How To Check a Chainsaw Coil: Genius Solution

To check a chainsaw coil, disconnect the spark plug, remove the starter cover and flywheel shroud, then inspect the coil for damage. Test its gap and resistance using a multimeter. A faulty coil often causes no spark, leading to engine failure. This guide provides a simple, step-by-step solution even for beginners.

Is your chainsaw refusing to start, sputtering, or just making a sad, silent protest when you pull the cord? It’s a common frustration for many DIYers and homeowners. Often, the culprit hiding inside that powerful machine is a faulty ignition coil. No spark means no combustion, and no way to get your work done.

Don’t worry, figuring out “how to check a chainsaw coil” isn’t as complicated as it sounds. With a few basic tools and this simple, step-by-step guide, you’ll be able to diagnose the problem yourself. We’ll walk through each part, making it easy to understand and even easier to fix. Let’s get your chainsaw roaring back to life!

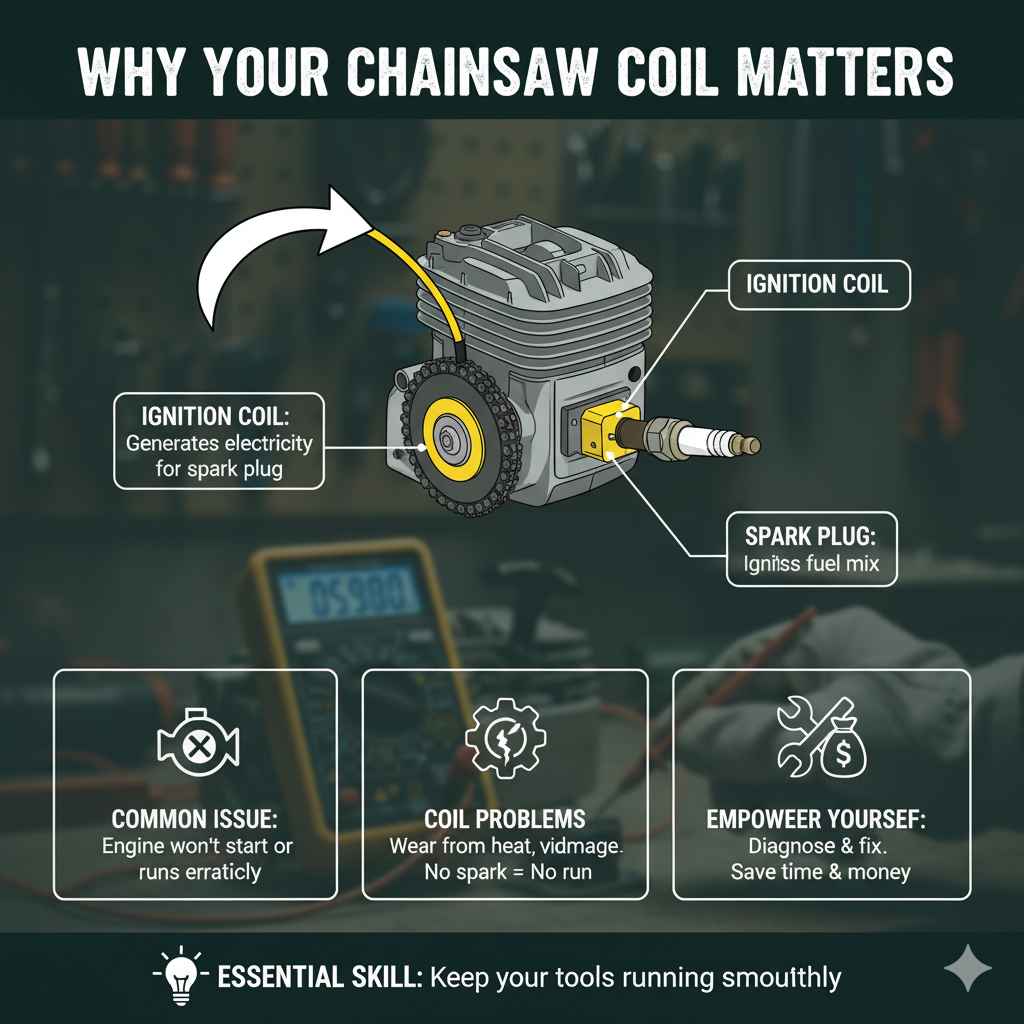

Why Your Chainsaw Coil Matters

The ignition coil is the unsung hero of your chainsaw’s engine. Think of it as the tiny powerhouse that generates the spark plug’s electricity. Without a healthy coil, your spark plug is just a piece of metal, unable to ignite the fuel mixture. This vital component typically sits near the flywheel and is connected to the spark plug via a spark plug wire.

When a chainsaw won’t start, or runs erratically, beginners often suspect the fuel or the spark plug itself. While these are common issues, an overlooked problem is the ignition coil. Over time, coils can wear out due to heat, vibration, or physical damage. A damaged coil can prevent your engine from getting the spark it needs to run.

Learning to check your chainsaw coil is an essential skill. It can save you time and money by helping you pinpoint the exact problem. Instead of immediately taking it to a repair shop, you can often perform this basic diagnosis yourself. This empowers you to understand your tools better and keep them running smoothly for years to come.

Tools You’ll Need for the Job

Before you begin, gather these essential tools. Having everything ready will make the process smoother and safer.

- Screwdriver Set: You’ll likely need Phillips head and flathead screwdrivers to remove various covers and parts.

- Socket Wrench Set: For removing flywheel nuts or other bolts.

- Pliers: Useful for disconnecting wires and small parts.

- Spark Plug Wrench: Specifically designed to remove and install spark plugs.

- Feeler Gauge: A thin metal strip used to measure the gap between the coil and the flywheel. This is crucial for the air gap test.

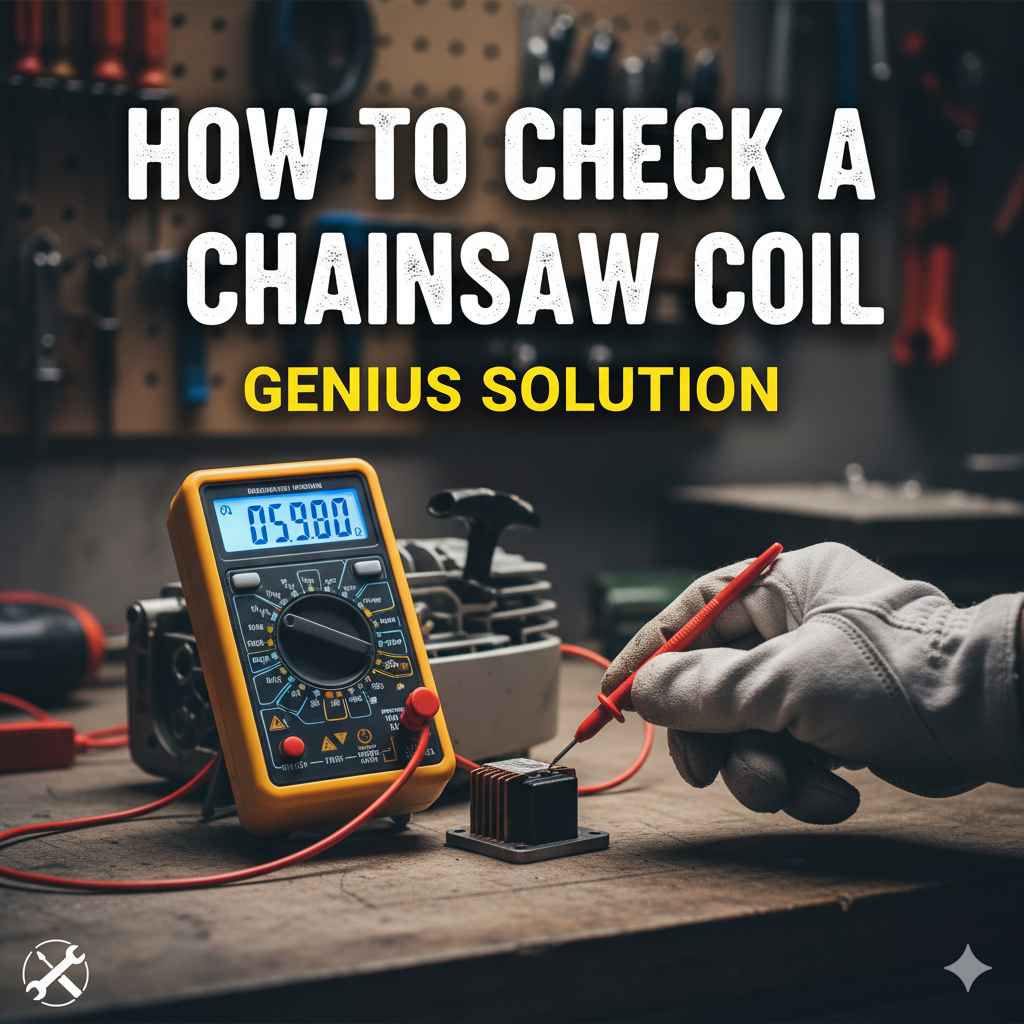

- Multimeter: An electronic measuring instrument that combines several measurement functions in one unit. You’ll need this to test the coil’s electrical resistance. You can find basic ones for a reasonable price at most hardware stores.

- Cleaning Rags: To wipe away dirt and debris.

- Safety Glasses: Always protect your eyes when working on machinery.

- Work Gloves: To protect your hands.

Safety First: Precautions Before You Start

Chainsaws are powerful and potentially dangerous tools. Safety should always be your top priority. Before you even think about touching the ignition coil, follow these critical safety steps:

- Disconnect the Spark Plug: This is the MOST important step. Always disconnect the spark plug wire from the spark plug before performing any maintenance or inspection. This prevents the engine from accidentally starting while you’re working on it.

- Ensure the Chainsaw is Cool: Let the engine cool down completely if it has been running recently. Hot engine parts can cause burns.

- Work in a Well-Lit Area: Good lighting helps you see small parts and potential issues clearly.

- Work on a Stable Surface: Place the chainsaw on a flat, stable workbench or surface.

- Read Your Owner’s Manual: Your specific chainsaw model might have unique instructions or components. Refer to your owner’s manual for model-specific information.

Step-by-Step Guide: How to Check a Chainsaw Coil

Now that you’re prepared and have safety in mind, let’s walk through checking your chainsaw’s ignition coil. This process is generally the same across most chainsaw brands, especially for gas-powered models.

Step 1: Access the Ignition Coil

The ignition coil is usually located beneath the starter assembly and the engine cylinder, near the flywheel. You’ll need to remove a few covers to get to it.

- Remove the Top Cover/Starter Housing: Most chainsaws have a top cover that is secured with screws or clips. Remove these to expose the engine and the starter mechanism.

- Remove the Flywheel Shroud: The shroud is a plastic or metal cover that protects the flywheel and often directs cooling air. It’s usually held on by a few screws. Carefully remove these screws and set them aside.

- Inspect the Area: Once the shroud is off, you should be able to see the flywheel (the rotating metal disc with fins) and the ignition coil mounted nearby, typically on the engine crankcase. The coil usually has a wire leading from it towards the spark plug.

Step 2: Visual Inspection of the Coil

With the coil exposed, look for obvious signs of damage.

- Check for Physical Damage: Look for cracks, burn marks, or melted plastic on the coil’s housing. If you see any, the coil is likely bad and needs replacement.

- Inspect the Wire: Examine the thick wire that runs from the coil to the spark plug. Ensure it’s not frayed, cracked, or disconnected. Check the boot that connects to the spark plug.

- Look for Debris: Sometimes, dirt, sawdust, or oil build-up can hinder the coil’s performance. Gently clean around the coil if it’s dirty, but be careful not to damage it.

Step 3: Test the Coil-to-Flywheel Gap (Air Gap)

The ignition coil needs a specific gap between itself and the flywheel magnets to function correctly. Too close, and it can get damaged; too far, and it won’t generate a strong enough spark. The recommended gap is usually very small, typically between 0.010 and 0.020 inches (0.25 mm to 0.50 mm). Always consult your owner’s manual for the exact specification for your model.

- Position the Flywheel: Rotate the engine until the flywheel is in a position where the coil is about to pass over a magnet but hasn’t yet. You can often feel or see the magnets on the flywheel.

- Use the Feeler Gauge: Insert the correct size feeler gauge blade between the coil and the flywheel magnet.

- Check the Fit: The gauge should slide in with a slight drag. If it’s too tight and won’t fit, or if it slides in too loosely with no resistance, the gap is incorrect.

- Adjustment (If Necessary): Some coils are adjustable by loosening mounting screws and repositioning the coil. If your coil is not adjustable, or if loosening/tightening screws doesn’t correct the gap, it might indicate a warped mounting surface or a damaged flywheel, or simply that the coil needs replacement.

Step 4: Test Coil Resistance with a Multimeter

This is where the multimeter comes in handy. It measures electrical resistance, which can tell you if the coil’s internal windings are intact. You’ll be testing two main resistances: primary and secondary.

Before you begin this test, ensure you have your chainsaw’s service manual or look up the specific resistance values for your model online. These values can vary significantly between different chainsaws.

- Set Up the Multimeter: Turn your multimeter to the Ohms (Ω) setting for resistance testing. Start with a higher range, like 20kΩ or 200kΩ, depending on your meter and expected values.

- Locate the Primary Coil Wires: The primary winding is usually accessed via small terminals on the coil itself or through the spark plug wire connection. For simplicity, many beginners test the connection between the spark plug wire lead (where it would connect to the plug) and a ground point on the engine or the primary terminals if accessible.

- Test Primary Resistance:

- Place one multimeter probe on the metal terminal inside the spark plug wire boot (or the spark plug wire itself if you can access it).

- Place the other probe on a clean, unpainted metal part of the engine block (a good ground).

- Read the resistance. Compare it to the manufacturer’s specified value. A reading of OL (Open Line, Infinite resistance) or a very low reading (close to 0Ω) often indicates a bad coil.

- Locate the Secondary Coil Wires (less common for DIYers): Some very advanced tests might involve accessing the secondary side directly if there are specific terminals for it, but often the spark plug wire is the primary way to test the secondary circuit.

- Test Secondary Resistance (Simplified – often inferred from plug wire test): The spark plug wire itself has resistance. If you have a separate coil and wire setup, you would test the coil’s internal secondary winding and the wire’s resistance separately. If your coil has an integrated wire, the previous test covers it. For integrated coils and wires, if the plug wire continuity is good (e.g., under 5kΩ, check manual), then the primary resistance test is the main indicator.

- Check for Shorts: Another crucial test is checking for shorts to ground.

- Place one probe on the spark plug wire terminal.

- Place the other probe on the engine block (ground).

- You should not get a reading close to 0Ω. If you do, the coil is shorted and is definitely bad.

Interpreting Multimeter Readings

Here’s a quick guide to what your multimeter readings might mean:

| Test | Expected Reading | Indicates a Bad Coil If… |

|---|---|---|

| Primary Resistance (Plug wire/terminal to ground) | Specific Ohm value (e.g., 1kΩ – 5kΩ, check manual!) | Reading is OL (Open Line/Infinite Resistance) or near 0Ω. |

| Short to Ground (Plug wire/terminal to ground) | Infinite Resistance (OL) | Reading is low (close to 0Ω) or shows continuity. |

Testing the coil can be tricky, as specifications vary. If you are unsure, testing for obvious physical damage and ensuring the air gap is correct are good starting points. If the coil looks fine and the gap is correct, but your chainsaw still won’t spark, it’s still a strong suspect.

Step 5: Check the Spark Plug and Wire

While you’re in there, it’s a good idea to check the spark plug and its wire. A faulty spark plug or a bad connection can mimic coil problems.

- Remove the Spark Plug: Use your spark plug wrench to remove the spark plug.

- Inspect the Spark Plug: Look at the electrode. Is it worn out, fouled with oil or carbon, or the gap incorrect? If so, replace it. A new spark plug is inexpensive and often solves starting issues.

- Check the Spark Plug Wire: Ensure the wire is securely attached to the spark plug and the coil. Wiggle it to make sure the connection is firm. If the wire looks damaged, it may need replacing.

Step 6: Bench Testing for Spark (Use Extreme Caution!)

This is a more direct way to see if your coil is producing a spark. It requires caution because you are dealing with high voltage.

- Reconnect the Spark Plug: Reconnect the spark plug wire to the spark plug.

- Ensure Proper Placement: Hold the spark plug against a good metal ground on the engine block with insulated pliers (do NOT hold the plug itself).

- Ensure Coil-to-Flywheel Gap is Correct: Make sure the coil has the proper air gap to the flywheel. If it’s too close, it could get damaged.

- Engage the Ignition: Have someone give the starter cord a sharp, quick pull while you hold the spark plug firmly against the engine block with the pliers.

- Observe for Spark: Look for a strong, blue spark jumping across the spark plug’s electrodes in the gap you created.

What to look for:

- Good Spark: A strong, consistent, blue spark indicates the coil is likely working. If you get a good spark but the engine still won’t start, the problem lies elsewhere (fuel, air, compression).

- Weak or Intermittent Spark: A pale yellow or weak spark, or one that appears only sometimes, suggests the coil is failing.

- No Spark: If there is absolutely no spark, and you’ve confirmed the spark plug is good and properly connected, your ignition coil is very likely the problem. You can learn more about general engine troubleshooting on resources like the University of Illinois Extension’s agricultural safety section, which often covers small engine maintenance.

Important Note: Only test for spark briefly. Holding the ignition energized for too long with no combustion can potentially damage the coil or other components.

When to Replace the Coil

You should consider replacing your chainsaw’s ignition coil if:

- There are visible signs of damage like cracks or burn marks on the coil body.

- The spark plug wire is frayed, broken, or has a damaged boot.

- The coil-to-flywheel gap cannot be set correctly because the coil is warped or damaged.

- Your multimeter tests show readings far outside the manufacturer’s specifications for resistance (e.g., open circuit, short circuit).

- You have performed a bench spark test and there is no spark, or only a very weak spark, and you’ve confirmed your spark plug is good and the air gap is correct.

Replacing an ignition coil is often a straightforward repair. You’ll typically need to remove the old coil (usually held by screws) and install the new one, ensuring the air gap is properly set. Always use a high-quality replacement part designed for your specific chainsaw model.

Common Chainsaw Coil Issues and Troubleshooting

Even when performing these tests, some common issues can arise:

Issue 1: No Spark at All

- Possible Causes: Completely failed coil, broken spark plug wire, faulty spark plug, loose connections.

- Troubleshooting Steps: Visually inspect all components. Test coil resistance (should have specific ohms, not OL or zero). Test for shorts. Try a new spark plug. Ensure all connections are secure.

Issue 2: Weak or Intermittent Spark

- Possible Causes: Coil winding damage, incorrect coil-to-flywheel gap, dirty flywheel magnets or coil surface, failing coil.

- Troubleshooting Steps: Adjust the air gap. Clean the flywheel and coil. Re-test coil resistance – it might be on the edge of failure.

Issue 3: Engine Starts But Runs Poorly or Dies Quickly

- Possible Causes: This can sometimes be related to the ignition system, but is more often fuel or air related. However, a coil that is failing might provide enough spark to start but not enough to sustain running under load.

- Troubleshooting Steps: Double-check fuel lines, carburetor, and air filter. If those are fine, re-evaluate the coil using the multimeter and spark test.

Issue 4: Coil Appears Damaged but is Getting Spark

- Possible Causes: Physical damage may not always affect spark immediately. However, continued use can lead to complete failure or shorting.

- Troubleshooting Steps: Even if it’s still sparking, replace a visibly damaged coil to prevent future failure and potential damage to the flywheel. Safety and reliability are key.

Where to find coil specifications: Look for your chainsaw’s make and model number. Many manufacturers offer online service manuals or parts diagrams. Reputable online parts suppliers often list the correct specifications and replacement parts. For example, sites like Oregonmowerparts.com (which handles many small engine parts, including chainsaw components) can be a good resource for identifying parts and sometimes specifications.

Frequently Asked Questions (FAQ)

Q1: How do I know if my chainsaw ignition coil is bad?

A1: You can suspect a bad coil if your chainsaw has no spark, a weak spark, or visible damage on the coil itself. Testing its resistance with a multimeter and performing a bench spark test are key diagnostic steps.