Pressure Treated Kiln Dried Lumber: Build to Last

Pressure treated kiln dried lumber undergoes a dual process of pressure treatment and kiln drying. This combination enhances durability and stability, making it suitable for various construction projects.

Pressure treated kiln dried lumber is a popular choice for outdoor and structural applications. The pressure treatment infuses the wood with preservatives, protecting it against decay, insects, and moisture. Kiln drying removes excess moisture, reducing the risk of warping and splitting.

This lumber is ideal for decks, fences, and landscaping projects. Homeowners and builders appreciate its longevity and strength, ensuring a solid investment. Choosing this type of lumber guarantees a reliable material that withstands the elements. Understanding its benefits can help you make informed decisions for your next building project, ensuring both quality and durability in your construction needs.

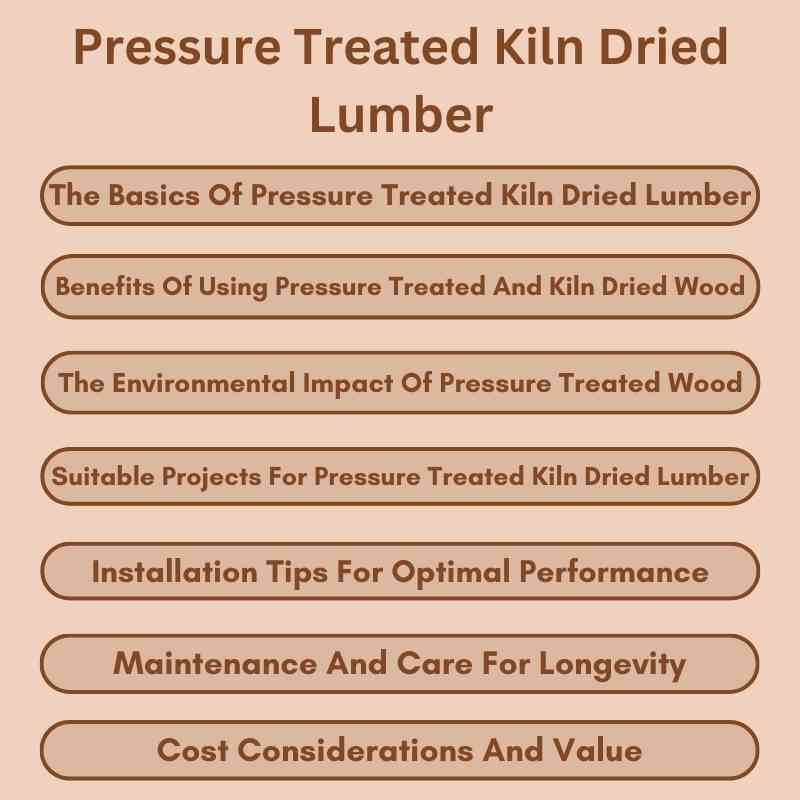

The Basics Of Pressure Treated Kiln Dried Lumber

Pressure treated lumber is wood that has been treated to resist rot and insects. It is commonly used for outdoor projects. The treatment involves using chemicals under pressure to protect the wood.

Kiln dried lumber undergoes a special drying process. This method removes moisture from the wood. It helps prevent warping and cracking over time. Kiln drying makes the wood more stable.

During the kiln drying process, logs are placed in a heated chamber. Hot air circulates to dry the wood evenly. This process can take several days, depending on the wood type.

Combining these two methods creates strong and durable lumber. It is ideal for decks, fences, and outdoor furniture. Homeowners and builders often prefer this type of lumber for its long-lasting benefits.

Benefits Of Using Pressure Treated And Kiln Dried Wood

Pressure treated and kiln dried wood offers enhanced durability. This wood can last for many years. It resists decay better than untreated wood. The treatment process protects the wood from moisture.

Another major benefit is resistance to pests. Insects like termites are less likely to damage it. Homeowners can save money on repairs. Choosing this wood means fewer worries about pests and rot.

The Environmental Impact Of Pressure Treated Wood

Pressure treated wood has some eco-friendly aspects. It can last longer than untreated wood. This means fewer trees need to be cut down. Using it helps reduce waste in landfills.

Disposal of pressure treated wood needs care. It often contains chemicals for protection. Burning it can release harmful toxins into the air. Always check local rules for safe disposal.

Recycling pressure treated wood is a good option. It can be reused in certain projects. Always ensure that it is safely handled during recycling.

Suitable Projects For Pressure Treated Kiln Dried Lumber

Pressure treated kiln dried lumber is ideal for outdoor structures. It resists moisture, insects, and decay. Use it for decks, fences, and pergolas. These projects benefit from the wood’s durability.

For interior applications, pressure treated lumber is less common. It can warp or have a strong chemical smell. Avoid using it for furniture or flooring. It is best for outdoor use only.

Installation Tips For Optimal Performance

Proper handling of pressure treated kiln dried lumber is essential for good results. Always store the lumber in a dry area to prevent moisture damage. Stack the boards off the ground to allow air circulation. Use spacers between the boards for better airflow.

For installation, check the weather conditions first. Avoid working in rainy or humid weather. Use the right tools to ensure a precise fit. Make sure to wear safety gear during the installation process.

Follow the manufacturer’s instructions for best results. Allow the lumber to acclimate to the environment before installation. This step helps prevent warping and cracking later on.

Maintenance And Care For Longevity

Regular inspections help maintain the beauty of pressure treated kiln dried lumber. Check for cracks, splits, or rot at least twice a year. Clean the surface using a gentle soap and water. This prevents dirt and grime from building up.

Sealing the wood is important for its protection. Apply a quality sealant every 1 to 3 years. This helps keep moisture out and prolongs the life of your lumber. Always follow the manufacturer’s instructions for the best results.

Treating the wood again may be necessary if you notice fading or wear. Look for signs of mold or mildew. Early treatment can save your wood from serious damage.

Cost Considerations And Value

Pressure treated kiln dried lumber often requires a higher initial investment. This cost can be offset by its long-term benefits. Durability and resistance to moisture and pests make it a smart choice.

Compared to non-treated wood options, the value of treated lumber is clear. Non-treated wood may cost less upfront but needs frequent replacements. Treated lumber lasts longer, saving money over time.

| Type of Lumber | Initial Cost | Longevity | Maintenance |

|---|---|---|---|

| Pressure Treated | Higher | 10-30 years | Low |

| Non-Treated | Lower | 5-10 years | High |

Future Of Wood Treatment Technologies

Wood preservation technologies are evolving rapidly. New methods help protect against decay and insects. Innovations focus on using safer chemicals and processes.

Sustainability is key in lumber production. Many companies now use eco-friendly treatments. These methods reduce harm to the environment.

Some new techniques include:

- Bio-based preservatives that are safe for humans and nature.

- Pressure treatment that minimizes chemical use.

- Advanced drying methods that improve durability.

These advancements ensure quality and promote a healthier planet.

Frequently Asked Questions

What Is Pressure Treated Kiln Dried Lumber?

Pressure treated kiln dried lumber is wood that has undergone a treatment process to resist decay and pests. This lumber is dried in a kiln after treatment, which reduces moisture content. The result is a durable, stable product ideal for outdoor projects, like decks and fences.

Why Use Pressure Treated Lumber?

Pressure treated lumber offers enhanced durability and resistance to environmental factors. It’s particularly effective against rot, insects, and moisture, making it perfect for outdoor use. This type of lumber extends the lifespan of your projects, ensuring they remain sturdy and reliable over time.

How Is Kiln Drying Done?

Kiln drying involves heating lumber in a controlled environment to reduce its moisture content. This process prevents warping and cracking, ensuring the wood remains stable. By removing moisture, kiln drying improves the wood’s performance and durability, making it suitable for various applications.

Is Pressure Treated Lumber Safe?

Yes, pressure treated lumber is safe when used correctly. It is treated with chemicals that are designed to be stable and not leach harmful substances when properly maintained. Always follow guidelines for handling and using this lumber, especially for projects involving food or pets.

Conclusion

Pressure treated kiln dried lumber offers durability and versatility for various projects. Its resistance to moisture and pests makes it an ideal choice for outdoor structures. Choosing this type of lumber ensures longevity and performance. Invest in quality materials to enhance your construction and woodworking endeavors.

Your projects deserve the best foundation.