Stair Gauges for Circular Saw: Precision Cutting Guide

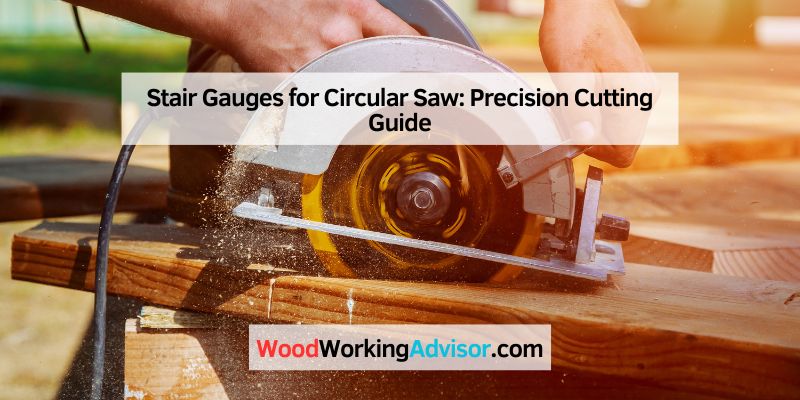

Have you ever found yourself struggling to make precise cuts with your circular saw? You’re not alone.

Many DIY enthusiasts and professionals alike face this challenge. That’s where stair gauges come into play. These small, yet incredibly powerful tools can transform your woodworking experience, turning frustration into satisfaction. Imagine achieving perfectly straight cuts every time, boosting both your confidence and productivity.

This guide will reveal how stair gauges can be your secret weapon for flawless circular saw projects. Keep reading to discover how you can elevate your craftsmanship and make every cut count.

Benefits Of Stair Gauges

Stair gauges make cutting wood more accurate. They help the saw stay straight. This tool is great for making stairs. It makes sure each step is the same size. Builders love them for this reason. Stair gauges help everyone cut better. Even if you are new to woodworking, you will see a difference.

Every cut looks the same with stair gauges. They keep the saw in the right place. This means less mistakes. Your stairs will look neat and even. No more uneven steps. It is important for safety and looks. Consistency makes projects look professional.

Stair gauges save time on projects. You do not need to measure each time. Just set the gauge once. Then cut many steps quickly. This tool helps finish work faster. Builders can do more in less time. Time saved can be used for other tasks.

Credit: thehammerstroke.com

Choosing The Right Stair Gauges

Material of stair gauges is very important. Metal gauges last longer. They are strong and resist rust. Plastic gauges are light and cheap. They can break easily. Choose the right material for your needs.

Compatibility is key for stair gauges. Not all gauges fit all saws. Check if the gauge fits your circular saw. Some gauges are made for specific brands. Make sure to read labels carefully. This ensures a perfect fit.

Adjustability makes stair gauges very useful. Some gauges can change size. This helps with different projects. Versatility is also important. One tool can do many tasks. Look for gauges that offer both features. This saves money and space in your toolbox.

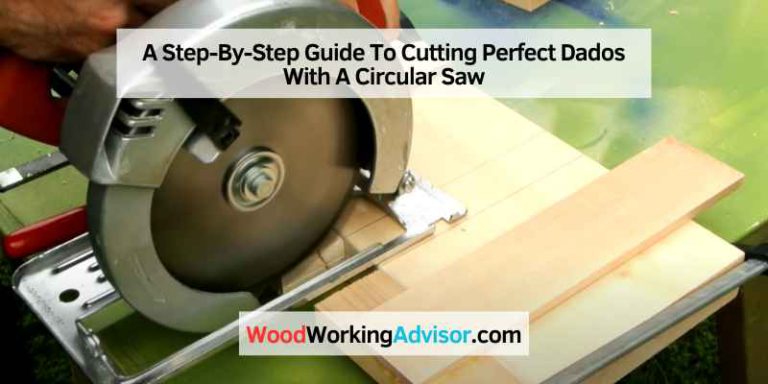

Setting Up Stair Gauges

Measure the stair’s rise and run. Mark these points clearly. Use a tape measure for accuracy. Keep the measurements consistent. Double-check each measurement. Errors can lead to problems.

Attach the stair gauges to the saw. Use the saw’s base for alignment. Ensure the gauges are tight. Loose gauges can cause mistakes. Check that they do not move. This keeps cuts straight.

Make a test cut on scrap wood. Check the cut’s accuracy. It should match your measurements. Adjust the gauges if needed. Repeat the test until it’s perfect. This ensures a precise final cut.

Credit: andrafarimarmores.com.br

Using Stair Gauges Effectively

Stair gauges help make straight cutseasy. Attach them to the saw base. Line them up with your mark. Push the saw steadily along the wood. This keeps the cut straight. Always measure twice. Cut once for the best result. Double-check your setup before cutting. It saves time and wood.

Angled cuts require careful setup. Adjust the stair gauge to the desired angle. Lock it in place. Align the saw with the marked angle. Move slowly and keep a steady hand. Angled cuts are useful in many projects. Practice makes perfect with angles.

Wear safety goggles at all times. Always check that the saw is unplugged when adjusting. Keep hands away from the blade. Use clamps to hold wood securely. A clean workspace prevents accidents. Have a first aid kit nearby. Being careful keeps you safe.

Troubleshooting Common Issues

Misalignment can happen with stair gauges. The saw might cut wrong. First, check if the gauge is tight. Loosen it and adjust it again. Make sure it is straight. Use a rulerto check. Also, see if the saw blade is bent. A bent blade can cause misalignment. Change the blade if needed. Proper alignment helps in better cuts.

Over time, gauges may get worn. This affects their performance. Inspect the gauges regularly. Look for scratchesand dents. Clean the gauges after each use. Dirt can cause wear. Use a soft cloth to clean. If parts are damaged, replace them. This keeps the gauges in good shape.

Keep gauges in top condition for best results. Store them in a dry place. Moisture can cause rust. Check the screws often. Tighten them if loose. Lubricate moving parts with oil. This helps them move smoothly. Always check for accurate settings before cutting. Proper care makes the gauges last longer.

Credit: www.amazon.com

Innovations In Stair Gauges

Stair gauges now have new and smart shapes. Some are lighter and easier to handle. Others have adjustable parts for better fit. Designers focus on user comfort and precision. These tools help in making straight cuts. They are becoming more popular with builders.

Modern stair gauges use technology to make work easier. Some models have digital displays. These show accurate measurements. Others connect to apps for better control. This helps builders work faster and with more accuracy. Technology makes these tools very useful.

Future stair gauges will have more smart features. They might use sensors to measure angles. Voice commands could become a feature. Builders will have more choices and efficiency. These tools will be more advanced in the future.

Frequently Asked Questions

What Are Stair Gauges Used For?

Stair gauges are used to ensure precise cuts for stair stringers. They attach to a framing square, helping to accurately mark angles and measurements. This tool simplifies the process of laying out stair components, ensuring consistent and repeatable cuts with a circular saw.

How Do Stair Gauges Work With Circular Saws?

Stair gauges work by providing a guide for marking cuts on lumber. They are used with a framing square to outline precise angles for stairs. With clear markings, using a circular saw becomes straightforward, ensuring accurate and clean cuts for stair components.

Can Stair Gauges Improve Cutting Accuracy?

Yes, stair gauges improve cutting accuracy by ensuring consistent measurements. They help mark precise angles on lumber, guiding circular saw cuts. This reduces errors and enhances efficiency, making stair building easier and more reliable, especially for DIY enthusiasts and professionals alike.

Are Stair Gauges Easy To Use?

Stair gauges are easy to use, even for beginners. Attach them to a framing square, adjust for desired angle, and mark. This simplicity makes them a popular choice for DIY projects, ensuring that stair components are cut accurately with a circular saw.

Conclusion

Stair gauges simplify circular saw cutting. They ensure precise, straight cuts. This tool saves time and reduces errors. Perfect for DIY enthusiasts. Easy to use. Affordable and reliable. Boosts your project efficiency. Ideal for both small and large tasks. No more guesswork or misalignments.

Improve your cutting skills. Enjoy smooth, clean results every time. Whether a pro or beginner, stair gauges are essential. Enhance your woodworking experience. Invest in quality tools. Make your projects shine. Stair gauges help you achieve those perfect lines. Get started today.

Your woodworking will never be the same.