How Long Does PVC Glue Take to Dry? Set Cure Time

You’ve just finished a DIY project or a plumbing repair, and the last thing you want is a wobbly joint or a leak. You carefully applied the PVC glue, pressing the pipes together firmly. Now comes the waiting game.

You start to wonder, how long does PVC glue take to dry? Getting this right is key to ensuring your connections are strong and reliable. This post will guide you through the set and cure times for PVC glue, helping you plan your projects and avoid common mistakes.

We’ll break down what affects drying times and what you need to know to achieve a solid bond every time, so you can move forward with confidence and get back to enjoying your work.

Understanding PVC Glue Drying and Curing

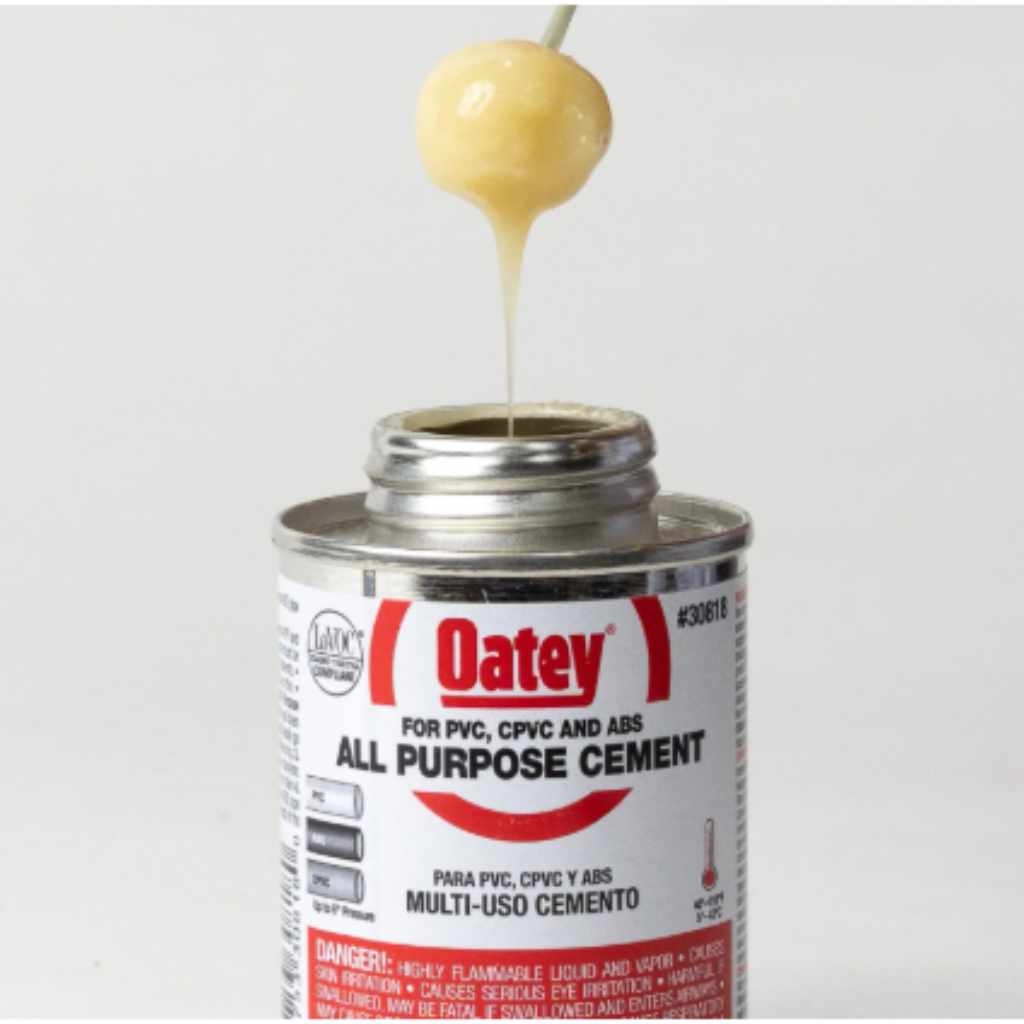

PVC (polyvinyl chloride) glue, often referred to as PVC cement or primer, is a solvent-based adhesive specifically designed for joining PVC pipes and fittings. It doesn’t simply stick surfaces together like traditional glues. Instead, it chemically softens the surfaces of the PVC, allowing them to fuse together as the solvent evaporates.

This fusion process is what creates a strong, permanent bond. Understanding how long does PVC glue take to dry set cure time is essential for a successful and long-lasting connection.

When we talk about PVC glue drying, we’re really discussing two main stages: setting time and curing time. These are distinct but related, and both are critical for the integrity of your PVC joints.

Setting Time The Initial Hold

Setting time is the initial period after applying the PVC glue and assembling the joint during which the cement begins to solidify, providing an initial hold. During this phase, the solvents in the cement have started to evaporate, and the softened PVC surfaces begin to fuse. This is the point where the joint gains enough strength to withstand minor movement or pressure without separating.

Think of it like this: the setting time is when the glue becomes “sticky” enough to hold things in place firmly. It’s the period where you can’t easily twist or pull the joint apart. However, this initial hold is not the final strength.

The joint can still be compromised if subjected to significant stress or liquid pressure during this early stage.

Factors influencing setting time include:

- The specific type of PVC cement used (e.g., regular, medium-bodied, heavy-bodied).

- Ambient temperature and humidity.

- The size and fit of the pipe and fitting.

Most manufacturers provide a general guideline for setting times on their product packaging. For example, a joint might set within a few minutes to about 30 minutes, depending on the conditions and the product. It’s always best to consult the product’s instructions for the most accurate information.

Curing Time The Full Strength Bond

Curing time is the extended period during which the chemical fusion process continues and the PVC cement reaches its maximum strength. While the joint might feel solid after the setting time, it’s still vulnerable. Curing is when the solvents have fully evaporated, and the PVC material has completely reformed into a solid, unified structure.

This is the phase where the joint achieves its full structural integrity and chemical resistance. It’s only after the curing time is complete that the pipe system can be safely put under pressure or exposed to the fluids it’s designed to carry. Rushing this process can lead to leaks or joint failure down the line.

Curing times are significantly longer than setting times and are influenced by a wider range of factors:

- Temperature: Lower temperatures slow down solvent evaporation and fusion.

- Humidity: High humidity can also slow down the drying process.

- Pipe Size: Larger diameter pipes and fittings generally require longer curing times due to the larger volume of cement and surface area involved.

- Ventilation: Good airflow helps solvents evaporate more quickly.

- Type of Cement: Different formulations have varying curing characteristics. Heavy-bodied cements, for instance, often require longer cure times.

- Primer Usage: If primer is used, it can affect how quickly the cement works.

The curing time is the most critical aspect for ensuring a reliable PVC connection, especially for pressurized systems like plumbing or irrigation.

Factors Affecting PVC Glue Drying Time

Several elements play a role in how quickly your PVC glue will set and cure. Being aware of these can help you adjust your expectations and ensure proper application. Understanding these factors is key to answering how long does PVC glue take to dry set cure time accurately for your specific situation.

Temperature

Temperature is perhaps the most significant environmental factor. PVC cement works by evaporation of solvents. Warmer temperatures accelerate this evaporation, leading to faster setting and curing.

Conversely, colder temperatures slow down evaporation, significantly extending the time it takes for the cement to dry and cure.

For instance, in hot weather (e.g., above 70°F or 21°C), you might experience faster setting times. In cold weather (e.g., below 40°F or 4°C), the curing process can be drastically delayed, sometimes doubling or tripling the recommended times.

Humidity

High humidity levels mean there’s more moisture in the air. This moisture can interfere with the evaporation of solvents from the PVC cement, slowing down the drying and curing process. In very humid conditions, it’s advisable to allow for extended curing times beyond the manufacturer’s standard recommendations.

Type of PVC Cement

PVC cements come in various formulations, often categorized by their body, which refers to their viscosity and the amount of solvent they contain. These categories have a direct impact on drying and curing times.

- Regular Body Cements: These are typically for smaller diameter pipes (up to 2 inches) and have faster drying times.

- Medium Body Cements: Suitable for a wider range of pipe sizes (up to 4 inches), these offer a balance of working time and relatively quick drying.

- Heavy Body Cements: These are thicker and contain more solvent, making them ideal for larger diameter pipes (over 4 inches) and filling small gaps. They generally have longer setting and curing times because there’s more solvent to evaporate.

- Fast-Setting Cements: As the name suggests, these are formulated for rapid drying and curing, often used in situations where speed is essential, like emergency repairs or tight deadlines.

Always check the product label. It will specify the type of cement and provide recommended set and cure times for different conditions.

Pipe Size and Fit

Larger diameter pipes and fittings require more PVC cement to create the bond. This means there’s a larger volume of solvent that needs to evaporate, leading to longer curing times. Similarly, if the fit between the pipe and fitting is loose, more cement will be used to fill the gap, extending the curing process.

Ventilation

Proper ventilation is crucial for efficient solvent evaporation. Working in a well-ventilated area allows the solvents to dissipate into the air more quickly, speeding up the drying and curing of the PVC cement. Confined or poorly ventilated spaces will prolong the process.

Primer Usage

Many PVC installations require the use of a primer before applying the cement. Primer helps to soften and clean the PVC surfaces more effectively, preparing them for a better fusion. While primer itself evaporates quickly, its application can influence the overall chemical reaction and, in some cases, slightly alter the drying time of the subsequent cement application.

Always follow the manufacturer’s recommendations regarding primer and cement application order and timing.

General PVC Glue Set and Cure Times

While specific times can vary based on the factors above and the exact product used, manufacturers provide general guidelines for set and cure times. These are typically based on specific temperature and humidity conditions, often around 70°F (21°C) and 50% humidity. It’s always best to refer to the product packaging for the most precise information.

Set Times (Initial Hold)

These are the times required before the joint has enough initial strength to be handled or moved without compromising the bond. For most standard PVC cements:

- Very Short Set Time (Fast Setting Cements): As little as 1-5 minutes.

- Short Set Time (Regular/Medium Cements): 10-30 minutes.

- Longer Set Time (Heavy Cements): 30-60 minutes.

During this set time, the joint can typically withstand minor repositioning but should not be subjected to any significant stress or pressure.

Cure Times (Full Strength)

These are the times required for the joint to achieve its full strength and be ready for use, especially under pressure.

Here’s a general guide, but remember these times increase significantly in colder temperatures and decrease in warmer ones. These figures are often for systems operating at moderate pressures (e.g., 0-60 psi).

| Pipe Size | Temperature Range | Set Time (Initial Hold) | Cure Time (for 0-60 psi pressure) | Cure Time (for >60 psi pressure) |

|---|---|---|---|---|

| 1/2″ to 1 1/2″ | 60°F – 100°F (16°C – 38°C) | 10 – 30 min | 1 – 2 hours | 4 – 6 hours |

| 2″ to 3″ | 60°F – 100°F (16°C – 38°C) | 15 – 45 min | 2 – 4 hours | 8 – 12 hours |

| 4″ to 6″ | 60°F – 100°F (16°C – 38°C) | 30 – 60 min | 4 – 8 hours | 12 – 24 hours |

| Below 60°F (16°C) | Add approximately 50% to all cure times. | |||

| Above 100°F (38°C) | Cure times may be slightly reduced, but caution is advised. | |||

It’s crucial to remember that these are general figures. Always read and follow the specific instructions provided by the manufacturer of the PVC cement and primer you are using.

Dealing with Cold Weather Installation

When installing PVC in cold temperatures (below 40°F or 4°C), the solvent evaporation process slows down considerably. This means both set and cure times will be significantly extended. In freezing conditions, PVC installation should generally be avoided.

If you must work in the cold:

- Use a slow-setting or medium-bodied cement.

- Ensure pipes and fittings are at a reasonable temperature if possible (bring them indoors to warm up if they’ve been stored outside).

- Allow for considerably longer cure times. Double the recommended times for moderate temperatures is a good starting point, but longer may be necessary.

- Consider using heated enclosures or heat lamps if possible to maintain a warmer working environment during the curing period.

- Never attempt to pressure test a system that hasn’t fully cured, especially in cold weather.

Fast-Setting Cements Explained

Fast-setting PVC cements are a popular choice for applications where time is critical. They are formulated with a higher concentration of solvents that evaporate quickly, allowing the joint to set and achieve a usable level of strength much faster than standard cements.

Benefits of fast-setting cements include:

- Reduced waiting time for subsequent steps in a project.

- Ideal for emergency repairs or situations where lines need to be put back into service quickly.

- Often suitable for wet conditions where quicker setting is advantageous.

However, they also have drawbacks:

- Shorter working time. Once applied, you have less time to adjust the pipe and fitting before the cement sets.

- May require more careful application to ensure a good bond within the limited working time.

- Cure times for full pressure rating are still significant and shouldn’t be rushed.

When using fast-setting cement, pay close attention to the specific manufacturer’s instructions, as set and cure times can be drastically different from standard formulas.

When Can You Pressure Test?

Pressure testing is a vital step to ensure the integrity of any plumbing or fluid conveyance system before putting it into full service. The question of how long does PVC glue take to dry set cure time directly impacts when you can safely pressure test.

For most standard PVC installations, it’s generally recommended to wait at least 24 hours for a full cure before pressure testing, especially for systems that will operate at higher pressures (above 60 psi). For lower pressure systems (0-60 psi), the cure times listed in the table earlier (e.g., 1-4 hours) might be acceptable, but again, always defer to the cement manufacturer’s specific recommendations.

In cold weather, this waiting period must be extended significantly. If you pressure test too soon, the partially cured joint can fail under pressure, leading to leaks or even catastrophic failure of the joint.

Always follow the pressure testing guidelines set by plumbing codes or the specific application standards for your project.

Frequently Asked Questions

Question: What happens if I don’t wait long enough for PVC glue to dry?

Answer: If you don’t wait long enough for PVC glue to cure, the joint may not have reached its full strength. This can lead to leaks, joint failure, or blowouts, especially when the system is under pressure. It compromises the integrity of your entire PVC system.

Question: Can I use a hairdryer to speed up PVC glue drying?

Answer: While heat generally speeds up solvent evaporation, using a hairdryer directly on PVC glue is generally not recommended. Excessive direct heat can cause the PVC itself to soften or deform, or it might cause the solvents to evaporate too quickly from the surface, leaving a weaker bond internally. It’s better to rely on ambient conditions or controlled warming if necessary.

Question: Is there a difference between PVC cement and PVC glue?

Answer: While the terms are often used interchangeably, “PVC cement” is the more technically correct term. It’s a solvent-based adhesive that chemically fuses PVC, whereas “glue” often implies a more traditional adhesive that forms a surface bond. For joining PVC pipes, you need PVC cement.

Question: Can I use PVC glue in extremely high temperatures?

Answer: While warmer temperatures accelerate drying, extremely high temperatures (above 100°F or 38°C) can also affect the cement’s performance. They can cause the solvents to evaporate too quickly, potentially leading to a poor bond if not applied correctly. Always follow manufacturer guidelines for temperature ranges.

Question: How do I know if the PVC glue has fully cured?

Answer: The best way to know is to follow the manufacturer’s recommended cure times for your specific conditions and pipe size. Visually, a fully cured joint will appear solid and uniform. However, you cannot reliably tell by looking or feeling alone; the internal chemical fusion takes time.

Pressure testing after the recommended cure time is the definitive check.

Final Thoughts

Effectively managing how long does PVC glue take to dry set cure time is paramount for successful PVC installations. It’s not just about slapping glue on and hoping for the best; it involves understanding the science behind solvent welding and respecting the environmental factors that influence it. From the initial set, giving you that crucial first hold, to the extensive cure that guarantees a strong, leak-proof bond, each stage demands patience and adherence to guidelines.

Factors like temperature, humidity, the type of cement you select, and the diameter of the pipes all play a significant role, dictating how long you’ll need to wait before your project is truly ready for action.

Remember that the figures provided are general; the product packaging is your most reliable source of information. Cold weather requires significantly longer waits, so always adjust your expectations and your timeline accordingly. When in doubt, err on the side of caution and wait longer.

A few extra hours or even a day can prevent costly failures and the need for rework. For any application that involves pressure, like plumbing or irrigation, proper curing before pressure testing is non-negotiable. By taking these steps and paying close attention to the details, you can ensure your PVC joints are not just functional but built to last, giving you peace of mind and a job well done.