3 Rail Wood Fence Calculator: Estimate with Ease!

A 3 rail wood fence calculator helps determine the materials needed for installation. It calculates the number of posts, rails, and other components based on the fence dimensions.

Building a 3 rail wood fence can enhance your property’s aesthetics and provide security. Using a calculator simplifies the planning process, ensuring you purchase the right amount of materials. These calculators take into account various factors, including the length of the fence and the spacing of posts.

Knowing how many rails and posts you need saves time and reduces waste. Whether you’re a DIY enthusiast or hiring professionals, accurate calculations are essential. This guide will cover how to effectively use a 3 rail wood fence calculator and the benefits of implementing one for your fencing project.

Introduction To 3 Rail Wood Fences

3 rail wood fences have gained popularity due to their aesthetic appeal and durability. They provide a charming look for both rural and suburban homes. Homeowners appreciate the versatility of these fences, as they can suit various landscapes. These fences also offer a secure boundary for pets and children.

Benefits include low maintenance and long-lasting materials. The open design allows for visibility and does not block views. Many people choose wood for its natural appearance and ability to blend with surroundings. Various wood types, like cedar and pine, enhance the fence’s longevity and style.

Key components of a 3 rail wood fence include posts, rails, and pickets. Proper spacing ensures stability and strength. Calculators can help determine the exact materials needed for installation.

Essential Measurements

To determine the fence length, measure the total perimeter of the area. This includes all sides where the fence will be installed. Make sure to note any gates or obstacles that may affect the length.

Calculating post spacing is essential for a sturdy fence. Typically, posts should be spaced 6 to 8 feet apart. This distance ensures the fence remains strong and stable. For a three-rail wood fence, consider the height of the rails and the total length to determine the number of posts needed.

| Post Spacing (Feet) | Number of Posts (for 100 FT fence) |

|---|---|

| 6 | 17 |

| 8 | 13 |

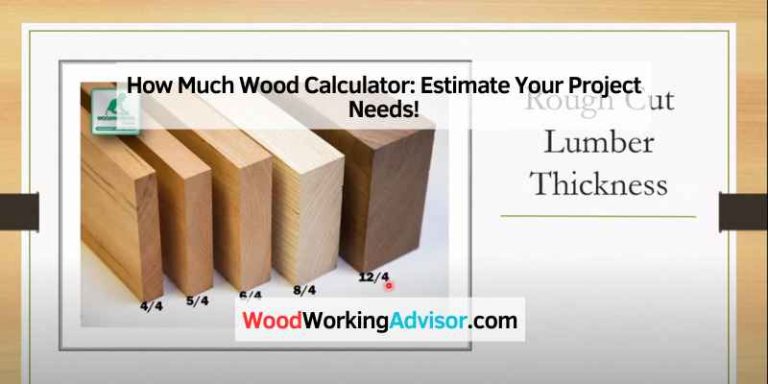

Material Estimates

Choosing the right wood for your fence is essential. Different types of wood offer various benefits. Common options include cedar, pine, and redwood. Cedar is known for its natural resistance to decay. Pine is affordable and easy to work with. Redwood has a beautiful color and is very durable.

Each option has its own cost and maintenance needs. Cedar may require less maintenance than pine. Redwood can be pricier but offers great longevity.

| Wood Type | Durability | Cost | Maintenance |

|---|---|---|---|

| Cedar | High | Medium | Low |

| Pine | Medium | Low | Medium |

| Redwood | Very High | High | Low |

Tools And Supplies

Gathering the right tools is essential for building a 3 rail wood fence. Here is a list of necessary tools:

- Post hole digger – For digging holes for the fence posts.

- Level – Ensures the fence is straight and even.

- Measuring tape – To measure distances accurately.

- Hammer – For driving nails into the wood.

- Saw – Needed for cutting wood to size.

Additional supplies needed include:

- Wooden rails – Essential for the fence structure.

- Fence posts – Required to support the rails.

- Nails or screws – To secure the rails to the posts.

- Concrete mix – To set the posts firmly in the ground.

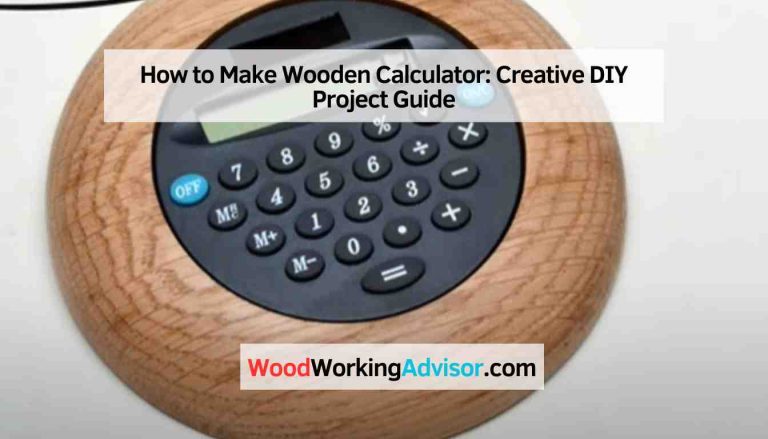

Step-by-step Calculation Process

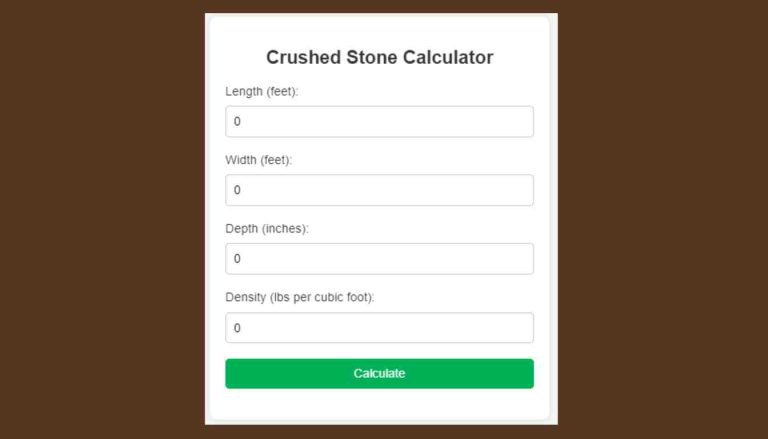

Begin by measuring the length and height of your desired fence. Use a tape measure for accuracy. Record these measurements clearly.

Next, input these values into a wood fence calculator. Most calculators will ask for fence length and rail spacing. Ensure you include the total number of posts needed.

Understanding the results is crucial. The calculator will display the total materials required. This includes the number of rails, posts, and boards.

Check the material costs displayed. Compare prices from different suppliers to get the best deal. This will help in budgeting for your fence project.

Cost Estimation

Estimating the cost of a 3 rail wood fence involves several factors. Material costs include lumber, hardware, and post requirements. Prices may vary based on local suppliers and the type of wood chosen.

Breaking down these costs helps in budgeting effectively. For example, a typical wood post costs around $5 to $10 each. Rails usually range from $3 to $7 per piece, depending on the quality.

| Material | Estimated Cost |

|---|---|

| Wood Post | $5 – $10 |

| Rails | $3 – $7 |

| Hardware | $50 – $100 |

Labor expenses also need consideration. Hiring a professional can cost between $25 to $50 per hour. The total labor cost will depend on the project size and complexity.

Installation Tips

Start by clearing the area where the fence will go. Remove any rocks, debris, or vegetation. This helps ensure a smooth installation.

Next, mark the fence line using stakes and string. This gives a clear path for your fence. Measure the distances between posts for accuracy.

For setting posts, dig holes that are at least two feet deep. This provides stability for your fence. Space the posts evenly, typically 6 to 8 feet apart.

After placing the posts, secure them with concrete. Allow the concrete to cure before moving on. This ensures your posts are strong and sturdy.

Attach the rails to the posts using screws or nails. Ensure they are level for a neat appearance. Check that the rails are securely fastened.

Advanced Considerations

Handling uneven terrain for a wood fence can be tricky. Adjust the fence height at various points to maintain a consistent look. Use stepped or contoured designs to follow the land’s shape.

For dealing with obstacles, measure around trees or rocks. This helps avoid damage and provides a clean line. Consider using gates or breaks in the fence to navigate these challenges. Planning ahead will save time and effort during installation.

Maintenance And Upkeep

Routine maintenance keeps your wood fence looking great. Regularly check for damaged boards or loose nails. Replace any broken parts immediately to avoid further issues. Clean the fence at least once a year to remove dirt and mildew. Use a gentle soap and water mixture for washing.

Applying a protective sealant every few years is crucial. This helps prevent wood rot and insect damage. Inspect the fence regularly for signs of rust or decay. Early detection can save time and money on repairs.

Long-term care requires occasional staining or painting. Choose a high-quality product that offers UV protection. This helps maintain the color and integrity of the wood. Proper upkeep will extend the lifespan of your fence significantly.

Frequently Asked Questions

What Is The Spacing For Rails On A 3 Rail Fence?

The spacing for rails on a 3-rail fence typically ranges from 5 to 7 inches apart. Ensure consistent spacing for a uniform look. Adjustments may be necessary based on the fence height and design preferences. Always consult local guidelines for specific requirements.

Do You Need 3 Rails For A 6 Foot Fence?

Yes, a 6-foot fence typically requires three rails for proper support and stability. The top, middle, and bottom rails ensure the panels remain secure and withstand wind pressure. Using three rails is advisable for durability and to maintain the fence’s integrity over time.

How Many Rails Do You Need For A Wooden Fence?

For a wooden fence, typically two to three rails are needed per section. The exact number depends on the fence height and design. Standard fences often use two rails for stability, while taller ones may require three. Always consider local building codes and personal preferences.

How Do You Calculate Post And Rail Fencing?

To calculate post and rail fencing, measure the total fence length. Divide by the rail length to find the number of rails needed. For posts, add one post for each rail section and two additional posts at ends. Adjust calculations based on local regulations and spacing preferences.

Conclusion

Calculating the materials for your rail wood fence is essential for a successful installation. Using a fence calculator simplifies this process, ensuring accuracy and efficiency. With the right tools and measurements, you can create a sturdy and attractive fence. Start planning today to enjoy your beautiful, functional outdoor space.