How to Use Polyurethane Sealant: Expert Tips & Tricks

To use polyurethane sealant, first insert the tube into a caulk gun and cut the end before puncturing the foil seal. Then, apply the sealant in an even bead along the seam or crack and smooth it with a damp rag or sealant tool.

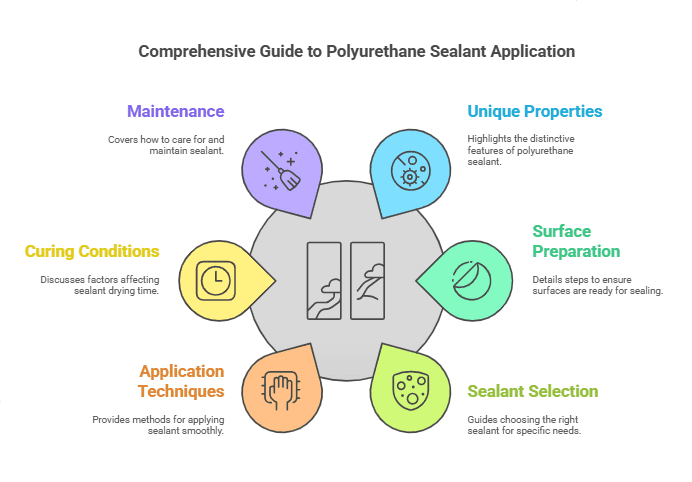

Polyurethane sealant is commonly used for sealing, filling gaps, and keeping water and air away from joints. It is also known for absorbing the natural movements of building materials. The sealant sets exceptionally fast and hard, making it suitable for outdoor use in industries such as road and bridge building.

Understanding how to properly apply polyurethane sealant is essential for achieving effective and long-lasting sealing results. We will discuss the step-by-step process for using polyurethane sealant and explore its various applications and advantages.

Introduction To Polyurethane Sealant

Polyurethane sealant is a versatile and popular material used for sealing and bonding a wide range of surfaces in various industries. It is known for its exceptional durability, flexibility, and adhesive properties, making it a go-to solution for many sealing applications. Whether you are a professional contractor or a DIY enthusiast, understanding how to use polyurethane sealant effectively can significantly enhance the quality and longevity of your projects.

What Makes Polyurethane Sealant Unique

Polyurethane sealant stands out due to its exceptional flexibility, adhesion, and durability. Unlike other sealants, it can withstand a wide range of temperatures, making it suitable for both indoor and outdoor applications. Additionally, its ability to bond to a variety of materials, including concrete, wood, metal, and plastics, makes it a versatile option for different projects.

Common Uses In Various Industries

From construction and automotive to marine and manufacturing industries, polyurethane sealant finds extensive use in diverse applications. It is commonly used for sealing joints, seams, and gaps in buildings, installing windows and doors, bonding automotive components, and sealing joints in marine vessels. Its resistance to weathering and chemicals makes it an ideal choice for outdoor and industrial environments.

Before You Begin: Preparing The Surface

Preparing the surface is crucial before using polyurethane sealant. Make sure the surface is clean, dry, and free of debris. Use a solvent or sandpaper to remove any old sealant or paint and ensure the surface is smooth.

When it comes to using polyurethane sealant, preparation is key. In order to achieve a strong bond and a long-lasting seal, the surface must be properly cleaned and dried before application. In this section, we will cover the necessary steps to prepare the surface before using polyurethane sealant.

Cleaning the Area

The first step in preparing the surface is to clean the area where the sealant will be applied. This can be done using a mild detergent and water solution or a specialized cleaner designed for the specific surface. Be sure to remove any dirt, dust, grease, or other debris that may be present. A clean surface will ensure proper adhesion and a strong bond.

Surface Drying Considerations

Once the surface is clean, it is important to ensure that it is completely dry before applying the sealant. Moisture can interfere with the bonding process and weaken the seal. The drying time will depend on the type of surface and the environmental conditions. In general, it is best to wait at least 24 hours after cleaning before applying the sealant.

If the surface is particularly damp or humid, additional steps may be necessary to ensure it is completely dry. This can include using a fan or dehumidifier to dry the area, or applying a drying agent to the surface.

In Conclusion

Properly preparing the surface is essential for achieving a strong and long-lasting seal with polyurethane sealant. By following these steps and ensuring the surface is clean and dry, you can ensure a successful application and a durable seal that will protect your project for years to come.

Choosing The Right Polyurethane Sealant

To use polyurethane sealant effectively, start by inserting the tube into the caulk gun and cutting the end. Then, apply the sealant in an even bead along the seam or crack, and use a damp rag or sealant tool to smooth the bead and seal the seam.

It’s essential to clean up immediately with a damp rag for a professional finish.

Types Of Polyurethane Sealants

When it comes to choosing the right polyurethane sealant, it’s important to understand the different types available. Polyurethane sealants are typically classified based on their curing mechanism, which determines their specific properties and applications. Here are the most common types of polyurethane sealants:

- One-component Polyurethane Sealants: These sealants come ready to use and cure when exposed to moisture in the air. They are easy to apply and suitable for a wide range of indoor and outdoor applications.

- Two-component Polyurethane Sealants: These sealants require mixing two components, a base and a curing agent, before application. They offer excellent bonding strength and are often used in high-stress environments or for specialized applications.

- Self-leveling Polyurethane Sealants: These sealants are designed to flow and level on their own, making them ideal for horizontal surfaces such as floors and driveways. They provide a smooth and even finish.

- High-temperature Polyurethane Sealants: These sealants are specifically formulated to withstand high temperatures, making them suitable for applications such as sealing joints in ovens, furnaces, or automotive engines.

Selecting For Indoor Vs Outdoor Use

When selecting a polyurethane sealant, it’s important to consider whether it will be used indoors or outdoors. The environmental conditions and specific requirements of the application will determine the type of sealant that is most suitable. Here are some key factors to consider:

- Weather Resistance: Outdoor sealants need to withstand exposure to UV rays, moisture, and temperature fluctuations. Look for sealants that offer excellent weather resistance to ensure long-lasting performance.

- Elasticity: Outdoor sealants should have good flexibility to accommodate movement caused by temperature changes or settling of the building. This helps prevent cracks and leaks over time.

- Chemical Resistance: If the sealant will be exposed to chemicals or solvents, choose a polyurethane sealant that offers high chemical resistance. This will ensure that it remains durable and unaffected by the surrounding substances.

- Indoor Air Quality: For indoor applications, it’s important to select a sealant that meets low volatile organic compound (VOC) requirements. This ensures that the sealant does not release harmful fumes into the indoor environment.

By considering these factors and selecting the appropriate type of polyurethane sealant for your specific needs, you can ensure a successful and long-lasting sealing solution. Whether it’s for indoor or outdoor use, the right polyurethane sealant will provide excellent adhesion, durability, and protection against moisture, weather, and other environmental factors.

Application Tools And Techniques

Learn the techniques for using polyurethane sealant effectively. From removing old sealant to applying a smooth and even bead along seams or cracks, this guide will help you achieve professional results. Say goodbye to leaks and protect your surfaces with polyurethane sealant.

Tools Required For Application

To effectively apply polyurethane sealant, you will need a few essential tools. Here are the tools you should have on hand before you begin the application process:

1. Caulk gun: A caulk gun is essential for dispensing the polyurethane sealant smoothly and evenly. Insert the tube into the caulk gun and cut the end of the tube, puncturing the foil seal.

2. Bristle brush: A tapered, bristle brush is ideal for applying the sealant to flat surfaces like tables or chairs. It allows you to follow the grain of the wood and create a thin, even coat.

3. Sealant tool: A sealant tool or a damp rag can be used to smooth the bead of sealant and seal the seam. It helps create a neat and professional finish.

Techniques For Smooth Application

Now that you have the necessary tools, let’s discuss some techniques to ensure a smooth and successful application of polyurethane sealant:

1. Prepare the surface: Before applying the sealant, make sure the surface is clean, dry, and free of any dust or debris. This will ensure proper adhesion and a long-lasting seal.

2. Apply in an even bead: Squeeze the caulk gun gently and apply the sealant in an even bead along the seam or crack that you want to seal. Take your time and maintain a steady hand to achieve a consistent application.

3. Smooth the bead: Immediately after applying the sealant, use a sealant tool or a damp rag to smooth the bead. This will help create a seamless and professional-looking finish.

4. Clean up: It’s important to clean up any excess sealant or smudges right away. Use a damp rag to wipe away any unwanted sealant before it dries.

Remember, practice makes perfect. If you are new to using polyurethane sealant, it may take a few tries to master the technique. Take your time, be patient, and follow these tips for a smooth and successful application.

By using the right tools and techniques, you can ensure that your polyurethane sealant application is not only effective but also aesthetically pleasing.

Applying Polyurethane Sealant Like A Pro

Mastering the art of applying polyurethane sealant requires precision and technique. Start by inserting the tube into the caulk gun, cutting the end, and puncturing the foil seal. Then, apply the sealant evenly along the seam or crack, and use a damp rag or sealant tool to smooth the bead and seal the seam for a professional finish.

Step-by-step Application Process

Applying polyurethane sealant can be a daunting task, but with the right technique, you can achieve a professional-looking finish. Here’s a step-by-step guide on how to apply polyurethane sealant like a pro:

- Insert the tube of polyurethane sealant into the caulk gun and cut the end of the tube at a 45-degree angle.

- Puncture the foil seal at the base of the nozzle using a long nail or wire.

- Apply the sealant in a continuous, even bead along the seam or crack. Use a steady and gentle pressure on the caulk gun trigger to control the flow of the sealant.

- Smooth the bead of sealant immediately using a damp rag or sealant tool. This will ensure an even and professional finish.

- Clean up excess sealant with a damp rag or paper towel. Make sure to do this before the sealant dries.

- Allow the sealant to dry and cure completely according to the manufacturer’s instructions before painting or exposing it to water.

Ensuring An Even Bead

One of the most challenging aspects of applying polyurethane sealant is ensuring an even bead. To achieve this, it is essential to hold the caulk gun at a consistent angle and maintain a steady pressure on the trigger. You can also use a sealant tool or a damp rag to smooth out any uneven areas and create a clean, professional-looking finish.

By following these simple steps and tips, you can apply polyurethane sealant like a pro. Remember to use a caulk gun, cut the nozzle at a 45-degree angle, puncture the foil seal, apply an even bead, smooth out any uneven areas, and clean up excess sealant before it dries. With practice, you’ll be able to achieve a professional-looking finish every time.

Expert Tips For Perfect Sealing

Discover expert tips for perfect sealing with polyurethane sealant. Start by thoroughly cleaning and drying the surface, then apply the sealant in an even bead along the seam or crack. Use a sealant tool to smooth the bead and clean up any excess immediately for a flawless finish.

Avoiding Common Mistakes

When using polyurethane sealant, ensure proper surface preparation to avoid adhesion issues. Clean and dry the surface thoroughly before application.

Achieving A Professional Finish

Apply the sealant in a steady, even bead for a neat and uniform look. Smooth the sealant with a damp rag or tool for a flawless finish.

Curing Time And Conditions

When using polyurethane sealant, understanding the curing time and conditions is crucial for a successful application.

Average Drying Times

- Polyurethane sealant typically dries to the touch within 30 minutes to 1 hour.

- Full curing can take 24 to 48 hours, depending on temperature and humidity.

Factors Affecting Curing

Several factors can impact the curing process of polyurethane sealant:

- Temperature: Higher temperatures accelerate curing, while lower temperatures slow it down.

- Humidity: Low humidity levels can prolong curing time.

- Thickness of Application: Thicker layers may require more time to cure completely.

- Ventilation: Adequate ventilation helps in expediting the curing process.

Maintenance And Care

To effectively use polyurethane sealant, ensure the surface is clean and dry before applying a smooth, even bead along the seam or crack. Use a damp rag or sealant tool to smooth the bead and seal the seam, and clean up any excess immediately for a professional finish.

Cleaning Cured Sealant

To clean cured sealant, use a utility knife to carefully cut away any excess sealant. Next, scrub the area with a mixture of soap and water to remove residue.

Repairing Damaged Sealant

To repair damaged sealant, soften the sealant using a heat gun or a specialized sealant softener. Then, remove the softened sealant with a putty knife before applying a fresh layer.

Safety Measures And Best Practices

To ensure safe and effective use of polyurethane sealant, it’s important to follow best practices. Before application, clean the surface thoroughly and ensure it’s dry. Use a caulking gun to apply the sealant in a steady bead, and smooth it with a damp rag or sealant tool.

Clean up any excess immediately to achieve a professional finish.

Health And Safety Tips

When using polyurethane sealant, remember to wear protective gear such as gloves and goggles to prevent skin irritation or eye contact.

Ensure proper ventilation in the work area to avoid inhaling harmful fumes that polyurethane sealants can emit.

Keep children and pets away from the work area to prevent accidental exposure to the sealant.

Environmental Considerations

Dispose of unused polyurethane sealant properly to prevent environmental contamination. Check local regulations for guidance.

Avoid releasing excess sealant into drains or water bodies to protect aquatic life and maintain environmental health.

Troubleshooting Common Issues

Learn how to effectively use polyurethane sealant with these troubleshooting tips. From removing fittings to sealing decks and installing through-hulls, this guide provides step-by-step instructions for a successful application. Discover the best techniques and avoid common issues to achieve a professional finish.

Polyurethane sealant is a versatile material that can be used for a variety of applications. However, even the most experienced DIYer can encounter issues when using it. Here are some common problems and their solutions.

Dealing with Leaks and Drips

Leaking and dripping can occur when the sealant is not applied properly. To prevent this, make sure to apply the sealant evenly and use a sealant tool to smooth the bead. If a leak or drip occurs, wipe it off with a damp rag and reapply the sealant in a thin, even layer.

Removing and Reapplying Sealant

Removing old sealant can be a daunting task, but it’s important to do it properly to ensure a strong bond with the new sealant. Use a sealant remover and follow the manufacturer’s instructions carefully. Once the old sealant is removed, clean the area thoroughly before applying the new sealant.

When reapplying sealant, make sure to use the right type for the job. Choose a sealant that is suitable for the material you are working with, such as wood, metal, or concrete. Apply the sealant in a thin, even layer and use a sealant tool to smooth the bead.

By following these tips, you can troubleshoot common issues when using polyurethane sealant and achieve a professional-looking finish.

Advanced Techniques For Professionals

When it comes to using polyurethane sealant, professionals often require advanced techniques to ensure optimal results. From construction projects to specialized applications, understanding how to use polyurethane sealant effectively can make a significant difference in the durability and longevity of the seal. In this article, we will explore advanced techniques for professionals, focusing on using sealant in construction and specialized applications.

Using Sealant In Construction

Sealants play a crucial role in construction projects, providing protection against moisture, air leakage, and other potential damages. Here are some advanced techniques for professionals when using sealant in construction:

- Prepare the surface: Before applying the sealant, it is essential to clean and prepare the surface properly. Remove any dirt, debris, or loose materials that can affect the adhesion of the sealant.

- Choose the right sealant: Selecting the appropriate type of polyurethane sealant is crucial for the specific construction application. Consider factors such as weather resistance, flexibility, and curing time.

- Apply the sealant evenly: Use a caulking gun to apply a consistent and even bead of sealant along the joints or gaps. Ensure that the sealant fully fills the void to create a watertight and airtight seal.

- Tool the sealant: After applying the sealant, use a sealant tool or a damp rag to smooth out the bead and remove any excess sealant. This technique helps to achieve a neat and professional finish.

- Allow proper curing time: Follow the manufacturer’s instructions regarding the curing time of the sealant. It is crucial to allow sufficient time for the sealant to fully cure before subjecting it to any stress or movement.

Specialized Applications

Polyurethane sealants also find applications in specialized areas where specific properties are required. Here are some advanced techniques for professionals when using polyurethane sealant in specialized applications:

- Submerged applications: In applications where the sealant will be submerged in water, it is essential to choose a polyurethane sealant specifically designed for underwater use. Ensure proper surface preparation and follow the manufacturer’s guidelines for installation.

- High-temperature applications: When sealing joints or gaps exposed to high temperatures, select a polyurethane sealant with excellent heat resistance. Ensure that the sealant can withstand the specific temperature range of the application.

- Expansion joints: For sealing expansion joints in buildings or structures, professionals should consider using a polyurethane sealant with high flexibility and movement capability. This allows for expansion and contraction without compromising the integrity of the seal.

- Industrial applications: In industrial settings, polyurethane sealants are often used for sealing joints and gaps in equipment, machinery, or pipelines. Professionals should select sealants with excellent chemical resistance and durability to withstand harsh industrial environments.

By applying these advanced techniques, professionals can ensure the effective use of polyurethane sealant in construction and specialized applications. Remember to follow proper surface preparation, choose the right sealant, apply it evenly, and allow sufficient curing time for optimal results.

Conclusion: Ensuring Longevity And Durability

To ensure longevity and durability when using polyurethane sealant, it’s crucial to apply a generous and even bead along the seam or crack, then smooth it with a damp rag or sealant tool. Clean up any excess immediately for a professional finish that will stand the test of time.

Final Thoughts

In conclusion, using polyurethane sealant is a great way to ensure longevity and durability in various applications. Whether you are sealing decks, installing through-hulls, or making seams that won’t leak, polyurethane sealant provides a reliable solution. By following the proper application techniques and considering the specific requirements of your project, you can achieve excellent results.

Further Resources

For more information on using polyurethane sealant effectively, here are some helpful resources:

- How to Apply Polyurethane to Wood – The Home Depot

- Comparison between Silicone and Polyurethane – Homeycons

- Why Use a Polyurethane Sealant over Silicone Sealant? – Ultrimax Coatings

- How Long Does Polyurethane Take to Dry? – Artisan Wood Floors LLC

- Applying Polyurethane Sealants Like a Pro – Loctite

These resources offer valuable insights, tips, and techniques to help you make the most out of your polyurethane sealant applications.

Frequently Asked Questions

What Is The Best Way To Apply Polyurethane?

To apply polyurethane, use a tapered, bristle brush for flat surfaces like tables or chairs. For rounded or vertical surfaces, use a thin coat following the grain to avoid drips. Apply additional coats as needed, allowing each coat to dry completely before adding another.

Clean up with a damp rag.

What Are The Disadvantages Of Polyurethane Sealant?

Polyurethane sealant has a few disadvantages. It can be more expensive compared to other sealants. It also has a strong odor during application, which may be unpleasant for some. Additionally, polyurethane sealant may not adhere well to certain surfaces and can be difficult to remove once cured.

Does Polyurethane Sealant Dry Hard?

Yes, polyurethane sealant dries hard. It sets quickly and forms a durable and strong surface. This makes it ideal for outdoor applications such as road and bridge building.

How Long Does Polyurethane Sealant Take To Cure?

Polyurethane sealant typically takes 24 to 48 hours to cure completely. However, the curing time may vary based on factors such as humidity, temperature, and the thickness of the sealant layer. It is important to avoid touching or disturbing the sealant during the curing process to ensure a proper bond.

Conclusion

Using polyurethane sealant requires careful application techniques for optimal results. The choice of sealant type and proper surface preparation are crucial. Understanding the curing time and the environmental conditions that affect it is essential. With the right knowledge and application, polyurethane sealant can provide durable and long-lasting protection.