Compared to a Common Drill an Impact Driver Has Genius Power

Compared to a common drill, an impact driver offers significantly more power and torque, making tough fastening tasks feel effortless. It’s a game-changer for driving long screws or working with dense materials where a regular drill struggles.

Ever felt that frustration when a screw just won’t go in? You know, the moment your drill bogs down, groans in protest, or worse, strips the screw head? It’s a common headache for DIYers and homeowners tackling projects. You end up pushing harder, wrestling with the tool, and maybe even questioning your DIY dreams. But what if there was a tool designed specifically to conquer those stubborn fasteners? What if that power was within reach? We’re talking about a tool that works smarter, not just harder. Let’s dive into how an impact driver, compared to a common drill, truly possesses genius power and how it can make your projects smoother and more enjoyable.

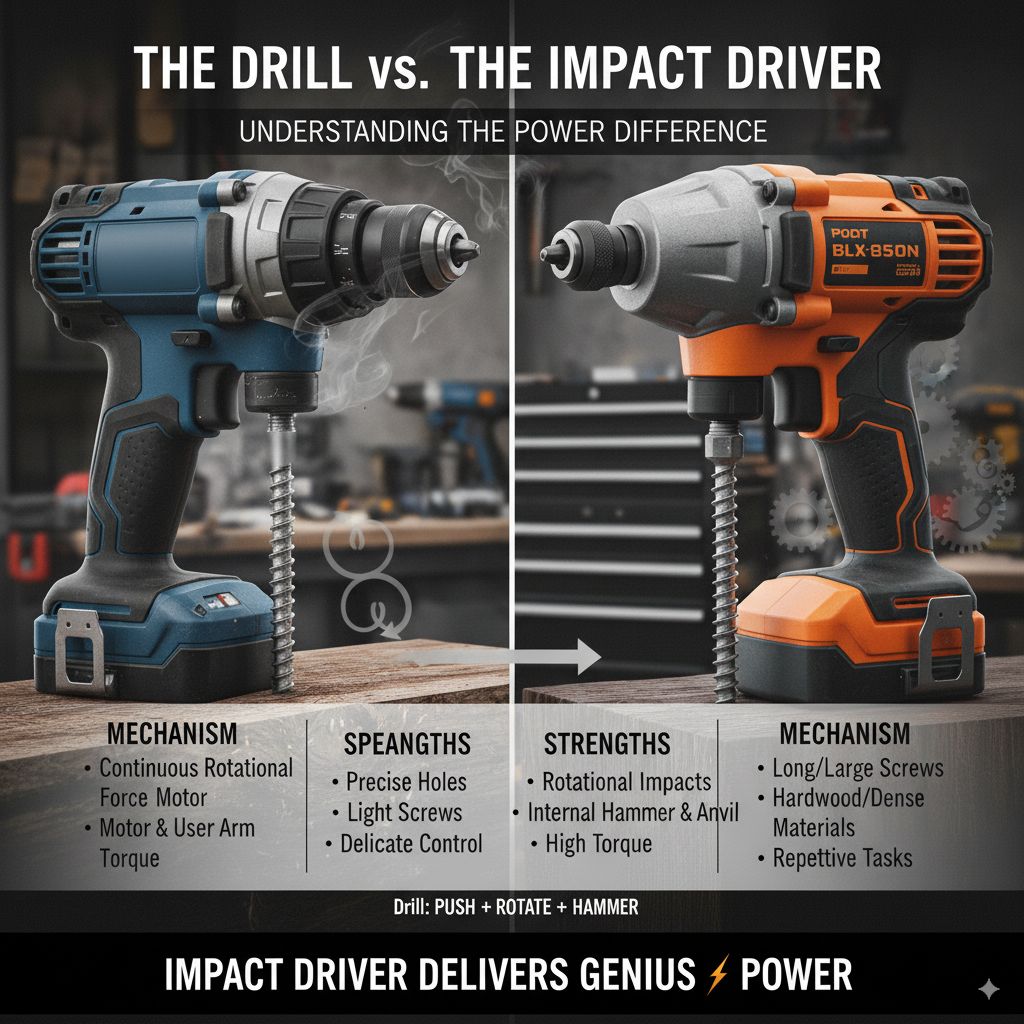

The Drill vs. The Impact Driver: Understanding the Power Difference

When you’re starting out in DIY or woodworking, the common drill is often your first go-to tool. It’s versatile, great for drilling holes, and can handle simple screw-driving tasks. However, when the going gets tough – think driving 3-inch screws into hardwood, assembling furniture, or working with lag bolts – the drill can start to show its limitations. This is where the impact driver steps in, boasting a design and mechanism that delivers a different kind of power, a “genius power” as we like to call it.

The core difference lies in how they deliver force. A drill primarily relies on continuous rotational force (torque) applied by your arm and the motor. An impact driver, on the other hand, adds a crucial element: concussive blows. When the impact driver senses resistance, its internal hammer mechanism strikes the anvil, simultaneously delivering short, powerful rotational impacts (also known as hammering action) and rotational force.

How an Impact Driver Delivers “Genius Power”

Imagine trying to hammer a nail with a spinning screwdriver – that’s a rough analogy, but it hints at the power surge. An impact driver’s mechanism is engineered to provide:

- Rotational Impacts: Instead of a steady, sometimes struggling, rotation, the impact driver delivers rapid, short bursts of rotational force. This “hammering” action helps to break through resistance without stalling the motor or camming out the bit.

- High Torque: The combined rotational force and impacts result in significantly higher torque output compared to most standard drills. This is the key to driving stubborn fasteners with ease.

- Reduced User Fatigue: Because the tool is doing the heavy lifting with those impacts, you don’t need to apply as much physical pressure. This means less strain on your wrist and arm, especially during prolonged use.

To put it simply, a drill pushes and rotates, while an impact driver pushes, rotates, and Hammers simultaneously. This makes it the champion for driving screws, especially into dense materials or when using longer fasteners.

Key Differences at a Glance

To really grasp why an impact driver shines, let’s break down the key distinctions between it and a standard drill. While both are fantastic tools, they excel in different areas. Understanding these differences will help you choose the right tool for the job and appreciate the impact driver’s unique capabilities.

| Feature | Standard Drill | Impact Driver |

|---|---|---|

| Primary Function | Drilling holes, light screw driving | Driving fasteners (screws, bolts) |

| Mechanism | Continuous rotational torque | Rotational torque + concussive impacts (hammering action) |

| Torque Output | Moderate | High |

| Speed Control | Variable speed trigger, often with clutch | Variable speed trigger, no clutch (impacts do the stopping) |

| Bit Holder | Chuck with adjustable jaws | Collet for quick bit changes (typically 1/4-inch hex shank) |

| Noise Level | Moderate | Higher (due to hammering action) |

| Vibration | Low | Moderate to High |

| Best For | Drilling, general assembly, light tasks | Driving long screws, lag bolts, working with hard materials, repetitive fastening |

| Can it Drill? | Yes, very well | Yes, but less precise, requires specific bits and torque control. Not ideal for precise holes. |

The Chuck vs. The Collet: A Small Detail with Big Implications

Notice the difference in the bit holder? A standard drill uses a chuck with jaws that tighten around the drill bit. This allows it to hold round or hexagonal shank bits securely. An impact driver typically features a collet chuck, designed to accept 1/4-inch hex shank bits. These bits lock firmly into place and are essential for handling the rapid impacts. This quick-change mechanism is a hallmark of impact drivers and contributes to their speed and efficiency in fastening tasks.

When “Genius Power” Truly Shines: Use Cases for Impact Drivers

So, when should you reach for the impact driver? Think of it as your heavy-duty screw-driving specialist. If you’re working on projects that demand serious fastening power, the impact driver is your best mate.

Top Tasks Where an Impact Driver Excels:

- Driving Long Screws: Tackling 3-inch, 4-inch, or even longer screws into wood? An impact driver will power through them without breaking a sweat, saving you immense effort and frustration.

- Working with Dense Materials: Hardwoods like oak, maple, or even some composite decking can be tough on a standard drill. The impact driver’s hammering action chews through this resistance.

- Assembling Furniture and Cabinets: Especially flat-pack furniture or cabinets that require numerous screws, the speed and power of an impact driver mean faster assembly and less arm fatigue.

- Driving Lag Bolts: These are large, heavy-duty fasteners often used in framing or large constructions. An impact driver is almost essential for driving them effectively.

- Demolition or Disassembly: Need to remove stubborn, rusted, or over-tightened bolts and screws? The impact driver’s powerful blows can help break them free.

- Deck Building: Driving hundreds of deck screws can be grueling. An impact driver makes this task significantly easier and faster.

- Metal Fastening: With the right bits, impact drivers can readily drive self-tapping screws into metal studs or other thin metal applications.

For these tasks, the impact driver’s ability to deliver high torque in short bursts is invaluable. It prevents the bit from slipping and stripping the screw head, a common problem with the continuous power of a regular drill when facing high resistance.

Can an Impact Driver Replace a Drill?

While impact drivers are powerful for fastening, they aren’t a direct replacement for a drill in all situations. Here’s why:

- Drilling Precision: Standard drills offer more control and precision for drilling holes. The impacting action of an impact driver can make it difficult to start a clean hole or maintain accuracy, especially in delicate materials or when a perfectly round, clean hole is needed.

- Clutch Functionality: Most drills have an adjustable clutch that allows you to set a maximum torque. This prevents over-tightening screws, which can strip the threads or damage the material. Impact drivers typically lack this clutch, meaning you rely on feel and the trigger for control, which takes practice.

- Drilling Large Holes: For very large holes (e.g., using a spade bit or hole saw), the sheer torque and impacting action of an impact driver can be excessive and difficult to control. A standard drill, especially a more powerful corded one, is often better suited.

In essence, think of them as complementary tools. For versatility, a drill is king. For raw fastening power, the impact driver reigns supreme. Many DIYers find having both in their toolkit is the ideal setup.

Understanding Torque and RPM: What They Mean for Your Project

When comparing tools, you’ll often see specifications like Torque and RPM (Revolutions Per Minute). These numbers tell us a lot about a tool’s capabilities, especially when considering less RPM does not mean less power for an impact driver!

Torque (in-lbs or Nm)

Torque is the rotational force of a tool. It’s essentially how much twisting power the tool has. Higher torque means the tool can turn something that’s harder to turn.

- Standard Drill: Typically offers moderate torque, often with a clutch to regulate it. This is great for control.

- Impact Driver: Boasts significantly higher torque. The combined rotational force and impacting blows allow it to overcome immense resistance. This is why it can drive larger screws or bolts more easily.

For example, a good cordless drill might offer anywhere from 300-600 inch-pounds (in-lbs) of torque, while an impact driver can easily deliver 1,000-2,000 in-lbs or more. That’s a massive difference!

RPM (Revolutions Per Minute)

RPM refers to how fast the tool’s chuck or collet spins. Higher RPM generally means faster drilling or fastening, assuming the torque is sufficient.

- Standard Drill: Often has higher RPMs than impact drivers, geared for faster drilling. They might have multiple speed settings (e.g., 0-400 RPM on low, 0-1400 RPM on high).

- Impact Driver: Typically has lower maximum RPMs (e.g., 0-2800 RPM), but this is perfectly suited for their primary job of fastening. The focus is on delivering force, not just speed.

Here’s where the “genius” part comes in for impact drivers. Even with a potentially lower RPM than some drills, the impacts allow them to achieve a higher effective driving speed because they don’t slow down or stall when encountering resistance. A drill might spin slower and slower as it struggles; an impact driver keeps hammering and turning.

Features to Look For in an Impact Driver

If you’re convinced that an impact driver is the right tool for your DIY arsenal, here are some features to consider:

- Brushless Motor: Brushless motors are more efficient, providing longer runtimes on a battery charge, more power, and a longer tool lifespan compared to brushed motors. They also run cooler.

- Variable Speed Trigger: Most impact drivers have this, allowing you to control the speed by how hard you squeeze the trigger. This is crucial for starting screws slowly and then increasing speed.

- LED Lights: An LED light, usually positioned around the chuck, illuminates your work area. Very helpful for those dimly lit corners!

- Gearing/Impact Control: Some higher-end impact drivers offer multi-speed settings or impact control modes. This might include settings for different types of fasteners or materials, giving you more precise control. For example, a “self-tapping screw” mode can prevent over-driving and stripping.

- Battery Platform: If you already own cordless tools, consider an impact driver from the same brand to share batteries. This can save you money and convenience.

- Ergonomics and Weight: Being comfortable with the tool is important. Larger or heavier drivers can be tiring to use for extended periods.

- Impact Rate (IPM): This is the number of impacts per minute. While related to RPM, a higher IPM generally means faster fastening, but it’s the combination with torque that matters most.

A great resource for understanding tool specifications from a consumer perspective can be found on sites like Consumer Reports, which offer unbiased reviews and buying guides for various tools.

Safety First: Using Your Impact Driver Responsibly

The power of an impact driver is impressive, but with great power comes the responsibility of using it safely. Always remember that safety should be your top priority in any DIY project.

Essential Safety Tips:

- Wear Eye Protection: Always wear safety glasses or goggles. Flying debris can occur unexpectedly.

- Secure Your Workpiece: Use clamps to hold your material firmly in place. This prevents it from shifting and reduces the risk of the bit slipping or the workpiece spinning.

- Use the Right Bit: Always use a bit specifically designed for impact drivers and ensure it’s the correct size and type (e.g., Phillips, Torx) for the screw head. A worn or incorrect bit is a recipe for stripped screws and potential injury.

- Maintain a Firm Grip: Impact drivers deliver significant rotational force. Hold the tool with both hands if possible, and maintain a stable stance to prevent losing control.

- Start Slow: Always begin driving a screw with the trigger held lightly to get the screw started straight. Gradually increase pressure as the screw goes in. This prevents the screw from going in crooked or stripping.

- Be Aware of Kickback: If the bit binds unexpectedly, the tool can twist violently. Be prepared for this and release the trigger immediately.

- Read the Manual: Familiarize yourself with your specific impact driver’s features and safety recommendations by reading the manufacturer’s manual.

- Avoid Over-Driving: While many impact drivers lack a clutch, learning to feather the trigger to avoid over-driving screws into softer materials or your workpiece is a skill that comes with practice. This prevents damaging the material or the screw head.

For more detailed safety guidelines on power tools, the Occupational Safety and Health Administration (OSHA) offers comprehensive resources on tool safety that are applicable to home workshops.

Impact Driver vs. Drill: When to Choose Which

To make it crystal clear, let’s summarize when your common drill is the hero and when your impact driver’s genius power is indispensable.

Choose Your Standard Drill For:

- Drilling precise holes: Especially in wood, metal, or drywall where a clean entry and exit are important.

- General screw-driving tasks: Assembling furniture with smaller screws, hanging pictures, or any task where overtightening is a concern.

- Jobs requiring delicate control: Working with softer materials or very fine threads where the clutch is invaluable.

- Using larger drill bits: Like spade bits or hole saws for sizable holes.

Choose Your Impact Driver For:

- Driving large or long screws: Effortlessly power through screws of 2 inches and longer.

- Working with hard woods or dense materials: Where a drill would struggle or stall.

- Repetitive fastening: When you have many screws to drive, like in deck building or framing.

- Removing stubborn or rusted fasteners: The hammering action helps break them free.

- Driving lag bolts and other heavy-duty fasteners.

Think of your drill as your versatile everyday driver and your impact driver as your powerful specialist for the tough jobs. They complement each other wonderfully.

Frequently Asked Questions (FAQ)

What is the biggest difference between a drill and an impact driver?

The biggest difference is how they deliver power. A standard drill uses continuous rotational force. An impact driver adds rapid rotational impacts or “hammering” blows when it encounters resistance, giving it significantly more torque for driving fasteners.

Can an impact driver drill holes?

Yes, an impact driver can drill holes, but it’s not ideal for precision. It requires hex-shank drill bits and the impacting action can make it harder to start a clean hole or maintain accuracy, especially in softer materials. A standard drill is generally better for most drilling tasks.

Why is an impact driver more powerful than a drill?

An impact driver is more powerful for fastening because its internal mechanism delivers short, powerful bursts of rotational force along with continuous torque. This “hammering” action helps overcome high resistance that would bog down a standard drill, resulting in significantly higher torque output for driving screws.

Will an impact driver strip screw heads?

An impact driver can strip screw heads if not used carefully. Because it has no clutch and delivers high torque, it’s important to feather the trigger and learn to stop before the screw is fully seated. Starting screws slowly and using the correct bit size also helps prevent stripping.