What Brush for Polyurethane: Expert Picks for Flawless Finish

Use a high-quality synthetic brush for applying polyurethane. A foam brush is also a good choice for smooth finishes.

Choosing the right brush for polyurethane can significantly affect your project’s outcome. The type of brush you select impacts the application and finish quality. Synthetic brushes work well with water-based polyurethane, ensuring a smooth, even coat. For oil-based polyurethane, consider using a natural bristle brush for the best results.

Foam brushes are ideal for small, detailed areas and provide a smooth finish without leaving brush marks. Understanding the characteristics of different brushes will help you achieve professional results. Invest in a good brush to enhance the durability and appearance of your finished piece. Your choice can make a noticeable difference in the final look.

Introduction To Polyurethane Finishes

Polyurethane finishes protect wood surfaces with a durable layer. They resist scratches, water, and stains. Choosing the right brush enhances application and finish quality. Different types of polyurethane require specific brushes for best results.

Importance Of The Right Brush

The right brush is crucial for a smooth finish. A good brush helps in:

- Even distribution of the finish.

- Reducing brush marks.

- Minimizing bubbles in the finish.

Using the wrong brush can lead to uneven coverage. This can ruin your project and waste time.

Brief On Polyurethane Types

Polyurethane comes in two main types: oil-based and water-based.

| Type | Drying Time | Odor | Durability |

|---|---|---|---|

| Oil-Based | 8-12 hours | Strong | Very Durable |

| Water-Based | 1-2 hours | Mild | Less Durable |

Choose your brush based on the polyurethane type:

- Oil-Based: Use a natural bristle brush.

- Water-Based: Use a synthetic bristle brush.

Knowing the type helps in selecting the best brush.

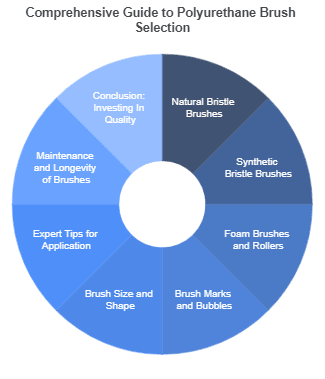

Natural Bristle Brushes

Natural bristle brushes are excellent tools for applying polyurethane. They hold more finish and spread it evenly. These brushes are made from animal hair, usually hog or ox. They provide a smooth finish, making them popular among woodworkers.

Best Uses For Oil-based Polyurethane

Natural bristle brushes work best with oil-based polyurethane. Here are some of their best uses:

- Applying a thick coat on wood surfaces.

- Reaching intricate areas like corners and edges.

- Achieving a smooth, professional finish.

Natural bristle brushes are less effective with water-based products. The bristles can absorb water and become limp.

Maintenance Tips

Taking care of your natural bristle brushes ensures their longevity. Follow these simple maintenance tips:

- Clean brushes immediately after use.

- Use mineral spirits for oil-based finishes.

- Gently reshape the bristles after cleaning.

- Store brushes in a dry, cool place.

Proper maintenance keeps brushes in great condition. This ensures better results with each use.

Synthetic Bristle Brushes

Synthetic bristle brushes are popular tools for applying polyurethane. They offer excellent control and smooth finishes. These brushes are made from man-made materials like nylon or polyester. They work well with both water-based and oil-based polyurethane.

Advantages With Water-based Polyurethane

Synthetic brushes shine when used with water-based polyurethane. Here are some key advantages:

- Less Brush Streaking: They leave fewer brush marks.

- Quick Drying: They dry fast, allowing for quicker coats.

- Easy to Clean: Simply rinse with soap and water.

- Durable: Synthetic bristles hold their shape well.

- Resistant to Water: They do not absorb water like natural bristles.

Cleaning And Care

Proper cleaning ensures your synthetic brush lasts longer. Follow these steps:

- Rinse the brush immediately after use.

- Wash with warm, soapy water.

- Use a brush comb to remove excess polyurethane.

- Rinse thoroughly until water runs clear.

- Let the brush dry flat or hang it up.

Store your brushes upright in a container. Avoid bending the bristles. This keeps them in great shape for your next project.

Foam Brushes And Rollers

Choosing the right tools for applying polyurethane is crucial. Foam brushes and rollers are popular choices. They help achieve a smooth, even finish. Each tool has its unique benefits and applications.

When To Use Foam Brushes

Foam brushes are ideal for small projects. Use them for:

- Touch-ups on furniture.

- Applying polyurethane on intricate areas.

- Working on crafts and DIY projects.

They hold a good amount of finish. Foam brushes leave fewer brush strokes. This makes them perfect for detailed work.

Achieving Smooth Surfaces With Rollers

Rollers are great for larger surfaces. They cover more area quickly. Use rollers for:

- Tables and desks.

- Cabinets and shelves.

- Floors and large panels.

Rollers produce a smooth finish. They minimize bubbles and drips. For the best results, follow these tips:

- Choose a roller with a short nap for a smooth finish.

- Use even pressure while rolling.

- Work in small sections for uniform coverage.

Both foam brushes and rollers have their strengths. Select the right tool based on your project size and detail.

Brush Marks And Bubbles

Brush marks and bubbles can ruin a beautiful finish. Proper techniques and the right brush can help. Understanding how to minimize these imperfections is key to a professional look.

Techniques To Avoid Imperfections

Follow these techniques to achieve a smooth finish:

- Apply thin coats. Thick layers often lead to bubbles.

- Use slow, even strokes. This helps eliminate brush marks.

- Work in small sections. This keeps the surface wet longer.

- Keep a wet edge. Avoid letting the finish dry before you blend.

- Use a foam brush for flat surfaces. Foam minimizes bubbles.

Selecting Brush For Minimizing Marks

Choosing the right brush is essential. Different brushes work better for polyurethane:

| Brush Type | Best Use | Pros | Cons |

|---|---|---|---|

| Natural Bristle | Oil-based finishes | Excellent coverage | Not for water-based finishes |

| Synthetic Bristle | Water-based finishes | Good for all types | May leave marks if not used properly |

| Foam Brush | Flat surfaces | Minimizes bubbles | Less control for detailed work |

Always clean your brush before use. A dirty brush can cause streaks. Select the right brush for your project.

Brush Size And Shape

Choosing the right brush for polyurethane is essential. The size and shape influence the finish quality. Using the right brush helps in achieving smooth and even coats. Here, we explore how to select the right brush size and shape for your project.

Matching Brush To Project Size

Different projects require different brush sizes. A brush that is too small or too large can cause issues. Here’s a quick guide:

| Project Size | Recommended Brush Size |

|---|---|

| Small Projects (e.g., furniture) | 1 to 2 inches |

| Medium Projects (e.g., cabinets) | 2 to 3 inches |

| Large Projects (e.g., floors) | 4 inches or more |

Use a small brush for tight spaces. Large brushes cover more area quickly. Select the size based on the surface area you are working on.

Shape Considerations For Detail Work

The shape of the brush affects precision. Choose the right shape for detail work and edges.

- Flat Brushes: Best for wide surfaces.

- Angled Brushes: Ideal for corners and edges.

- Round Brushes: Great for detailed designs and touch-ups.

Flat brushes provide smooth, even strokes. Angled brushes reach tight corners easily. Round brushes allow for intricate detailing.

Selecting the right brush shape enhances your project’s finish. Think about the details you want to achieve.

Expert Tips For Application

Applying polyurethane correctly enhances the final look. Follow these expert tips for a smooth finish.

Prepping The Surface

Proper surface preparation is key to a successful application. Here’s how to get started:

- Clean the Surface: Remove dust and debris.

- Sanding: Use fine-grit sandpaper. Sand lightly for a smooth finish.

- Wipe Down: Use a damp cloth to remove dust after sanding.

- Dry Completely: Ensure the surface is dry before applying.

Brushing Techniques For Even Coats

Using the right technique is essential for even application. Follow these steps:

- Choose the Right Brush: A high-quality brush works best.

- Load the Brush: Dip the brush into the polyurethane. Don’t over-saturate.

- Apply Evenly: Start from one end. Use long, smooth strokes.

- Work in Sections: Apply to a small area first. This prevents drying before you finish.

- Check for Bubbles: Pop any bubbles with the brush. This helps avoid imperfections.

Follow these tips for a professional look. Enjoy your beautiful finish!

Maintenance And Longevity Of Brushes

Taking care of your brushes ensures they last longer. Polyurethane application requires proper tools. A well-maintained brush provides better results. Understanding maintenance steps is key.

Proper Cleaning Post-application

Cleaning brushes after use is essential. Follow these steps for effective cleaning:

- Rinse Immediately: Use warm water to rinse off excess polyurethane.

- Use Soap: Apply a mild soap to remove remaining residue.

- Gently Brush: Use your fingers or another brush to clean bristles.

- Rinse Again: Ensure all soap is washed out thoroughly.

- Shake Off Water: Remove excess water by shaking the brush.

- Reshape Bristles: Restore the original shape of the brush head.

These steps help maintain the brush’s shape and functionality. Clean brushes lead to smoother finishes.

Storage Solutions For Brushes

Storing brushes correctly keeps them in good condition. Follow these tips for proper storage:

- Hang Brushes: Use hooks to hang brushes, preventing bristle damage.

- Store Vertically: Place brushes upright in a container to avoid bending.

- Avoid Heat: Keep brushes away from direct sunlight or heat sources.

- Use Brush Covers: Protect bristles with covers to maintain shape.

Proper storage extends the life of your brushes. It helps maintain their performance and quality.

Conclusion: Investing In Quality

Choosing the right brush for polyurethane is crucial. Quality brushes enhance the finish and durability of your project. Investing in a high-quality brush pays off in the long run.

Cost Versus Quality Debate

The debate between cost and quality often arises. Some brushes are cheaper but lack performance. Here’s a breakdown of the key factors:

| Brush Type | Cost | Quality | Durability |

|---|---|---|---|

| Synthetic Brush | Low to Medium | Good | Moderate |

| Natural Bristle Brush | Medium to High | Excellent | High |

| Foam Brush | Low | Fair | Low |

Investing in a high-quality brush improves your results. A good brush applies polyurethane evenly. It helps avoid streaks and bubbles.

Final Thoughts On Brush Selection

- Choose a brush that suits your project type.

- Consider the finish you want to achieve.

- Quality brushes save time and effort.

- Durability leads to long-term savings.

Quality brushes lead to better finishes. They enhance your skill as a DIYer. Make the right choice for successful projects.

Frequently Asked Questions

What Type Of Brush Is Best For Polyurethane?

The best brush for polyurethane is a high-quality synthetic bristle brush. Synthetic bristles provide a smooth finish and resist solvent absorption. They work well with both water-based and oil-based polyurethanes. Avoid natural bristle brushes as they can absorb moisture and lead to a less even application.

Can I Use A Foam Brush For Polyurethane?

Yes, foam brushes can be used for applying polyurethane. They are great for achieving a smooth finish without brush marks. However, they may not hold as much product as bristle brushes. For larger surfaces, consider using a bristle brush for better coverage and efficiency.

How Do I Clean A Brush After Polyurethane Use?

To clean a brush after using polyurethane, use mineral spirits for oil-based products. For water-based polyurethane, warm soapy water works effectively. Rinse the brush thoroughly to remove all residue. Allow it to dry completely to maintain its shape for future use.

Should I Sand Between Coats Of Polyurethane?

Yes, sanding between coats of polyurethane is recommended. This process helps to create a smoother finish and improves adhesion of subsequent layers. Use fine-grit sandpaper to avoid damaging the previous coat. Clean the surface thoroughly before applying the next coat for the best results.

Conclusion

Choosing the right brush for polyurethane is essential for achieving a smooth finish. Synthetic brushes work well with water-based poly, while natural bristle brushes excel with oil-based products. Taking the time to select the appropriate brush will enhance your project and ensure lasting results.

Happy painting!