Why is My Polyurethane Sticky?: Quick Fixes Revealed

Polyurethane becomes sticky due to improper curing, high humidity, or applying too many layers without proper drying time. Environmental conditions and the type of polyurethane used can also contribute to this issue.

Polyurethane is a popular finish for various surfaces, known for its durability and sheen. Many people choose it for wood floors, furniture, and crafts. Despite its benefits, users sometimes encounter a sticky texture after application. This stickiness can be frustrating, especially when you expect a smooth finish.

Understanding the reasons behind this problem can help you troubleshoot effectively. Factors like humidity, application techniques, and product choices play crucial roles. Addressing these issues can lead to successful projects and a satisfying end result. Let’s explore the common causes of sticky polyurethane and how to fix them.

Introduction To Sticky Polyurethane Issues

Sticky polyurethane can be frustrating. It often occurs in various projects, from furniture to flooring. Understanding the causes and effects helps in finding solutions.

Common Causes

- Humidity: High moisture levels can make polyurethane sticky.

- Temperature: Cold temperatures slow down drying.

- Incorrect Mixing: Improperly mixed components can cause issues.

- Old Product: Expired polyurethane might not cure properly.

- Too Thick Application: Applying too much can lead to stickiness.

Impact On Surfaces

Sticky polyurethane affects various surfaces in several ways:

| Surface Type | Impact |

|---|---|

| Wood | Can trap dust and dirt. |

| Metal | May cause corrosion over time. |

| Concrete | Leaves an uneven finish. |

Sticky polyurethane can ruin the appearance of your project. It creates an unpleasant surface that attracts dirt. Regular maintenance becomes necessary to keep surfaces clean.

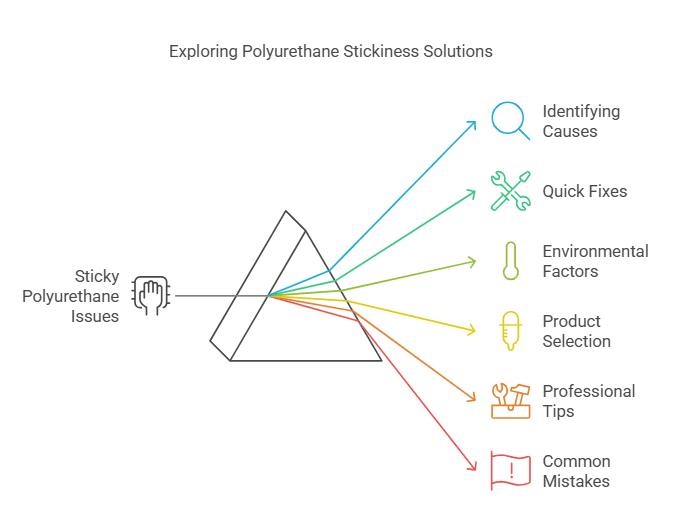

Identifying The Source Of Stickiness

Understanding why your polyurethane is sticky helps you solve the issue. Two main reasons often cause this problem. They are incorrect application techniques and environmental factors. Let’s explore these sources in detail.

Incorrect Application Techniques

Improper methods can lead to a sticky finish. Common mistakes include:

- Applying too thick a layer

- Not mixing components properly

- Using the wrong type of brush or roller

- Skipping the recommended drying time

Here’s a quick overview of application techniques:

| Technique | Issue | Solution |

|---|---|---|

| Thick Application | Traps moisture | Apply thin layers |

| Poor Mixing | Inconsistent cure | Mix thoroughly |

| Wrong Tools | Poor finish | Use recommended tools |

| Skipping Dry Time | Sticky residue | Follow drying instructions |

Environmental Factors

Environmental conditions greatly affect polyurethane drying. High humidity can slow drying times. Low temperatures can also lead to stickiness.

- Ideal temperature: 70-85°F

- Humidity levels: 40-60%

Check your workspace for:

- Ventilation

- Temperature control

- Humidity levels

Maintaining these conditions promotes a smooth, non-sticky finish.

Quick Fixes For Sticky Polyurethane

Sticky polyurethane can be frustrating. Fortunately, there are quick fixes to resolve this issue. Proper surface preparation and reapplication techniques can help restore your finish.

Surface Preparation

Start by preparing the surface properly. Follow these steps:

- Clean the Surface: Use a mild soap solution.

- Dry Completely: Ensure the surface is fully dry.

- Sand Lightly: Use fine-grit sandpaper for smoothness.

- Remove Dust: Wipe away dust with a damp cloth.

Proper surface preparation can reduce stickiness.

Reapplication Tips

Reapplying polyurethane correctly can fix stickiness. Follow these tips:

- Choose the Right Product: Use high-quality polyurethane.

- Thin Layers: Apply thin coats for better drying.

- Wait Time: Allow sufficient drying time between coats.

- Temperature Control: Keep the area warm and well-ventilated.

These steps will help you achieve a smooth, non-sticky finish.

The Role Of Humidity And Temperature

Humidity and temperature greatly affect polyurethane drying. Understanding their impact helps solve sticky issues. High humidity and low temperatures can cause problems. Knowing the optimal conditions is key for success.

Optimal Conditions For Drying

Polyurethane dries best in specific conditions. Here are the optimal settings:

| Condition | Optimal Level |

|---|---|

| Temperature | 70°F to 80°F (21°C to 27°C) |

| Humidity | 40% to 60% |

These conditions help polyurethane cure properly. Avoid areas with high moisture or extreme heat.

Adjustments For Humid Climates

In humid climates, adjustments are necessary. Here are effective strategies:

- Use a Dehumidifier: This lowers moisture in the air.

- Avoid Outdoor Application: Stay indoors on humid days.

- Choose Fast-Drying Formulas: These cure quicker in humidity.

- Increase Airflow: Fans can help circulate air.

Applying these tips helps reduce stickiness. Proper care leads to a smooth finish.

Choosing The Right Polyurethane Product

Choosing the right polyurethane product is crucial. The type you select affects performance and finish. Understanding different options helps avoid sticky situations.

Oil-based Vs. Water-based

Oil-based and water-based polyurethane serve different needs. Below are their key differences:

| Feature | Oil-Based | Water-Based |

|---|---|---|

| Drying Time | Longer drying time | Faster drying time |

| Durability | More durable | Less durable |

| Odor | Stronger odor | Low odor |

| Cleaning | Requires solvents | Soap and water |

| Finish | Rich, amber tone | Clear, non-yellowing |

Brand And Quality Considerations

Choosing a reputable brand matters. High-quality polyurethane prevents stickiness. Consider these factors:

- Brand Reputation: Research customer reviews.

- Ingredients: Check for high-quality components.

- Application: Follow specific application guidelines.

- Warranty: Look for product guarantees.

Investing in quality saves time and effort. Avoid cheap brands. They often lead to sticky results.

Professional Tips For Smooth Application

Achieving a smooth finish with polyurethane can be challenging. Follow these professional tips to avoid stickiness and ensure a flawless application.

Tool Selection

Choosing the right tools makes a big difference. Here are some recommended tools:

- High-Quality Brushes: Use natural bristle brushes for oil-based polyurethane.

- Foam Rollers: Ideal for water-based products.

- Lint-Free Cloths: Useful for wiping surfaces before application.

- Drop Cloths: Protect floors and furniture from spills.

Ensure your tools are clean and dry. Dirty tools can lead to a sticky finish.

Applying Thin Layers

Thin layers help prevent stickiness. Follow these steps for best results:

- Start with a clean, dust-free surface.

- Pour a small amount of polyurethane into a tray.

- Dip your brush or roller lightly into the product.

- Apply in long, even strokes. Avoid overloading the brush.

- Allow each coat to dry completely before applying the next.

Typically, two to three thin layers work best. This technique ensures a smooth, durable finish.

Troubleshooting Common Mistakes

Understanding why your polyurethane is sticky can help solve problems. Common mistakes can lead to this sticky issue. Let’s explore some frequent errors and how to fix them.

Mixing Brands

Using different brands of polyurethane can cause issues. Each brand has unique chemicals. Mixing them can lead to a sticky finish. Here are some tips:

- Always use the same brand for all coats.

- Check the manufacturer’s recommendations.

- Test on a small area before full application.

Failing To Sand Between Coats

Sanding between coats is crucial for a smooth finish. Skipping this step can trap moisture and create stickiness. Follow these steps for best results:

- Allow each coat to dry completely.

- Use fine-grit sandpaper (220 grit or higher).

- Clean the surface to remove dust after sanding.

By avoiding these common mistakes, you can achieve a perfect polyurethane finish. A little care goes a long way in preventing stickiness.

Maintaining Polyurethane-finished Surfaces

Maintaining polyurethane-finished surfaces is essential for their longevity. Proper care ensures they remain beautiful and functional. A well-maintained surface prevents issues like stickiness. Regular upkeep saves time and money in the long run.

Regular Cleaning

Clean your polyurethane surfaces regularly to keep them looking new. Use a soft cloth and mild soap. Avoid harsh chemicals. Follow these steps for effective cleaning:

- Dust the surface with a soft cloth.

- Mix water with a few drops of mild soap.

- Dampen a cloth in the mixture.

- Wipe the surface gently.

- Dry with a clean, soft cloth.

Cleaning frequency depends on usage. High-traffic areas need more attention. Consider cleaning every few weeks.

When To Reapply

Reapplying polyurethane maintains the finish. Look for signs of wear, like:

- Fading color

- Visible scratches

- Sticky or tacky feel

Reapply every few years or as needed. Follow these steps for reapplication:

- Sand the surface lightly.

- Clean any dust or debris.

- Apply a fresh coat of polyurethane.

- Let it dry completely.

Proper maintenance prevents stickiness and keeps surfaces appealing. Regular cleaning and timely reapplication are key.

Frequently Asked Questions

Why Is My Polyurethane Not Drying Properly?

Polyurethane may not dry due to high humidity or low temperatures. Ensure your workspace is well-ventilated and the temperature is between 70-80°F. Also, check if the product is expired, as old polyurethane may not cure correctly. Using thick coats can also delay drying time.

How Can I Fix Sticky Polyurethane?

To fix sticky polyurethane, lightly sand the surface with fine-grit sandpaper. After sanding, clean the dust off and apply a fresh coat of polyurethane. Make sure to follow the manufacturer’s instructions regarding application thickness and drying times to prevent stickiness in the future.

Is Sticky Polyurethane Dangerous?

Sticky polyurethane is generally not dangerous, but it can be problematic. The stickiness indicates that the finish hasn’t cured properly, which can attract dust and debris. Ensure proper ventilation while working with polyurethane to minimize any potential health risks from fumes.

How Long Does Polyurethane Take To Cure?

Polyurethane typically takes 24 to 48 hours to dry to the touch. However, full curing can take up to a month, depending on the product and environmental conditions. Always refer to the manufacturer’s guidelines for specific curing times to ensure optimal results.

Conclusion

Sticky polyurethane can be frustrating, but understanding its causes helps. Factors like humidity, improper mixing, or insufficient curing time contribute to this issue. By following best practices during application, you can achieve a smooth, durable finish. Addressing these concerns ensures your projects look great and last longer.

Don’t let stickiness ruin your hard work!