Homemade Table Saw: Build Your Own DIY Woodworking Tool

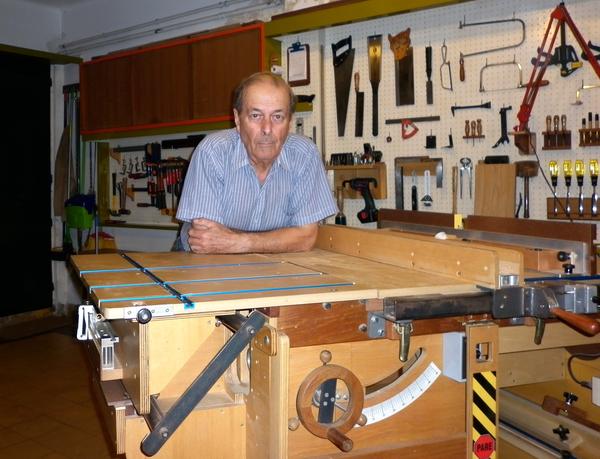

A homemade table saw can be a valuable tool for any woodworking enthusiast. Building your own allows customization to fit specific needs and can save money.

Creating a table saw at home offers many advantages. You can tailor it to your projects and workspace. Store-bought saws often come with features you don’t need, or they lack ones you do. A homemade version lets you decide everything.

The process also provides a sense of accomplishment. Working with your hands and seeing the final product is rewarding. Plus, you learn new skills that can be applied to future projects. This guide will help you understand the basics of building a homemade table saw, ensuring you have the right tools and knowledge for a successful build.

Credit: www.youtube.com

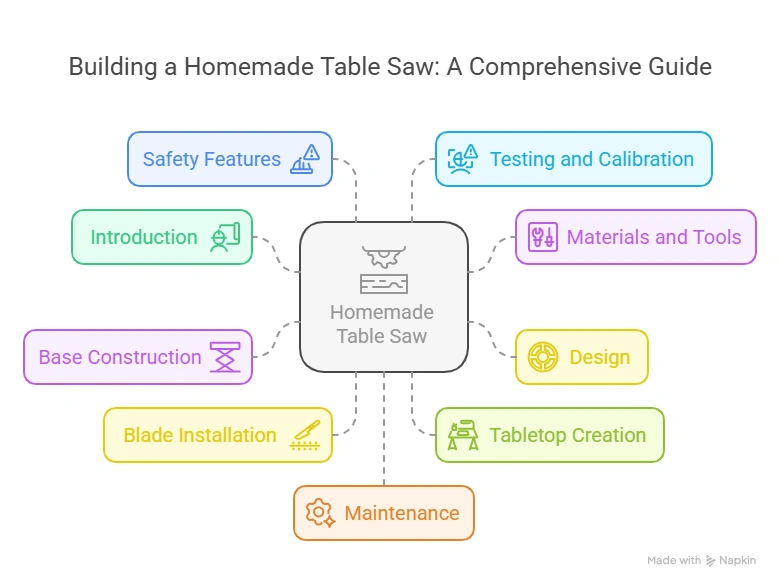

Introduction To Homemade Table Saw

Building a table saw at home can save money. It lets you use spare parts. This is great for the environment. You can build it to fit your needs. A homemade table saw can be customized. Adjust it to your preferred height and size. It offers a sense of achievement. You will learn new skills.

Safety is very important. Always wear safety goggles. Gloves can protect your hands. Keep your workspace clean. Make sure the saw is stable. A wobbly saw is dangerous. Use a push stick for small pieces. This keeps fingers safe. Unplug the saw when not in use. Check the saw blade often. A dull blade can cause accidents.

Materials And Tools Needed

You will need wood for the table base. Get a sheet of plywood for the surface. Metal brackets are needed for support. Screws and bolts are essential. Glue for the joints. Paint if you want a nice finish.

A saw for cutting wood is necessary. Drill for making holes. Screwdriver is needed for screws. Measuring tape to ensure accuracy. Sandpaper for smoothing edges. Clamps to hold pieces together while working.

Designing Your Table Saw

Start with clear plans. These plans guide you step by step. Blueprints should be simple to follow. Look for detailed diagrams. Make sure measurements are exact. Easy instructions help a lot. Find plans that fit your skill level. Beginners need simpler plans. Advanced builders can use complex ones.

Think about what you need. Do you need a portable saw? Maybe a fixed one suits you better. Add features you need most. Blade height and angle adjustment are useful. Storage space is important. Safety features like guards help keep you safe. Customize to fit your workshop space. Make sure it matches your projects.

.jpg)

Credit: ibuildit.ca

Building The Base

Start with four strong wooden legs. Connect them with solid beams on all sides. Use screws and glue for a tight fit. Make sure the frame is even. Check all corners for level.

Add cross braces for more support. These go between the legs. They stop the frame from wobbling. A sturdy frame is key. It keeps the saw steady while you work.

Attach four caster wheels to the bottom of the legs. Choose wheels with locks. This keeps the saw in place when needed. Use screws to secure the wheels tightly. Make sure the wheels can swivel. This helps you move the saw in any direction.

Test the wheels. Push the frame around. It should move easily. Lock the wheels. The frame should stay still. Now your table saw is mobile and stable.

Installing The Saw Blade

The right blade makes a big difference. Choose a blade designed for your cutting needs. Wood blades are different from metal blades. Look at the teeth on the blade. More teeth mean smoother cuts. Fewer teeth mean faster cuts.

Secure the blade properly. A loose blade is dangerous. Tighten the blade with a wrench. Make sure it does not wobble. Test the blade by spinning it manually. Check for any movement. If it moves, tighten it more.

Credit: woodgears.ca

Creating The Tabletop

Pick the right surface material for your table saw. Plywood is a great choice. It’s strong and easy to cut. MDF is another option. It is smooth and cheaper. But, it can get damaged by water. Hardboard is also good. It is very hard and smooth. But, it is heavy and hard to cut. Always choose a material that suits your needs.

Sand the surface to make it smooth. Use fine-grit sandpaper for this. After sanding, apply wood sealer. This will protect the surface. Next, use a primer. This helps paint stick better. Finally, apply paint or varnish. This gives a nice finish and protects the wood.

Adding Safety Features

Blade guards are important. They protect fingers from the sharp blade. Make sure the guard covers the blade completely. It should move easily with the wood. Check that it does not get stuck. This is very important for safety. Regularly inspect the guard. Replace it if it gets damaged.

An emergency stop button is vital. It can quickly stop the saw. Place it in an easy-to-reach spot. This ensures quick access. Test the button often. Confirm it works every time. This can prevent accidents. A foot pedal can also be used. It allows hands-free stopping. Both options are good for safety.

Testing And Calibration

Ensure the table saw is unplugged. Rotate the blade by hand. Check if it stays even with the table. Use a square to measure gaps between the blade and table. Any gap means the blade is not aligned. Adjust the blade until it is straight.

First, tighten all screws and bolts. Next, use a ruler to measure the distance from the blade to the fence. This distance should be the same at the front and back. If not, adjust the fence until both distances match. Finally, check with a test cut. The cut should be clean and straight.

Maintenance And Upkeep

Keep your table saw clean. Dust and debris can build up. This can affect the saw’s performance. Use a brush or vacuum often. Clean all parts carefully. Don’t forget the motor and vents. A clean saw works better and lasts longer.

Blades become dull with use. A dull blade can cause rough cuts. Sharpen the blade regularly. Use a sharpening tool. Sometimes, blades need replacing. Always follow the saw’s manual. Check blades for damage often. A sharp blade makes clean cuts.

Advanced Modifications

A dust collection system keeps your workspace clean. It helps reduce dust build-up. Attach a hose to the saw. Connect the hose to a vacuum. Ensure the vacuum is strong enough. Regular cleaning is needed. Check the filters often. They can get clogged. Clean them or replace them.

Jigs and fixtures make cutting easier. They help with precision. Use a miter gauge for angle cuts. Create custom jigs for special tasks. Secure the jig to the table. This prevents movement. Test the jig before use. Adjust if needed. Safety first, always.

Frequently Asked Questions

What Can I Use Instead Of A Table Saw?

Use a circular saw, jigsaw, or handsaw instead of a table saw. Miter saws and track saws are also effective alternatives.

What Is The #1 Danger When Using A Table Saw?

The #1 danger when using a table saw is kickback. It can cause serious injuries by forcefully throwing the wood back at you.

What Hand Tool Is Equivalent To A Table Saw?

A circular saw is the hand tool equivalent to a table saw. It offers similar cutting capabilities but with more portability.

Can Circular Saw Blades Be Used In Table Saws?

Yes, you can use circular saw blades in table saws. Ensure the blade size and arbor hole match your table saw specifications.

Conclusion

Building a homemade table saw offers many benefits. It saves money and provides a sense of accomplishment. With the right tools and safety measures, anyone can make one. Enjoy creating and using your new table saw. Happy woodworking!