Wood shrinkage can be calculated by measuring the initial and final dimensions of the wood and using the formula (initial dimension – final dimension) / initial dimension * 100%. Wood shrinkage is a common concern when working with wood materials.

As wood contains moisture, it tends to shrink as it loses moisture. This can lead to changes in the dimensions and shape of the wood, which can be problematic in various applications. To accurately calculate wood shrinkage, it is necessary to measure the initial dimensions of the wood and then measure the final dimensions after the wood has dried.

By subtracting the final dimensions from the initial dimensions and dividing the result by the initial dimensions, and then multiplying by 100%, the percentage of wood shrinkage can be determined. This calculation is essential to ensure precise measurements and to anticipate any potential issues that may arise due to wood shrinkage.

Understanding Wood Shrinkage

Understanding wood shrinkage is crucial for anyone working with wood, whether it’s for construction, woodworking, or even furniture making. Wood shrinkage refers to the reduction in size of wood material, which occurs as the wood loses moisture. This shrinkage can have significant implications on the quality and durability of any wood-based project. In this article, we will delve into the science behind wood shrinkage and the factors that can affect it.

The Science Behind Shrinkage

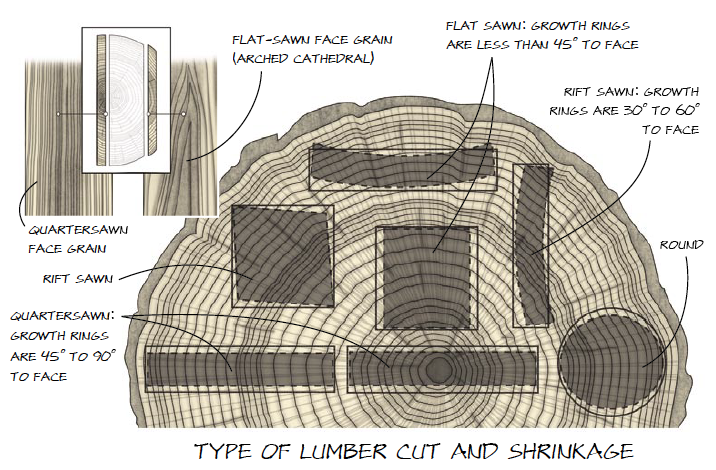

Wood shrinkage is primarily driven by the moisture content within the wood. As wood fibers lose moisture, they naturally contract and become smaller in size. The shrinkage occurs in three dimensions: radial, tangential, and longitudinal. Radial shrinkage happens perpendicular to the annual rings of the wood, tangential shrinkage occurs parallel to the annual rings, and longitudinal shrinkage happens along the length of the wood.

Factors Affecting Wood Shrinkage

Several factors can influence the extent and rate of wood shrinkage. It’s important to understand these factors in order to accurately calculate and anticipate wood shrinkage. Let’s take a look at the most significant factors:

- Wood Species: Different wood species have varying cell structures, which can affect their shrinkage properties. Softwoods, such as pine, tend to shrink more than hardwoods like oak or walnut.

- Initial Moisture Content: The moisture content of wood when it is initially harvested and processed can impact its subsequent shrinkage. Wood with high initial moisture content will experience more shrinkage as it dries out.

- Grain Orientation: The grain orientation within a piece of wood can affect its shrinkage. Wood grains that are oriented perpendicular to the direction of shrinkage will experience the most significant dimensional changes.

- Temperature and Humidity: Environmental conditions play a crucial role in wood shrinkage. Wood exposed to high temperatures and low humidity will lose moisture more rapidly, resulting in greater shrinkage.

- Wood Processing: The way wood is processed, including sawing, drying, and milling, can also impact its shrinkage. Improper drying techniques or uneven milling can lead to uneven shrinkage and warping.

By understanding the science behind wood shrinkage and considering the factors that affect it, woodworkers and construction professionals can accurately calculate and predict the amount of shrinkage in their wood projects. This knowledge allows for better planning and execution to ensure the longevity and structural integrity of wood-based creations.

Credit: www.thepinnaclelist.com

Measuring Wood Shrinkage

When it comes to working with wood, one crucial factor to consider is wood shrinkage. Wood has the ability to expand or contract, depending on the moisture content of the surrounding environment. Measuring wood shrinkage is important to predict and account for these changes, ensuring proper fit and functionality of finished products. In this article, we will explore how to calculate wood shrinkage and the tools you need to measure it accurately.

Calculating Percentage Shrinkage

Calculating the percentage shrinkage of wood is essential to understand the extent of dimensional changes. To calculate the percentage shrinkage, you need two specific measurements: the initial dimension and the final dimension. Here’s the formula:

Percentage Shrinkage = ((Initial Dimension – Final Dimension) / Initial Dimension) x 100

For example, let’s say you have a piece of wood that measures 12 inches initially but shrinks to 10 inches after it has dried. To calculate the percentage shrinkage:

Percentage Shrinkage = ((12 – 10) / 12) x 100 = 16.67%

Tools For Measuring Shrinkage

Accurate measurements are crucial when it comes to determining wood shrinkage. Here are some tools you can use to measure shrinkage:

- Calipers: Calipers are versatile tools that allow you to measure the thickness and diameter of wood with precision. They are especially useful for measuring small pieces of wood.

- Vernier Calipers: Vernier calipers provide more accurate measurements than regular calipers, as they have a sliding scale that allows for precise readings in fractions of a millimeter or inch. They are suitable for both small and large pieces of wood.

- Moisture Meter: A moisture meter is an essential tool for measuring the moisture content of wood. By regularly checking the moisture content, you can track changes and anticipate potential shrinkage or expansion.

By utilizing these tools, you can accurately measure wood shrinkage and make necessary adjustments to your woodworking projects. Keep in mind that wood shrinkage can vary depending on the species and moisture content, so it’s essential to conduct regular measurements to ensure the best possible results.

Preventing Wood Shrinkage

When working with wood, it’s crucial to understand how to prevent wood shrinkage, as this can impact the quality and longevity of your woodworking projects. By implementing proper wood selection and effective moisture control, you can minimize the risk of wood shrinkage and ensure the durability of your creations.

Proper Wood Selection

Selecting the right type of wood is the first step in preventing shrinkage. Opt for well-seasoned and kiln-dried wood with low initial moisture content. Choose hardwood over softwood as it tends to shrink less. Avoid using wood with large knots and excessive grain irregularities.

Effective Moisture Control

Maintaining an optimal moisture level is essential to prevent wood shrinkage. Store wood in a controlled environment with consistent humidity levels. Utilize a moisture meter to monitor the wood’s moisture content. Apply sealants and finishes to minimize moisture absorption and loss.

Dealing With Shrunken Wood

Wood shrinkage can be calculated by measuring the initial and final dimensions of the wood. To calculate the wood shrinkage, subtract the final dimension from the initial dimension, and then divide the result by the initial dimension. This will give you the percentage of wood shrinkage.

Repairing Shrunken Wood

If you notice shrunken wood in your project, there are ways to repair it. One option is to use wood filler to fill in the gaps. Another method is to sand down the wood to even it out.

Applying wood glue along the seams can also help to strengthen the wood and prevent further shrinkage. Once repaired, you can refinish the wood to restore its appearance.

Using Shrunken Wood In Projects

Despite its shrunken state, you can still utilize wood effectively in new projects. Consider cutting the wood into smaller pieces to create unique designs. Or, use it as accents in other woodworking projects.

Seasoning And Drying Wood

Wood shrinkage is a natural process that occurs when moisture exits the wood fibers, affecting the size and shape of the wood. Understanding how to calculate wood shrinkage requires knowledge of seasoning and drying wood techniques.

Role Of Seasoning In Minimizing Shrinkage

Seasoning wood involves reducing the moisture content to minimize shrinkage. It allows the wood to acclimate to the environment, preventing rapid changes in size that can lead to warping or cracking. Proper seasoning is crucial in minimizing overall wood shrinkage.

Best Practices For Drying Wood

- Ensure proper air circulation around the wood pieces

- Avoid direct exposure to sunlight or extreme heat

- Use a dehumidifier or fan to facilitate drying

- Regularly check moisture levels during the drying process

Credit: www.popularwoodworking.com

Understanding Moisture Content

Moisture content plays a crucial role in wood shrinkage. When wood absorbs or loses moisture, its dimensions change, resulting in shrinkage or swelling. Understanding the impact of moisture content on wood shrinkage and how to measure it is essential for woodworkers and anyone involved in construction or woodworking projects.

Impact Of Moisture Content On Shrinkage

Excessive moisture content in wood can lead to swelling, while low moisture content can cause shrinkage. Wood shrinkage occurs as the moisture content decreases, resulting in the contraction of the wood fibers. This can lead to problems such as warping, cracking, and structural instability in wood-based products. The higher the moisture content, the higher the chance of shrinkage. Therefore, it’s crucial to monitor and control moisture levels to minimize potential shrinkage issues in wood.

Measuring Wood Moisture Content

There are various methods to measure wood moisture content, including oven-drying, moisture meters, and equilibrium moisture content calculations. Using a moisture meter is one of the most effective and practical ways to measure the moisture content of wood. It provides instant and accurate readings, allowing woodworkers to assess the moisture levels and determine if further drying or conditioning is necessary. Equilibrium moisture content (EMC) calculations are also commonly used to measure the moisture content of wood in specific environmental conditions. By understanding how to measure and interpret wood moisture content, individuals can make informed decisions to minimize wood shrinkage and ensure the quality and stability of wood products.

Calculating Shrinkage In Different Wood Species

Calculate wood shrinkage by measuring initial and final dimensions, then using a formula to determine the percentage. Different wood species have varying rates of shrinkage due to their cellular structure and moisture content. Understanding this process is crucial for woodworking projects to prevent warping and ensure precision.

Variations In Shrinkage Across Wood Species

Wood shrinkage – a natural process that can impact woodworking projects and furniture stability. Calculating shrinkage is crucial to anticipate the dimensional changes that occur as wood dries. It’s important to note that different wood species have varying rates of shrinkage, making it essential to understand these variations to ensure successful woodworking projects.

When working with different wood species, there are a few key factors to consider when calculating shrinkage:

Specific Gravity: Each wood species has its own specific gravity, which is a measure of its density and moisture content. Higher specific gravity indicates denser wood, leading to lesser shrinkage.

– Radial and Tangential Shrinkage: Wood shrinks differently in different directions. Radial shrinkage refers to the reduction in size along the radius of a tree trunk, while tangential shrinkage occurs parallel to the tree’s growth rings. Understanding these variations allows for more accurate calculations.

– Initial Moisture Content: The moisture content of wood when harvested affects its shrinkage characteristics. Wood with higher initial moisture content will shrink more as it dries.

Calculating Shrinkage For Specific Woods

Calculating shrinkage for specific wood species requires accurate data and formulas. One common method is to use the tangential and radial shrinkage values, often expressed as percentages, provided by wood shrinkage databases or reliable sources. Here’s a simple formula to help you calculate shrinkage:

Shrinkage Percentage = (Tangential Shrinkage Percentage + Radial Shrinkage Percentage) / 2

By plugging in the tangential and radial shrinkage percentages for a specific wood species into this formula, you can quickly determine the overall shrinkage percentage. This percentage helps estimate the size reduction that may occur during the drying process.

Here’s a table with examples of shrinkage percentages for a few common wood species:

| Wood Species | Tangential Shrinkage Percentage | Radial Shrinkage Percentage | Shrinkage Percentage |

|---|---|---|---|

| Maple | 7.1% | 4.7% | 5.9% |

| Oak | 9.3% | 4.5% | 6.9% |

| Walnut | 4.9% | 2.6% | 3.8% |

Remember, these values serve as estimates and can vary depending on factors like growth conditions and the wood’s specific characteristics. It’s always advisable to consult reliable sources and test wood samples for accurate calculations.

Calculating shrinkage in different wood species is a crucial step in woodworking. Understanding the variations in shrinkage rates and employing accurate formulas helps ensure the success of your projects. So, before you embark on your next woodworking endeavor, be sure to research and calculate the shrinkage values of the wood species you plan to use.

Credit: www.myexcelonline.com

Real-life Applications

Wood shrinkage calculation is vital in real-life applications like woodworking and construction projects. By measuring initial and final dimensions, one can use a simple formula to accurately determine the percentage of wood shrinkage. This helps ensure precise fittings and prevent issues due to shrinkage over time.

Wood Shrinkage In Construction

Wood shrinkage is a crucial factor to consider in construction projects. When wood dries, it naturally shrinks in size, and this can lead to various issues if not taken into account. For example, if a wooden beam is installed with insufficient clearance for shrinkage, it may warp or crack when it dries, compromising the structural integrity of the building. Similarly, when wooden boards are used for flooring or siding, they need to be properly spaced to anticipate shrinkage and prevent buckling or gaps. By understanding how to calculate wood shrinkage, construction professionals can ensure the long-term durability of their projects.

Woodworking And Shrinkage Considerations

In woodworking, wood shrinkage is a common challenge that can affect the accuracy and quality of the final product. When crafting furniture, cabinets, or any other wooden item, it is essential to account for the potential shrinkage of the wood. This means carefully planning the dimensions, especially for components that will be joined together. If the wood shrinks after assembly, it can lead to loose joints or misaligned parts. By understanding the properties of the particular wood species being used and calculating its expected shrinkage, woodworkers can make precise adjustments to account for this natural process. This ensures that the finished product maintains its structural integrity and aesthetic appeal over time.

Now that we’ve explored real-life applications of wood shrinkage in construction and woodworking, let’s delve into how wood shrinkage is accurately calculated and factors that affect it.

Frequently Asked Questions For How Do You Calculate Wood Shrinkage

How Does Moisture Affect Wood Shrinkage?

Wood absorbs or releases moisture based on the environment, causing expansion or contraction, leading to wood shrinkage.

What Factors Influence Wood Shrinkage?

Factors like wood species, grain orientation, moisture content, and drying methods can impact wood shrinkage.

Why Is It Important To Calculate Wood Shrinkage?

Understanding wood shrinkage helps in proper planning and design to prevent issues like warping or splitting in wood projects.

Conclusion

Understanding how to calculate wood shrinkage is essential for anyone working with wood. By using the proper formulas and techniques, you can anticipate and account for the changes in wood dimensions, ensuring precise and professional results. With this knowledge, you can confidently navigate the challenges of wood shrinkage and produce high-quality woodworking projects.