of magnetite). Titanium bits usually have a golden, bronze, or a slightly iridescent, colorful sheen. Uncoated HSS bits are a shiny, silvery-gray. Cobalt bits are often a darker gray than HSS.

- Markings: High-quality drill bits will often be stamped with their size and material type. Look for “HSS,” “TiN,” or “Black Oxide” markings, though affordability often means some budget bits skip these.

- Packaging: The packaging will almost always specify the type of coating and material. Always check the label!

Safety First!

Regardless of the drill bit type, safety is paramount. Always wear safety glasses to protect your eyes from flying debris. If drilling metal or dealing with a lot of dust, consider hearing protection and a dust mask. Ensure your workpiece is securely clamped and that you have a firm grip on your drill. Understanding your tools is the first step to using them safely and effectively.

Frequently Asked Questions (FAQ)

Q1: Can I use black oxide drill bits on metal?

A: Yes, you can use black oxide drill bits on softer metals like aluminum, brass, and mild or thin gauge steel. However, for frequent or heavy-duty metal drilling, especially on harder steels, titanium or cobalt bits are far more suitable and will last much longer.

Q2: Are titanium drill bits worth the extra cost for woodworking beginners?

A: For most general woodworking tasks on common woods like pine or plywood, black oxide bits will serve you well and are more budget-friendly. If you plan to work with very dense hardwoods regularly or want bits that will last through many projects, titanium can be a good investment, but it’s not strictly necessary for beginners just starting out.

Q3: How do I keep my drill bits sharp?

A: For black oxide and standard HSS bits, you can hone them on a sharpening stone or use a guided drill bit sharpener. Titanium bits are much harder, and while they resist dulling, a specialized diamond-coated sharpener or professional sharpening service is usually required if they do become dull over time. The best approach is to avoid overheating and excessive wear by using them correctly.

Q4: What’s the difference between black oxide and a regular HSS (High-Speed Steel) drill bit?

A: A regular HSS drill bit is made of high-speed steel. Black oxide is a coating applied to HSS that enhances its corrosion resistance, reduces friction, and helps it retain lubricant. An uncoated HSS bit is essentially the bare steel, offering good performance but less protection and durability than a coated bit.

Q5: Can I use oil or lubricant with black oxide drill bits?

A: Yes, using a cutting fluid or lubricant is highly recommended when drilling into metal with black oxide bits, and it can also be beneficial for some harder woods. It helps to reduce friction and heat, making the drilling process smoother and extending the life of the bit.

Q6: How can I tell if my drill bit is overheating?

A: If the bit starts to change color, particularly turning blue or purple, it’s a sign of excessive heat. You might also smell a burning odor. If you notice this, stop drilling immediately, let the bit cool down completely, and consider using a slower speed, lighter pressure, or a lubricant.

Q7: Are there other types of drill bits I should know about?

A: Absolutely! Besides black oxide and titanium, you’ll also encounter uncoated High-Speed Steel (HSS), Cobalt (often for very hard metals), Carbide (extremely hard, used for concrete or very tough materials), and bits designed for specific tasks like spade bits for wood or twist bits for general purposes. For home and general woodworking, HSS, black oxide, and titanium cover most needs.

Conclusion

Choosing between black oxide and titanium drill bits doesn’t have to be a headache. For the majority of home repairs, light woodworking, and general DIY tasks involving wood, plastic, or soft metals, a good set of black oxide drill bits offers fantastic value and performance that will serve you well. They are durable enough for most common jobs and significantly more affordable.

However, when your projects take you into the realm of hard, dense woods or tougher metals like stainless steel, or if you’re involved in frequent, heavy-duty drilling, the superior hardness, heat resistance, and longevity of titanium-coated drill bits become invaluable.