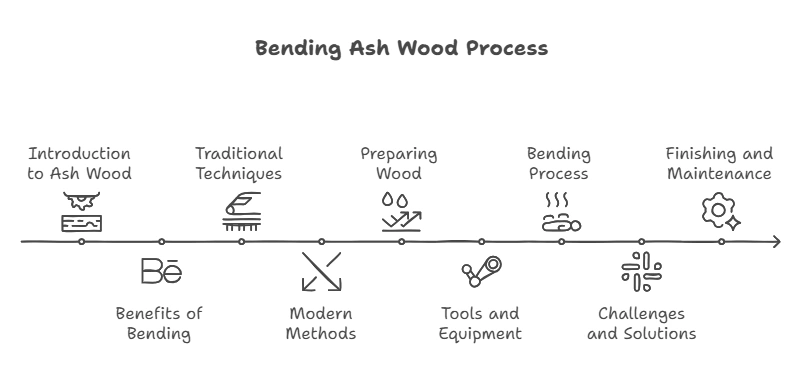

Can Ash Wood Be Bent: Techniques and Tips for Woodworkers

Yes, ash wood can be bent. Woodworkers often use it for its flexibility and strength.

This makes ash wood a popular choice for creating curved designs. Ash wood’s bending properties come from its unique grain and fiber structure. Steam bending is a common method used to shape ash wood. By applying heat and moisture, the wood becomes pliable.

Skilled craftsmen then mold it into the desired shape. Once cooled and dried, the wood retains its new form. Ash wood’s durability and resilience also make it ideal for furniture, boat building, and sports equipment. Understanding how to bend ash wood opens up many creative possibilities. This blog will explore the techniques and benefits of bending ash wood, helping you harness its full potential in your projects.

Introduction To Ash Wood

Have you ever wondered if ash wood can be bent? You’re in the right place! In this post, we’ll dive deep into ash wood, explore its characteristics, and discover its many uses. Let’s begin with an introduction to ash wood.

Ash wood is a popular choice for many woodworkers and furniture makers. Known for its strength and flexibility, it’s a versatile material. But what makes ash wood so special? Let’s take a closer look.

Characteristics Of Ash Wood

Ash wood is a hardwood. It has a light color, which can range from white to light brown. Here are some key characteristics:

- Strength: Ash wood is very strong and durable. It can withstand a lot of pressure.

- Flexibility: Despite its strength, ash wood is flexible. This makes it great for bending.

- Grain: The grain of ash wood is usually straight and uniform. This gives it a clean look.

- Workability: It’s easy to work with. You can cut, sand, and finish it without much trouble.

These characteristics make ash wood a favorite among many craftsmen.

Popular Uses Of Ash Wood

Because of its unique properties, ash wood is used in many different ways. Here are some common uses:

- Furniture: Ash wood is often used to make chairs, tables, and cabinets. It’s strong and looks great.

- Sports Equipment: Items like baseball bats and tool handles are made from ash wood because it’s tough and flexible.

- Flooring: Ash wood floors are beautiful and durable. They can handle heavy foot traffic.

- Musical Instruments: Some guitars and drums are made from ash wood. It gives a nice sound.

As you can see, ash wood is everywhere! Its strength and beauty make it a top choice for many projects.

So, can ash wood be bent? Absolutely! Its flexibility is one of its best features. Whether you’re crafting a new piece of furniture or a musical instrument, ash wood can be shaped to fit your needs.

Benefits Of Bending Ash Wood

Ash wood offers excellent flexibility, making it ideal for bending. This quality allows for creative and unique furniture designs. The wood’s strength also ensures durability in bent forms.

Bending ash wood offers many advantages. This versatile material is strong and flexible, making it ideal for various applications. Its natural beauty also adds an aesthetic appeal to any project.

Strength And Flexibility

Ash wood is known for its strength. It can endure significant pressure without breaking. This makes it perfect for furniture and construction. The flexibility of ash wood also allows for intricate designs. Bent ash wood can form curves and arches, adding a unique touch to any piece.

Aesthetic Appeal

Ash wood has a light, creamy color. It complements many interior styles. Its fine grain pattern adds visual interest. Bent ash wood creates fluid lines and shapes. This enhances the overall look of furniture and other items. The bending process highlights the wood’s natural beauty. It turns simple pieces into works of art.

Using bent ash wood in your projects can elevate their appeal. Its strength and flexibility, combined with its aesthetic charm, make it an excellent choice.

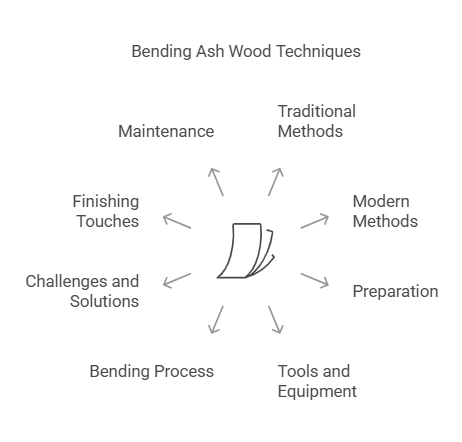

Traditional Bending Techniques

Ash wood is known for its strength and flexibility. Traditional bending techniques make it even more versatile. Two common methods are steam bending and laminating. Each technique has unique benefits.

Steam Bending

Steam bending is a popular method for bending ash wood. It involves exposing the wood to steam. This softens the fibers, making them pliable. Craftsmen place the steamed wood in a mold. They then let it cool and dry. The wood retains the new shape once cooled. This method is ideal for creating smooth, continuous curves.

Steam bending is often used in furniture making. It allows for beautiful, natural shapes. Chairs, tables, and other pieces can benefit from this technique. The process requires patience and skill. But the results are worth the effort.

Laminating

Laminating is another effective technique for bending ash wood. It involves gluing thin layers of wood together. These layers are called laminates. Each layer is bent over a form. The glue holds the layers in place. Once dry, the wood maintains the new shape.

Laminating allows for more complex shapes. It is often used in making curved furniture. The process also adds strength to the wood. This makes it suitable for structural elements. Laminated wood is less likely to crack or warp. This technique is both practical and artistic.

Modern Bending Methods

Ash wood is known for its flexibility and strength. These qualities make it a popular choice for bending. Modern methods have made the process easier and more efficient. Let’s explore some modern bending techniques.

Cold Bending

Cold bending involves using mechanical force to bend the wood without heat. This method works well for thin pieces. They are flexible and can be shaped easily. Clamps and forms help hold the wood in place. The process is simple yet effective.

Cold bending is also cost-effective. No special equipment is needed. Just a few basic tools are enough. This makes it accessible for many woodworkers.

Kerf Cutting

Kerf cutting is another modern method. It involves making small cuts along the wood. These cuts make the wood more flexible. The more cuts, the more it can bend. The cuts are called “kerfs.” They do not go all the way through. This keeps the wood strong.

Kerf cutting allows for precise bends. It is useful for complex shapes. The process requires careful planning. Each cut must be placed correctly. But the results are impressive.

Preparing Ash Wood For Bending

Preparing ash wood for bending is a crucial step in woodworking. This process ensures the wood is flexible enough to achieve the desired shape. Proper preparation involves selecting the right type of wood and controlling its moisture content. Follow these steps to get the best results.

Selecting The Right Wood

Choosing the right piece of ash wood is vital. Look for straight-grained wood. It should be free of knots and defects. The wood must have consistent growth rings. This ensures even bending and reduces the chance of breaks.

Moisture Content

Moisture content plays a key role in bending wood. Ash wood should have a moisture content of 20-30%. You can check this with a moisture meter. Wood with the right moisture level is more pliable. Too dry or too wet wood can break or not bend well.

To adjust moisture, steam the wood. Steaming makes the wood fibers flexible. Place the wood in a steam box for an hour per inch of thickness. Ensure the steam box maintains a steady temperature. This process helps achieve the perfect moisture content for bending.

Tools And Equipment

Bending ash wood requires specific tools and equipment. Using the right tools ensures the wood bends smoothly without breaking. Below are essential components to consider for bending ash wood.

Steam Box Setup

A steam box is crucial for bending ash wood. It softens the wood fibers, making them pliable. To set up a steam box, you need a sturdy box, a steam generator, and a hose. The box should be long enough to hold the ash wood pieces. Ensure it is sealed to trap the steam inside.

Attach the hose from the steam generator to the box. This allows steam to fill the box and heat the wood. Monitor the temperature to keep it steady. A thermometer can help maintain the right heat. This setup will prepare the ash wood for bending.

Clamps And Molds

Clamps and molds shape the steamed ash wood. They hold the wood in the desired form as it cools and dries. You need various clamps to secure the wood tightly. Spring clamps, C-clamps, and bar clamps are common choices.

Molds are custom forms that match the shape you want the wood to take. They can be made from metal, plastic, or even wood. Place the steamed ash wood into the mold and clamp it down. This ensures the wood holds its new shape as it dries.

Using clamps and molds correctly guarantees a smooth bending process. The wood retains its shape and gains strength as it cools. This method provides the best results for bending ash wood.

Step-by-step Bending Process

Ash wood is known for its flexibility and strength. Crafting unique shapes from ash wood involves a meticulous bending process. This section covers the step-by-step bending process, ensuring you achieve the desired shape.

Heating The Wood

The first step is heating the ash wood. Heat makes the wood pliable. You can use steam or boiling water for this. Place the wood in a steam box or boiling water for about an hour. This softens the wood fibers, making them easier to bend.

Forming The Shape

Once the wood is heated, it’s time to form the shape. Use a bending form or jig to create the desired curve. Secure the wood to the form using clamps. Ensure the wood is tightly secured to maintain the shape as it cools. Allow the wood to dry completely while still clamped. This step can take several hours or overnight.

Common Challenges And Solutions

Bending ash wood can be a rewarding yet challenging task. It’s a process that requires skill, patience, and the right techniques. But don’t worry, I’ve got you covered. Let’s dive into some common challenges you might face when bending ash wood and how to overcome them.

Preventing Cracks

One of the most common issues when bending ash wood is cracking. Imagine spending hours preparing your wood only to see it split – frustrating, right? Here are some tips to prevent this:

- Soak the Wood: Before you start bending, soak the ash wood in water. This makes it more pliable and less likely to crack.

- Use a Steam Box: Steaming the wood helps in softening it. A homemade steam box can do wonders. Just ensure the wood is evenly steamed.

- Slow and Steady: When bending, go slow. Rushing can cause the wood to crack. Gentle, consistent pressure is key.

Remember, patience is a virtue when it comes to bending wood. Take your time, and you’ll see better results.

Maintaining Shape

Once you’ve successfully bent your ash wood, the next challenge is maintaining its shape. Nobody wants their beautifully bent wood to spring back to its original form. Here’s how to keep your wood in the desired shape:

- Use a Form: After bending, immediately secure the wood to a form or mold. This holds it in place as it dries.

- Clamps Are Your Best Friend: Use clamps to keep the wood attached to the form. The more, the merrier. Clamps ensure the wood stays in place and dries properly.

- Let It Dry Completely: This is crucial. Give the wood enough time to dry completely. Depending on the thickness, it might take a few days to a week.

As a woodworker, there’s nothing more satisfying than seeing your project take shape – literally! By following these tips, you’ll ensure that your bent ash wood maintains its form beautifully.

So, next time you’re up for a wood bending project, keep these solutions in mind. Happy bending!

Finishing And Maintenance

Finishing and maintaining bent ash wood ensures its longevity and beauty. Proper care keeps the wood strong and preserves its natural appeal. Two key steps in this process are sanding and sealing, followed by long-term care.

Sanding And Sealing

Sanding prepares the wood surface for sealing. Use fine-grit sandpaper to smooth the wood. Make sure to sand in the direction of the grain. This step removes any rough spots or splinters. It also helps the sealant adhere better.

After sanding, clean the wood with a soft cloth. Remove all dust and debris. Then, apply a wood sealer evenly over the surface. Use a brush or a cloth for this step. The sealant protects the wood from moisture and wear. Allow it to dry completely before using the bent ash wood.

Long-term Care

Long-term care involves regular cleaning and maintenance. Dust the wood with a soft, dry cloth. This prevents dirt buildup and keeps the wood looking fresh.

Inspect the wood periodically for signs of damage. Small scratches or dents can be sanded and resealed. Avoid exposing the wood to extreme temperatures or humidity. This helps maintain its shape and strength.

Applying a wood conditioner yearly can also help. It nourishes the wood and keeps it from drying out. With proper care, bent ash wood can last for many years.

Frequently Asked Questions

What Is The Disadvantage Of Ash Wood?

Ash wood can be prone to insect infestations and rot. It may also warp with moisture exposure.

What Is The Bending Strength Of Ash Wood?

The bending strength of ash wood is approximately 15,000 psi. It is known for its durability and flexibility.

Does Ash Wood Warp?

Ash wood can warp if not properly dried or if exposed to moisture. Proper sealing and maintenance help prevent warping.

How Flexible Is Ash Wood?

Ash wood is highly flexible and strong. It bends easily without breaking, making it ideal for furniture and sports equipment.

Conclusion

Ash wood bending is achievable with the right techniques. This wood offers flexibility and strength, making it a great choice for many projects. Patience and practice are key. Always ensure proper preparation and follow safety guidelines. By doing so, you can create beautiful, curved wood pieces.

Happy woodworking!