Contact Cement Glue: Your Ultimate Adhesion Solution

Contact cement glue is a strong adhesive used for bonding various materials. It provides instant hold and is ideal for projects requiring durable bonds.

Contact cement glue is a versatile adhesive known for its strong, permanent bonds. It works well on materials like wood, plastic, and leather. This glue is particularly popular in woodworking and crafting due to its ability to bond large surfaces quickly.

Unlike traditional adhesives, contact cement forms an immediate hold upon contact, reducing wait times for drying. Users often appreciate its flexibility, as it can accommodate different materials and applications. Whether you are a DIY enthusiast or a professional, understanding how to use contact cement effectively can enhance your projects. With proper application techniques, you can achieve strong, lasting results for your crafting and repair needs.

Introduction To Contact Cement Glue

Contact cement glue is a strong adhesive used for various projects. It creates a permanent bond when two surfaces are pressed together.

Contact adhesives are versatile and easy to use. They work well with many materials like wood, metal, and plastic.

| Application | Description |

|---|---|

| Furniture Making | Attach laminate to surfaces for a smooth finish. |

| Craft Projects | Bond paper, fabric, and other craft materials. |

| Flooring Installation | Secure vinyl or laminate flooring to the subfloor. |

| Upholstery | Attach fabric to cushions and frames easily. |

Using contact cement glue offers quick and reliable results. Always follow the manufacturer’s instructions for best outcomes.

Types Of Contact Cement

Solvent-based adhesives are strong and durable. They work well on many surfaces. These adhesives dry quickly and form a strong bond. They are perfect for tough materials like wood and metal. Caution is necessary due to strong fumes.

Water-based alternatives are safer and easier to use. They have low odor and are non-toxic. These adhesives take longer to dry but are great for indoor projects. They bond well with paper, fabric, and light wood. Clean-up is simple with just soap and water.

Advantages Of Using Contact Cement

Contact cement offers an immediate bond when applied. This means you can join surfaces quickly. No waiting time is needed for drying.

The bond is also very strong. It can hold heavy materials without breaking. This strength makes it perfect for various projects.

Durability is another great feature. Surfaces bonded with contact cement resist wear and tear. They can last for years, even in tough conditions.

Overall, using contact cement saves time and effort. It works well for both small and large tasks.

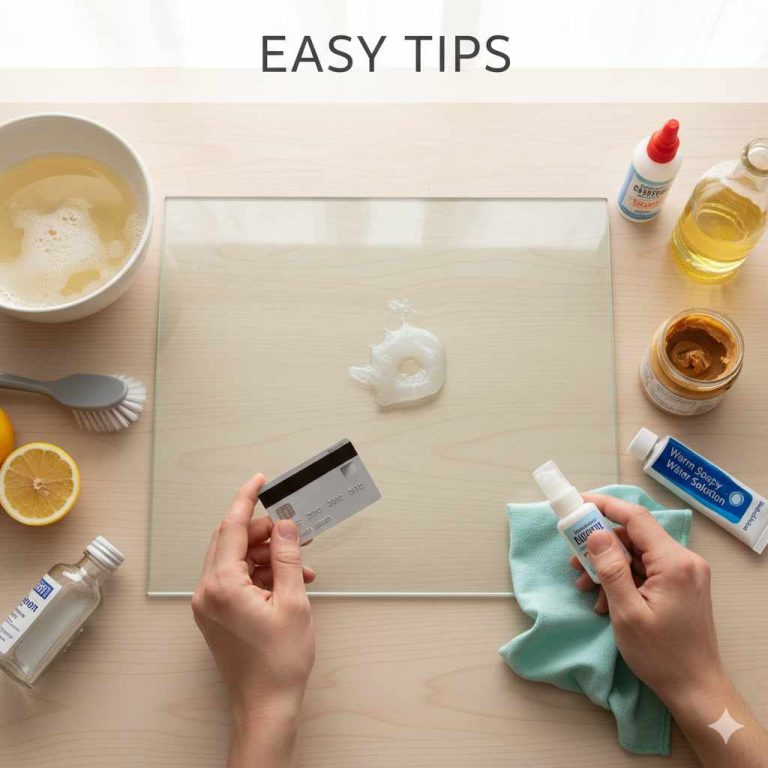

Preparation And Application Tips

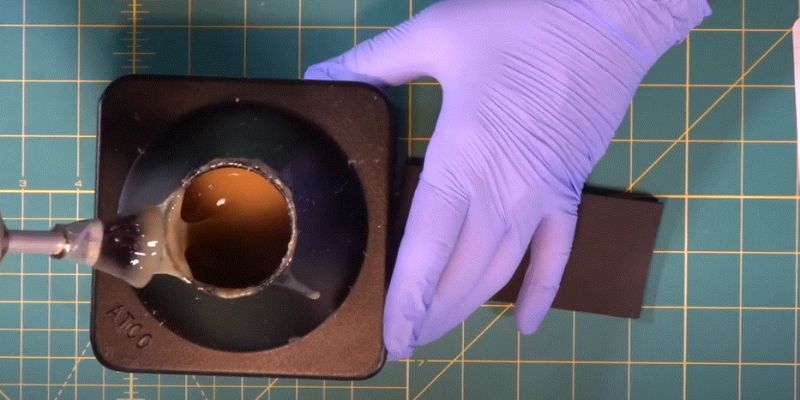

Proper surface preparation is key for optimal adhesion. Clean the surfaces thoroughly to remove dust and grease. Use a mild detergent and water for cleaning. Allow the surfaces to dry completely before applying the glue.

Roughen smooth surfaces with sandpaper. This creates a better grip for the contact cement. Avoid using too much pressure, which can damage the material.

Follow best practices for applying contact cement. Apply a thin, even layer on both surfaces. Use a brush or roller for a smooth finish. Wait for the glue to become tacky before joining the surfaces together.

Press the materials firmly together. Ensure they are aligned correctly before full contact. Once bonded, avoid moving the materials to maintain a strong bond.

Safety Measures And Precautions

Contact cement glue can be very strong but also very dangerous. Use it only in well-ventilated areas. Open windows and doors to allow fresh air to flow. Always wear protective gear like gloves and masks. This helps keep harmful fumes away from your body.

Store contact cement in a cool, dry place away from heat sources. Keep it out of reach of children and pets. Make sure the lid is tightly closed after use. This prevents spills and keeps the glue fresh.

Check the label for safety instructions. Follow all warnings and guidelines closely. Proper handling ensures safety while working with this powerful adhesive.

Troubleshooting Common Issues

Weak bonds can happen for many reasons. Ensure surfaces are clean and dry. Use enough contact cement for a strong hold. Press surfaces together firmly for best results. Wait for the recommended drying time.

Excess or spilled adhesive can be messy. Use a razor blade to carefully scrape away excess glue. A damp cloth can help wipe small spills. Always work gently to avoid damaging surfaces. Clean up any spills quickly for the best outcome.

Comparing Contact Cement To Other Adhesives

Contact cement offers quick bonding and flexibility. It works best on flat surfaces. This adhesive provides a strong hold and can bond various materials.

On the other hand, epoxy has a longer curing time but creates an even stronger bond. It fills gaps well and is great for heavy-duty projects.

| Criteria | Contact Cement | Epoxy |

|---|---|---|

| Bonding Speed | Fast | Slow |

| Flexibility | High | Low |

| Gap Filling | Limited | Excellent |

Choose silicone for waterproof needs. It stays flexible and works on many surfaces. Polyurethane is ideal for outdoor use. It handles temperature changes well.

Consider the project type before selecting the adhesive. Each adhesive serves different purposes.

Future Of Adhesives: Innovations In Contact Cement

Eco-friendly formulations in contact cement are gaining popularity. These innovations aim to reduce harmful chemicals. Manufacturers are now using natural ingredients. This approach helps protect the environment while maintaining strong bonds.

Advancements in bonding technology are impressive. New methods improve adhesion and speed. Smart adhesives can change properties based on temperature. This allows for better performance in different conditions. Users now enjoy stronger and more reliable bonds.

| Innovation | Benefit |

|---|---|

| Eco-Friendly Materials | Safer for the environment |

| Smart Adhesives | Adaptive performance |

| Quick Bonding | Increased efficiency |

Frequently Asked Questions

What Is Contact Cement Glue Used For?

Contact cement glue is widely used for bonding materials like wood, laminate, and plastic. It creates a strong, flexible bond that is resistant to heat and moisture. Ideal for projects requiring immediate adhesion, it is popular in woodworking, upholstery, and crafting.

Always follow manufacturer instructions for best results.

How Do You Apply Contact Cement Glue?

To apply contact cement glue, start by cleaning both surfaces. Then, use a brush or roller to spread an even layer on each surface. Allow it to dry until tacky, usually around 15-30 minutes. Finally, carefully align and press the materials together for a strong bond.

Is Contact Cement Glue Waterproof?

Yes, many contact cement glues are waterproof. Once cured, they can withstand exposure to moisture, making them suitable for outdoor applications. However, it’s essential to check the specific product’s specifications. Not all contact cements are created equal, so read labels for waterproof claims before use.

How Long Does Contact Cement Glue Take To Dry?

Contact cement glue typically dries within 15 to 30 minutes. Full curing time can take 24 hours, depending on conditions. Humidity and temperature can affect drying time. Always allow adequate time for the bond to set before applying stress or weight to the glued surfaces.

Conclusion

Choosing the right contact cement glue can significantly impact your projects. With its strong bonding capabilities, it’s perfect for various materials. Always follow the manufacturer’s instructions for the best results. By understanding its applications and benefits, you can enhance your crafting and repair tasks.

Make informed choices and enjoy successful bonding every time.