Ash Lumber Prices: Proven Savings

Get the most for your money with ash lumber by understanding price factors, buying smart, and minimizing waste. Learn how slight shifts in your approach can lead to significant savings on your next woodworking project, turning what seems like an expense into a wise investment.

Hey there, woodworking friends! Md Meraj here. Have you ever looked at the price tag on lumber and felt a little overwhelmed? It’s a common feeling, especially when you’re just starting out. Ash lumber is beautiful and strong, perfect for so many projects, but sometimes its price can seem a bit steep. You might be wondering if there are secret ways to get great ash wood without breaking the bank. Well, you’re in the right place!

Many beginners feel this pinch, but I promise, with a few smart tips and a little know-how, you can absolutely make ash lumber work for your budget. We’ll walk through everything you need to know to find the best deals and use your wood wisely. Let’s uncover some proven ways to save on ash lumber!

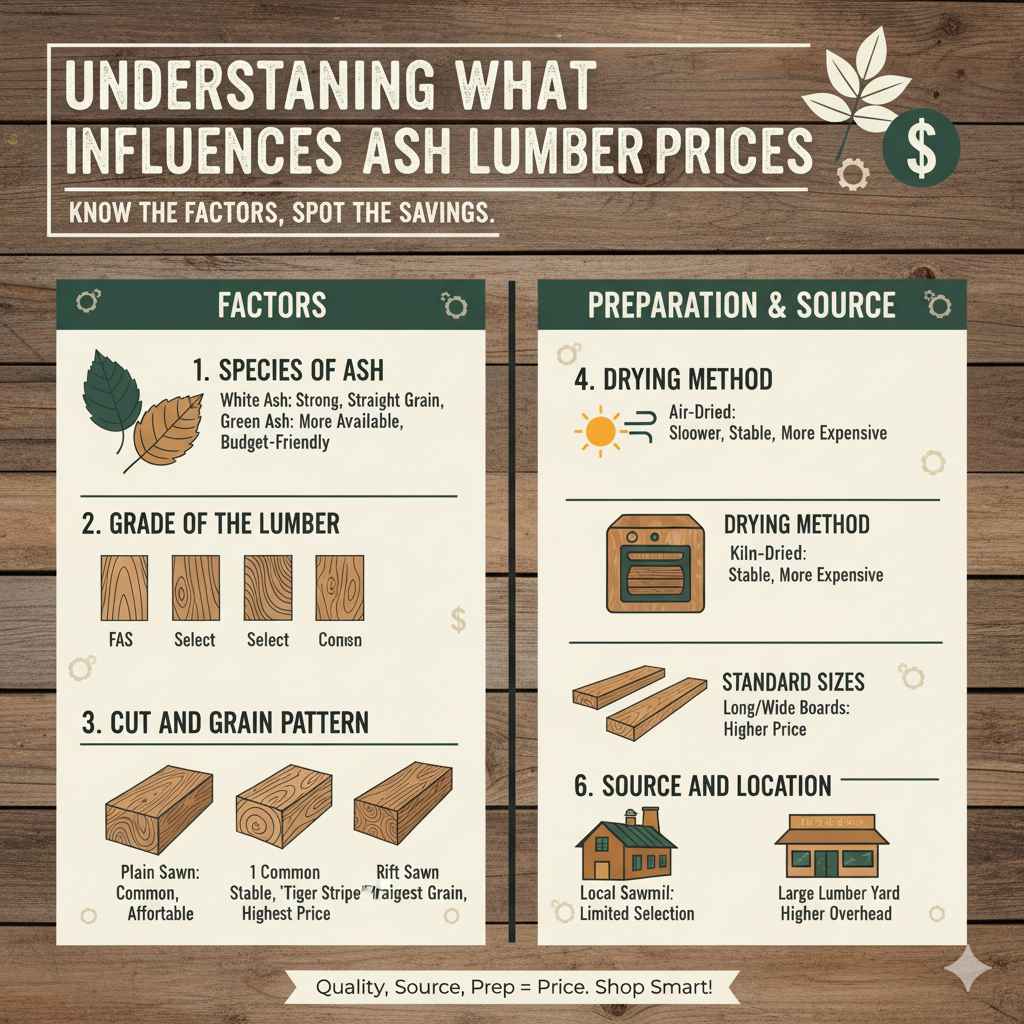

Understanding What Influences Ash Lumber Prices

Before we dive into saving money, it’s super important to understand why ash lumber costs what it does. Think of it like shopping for anything else – the quality, the source, and how it’s prepared all play a big role. Knowing these factors helps you spot a good deal and avoid overpaying.

1. Species of Ash

Did you know there are different types of ash trees? The most common ones you’ll find in lumber yards are White Ash (Fraxinus americana) and Green Ash (Fraxinus pennsylvanica). White Ash is generally considered more desirable for woodworking because of its strength and straight grain, making it a bit pricier. Green Ash is often more readily available and can be a more budget-friendly option, though its properties might vary.

2. Grade of the Lumber

Lumber is graded based on the size and number of defects (like knots, checks, and sapwood) present. Higher grades mean fewer defects and a more visually appealing, consistent board. Expect to pay more for higher grades like FAS (Firsts and Seconds) or Select, which are ideal for furniture and fine woodworking. Lower grades, like 1 Common or 2 Common, have more imperfections but are perfectly suitable for many projects where aesthetics are less critical or where you plan to paint or cover them.

FAS (Firsts and Seconds): The highest grade, with very few defects. Best for quality furniture.

Select: Similar to FAS, often used for solid wood components like doors and trim.

1 Common: Good for furniture and cabinets, allows for more knots but still generally usable.

2 Common: More knots and imperfections, suitable for utility purposes or projects where those are acceptable.

3. Cut and Grain Pattern

How the lumber is cut from the log affects its appearance and price. Plain sawn lumber is the most common and least expensive. Quarter sawn lumber, which is cut at a 90-degree angle to the growth rings, results in a more stable board with a beautiful straight grain (often called “tiger stripe” in ash) and is significantly more expensive. Rift sawn is another variation, offering even straighter grain but at a premium price. For most DIY projects, plain sawn ash offers the best balance of cost and appearance.

4. Drying Method

Lumber can be air-dried or kiln-dried. Air-dried wood is left to dry naturally, which is a slower process and can be more economical. However, it may take longer to become stable and can be more prone to insect damage or warping if not stored properly. Kiln-dried lumber is dried in a specialized oven, which is faster and results in a more uniformly dried, stable product. Kiln-dried wood is generally more expensive due to the energy and time involved. For most indoor projects, kiln-dried is preferred for its stability.

5. Dimensions (Thickness, Width, Length)

Standard lumber dimensions are more readily available and typically cheaper than custom or non-standard sizes. For instance, buying common thicknesses like 4/4 (1 inch nominal), 6/4, or 8/4 will usually be more economical than ordering custom thicknesses. Longer or wider boards also tend to be more expensive because they are rarer. Planning your project to use readily available dimensions can significantly cut costs.

6. Source and Location

Where you buy your lumber matters. Buying directly from a local sawmill can often be cheaper than purchasing from a large lumber yard, as you cut out the middleman. However, availability and selection might be limited. Large lumber yards can offer wider selections and more consistent quality but may have higher overheads reflected in their prices. Prices also fluctuate based on regional supply and demand.

Proven Strategies for Saving on Ash Lumber

Now that we understand the “why” behind ash lumber prices, let’s get to the “how” of saving money. These strategies are tried and true, and they’ll help you stretch your lumber budget further without sacrificing quality.

1. Buy from Local Sawmills or Wood Turners

The biggest savings often come from bypassing traditional retail lumber yards. Local sawmills are fantastic sources for ash lumber. They often sell directly to the public at lower prices. You might need to be a bit flexible with dimensions and grading, but the savings can be substantial. Some sawmills also sell “off-cuts” or slightly imperfect pieces at a steep discount – perfect for smaller projects or learning.

Wood turners or woodworkers who deal in larger quantities might also have surplus ash lumber they are willing to sell. It’s worth reaching out to local woodworking guilds or associations to see if anyone has stock they’d like to move.

2. Purchase Less Than “Perfect” Grades Strategically

Don’t be afraid of lower-grade lumber if your project allows for it! For example, if you’re building shop cabinets, a workbench, or a painted piece of furniture, #1 Common or even #2 Common ash can be an excellent choice. You can often cut around smaller knots or stains. The savings per board foot can be significant. You’ll just need to be a bit more mindful during the cutting and design phase to work around the imperfections.

3. Buy in Bulk (When It Makes Sense)

If you have a large project or a series of projects planned, buying ash lumber in larger quantities can sometimes lead to a better per-board-foot price. Many lumber suppliers offer discounts for bulk purchases. However, be cautious here:

Storage: Do you have adequate, dry space to store the lumber properly? Improper storage can lead to warping or damage, negating any savings.

Need: Are you sure you’ll use it all? Buying too much can be wasteful.

Capital: Ensure you have the upfront cash flow for a large purchase.

4. Utilize Standard Dimensions and Sourcing

When planning your project, try to design around commonly available lumber dimensions. For instance, 4/4 (1-inch nominal), 6/4 (1.5-inch nominal), and 8/4 (2-inch nominal) thicknesses are usually stocked and priced better than special orders. Similarly, standard widths like 6-inch, 8-inch, and 10-inch boards are more common. Sourcing from suppliers who carry these standard sizes will almost always be cheaper than requesting custom cuts.

5. Look for Off-Cuts and Scraps

Many lumber yards and sawmills have bins or areas filled with off-cuts and shorter pieces of lumber. These are often sold at a significant discount. While they might not be long enough for a large tabletop, they are perfect for smaller projects, drawer parts, decorative trim, tool handles, or practice pieces for joinery. Always check these areas first!

6. Consider Rough Sawn Lumber (If You Have the Tools)

Rough sawn lumber is lumber that has not been planed or jointed after it was cut at the mill. It’s often sold for a lower price per board foot than surfaced lumber. If you have a jointer and planer, you can save money by buying rough lumber and milling it yourself. This requires extra tools and time, but the savings can be substantial, especially for larger projects. A good resource for milling lumber is often found through woodworking associations or DIY forums like those on WoodworkingTalk.

7. Learn to Identify and Work Around Defects

Part of the savings comes from your own skill. Learning to identify potential problems in lumber (like cupping, bowing, twisting, or checks) before you buy it is crucial. Inspect boards carefully. Sometimes, a board with a slight warp can be straightened with careful clamping and glue-ups if you have enough excess length. Learning to read the wood means you can sometimes buy a board that others might pass over, at a lower price, and still end up with usable material.

8. Plan Your Cuts Meticulously

Measure twice, cut once is more than a saying; it’s a money-saving mantra. Before you even buy the wood, create a cutting diagram for your project. Lay out your desired pieces on the dimensions of the lumber you plan to buy. This helps you:

Buy only what you need: Avoid purchasing excess lumber.

Maximize yield: Plan cuts to get the most pieces from each board.

Identify usable scraps: See which off-cuts might be useful for other parts.

Software like SketchUp or even just graph paper can help you plan your cuts efficiently.

9. Look for Sales and Second-Hand Sources

Keep an eye out for seasonal sales at lumber yards. Sometimes, they’ll have promotions on specific wood species. Also, explore local classifieds, online marketplaces like Facebook Marketplace, or even auctions. You might find a hobbyist or contractor selling off excess ash lumber at a fraction of retail price. Just be sure to inspect the wood carefully in person before purchasing.

Comparing Ash Lumber Prices: A Sample Table

To give you a clearer picture, let’s look at a hypothetical price comparison for ash lumber. Prices can vary wildly based on the factors we discussed, but this table illustrates common ranges. Remember to always get current quotes from your local suppliers!

| Lumber Type/Grade | Typical Thickness | Estimated Price Range (per Board Foot) | Best Use Case |

|---|---|---|---|

| White Ash, FAS Grade | 4/4 (1 inch) | $6.00 – $10.00 | High-end furniture, projects where appearance is paramount. |

| White Ash, #1 Common | 4/4 (1 inch) | $4.50 – $7.00 | Cabinet doors, tabletops, general furniture construction. |

| Green Ash, #1 Common | 4/4 (1 inch) | $4.00 – $6.00 | Utility projects, shop furniture, painted pieces. |

| Ash, Rough Sawn (Unspecified Grade) | 4/4, 6/4, 8/4 | $3.00 – $5.00 | Projects requiring milling, cost-conscious large projects. |

| Ash Off-cuts/Scraps | Varies | $1.00 – $2.50 | Small projects, turning blanks, jigs, craft items. |

Note: Prices are estimates and can vary significantly by region, supplier specialization, and current market conditions.

What Can You Make with Ash Lumber? (Budget-Friendly Ideas)

Ash is a versatile hardwood, known for its shock resistance and strength, making it suitable for a wide range of projects. Here are some ideas, keeping budget and beginner-friendliness in mind:

- Shop Workbench: Ash is incredibly durable and can handle heavy use. Building a sturdy shop workbench with ash legs and a top is a fantastic project that pays for itself in workshop utility. You might even use lower-grade or rougher ash for this.

- Tool Handles: Ash’s shock resistance makes it ideal for tool handles (like for hammers or axes). You can often find smaller pieces or off-cuts perfect for this.

- Cutting Boards: While maple is more common, ash can be used for cutting boards, especially if you prioritize its beautiful grain. You’ll need to ensure it’s food-safe and sealed properly.

- Small Furniture Accents: Think end tables, simple stools, or shelving units. Ash provides a beautiful, strong wood for these items, and smaller projects mean less lumber cost upfront.

- Picture Frames or Mirror Frames: For a more upscale look, ash can create stunning frames. The straight grain of ash works particularly well here, and you can often use narrower, less expensive boards.

- Decorative Boxes: Whether for keepsake or storage, ash offers a lovely grain pattern that can make even simple box designs look elegant.

- Veneer Projects: If you can find ash veneer at a good price, you can apply it to less expensive substrates like MDF or plywood for a high-end look at a fraction of the cost of solid ash.

Safety First When Buying and Using Lumber

Even when you’re focused on saving money, safety should always be your top priority. Here are some essential safety considerations:

- Inspect Lumber for Pests: Ensure the lumber you buy is free from active insect infestations. While some old insect trails are fine, look for sawdust or live insects.

- Wear Safety Gear: Always wear safety glasses when handling or cutting wood. Hearing protection is also crucial when using loud machinery.

- Handle Lumber Safely: Lumber can be heavy and awkward. Use proper lifting techniques and get help if needed. Be aware of sharp edges or splinters.

- Dust Control: Wood dust, especially from hardwoods like ash, can be harmful if inhaled over time. Use dust collection systems and wear a dust mask. The Occupational Safety and Health Administration (OSHA) provides valuable resources on wood product safety.

- Familiarize Yourself with Tools: Before cutting or shaping ash, ensure you are comfortable and safe with your tools. Read manuals and consider taking a basic woodworking safety course if you’re new to certain equipment.

Frequently Asked Questions (FAQs)

Here are some common questions beginners have about ash lumber prices and how to save.

Q1: Is ash lumber more expensive than oak?

Generally, ash and oak are in a similar price range for comparable grades and species. White ash can sometimes be slightly less expensive than red or white oak, but this varies greatly by region and availability. Both are excellent, durable hardwoods.

Q2: Where can I find the cheapest ash lumber?

The cheapest ash lumber is typically found directly from local sawmills, especially if you’re willing to buy rough-sawn, lower-grade, or slightly imperfect boards. Checking online marketplaces and even asking around at woodworking clubs can also lead to great deals.

Q3: Should I buy rough-sawn ash or surfaced ash?

If you have a jointer and planer, buying rough-sawn ash is usually significantly cheaper per board foot. You save money by doing the milling yourself. If you don’t have this equipment, buy surfaced (S4S – surfaced four sides) ash, which will be more expensive but ready to use.

Q4: How do I store ash lumber to prevent problems?

Store ash lumber flat in a dry, climate-controlled environment. Use stickers (small strips of wood) between boards to allow for air circulation. Avoid storing it where it will be exposed to direct sunlight, extreme humidity changes, or moisture, as this can cause warping, cracking, or mold.

Q5: What’s the difference between White Ash and Green Ash pricing?

White Ash is often slightly more expensive because it’s generally considered superior for furniture due to its straighter grain and specific workability. Green Ash is more common and robust in varied conditions, making it a more accessible and often cheaper option, though its visual appeal and working properties can be slightly less refined.

Q6: Can I use ash lumber for outdoor projects?

While ash is quite strong, it’s not naturally as rot-resistant as some other hardwoods like cedar or redwood. For outdoor projects that will be exposed to the elements, it’s best to use White Ash and seal it very thoroughly with a good exterior finish or consider a more rot-resistant wood. Some sources, like USDA Forest Products Laboratory, provide extensive data on wood properties.

Conclusion: Smart Shopping for Beautiful Ash Wood<

Saving money on ash lumber is entirely achievable with the right approach. By understanding how it’s priced, being strategic about where and what you buy, and planning your projects wisely, you can significantly reduce your material costs. Don’t shy away from slightly imperfect grades if your project allows, explore local sawmills, and always inspect wood carefully. Remember, woodworking is about creativity and resourcefulness. With these tips, you can confidently select beautiful, strong ash lumber that fits your budget, allowing you to craft wonderful projects without the financial worry. Happy building!