LVP Flooring Cutter: Essential Tool for Perfect Floors

An LVP flooring cutter is a specialized tool designed for cutting luxury vinyl plank flooring. It ensures precise cuts for a professional finish.

Choosing the right flooring can significantly impact the aesthetic and functionality of your space. Luxury vinyl plank (LVP) flooring is popular due to its durability, easy maintenance, and beautiful designs. Installing LVP often requires specific tools to achieve clean and accurate cuts.

An LVP flooring cutter simplifies the process, making it a valuable addition to any DIY enthusiast’s toolkit. Whether you’re a professional installer or a homeowner tackling a renovation project, understanding how to use this tool effectively can save time and enhance the quality of your work. A well-cut plank creates a seamless look, elevating the overall appearance of your floors.

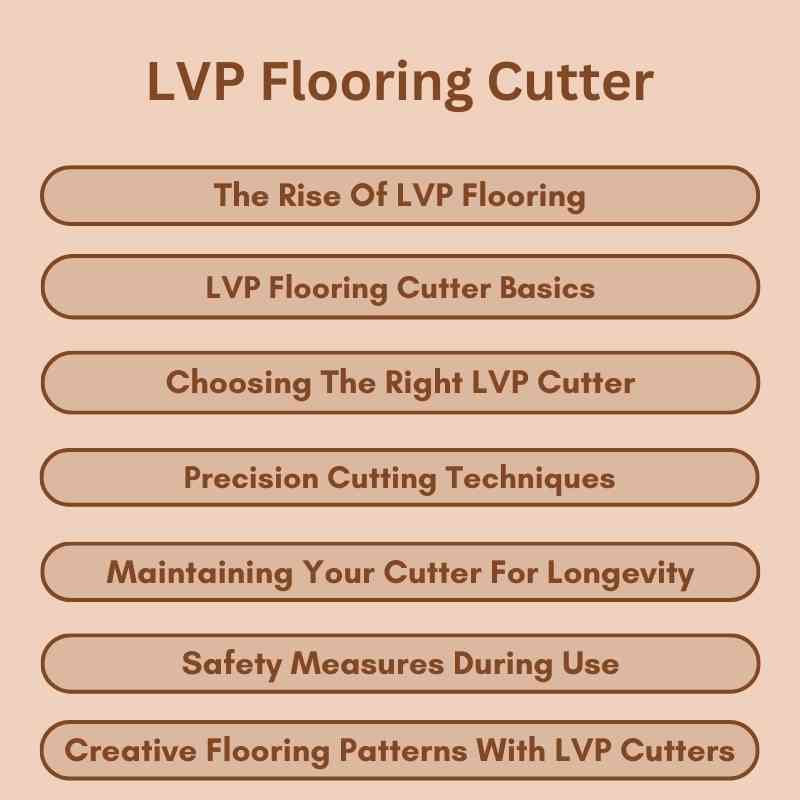

The Rise Of LVP Flooring

Luxury Vinyl Plank (LVP) flooring has gained immense popularity. It combines style, durability, and affordability. Many homeowners now prefer LVP over traditional materials. This flooring option suits various design aesthetics. Let’s explore the reasons behind its rise.

Popularity In Modern Design

LVP flooring fits perfectly in modern homes. Its versatility allows for endless design options. Here are some reasons for its popularity:

- Variety of Styles: LVP mimics wood, stone, and tile.

- Rich Colors: A wide range of colors is available.

- Easy Installation: Many products feature a click-lock system.

Interior designers love LVP for these reasons. It enhances the overall aesthetic without breaking the bank.

Benefits Over Traditional Materials

LVP offers several advantages compared to traditional flooring. Here’s a quick comparison:

| Feature | LVP | Traditional Flooring |

|---|---|---|

| Cost | Affordable | Often expensive |

| Durability | Highly durable | Can wear down |

| Water Resistance | Waterproof | Not always |

| Maintenance | Low maintenance | Higher maintenance |

Here are more benefits of LVP:

- Comfort: LVP feels warm underfoot.

- Sound Absorption: Reduces noise in the home.

- Eco-Friendly: Many products are made from recycled materials.

Choosing LVP flooring means selecting a smart, stylish option. It meets the needs of modern living.

LVP Flooring Cutter Basics

LVP flooring cutters are essential tools for installing luxury vinyl plank flooring. They make precise cuts, ensuring a perfect fit for your flooring. Understanding the basics helps in choosing the right cutter for your project.

Key Features

- Precision Cutting: Ensures accurate cuts for seamless installation.

- Durability: Made from high-quality materials for long-lasting use.

- Portability: Lightweight and easy to transport to different job sites.

- User-Friendly: Designed for both professionals and DIY enthusiasts.

- Safety Features: Includes safety guards to prevent accidents.

Different Types Available

| Type | Description | Best For |

|---|---|---|

| Manual Cutter | Operated by hand for simple cuts. | Homeowners and light use. |

| Electric Cutter | Powered tool for fast and easy cuts. | Professionals and heavy-duty jobs. |

| Score-and-Snap Cutter | Scores the plank and snaps it for a clean edge. | Quick projects and DIY tasks. |

Choosing The Right LVP Cutter

Selecting the perfect LVP cutter is essential for your project. A suitable cutter saves time and ensures clean, precise cuts. Consider different factors to find the best option for your needs.

Size And Capacity Considerations

Size matters when choosing an LVP cutter. A compact tool is easier to handle but may limit cutting capacity.

- Small Cutters: Best for tight spaces.

- Large Cutters: Handle bigger planks with ease.

Evaluate your project area. Measure the space to ensure your cutter fits. A larger cutter can make straight cuts faster.

| Size | Best Use |

|---|---|

| Compact | Small spaces, detailed work |

| Standard | General projects, home use |

| Large | Commercial jobs, extensive flooring |

Blade Types And Sharpness

The blade type significantly affects the cutting experience. Different blades cater to various tasks.

- Standard Blades: Great for most LVP types.

- Specialized Blades: Designed for thicker planks.

Sharpness is key. A sharp blade makes cleaner cuts. Dull blades can cause tearing and splintering.

- Check blade sharpness regularly.

- Replace dull blades promptly.

- Use proper cutting technique for best results.

Invest in a quality blade for long-lasting performance. A good blade enhances both speed and accuracy.

Precision Cutting Techniques

Precision cutting is essential for a perfect LVP flooring installation. Accurate cuts ensure a seamless fit. They help avoid gaps and misalignments. Use the right tools and techniques for the best results.

Step-by-step Guide

Follow these simple steps for precise LVP flooring cuts:

- Gather Tools: Use an LVP flooring cutter, measuring tape, and square.

- Measure Carefully: Measure the area where the plank will fit.

- Mark the Cut: Use a pencil to mark the cut line.

- Set the Cutter: Place the plank in the cutter, aligning the mark.

- Make the Cut: Press down firmly on the handle to cut.

- Check the Fit: Test the plank in the designated area.

Tips For Accurate Measurements

Accurate measurements are crucial for successful cutting. Use these tips to improve your accuracy:

- Measure Twice: Always double-check measurements before cutting.

- Use a Straight Edge: A straight edge helps create clear lines.

- Account for Expansion: Leave space for expansion around the edges.

- Mark Clearly: Use a bold pencil to make your marks visible.

Applying these precision cutting techniques ensures a professional-looking finish. Proper cutting leads to a durable and attractive floor.

Maintaining Your Cutter For Longevity

Proper maintenance of your LVP flooring cutter ensures it lasts longer. A well-cared cutter performs better and saves you money. Follow these tips to keep your cutter in top shape.

Cleaning Practices

Regular cleaning keeps your cutter efficient. Dirt and debris can affect performance. Here are some cleaning tips:

- Wipe down the surface after each use.

- Remove any LVP scraps to prevent buildup.

- Use a soft cloth to clean the blade area.

- Avoid harsh chemicals that can damage the cutter.

Set a cleaning schedule. Daily cleaning is ideal for busy users. Weekly deep cleaning will help maintain performance.

Blade Replacement And Care

The blade is the heart of your cutter. Keeping it sharp is crucial. Here’s how to care for your blades:

- Inspect the blade regularly for dullness.

- Replace the blade when it shows signs of wear.

- Use only compatible blades for replacement.

- Store extra blades in a dry place.

Follow these tips for blade longevity:

| Tip | Description |

|---|---|

| Keep it Dry | Moisture can rust blades. Store them dry. |

| Handle with Care | Avoid dropping blades. This can cause damage. |

| Sharpen Regularly | Use a sharpening tool for best results. |

Regular blade maintenance improves cutting accuracy. Invest time in blade care for better results.

Safety Measures During Use

Using an LVP flooring cutter requires strict safety measures. Protecting yourself ensures a smooth and safe experience. Follow these guidelines to stay safe while using your flooring cutter.

Personal Protective Equipment

Wearing proper personal protective equipment (PPE) is crucial. Here’s a list of essential items:

- Safety goggles: Protect your eyes from debris.

- Gloves: Use cut-resistant gloves for hand safety.

- Dust mask: Avoid inhaling dust particles.

- Steel-toed boots: Protect your feet from heavy tools.

Ensure all equipment fits properly. Check for damages before use. Replace any faulty gear immediately.

Proper Handling And Operation

Handling the LVP flooring cutter correctly is vital. Follow these steps for safe operation:

- Read the manufacturer’s manual thoroughly.

- Inspect the cutter for any issues before use.

- Keep hands clear of the cutting blade.

- Use the cutter on a stable surface.

- Store the cutter in a safe place when not in use.

Always cut away from your body. Maintain a firm grip on the tool. Ensure a clutter-free workspace to avoid accidents.

| Safety Equipment | Purpose |

|---|---|

| Safety goggles | Protects eyes from debris |

| Cut-resistant gloves | Protects hands from cuts |

| Dust mask | Prevents inhalation of dust |

| Steel-toed boots | Protects feet from heavy tools |

Creative Flooring Patterns With LVP Cutters

LVP (Luxury Vinyl Plank) flooring offers endless design possibilities. Using an LVP cutter allows for precise cuts, enabling creative patterns. Unique spaces can shine with custom designs. Transform any room into a masterpiece.

Design Possibilities

With LVP cutters, you can explore various design styles. Here are some popular options:

- Herringbone: Classic, zigzag pattern.

- Chevron: V-shaped, modern look.

- Plank Layout: Traditional straight rows.

- Tile Effect: Mimics the appearance of tiles.

Mix colors and textures for a unique floor. Play with different plank sizes to enhance visual interest.

Custom Cutting For Unique Spaces

Custom cutting with LVP cutters allows for tailored solutions. Perfect for:

- Odd-Shaped Rooms: Fit planks to any corner.

- Accent Areas: Create focal points in a room.

- Transitional Spaces: Seamlessly connect different areas.

Consider using LVP cutters for:

| Application | Benefit |

|---|---|

| Entryways | Durable and stylish first impression. |

| Kitchens | Water-resistant and easy to clean. |

| Living Rooms | Comfortable and inviting atmosphere. |

Custom cuts elevate your flooring. Let your creativity flow with every cut!

Real-life Examples

Seeing is believing. Real-life examples of LVP flooring cutters show their impact. These stories highlight how easy and effective they are for various projects.

Case Studies

Here are some interesting case studies showcasing LVP flooring cutters:

| Project | Location | Outcome |

|---|---|---|

| Home Renovation | Los Angeles | Transformed a dull space into a vibrant area. |

| Office Upgrade | New York | Created a modern workspace with improved aesthetics. |

| Rental Property | Miami | Increased value and tenant appeal. |

Before And After Transformations

Transformations show the power of LVP flooring cutters. Here are some stunning examples:

- Living Room: Dark carpet replaced with light LVP flooring. The room feels bigger.

- Kitchen: Old tiles removed for sleek LVP. Cleaning is now a breeze.

- Bathroom: Worn-out linoleum replaced. A fresh look emerged.

- Before: Dark and cramped.

- After: Bright and spacious.

These transformations demonstrate how LVP flooring cutters can change spaces. They make projects quicker and easier, resulting in beautiful outcomes.

Troubleshooting Common Issues

Having trouble with your LVP flooring cutter? You’re not alone. Many users face issues. Understanding how to troubleshoot can save time and money. Here are some common problems and their solutions.

Dealing With Malfunctions

Sometimes your cutter may not work as expected. Here are common malfunctions:

- Blade jams: This often happens with dirty blades.

- Inconsistent cuts: Check if the blade is dull.

- Slippage: Ensure the material is securely held.

- No power: Check the power source or battery.

For each issue, follow these steps:

- Inspect the blade for dirt or damage.

- Replace the dull blade with a new one.

- Secure the material using clamps.

- Test the power source with another device.

Adjustments For Optimal Performance

Making adjustments can enhance your cutter’s performance. Here are some tips:

| Adjustment | Purpose |

|---|---|

| Blade height | Ensure it matches the thickness of the LVP. |

| Cutting angle | Achieve precise and clean cuts. |

| Pressure settings | Adjust for different material densities. |

Regularly check these adjustments. Doing so keeps your LVP flooring cutter in top shape. Always remember to clean the cutter after each use. This simple task prevents many common issues.

The Future Of Flooring Installation

The future of flooring installation is bright and innovative. Technology is changing how we install flooring. The LVP flooring cutter plays a key role in this transformation. It makes cutting easier, faster, and more accurate.

Innovations In Cutting Tools

New cutting tools are revolutionizing flooring installation. The LVP flooring cutter is at the forefront of this change. It offers several features that stand out:

- Precision Cuts: Achieves clean edges without chipping.

- Lightweight Design: Easy to carry and handle.

- Ergonomic Grip: Reduces hand fatigue during use.

- Adjustable Blades: Suitable for various thicknesses of flooring.

These innovations enhance speed and efficiency. Installers can complete projects faster than ever before. This leads to satisfied clients and repeat business.

Sustainability In Flooring Materials

Sustainability is a major trend in the flooring industry. Consumers care about eco-friendly products. LVP flooring is made from recyclable materials. This reduces waste and conserves resources.

| Feature | LVP Flooring | Traditional Flooring |

|---|---|---|

| Material Source | Recycled | Virgin Resources |

| Environmental Impact | Low | High |

| Life Cycle | Long-lasting | Shorter |

Choosing sustainable flooring benefits the planet. It also attracts eco-conscious customers. The future of flooring installation embraces both technology and sustainability.

Frequently Asked Questions

What Is An LVP Flooring Cutter?

An LVP flooring cutter is a specialized tool designed to cut luxury vinyl plank (LVP) flooring. It offers precise cuts without damaging the planks. This tool is essential for DIY projects and professional installations, ensuring clean edges and a perfect fit for your flooring.

How To Use An LVP Flooring Cutter?

Using an LVP flooring cutter is straightforward. First, measure and mark the plank where you want to cut. Align the marked line with the cutter’s blade. Press down firmly to slice through the vinyl. Always follow safety guidelines to prevent accidents during the cutting process.

Can I Cut LVP Flooring With A Utility Knife?

Yes, you can cut LVP flooring with a utility knife. However, it may require more effort and precision. Ensure the blade is sharp for cleaner cuts. For better results, consider using a dedicated LVP cutter for efficiency and ease, especially for larger projects.

Is LVP Flooring Cutter Necessary?

While not strictly necessary, an LVP flooring cutter is highly recommended. It simplifies the cutting process and ensures accuracy. Using the right tool can save time and effort, making your flooring installation smoother and more professional-looking. Investing in a cutter can enhance your DIY experience.

Conclusion

Choosing the right LVP flooring cutter can make a significant difference in your installation experience. A quality cutter ensures clean, precise cuts, saving you time and effort. Investing in the right tools enhances the overall look and durability of your flooring.

Take your time to select the best option for your needs.