Why is My Chainsaw Not Cutting? Quick Troubleshooting Tips

Possible answer: Your chainsaw may not be cutting because the chain is dull or damaged, the chain tension is loose, the bar is worn or bent, the fuel or air filter is dirty, the spark plug is faulty, or the carburetor needs cleaning or adjustment. Check these components and make necessary repairs or replacements to ensure proper cutting performance.

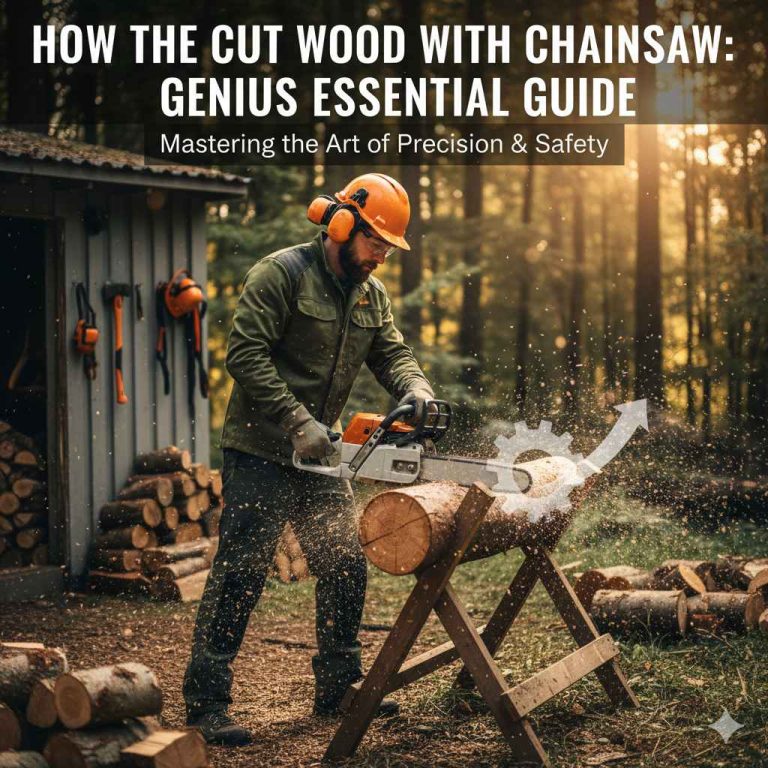

A chainsaw is a powerful tool that can make cutting wood faster and easier, but it requires proper maintenance and operation to work effectively and safely. If your chainsaw is not cutting as it should, you may encounter problems such as uneven cuts, slow progress, or kickbacks that can damage the chain or harm you.

To prevent these issues and get the most out of your chainsaw, you need to know why it is not cutting and how to fix it. We will explain the common causes of chainsaw cutting problems and provide some tips on how to troubleshoot and solve them.

Introduction To Chainsaw Cutting Issues

Experiencing issues with your chainsaw not cutting? Several factors could be causing this problem, such as a dull chain, improper chain tension, or a damaged cutting blade. Regular maintenance and proper adjustments are crucial to ensure smooth and efficient cutting performance.

Common Symptoms Of Cutting Problems

If you’re wondering why your chainsaw is not cutting properly, there are several common symptoms that you may encounter. These issues can hinder the performance of your chainsaw and make it difficult to complete your tasks efficiently. By understanding these symptoms, you can identify the root cause of the problem and take appropriate action to resolve it.

Here are some common symptoms of cutting problems with a chainsaw:

1. Dull chain: A dull chain is one of the most common causes of cutting issues. Over time, the cutting teeth of the chain can become worn down, reducing its effectiveness. This can lead to slower cutting speeds, increased effort required, and even the chainsaw getting stuck in the wood.

2. Incorrect chain tension: If the chain on your chainsaw is too loose or too tight, it can negatively affect the cutting performance. A loose chain may slip off the guide bar, while a tight chain can strain the engine and cause excessive wear on the chain and bar.

3. Dirty or clogged air filter: A dirty or clogged air filter can restrict the airflow to the engine, resulting in poor performance and reduced cutting power. Regularly cleaning or replacing the air filter can help maintain optimal cutting performance.

4. Worn or damaged bar: The guide bar, which supports the chain, can wear out or become damaged over time. A worn or damaged bar can cause the chain to bind or slip, leading to inefficient cutting and potential safety hazards.

5. Insufficient chain lubrication: Proper chain lubrication is crucial for smooth cutting operation. If the chain is not adequately lubricated, it can overheat and become less effective. This can result in slower cutting speeds, increased wear on the chain, and even damage to the bar.

Importance Of Timely Troubleshooting

Timely troubleshooting is essential to address any cutting issues with your chainsaw. Ignoring or delaying the resolution of these problems can have several negative consequences. By taking immediate action, you can prevent further damage to your chainsaw and ensure its optimal performance.

Here are the reasons why timely troubleshooting is important:

1. Efficiency: Addressing cutting problems promptly helps restore the efficiency of your chainsaw. By resolving issues like a dull chain or improper chain tension, you can ensure smooth cutting operation, saving time and effort.

2. Longevity: Regular maintenance and troubleshooting can extend the lifespan of your chainsaw. By promptly addressing issues like a worn bar or insufficient lubrication, you can prevent further damage and keep your chainsaw in good working condition for longer.

3. Safety: A malfunctioning chainsaw can pose a safety risk to the operator. By troubleshooting and fixing cutting problems, you reduce the chances of accidents or injuries that can occur due to a chainsaw not cutting properly.

4. Cost-effectiveness: Timely troubleshooting can save you money in the long run. By identifying and resolving cutting issues early on, you can prevent more severe damage that may require costly repairs or even replacement of parts.

In conclusion, understanding the common symptoms of cutting problems and the importance of timely troubleshooting can help you maintain the optimal performance of your chainsaw. By regularly inspecting and addressing any issues, you can ensure that your chainsaw cuts smoothly and efficiently, making your tasks easier and safer.

Dull Blades: The Primary Culprit

Dull blades are often the primary culprit when your chainsaw is not cutting properly. Blunt edges can cause the saw to struggle and result in inefficient cuts. Sharpening or replacing the blades is essential to restore the cutting performance of your chainsaw.

If you’re struggling with your chainsaw not cutting through wood like it used to, dull blades may be the primary culprit. Dull chainsaw blades can cause a variety of issues, including a slower cutting speed, rough cuts, and even an increased risk of kickback.

Signs Of Blade Dullness

The first step in diagnosing a dull chainsaw blade is understanding the signs. One of the most obvious signs is a slower cutting speed. If you find that you’re having to force the saw through the wood or that it’s taking longer than usual to cut through a log, your blades may need sharpening. You may also notice rougher cuts that leave behind jagged edges, as well as an increase in sawdust and debris.

Proper Sharpening Techniques

Proper sharpening techniques are crucial to maintaining a sharp chainsaw blade. Before sharpening, it’s important to clean the blade thoroughly and inspect it for any damage. Then, using a round file and a guide, you can sharpen each tooth to the appropriate angle. It’s important to maintain the same angle for each tooth to ensure an even and consistent cut. If you’re not comfortable sharpening the blade yourself, it’s best to take it to a professional.

In conclusion, dull blades are the primary culprit when your chainsaw is not cutting properly. Signs of blade dullness include slower cutting speed and rough cuts. Proper sharpening techniques involve cleaning the blade, inspecting for damage, and using a round file and guide to sharpen each tooth. Remember to maintain the same angle for each tooth to ensure an even cut.

Chain Tension Troubles

Effects Of Improper Chain Tension

Improper chain tension can significantly impact the performance of your chainsaw. When the chain is too loose, it can derail from the guide bar, posing a safety risk and reducing cutting efficiency. On the other hand, excessive tightness can lead to overheating, premature wear, and reduced cutting ability. Both scenarios can also lead to an increased risk of kickback, which is a dangerous and potentially lethal occurrence.

Steps To Adjust Chain Tension Correctly

Proper chain tension is crucial for the safe and efficient operation of a chainsaw. Follow these steps to ensure the correct chain tension:

- Turn off the chainsaw and allow it to cool down before proceeding.

- Using a screwdriver, loosen the nuts on the guide bar cover.

- Adjust the tension by turning the tensioning screw according to the manufacturer’s specifications.

- Once the correct tension is achieved, tighten the nuts on the guide bar cover.

- Test the chain tension by pulling it away from the guide bar. It should rotate freely without sagging.

- Finally, ensure the chain is properly lubricated before resuming operation.

Lubrication: Essential For Smooth Cuts

Proper lubrication is crucial for ensuring that your chainsaw operates smoothly and effectively. Without adequate lubrication, your chainsaw’s cutting performance can be severely affected, leading to a frustrating and inefficient experience. In this section, we will explore the consequences of inadequate lubrication and provide you with essential tips on how to lubricate your chainsaw properly.

Consequences Of Inadequate Lubrication

Inadequate lubrication can have detrimental effects on both the performance and longevity of your chainsaw. Here are some of the consequences you may encounter:

- Premature wear and tear: Without proper lubrication, the chainsaw’s chain and bar can experience excessive friction, leading to accelerated wear and tear. This can result in a shorter lifespan for these components and the need for frequent replacements.

- Poor cutting performance: Insufficient lubrication can cause the chain to drag and bind, resulting in a noticeable decrease in cutting efficiency. This can make your chainsaw struggle to cut through wood, leading to uneven and jagged cuts.

- Increased risk of chain damage: Without adequate lubrication, the chain’s drive links can become overheated, leading to increased tension and potential damage. This can lead to chain breakage, posing a safety hazard during operation.

How To Lubricate Your Chainsaw Properly

To ensure optimal performance and longevity of your chainsaw, it is essential to lubricate it properly. Here’s a step-by-step guide on how to do it:

- Choose the right oil: Select a high-quality chainsaw bar and chain oil specifically designed for lubricating chainsaws. Avoid using generic oils or motor oils, as they may not provide adequate lubrication.

- Inspect the oil reservoir: Before starting, check the oil reservoir to ensure it is filled with the appropriate amount of oil. Make sure there are no leaks or blockages that may hinder the oil flow.

- Clean the bar and chain: Use a brush or rag to remove any debris or sawdust from the chain and bar. This will help prevent clogs and allow the lubrication to reach the necessary areas effectively.

- Apply the oil: With the chainsaw turned off, apply the oil directly to the bar and chain. Move the chain manually to ensure even distribution of the lubricant. Avoid over-lubricating, as this can lead to excessive oil consumption and messy operation.

- Monitor the oil level: During operation, periodically check the oil level in the reservoir. Refill it as needed to maintain proper lubrication.

By following these simple steps and ensuring regular lubrication, you can greatly enhance the cutting performance and longevity of your chainsaw. Remember, a well-lubricated chainsaw is a happy chainsaw!

Fuel Issues And Engine Performance

When it comes to chainsaw performance, fuel issues and engine health play a crucial role. If you find your chainsaw struggling to cut through wood or not cutting at all, it may be due to fuel-related problems or engine performance issues. In this section, we will discuss how to identify fuel-related problems and provide tips for maintaining engine health to ensure optimal chainsaw performance.

Fuel-related problems can significantly impact the cutting ability of your chainsaw. Here are a few common fuel issues you may encounter:

- Dirty or clogged fuel filter

- Stale or contaminated fuel

- Incorrect fuel mixture

- Fuel line blockage

- Faulty carburetor

Identifying these issues is crucial to resolve them effectively and restore your chainsaw’s cutting power. Here’s how you can troubleshoot fuel-related problems:

- Check the fuel filter: A dirty or clogged fuel filter can restrict fuel flow, leading to poor engine performance. Regularly inspect and clean the fuel filter to ensure proper fuel flow.

- Inspect the fuel quality: Stale or contaminated fuel can cause engine problems. Make sure to use fresh, high-quality fuel that is specifically recommended for your chainsaw model.

- Verify the fuel mixture: Using the correct fuel mixture is vital for two-stroke engines. Check the manufacturer’s guidelines to ensure you are using the right ratio of gasoline and oil for your chainsaw.

- Clear any fuel line blockages: Blockages in the fuel line can disrupt the fuel supply to the engine. Carefully inspect and remove any debris or obstructions from the fuel line.

- Examine the carburetor: A faulty carburetor can cause fuel delivery problems, affecting the chainsaw’s performance. If you suspect carburetor issues, it is recommended to seek professional assistance for repair or replacement.

Tips For Maintaining Engine Health

In addition to addressing fuel-related problems, maintaining engine health is essential for optimal chainsaw performance. Here are some tips to keep your chainsaw’s engine in top shape:

- Regularly clean the air filter: A clogged air filter can restrict airflow, leading to decreased engine performance. Clean or replace the air filter as recommended by the manufacturer.

- Keep the spark plug clean: The spark plug plays a vital role in the combustion process. Regularly inspect and clean the spark plug to ensure a consistent spark for efficient engine operation.

- Properly lubricate the chain: Insufficient chain lubrication can cause increased friction and premature wear. Regularly lubricate the chain with the recommended oil to maintain smooth cutting performance.

- Monitor engine temperature: Overheating can damage the engine. Avoid prolonged use without breaks and ensure proper cooling to prevent engine overheating.

- Follow maintenance schedules: Adhere to the manufacturer’s recommended maintenance schedules, including regular servicing and tune-ups, to keep your chainsaw running smoothly.

By addressing fuel-related problems and maintaining engine health, you can ensure your chainsaw stays in excellent cutting condition, allowing you to tackle your cutting tasks with ease.

Air Filter Maintenance

When it comes to maintaining your chainsaw, one of the crucial factors to consider is the air filter. The air filter plays a vital role in ensuring proper airflow to the engine, which directly impacts the chainsaw’s performance. Neglecting air filter maintenance can result in reduced cutting efficiency and potential damage to the engine. In this section, we will delve into the impact of a dirty air filter and the importance of cleaning and replacing air filters regularly.

Impact Of A Dirty Air Filter

A dirty air filter restricts airflow to the engine, leading to an imbalanced air-fuel mixture. This imbalance hinders the chainsaw’s ability to generate sufficient power, resulting in decreased cutting performance. Additionally, a clogged air filter can cause the engine to overheat, potentially leading to irreparable damage. Regular inspection of the air filter is essential to prevent these issues and maintain optimal chainsaw functionality.

Cleaning And Replacing Air Filters

Regular cleaning and replacement of the air filter are imperative to ensure uninterrupted chainsaw operation. Begin by removing the air filter cover and gently tapping the filter to dislodge any accumulated debris. Next, use compressed air or a mild detergent solution to clean the filter thoroughly. Allow the filter to dry completely before reinstalling it. If the air filter shows signs of wear or damage, it is advisable to replace it with a compatible filter to maintain peak performance.

Bar Damage And Wear

One common reason why your chainsaw may not be cutting efficiently is due to bar damage and wear. Detecting issues with the bar is crucial for maintaining the performance and longevity of your chainsaw.

Detecting Bar Damage

- Look for visible signs of wear such as grooves or cracks on the bar surface.

- Check for bent or warped areas that can affect the alignment of the chain.

- Inspect the rails for any burrs or uneven surfaces that can hinder smooth chain movement.

Repair Or Replace? Making The Right Choice

- If the damage is minimal, you can try to repair it by filing out minor imperfections.

- For extensive damage or wear, it is advisable to replace the bar to ensure optimal cutting performance.

- Consult a professional if you are unsure about the extent of the damage or the best course of action.

Troubleshooting Guide: Step By Step

Initial Assessment For Quick Fixes

When your chainsaw isn’t cutting, follow these steps:

- Check the chain tension and alignment.

- Inspect the chain for dull or damaged teeth.

- Ensure the chain brake is disengaged.

In-depth Inspection For Persistent Issues

For more complex problems, conduct a detailed examination:

- Inspect the chain bar for damage or warping.

- Examine the drive sprocket for wear and tear.

- Clean the air filter and check the spark plug.

Preventative Measures For Long-term Performance

Ensure long-term performance of your chainsaw by taking preventative measures. Identify potential issues like a dull chain, improper lubrication, or worn-out parts. Regular maintenance and following manufacturer’s guidelines will keep your chainsaw cutting efficiently.

Routine Maintenance Checklist

Regularly inspect chain tension, sharpness, and lubrication levels.

Clean air filters and spark plugs, and check for fuel leaks.

Replace worn-out parts promptly to avoid damage.

Best Practices For Chainsaw Storage

Keep chainsaws in a dry, cool place away from direct sunlight.

Store them in a secure location out of reach of children.

Use fuel stabilizers and empty the tank before long-term storage.

Preventative Measures for Long-Term Performance

To ensure your chainsaw’s longevity, follow a routine maintenance checklist and implement best practices for storage.

By regularly maintaining and properly storing your chainsaw, you can enhance its durability and performance.

Conclusion: Ensuring Cutting Precision

To ensure cutting precision with your chainsaw, first check the chain tension and sharpness. Proper lubrication and correct technique are also crucial for effective cutting. Additionally, inspect the guide bar for any damage that may affect the cutting performance. Regular maintenance is key to keeping your chainsaw in top cutting condition.

Recap Of Key Troubleshooting Tips

Ensure chain tension, sharpen blades, use proper fuel mix.

The Value Of Regular Chainsaw Care

Regular care prevents blade dullness, maximizes cutting efficiency.

Frequently Asked Questions

Why Is My Chainsaw Not Cutting Properly?

If your chainsaw is not cutting effectively, it may need a sharpened chain, proper chain tension, or a clean air filter.

How Often Should I Sharpen My Chainsaw Chain?

Sharpen your chainsaw chain after every 2-3 uses or when you notice it starts to cut less efficiently.

What Can Cause A Chainsaw Chain To Become Dull?

Factors like hitting the ground, cutting dirty wood, or hitting rocks can contribute to a chainsaw chain becoming dull.

How Do I Properly Tension The Chainsaw Chain?

To ensure proper tension, adjust the tension until the chain can be pulled easily by hand but is not sagging from the bar.

Conclusion

Troubleshooting why your chainsaw is not cutting is essential for its performance. By understanding the potential issues and implementing the appropriate solutions, you can ensure that your chainsaw operates effectively. Regular maintenance and proper usage are key factors in preventing cutting problems and extending the lifespan of your chainsaw.