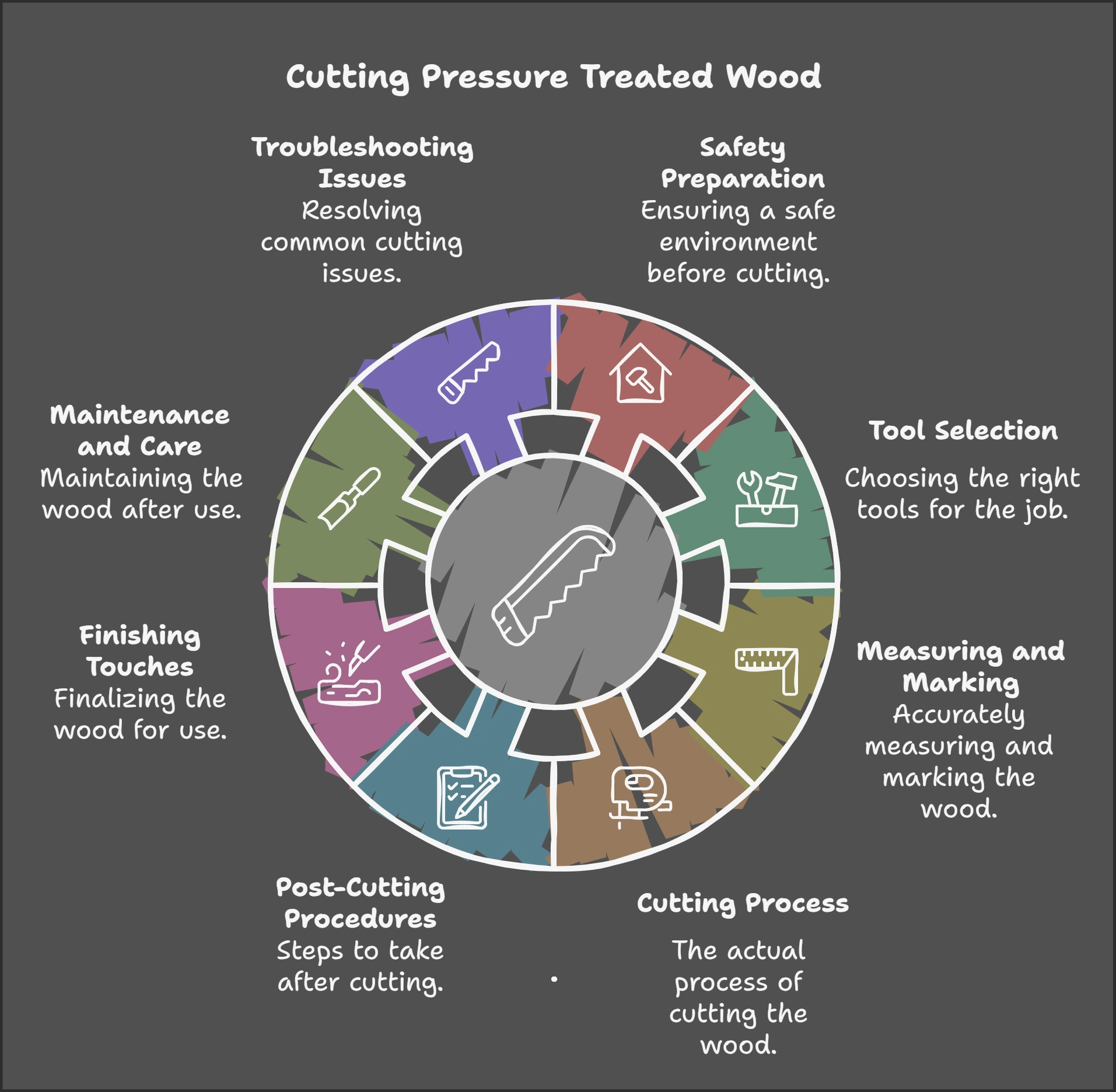

How to Cut Pressure Treated Wood: Quick & Safe Guide

To cut pressure-treated wood, use a carbide-tipped saw blade for clean cuts. Always wear safety gear, including goggles and a mask.

Cutting pressure-treated wood requires specific techniques and tools to ensure safety and precision. This type of wood is infused with chemicals to resist rot and pests, making it different from untreated lumber. Proper cutting methods help maintain the integrity of the wood and prevent hazardous dust.

It’s essential to use a sharp blade to achieve clean cuts without splintering. Safety gear is crucial to protect against dust and debris. Understanding how to handle this material correctly ensures a successful project, whether building a deck, fence, or outdoor furniture. Mastering these skills will enhance your woodworking capabilities and ensure durability in your creations.

Introduction To Pressure Treated Wood

Pressure treated wood is a popular choice for many projects. It resists decay and insects, making it durable. This wood is ideal for outdoor use, including decks and fences.

The benefits of using pressure treated wood include:

- Longevity: It lasts longer than untreated wood.

- Cost-effective: It saves money in the long run.

- Versatility: It can be used in many different projects.

Common uses in construction and DIY projects:

| Application | Description |

|---|---|

| Decking | Perfect for building outdoor decks. |

| Fencing | Great for durable fence posts. |

| Garden Beds | Ideal for raised garden beds. |

Safety First: Preparing To Cut

Cutting pressure treated wood can be risky. Chemical preservatives used in this wood can be harmful. Always wear safety goggles to protect your eyes. Gloves are essential to keep your hands safe. A dust mask helps you avoid breathing in harmful particles.

Use ear protection if your tools are loud. Make sure your work area is clear of hazards. Keep children and pets away while cutting. Check your tools for safety before starting.

Follow all safety guidelines to prevent accidents. Be aware of the risks involved with pressure treated wood. Proper preparation ensures a safer cutting experience.

Selecting The Right Tools

Choosing the right saw is very important for cutting pressure treated wood. A circular saw is great for straight cuts. It is easy to use and portable. A miter saw offers precise angles. This is helpful for making complex cuts. Pick the saw that fits your project needs.

Sharp blades are essential for clean cuts. Dull blades can splinter the wood. Always check the blade sharpness before starting. A sharp blade makes cutting easier and safer. It also saves time and effort.

| Tool | Advantages |

|---|---|

| Circular Saw | Portable and good for straight cuts |

| Miter Saw | Great for precise angle cuts |

Measuring And Marking

Measuring pressure treated wood correctly is very important. Use a measuring tape for accurate length. Mark the wood with a pencil for clear visibility. This helps in making precise cuts.

For marking techniques, consider using a square. This tool ensures your lines are perfectly straight. You can also use a chalk line for longer pieces. Simply snap the line to create a straight guide.

Always double-check your measurements before cutting. Even small mistakes can lead to bigger problems. Ensure your marks are clear and easy to follow.

The Cutting Process

Cutting pressure treated wood can be simple and effective. Follow this step-by-step guide for best results.

- Gather your tools: You need a saw, measuring tape, and safety gear.

- Measure twice: Ensure accurate measurements to avoid mistakes.

- Mark your cut: Use a pencil to draw a clear line on the wood.

- Use a straight edge: This helps keep your cut line straight.

- Cut slowly: Take your time for a clean and precise cut.

To achieve straight and clean cuts, remember these tips:

- Always use a sharp blade.

- Support the wood securely while cutting.

- Cut with the grain for smoother edges.

Post-cutting Procedures

Sanding the edges of pressure treated wood is important for safety. Use a fine-grit sandpaper to smooth rough spots. This helps prevent splinters and makes the wood safer to handle. Sanding also improves the wood’s appearance.

For best results, sand in the direction of the grain. This method avoids scratches and ensures a smooth finish. Always wear a mask and goggles to protect yourself from dust.

Disposal of treated wood offcuts requires careful handling. Treated wood contains chemicals that can be harmful. Always check local regulations for proper disposal methods.

Some areas allow treated wood to be placed in regular trash. Others may require special disposal facilities. Never burn treated wood, as it releases toxic fumes.

Finishing Touches

After cutting pressure treated wood, it’s important to seal the cut ends. This helps protect the wood from moisture and decay. Use a high-quality sealant designed for treated wood. Apply it generously to all cut surfaces.

For staining or painting, ensure the wood is dry. Wait at least a few days after cutting. Choose a stain or paint that is compatible with pressure treated wood. Always follow the manufacturer’s instructions for the best results.

Regular maintenance helps extend the life of your wood. Reapply sealant and stain as needed. This keeps your projects looking great and performing well.

Maintenance And Care

Regular inspection is key to maintaining pressure treated wood. Check for signs of damage, such as cracks or warping. Look for insects or mold that might affect the wood. Clean the wood surface to prevent buildup of dirt and grime.

Replacing damaged or worn pieces ensures the wood remains strong. Identify sections that need replacement. Use the same type of pressure treated wood for best results. Secure the new pieces tightly to avoid gaps. Regular upkeep helps extend the life of your wood.

Troubleshooting Common Issues

Splitting wood can be a common problem. This often happens due to improper cutting techniques. Always use a sharp blade to minimize splitting. Cut slowly and follow the wood grain for best results.

For measurement mistakes, double-check all dimensions before cutting. Use a tape measure and mark the wood clearly. If a cut is too short, try using wood glue and clamps for a quick fix. For larger mistakes, consider replacing the piece.

| Issue | Solution |

|---|---|

| Splitting | Use a sharp blade; cut along the grain. |

| Measurement Mistake | Double-check measurements; use wood glue for small errors. |

Frequently Asked Questions

How Do You Safely Cut Pressure Treated Wood?

To safely cut pressure treated wood, wear protective gear like gloves and goggles. Use a sharp saw to ensure clean cuts. Make sure to work in a well-ventilated area. After cutting, clean the saw and dispose of sawdust properly, as it may contain chemicals.

What Tools Are Best For Cutting Pressure Treated Wood?

The best tools for cutting pressure treated wood include a circular saw, miter saw, or jigsaw. These tools provide precision and efficiency. Ensure your blades are designed for wood cutting. A fine-tooth blade reduces splintering and gives a cleaner finish.

Can You Use A Regular Saw For Pressure Treated Wood?

Yes, you can use a regular saw for pressure treated wood. However, it’s essential to choose the right blade. A carbide-tipped blade is recommended for durability. Regular blades may wear out quickly due to the wood’s density and chemical treatment.

Is It Safe To Burn Pressure Treated Wood?

No, burning pressure treated wood is not safe. It releases harmful chemicals into the air, posing health risks. Always dispose of treated wood according to local regulations. Consider recycling or using it for non-combustible projects to minimize environmental impact.

Conclusion

Cutting pressure treated wood requires the right tools and techniques. Safety should always be your top priority. By following the steps outlined in this guide, you can achieve precise cuts and maintain the integrity of the wood. Proper preparation and care will ensure your projects are successful and long-lasting.

Happy building!