Is MDF Particle Board: Choosing the Right Material

MDF particle board and particle board are not the same. MDF, or Medium Density Fiberboard, is stronger and denser than particle board.

It is made of wood fibers instead of sawdust and is typically used for projects that require higher quality. On the other hand, particle board is a type of particleboard that is less dense and not as strong as MDF.

It is made of wood chips and can be a more cost-effective option for certain applications. However, particle board is more susceptible to moisture damage and has a shorter lifespan compared to MDF.

Introduction To Wood Composites

Wood composites are engineered wood products that are made by binding wood fibers, particles, or veneers together with adhesives. These materials are becoming increasingly popular because they offer a range of advantages over traditional solid wood, including cost-effectiveness, durability, and versatility. There are different types of wood composites, and in this article, we will focus on two of the most commonly used: Medium Density Fiberboard (MDF) and Particle Board.

Mdf And Particle Board Basics

MDF and Particle Board are both composite materials made from wood fibers and resin or glue. However, they have different properties and uses.

| MDF | Particle Board |

|---|---|

| Made from fine wood fibers | Made from larger wood particles |

| Denser and stronger than Particle Board | Less dense and weaker than MDF |

| Smooth surface that is easy to paint or laminate | Rough surface that is harder to finish |

| More expensive than Particle Board | Less expensive than MDF |

Why Choose Engineered Wood?

There are several reasons why you might choose engineered wood products like MDF or Particle Board over solid wood. Firstly, they are more cost-effective, as they are made from waste wood materials. They are also more durable than solid wood, as they are less prone to warping, cracking, or splitting. Additionally, they offer more design flexibility, as they can be made in various sizes and shapes, and can be finished with different colors and textures.

However, it is important to note that engineered wood products like MDF and Particle Board may have some disadvantages. For example, MDF contains VOCs that can cause irritation to the lungs and eyes, and it is weaker than solid wood. Particle Board, on the other hand, is less dense and less strong than MDF, and it has a rough surface that is harder to finish.

In conclusion, MDF and Particle Board are two popular wood composite materials that offer many advantages over solid wood. They are cost-effective, durable, and versatile, making them suitable for a wide range of applications. However, it is important to choose the right material for your specific project, taking into account factors such as strength, surface finish, and environmental impact.

Mdf: Characteristics And Uses

Medium Density Fiberboard (MDF) is a popular engineered wood product that is commonly used in construction and furniture making. It is made by compressing wood fibers with resin under high pressure and temperature. MDF is a versatile and cost-effective material that offers several advantages over traditional wood products such as plywood and particle board.

How Mdf Is Made

MDF is made by breaking down hardwood or softwood residuals into wood fibers. These fibers are then combined with wax and a resin binder to form panels under high temperature and pressure. The wax helps to make the panels more water-resistant, while the resin binder holds the fibers together. The resulting panels are smooth, uniform, and free from knots and other defects.

Advantages Of Using Mdf

- MDF is stronger and more dense than particle board, making it more durable and less prone to warping or cracking.

- MDF has a smooth and uniform surface that is ideal for painting or laminating.

- MDF is easy to work with and can be cut, drilled, and machined using standard woodworking tools.

- MDF is a cost-effective alternative to traditional wood products such as plywood, making it a popular choice for furniture makers and cabinet makers.

Common Applications

MDF is commonly used in a variety of applications, including:

- Furniture making: MDF is often used as a substrate for veneers or laminates in furniture making.

- Cabinetry: MDF is a popular choice for cabinet construction due to its strength, durability, and smooth surface.

- Architectural millwork: MDF is commonly used for decorative moldings, trim, and paneling in residential and commercial applications.

- Doors: MDF is often used as a core material for interior doors due to its strength and stability.

Overall, MDF is a versatile and cost-effective material that offers several advantages over traditional wood products. It is easy to work with, durable, and ideal for a wide range of applications in construction and furniture making.

Particle Board: An Overview

MDF, or Medium Density Fiberboard, is stronger and denser than particle board. It is a waste-wood material, comprised of wood fibers rather than sawdust, making it more elegant and heavier. The project requirements determine whether the quality of MDF is needed.

Particle board, also known as chipboard, is a widely used engineered wood product that offers a cost-effective alternative to solid wood. It is made by compressing wood chips, sawmill shavings, and other wood particles together with a resin binder under high pressure and temperature. This manufacturing process creates a strong and versatile material that has a smooth surface and uniform density.

Manufacturing Process

The manufacturing process of particle board involves several steps:

- Gathering wood particles: Wood chips, sawmill shavings, and other wood particles are collected from various sources.

- Mixing with resin: The wood particles are mixed with a resin binder, typically a urea-formaldehyde adhesive, which helps hold the particles together.

- Forming the board: The mixture is then spread evenly onto a flat surface and compressed under high pressure to form a solid board.

- Curing: The board is then heated to cure the resin binder, ensuring the particles bond together firmly.

- Sanding and finishing: The surface of the board is sanded to achieve a smooth finish and can be further treated with laminates or veneers for added aesthetics.

Benefits Of Particle Board

Particle board offers several benefits that make it a popular choice for various applications:

- Affordability: Particle board is generally more affordable compared to solid wood or plywood, making it a cost-effective option for budget-conscious projects.

- Uniformity: Due to its manufacturing process, particle board has a uniform density and consistent strength throughout the entire board.

- Smooth surface: The surface of particle board is smooth and even, making it ideal for applications where a consistent surface is required.

- Easy to work with: Particle board is easy to cut, shape, and drill, allowing for flexibility in design and installation.

- Environmentally friendly: Particle board is made from recycled wood particles, reducing the demand for virgin timber and promoting sustainability.

Typical Uses

Particle board finds a wide range of applications in various industries and settings:

| Industry | Applications |

|---|---|

| Furniture | Cabinets, shelves, tables, and other furniture pieces |

| Construction | Interior walls, subflooring, and underlayment |

| Packaging | Crates, pallets, and shipping containers |

| Retail | Store fixtures, displays, and signage |

| Automotive | Interior components and trim |

Overall, particle board offers a cost-effective, versatile, and environmentally friendly solution for various construction and manufacturing needs.

Comparing Mdf And Particle Board

MDF, or Medium Density Fiberboard, is stronger and denser than particle board. It is also a waste-wood material, comprised of wood fibers rather than sawdust. The choice between the two depends on the specific needs of the project.

Density And Strength

MDF: Medium Density Fiberboard, denser and stronger than particle board.

Particle Board: Comprised of sawdust, less dense and strong compared to MDF.

Moisture Resistance

MDF: Absorbs water quickly, prone to warping and swelling in humid environments.

Particle Board: Less resistant to moisture compared to MDF, can also warp and swell.

Cost Considerations

MDF: Typically more expensive due to higher density and strength.

Particle Board: Generally more cost-effective option compared to MDF.

Environmental Impact

When it comes to the environmental impact of MDF (Medium Density Fiberboard) and particle board, it’s essential to consider factors such as VOCs and the sustainability of materials. These aspects play a significant role in determining the eco-friendliness of these popular wood-based products.

Vocs In Mdf And Particle Board

MDF and particle board are known to release volatile organic compounds (VOCs) into the air. These compounds, such as urea-formaldehyde, can contribute to indoor air pollution and have potential health implications for humans. The emission of VOCs from these materials can impact indoor air quality, making it crucial to consider these factors when using MDF and particle board in indoor spaces.

Sustainability Of Materials

When looking at the sustainability of MDF and particle board, it’s important to evaluate the sourcing of raw materials and the manufacturing processes. Both MDF and particle board are typically made from recycled wood fibers, making them a sustainable choice in terms of utilizing wood by-products. However, it’s essential to ensure that the manufacturing processes adhere to sustainable practices and minimize environmental impact.

Challenges With Mdf

MDF, or Medium Density Fiberboard, is a denser and stronger material compared to particle board. Made from wood fibers instead of sawdust, MDF is more elegant and heavier, offering quality depending on the project requirements.

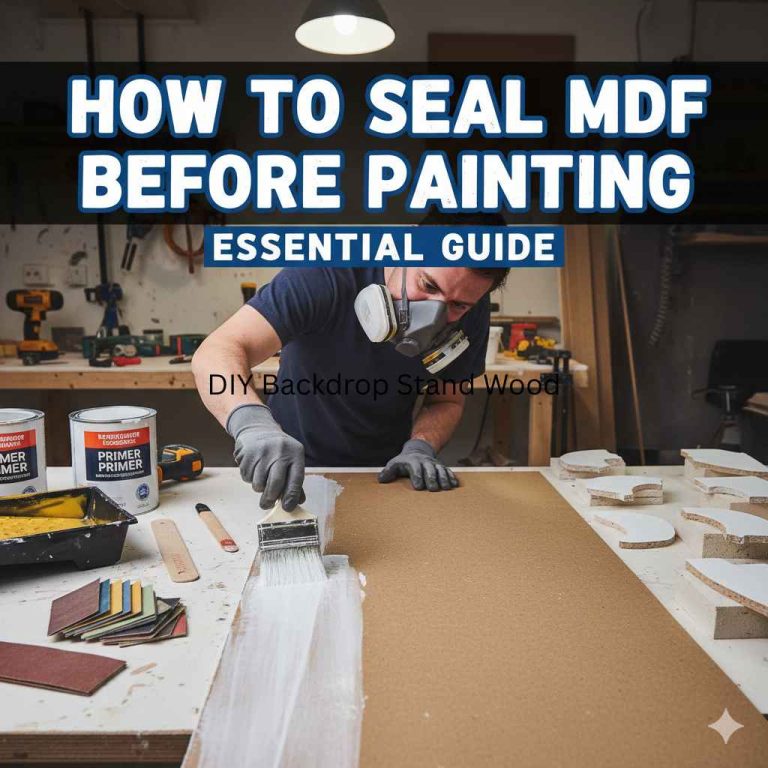

Vulnerability To Moisture

MDF is highly vulnerable to moisture, making it unsuitable for areas with high humidity or exposure to water. When MDF comes into contact with moisture, it can swell, warp, or even disintegrate, compromising its structural integrity and aesthetics. This makes it essential to avoid using MDF in environments prone to dampness or moisture, as it can lead to significant damage and deterioration.

Durability Concerns

While MDF is cost-effective and versatile, its durability is a concern compared to solid wood or plywood. MDF is more prone to dents, scratches, and structural damage, especially in high-traffic areas. Additionally, it has a shorter lifespan compared to solid wood and plywood, as it is susceptible to splitting, cracking, and other forms of damage under excessive stress or pressure. This makes it crucial to assess the anticipated wear and tear when considering MDF for a project.

Health And Safety

Health and safety considerations are paramount when working with MDF. MDF contains urea-formaldehyde, a volatile organic compound (VOC) that can emit harmful gases, contributing to indoor air pollution. Prolonged exposure to these emissions can cause respiratory issues and irritation to the eyes and skin. It’s imperative to use MDF in well-ventilated areas and employ appropriate safety measures, such as wearing protective gear and using respiratory protection, to minimize health risks associated with MDF.

When Not To Use Mdf

While Medium Density Fiberboard (MDF) has a wide range of applications, there are certain scenarios where it may not be the best choice. It’s important to consider the limitations of MDF to avoid potential issues in your projects.

Applications To Avoid

There are specific situations where using MDF may not be suitable:

- Outdoor or high-moisture environments

- Structural applications requiring load-bearing capabilities

- Areas prone to impacts or heavy wear and tear

Alternatives To Consider

When MDF is not the ideal choice, consider these alternatives:

- Plywood: Suitable for outdoor use and structural applications

- Solid Wood: Provides durability and natural aesthetic appeal

- Particle Board: Cost-effective option for non-structural projects

Making The Right Choice

When it comes to choosing the right material for your woodworking or construction projects, the decision between MDF, plywood, and particle board can significantly impact the outcome. Understanding the differences and considering various factors is crucial to making an informed decision.

Factors To Consider

Before deciding on the type of board to use for your project, consider the following factors:

- Strength and durability

- Cost-effectiveness

- Moisture resistance

- Workability and versatility

- Environmental impact

Mdf Vs. Plywood Vs. Particle Board

Each material has its own set of advantages and disadvantages:

| Material | Advantages | Disadvantages |

|---|---|---|

| MDF | Smooth surface, uniform density, cost-effective | Not moisture-resistant, weaker than plywood |

| Plywood | High strength, natural wood grain, moisture-resistant options available | More expensive, may have voids or patches |

| Particle Board | Low cost, uniform and smooth surface | Prone to swelling and sagging, not as strong as plywood |

Final Recommendations

Based on the factors and comparison, the following recommendations can be made:

- If cost-effectiveness and smooth surface are priorities, MDF can be a suitable choice for indoor projects.

- For outdoor or high-moisture applications, plywood’s strength and moisture resistance make it a preferred option.

- When cost is a primary concern and moisture exposure is minimal, particle board can be a viable option for certain projects.

Frequently Asked Questions

Are Particle Board And Mdf The Same?

No, particle board and MDF are not the same. MDF, or Medium Density Fiberboard, is stronger and denser than particle board. It is made of wood fibers rather than sawdust. MDF is more elegant and heavier, but whether you need its quality depends on the project.

What Is The Disadvantage Of Using Mdf?

The disadvantage of using MDF is that it is weaker than wood and has a shorter lifespan. It can crack or split under extreme stress, absorbs water quickly, and contains VOCs that can cause lung and eye irritation. MDF should not be used in humid environments and is not as durable or moisture-resistant as plywood.

When Should You Not Use Mdf?

MDF should not be used in humid environments as it can warp and swell. Additionally, it contains volatile organic compounds (VOCs), including urea-formaldehyde, which can be harmful to health. While MDF is denser and stronger than particle board, it has a shorter lifespan compared to wood and can crack or split under extreme stress.

It is important to consider the project’s requirements before choosing MDF over plywood or particle board.

Is Mdf Stronger Than Plywood?

MDF is denser and stronger than plywood, making it a suitable choice for various projects.

Conclusion

While MDF and particle board share similarities, MDF is denser and stronger. The choice between them depends on the project requirements. Consider MDF for its elegance and durability, but be cautious of its limitations, such as water absorption and VOC content.

Make an informed decision based on your specific needs.