Bcx Vs Cdx Plywood: Which is Best for Your Project?

Choosing the right plywood can be tricky. BCX and CDX are popular options.

Both have their strengths and weaknesses. Understanding the differences between BCX and CDX plywood is crucial for your projects. BCX plywood is known for its smoother surface, making it ideal for visible areas. On the other hand, CDX plywood is often used for structural purposes.

Knowing when to use each type can save you time and money. This comparison will help you decide which plywood fits your needs best. Let’s dive into the key differences and uses of BCX and CDX plywood.

Credit: www.reddit.com

Introduction To Bcx And Cdx Plywood

BCX Plywood is a type of wood panel. It has a smooth surface on one side. The other side is rough. BCX stands for B-grade on one side and C-grade on the other. It is often used for outdoor projects. The smooth side is nice to look at. The rough side is usually hidden. BCX Plywood is strong and durable. It can handle moisture and weather.

CDX Plywood is another type of wood panel. It has C-grade on one side and D-grade on the other. The “X” means it has exterior glue. CDX is less smooth than BCX. It is often used for subfloors and roofs. CDX Plywood is also durable. It can handle moisture and weather. But it is not as smooth as BCX.

Key Differences

BCX plywood has a smooth surface. It is sanded and looks neat. CDX plywood has a rough surface. It is not sanded. BCX is better for painting. CDX is best for roofing and walls.

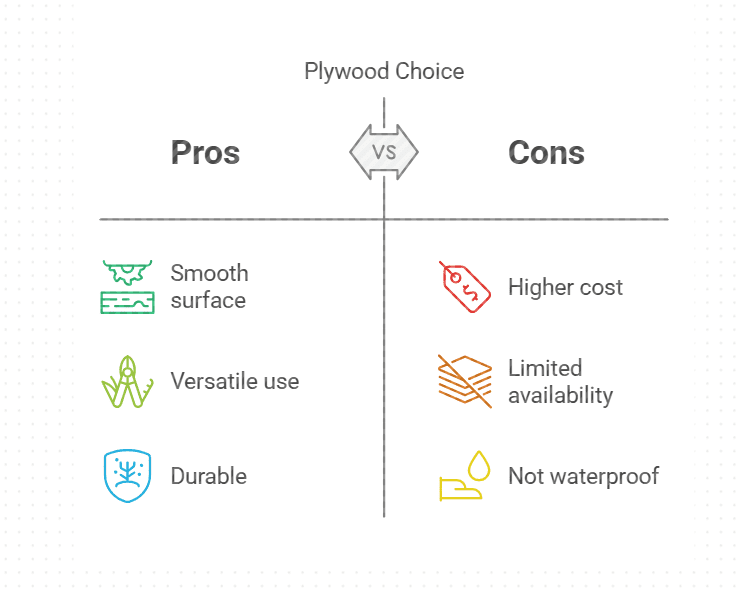

BCX plywood has fewer voids. It is made with higher quality layers. CDX plywood has more gaps. It uses lower quality layers. BCX is stronger and lasts longer. CDX is cheaper and used for construction.

Cost Comparison

Bcx plywood costs more than Cdx plywood. The higher price is due to the better quality of Bcx. Cdx plywood is cheaper because it is made with lower-grade wood. This makes it more affordable for many projects.

While Bcx plywood is more expensive, it offers better durability. This can save money in the long run. Cdx plywood is good for short-term projects. It is cost-effective but may not last as long. Choose based on your needs and budget.

Durability And Strength

BCX plywood is known for its strong construction. The outer layer is smooth. It resists water and wear. The glue used is durable. This plywood is good for both indoor and outdoor use. BCX is stronger and lasts longer than regular plywood. It handles pressure well. It does not bend easily. Perfect for furniture and cabinets.

CDX plywood is often used for roofing. It is strong but not as smooth as BCX. CDX is water-resistant but not waterproof. It can handle some moisture. This makes it good for construction projects. CDX is less expensive. It is durable but not as refined. It works well for floors and walls. It does not last as long as BCX.

Common Uses

BCX plywood is good for indoor projects. It is often used for cabinets, shelves, and furniture. This type of plywood has a smooth surface. It is also easy to paint. People like it because it looks nice. It is strong and can hold weight.

CDX plywood is best for outdoor projects. It is used in roofing, walls, and floors. This plywood is less smooth. It is also cheaper than BCX. CDX can handle wet conditions. It is good for construction jobs. This plywood is strong and durable.

Installation And Handling

Both BCX and CDX plywood are easy to install. BCX plywood is smoother and easier to cut. CDX plywood is rougher but still manageable. BCX is often preferred for interior projects. CDX is used for exterior projects. BCX is more expensive but worth it for fine finishes. CDX is cheaper and good for basic constructions.

Wear gloves to protect your hands. Use safety goggles when cutting plywood. Measure twice before cutting. Store plywood in a dry place. Avoid moisture to prevent warping. Lift with care to avoid injuries. Stack plywood flat and evenly. Check for defects before using. Use proper tools for best results.

Environmental Considerations

BCX plywood is often made from renewable wood. It comes from trees grown in managed forests. These forests are replanted after harvest. This helps keep the forest healthy. Less pollution is created when making BCX plywood. It’s treated with fewer chemicals. Many people choose BCX plywood for its eco-friendly properties.

CDX plywood also comes from managed forests. These forests are replanted too. CDX plywood is strong and durable. It lasts a long time. This means less wood is needed. But, CDX plywood uses more chemicals in its treatment. This can be less friendly to the environment. Some prefer CDX plywood for its strength and cost.

Choosing The Right Plywood

BCX plywood has a fine surface on one side. It works well for projects needing a smooth finish. CDX plywood is rougher. It suits outdoor or structural uses best. Think about the end look. Choose BCX for visible surfaces. Pick CDX for unseen, strong support.

Decide based on your tools. If you can sand and paint, BCX is great. If not, CDX is simpler. Some people like working with smoother wood. Others prefer rougher, stronger pieces. Both types have their place. Choose what fits your skill and taste.

Credit: sherwoodlumber.com

Frequently Asked Questions

What Is Bcx Plywood Used For?

BCX plywood is used for construction, cabinetry, and indoor projects. It offers durability and a smooth finish. Ideal for shelves, countertops, and furniture.

What Is Cdx Plywood Good For?

CDX plywood is ideal for exterior applications, including roofing, walls, and subflooring. It offers strength and moisture resistance.

Which Is Better, Acx Or Bcx Plywood?

ACx plywood is better for indoor use due to its smooth finish. BCx plywood is more suitable for outdoor projects.

What Are The Disadvantages Of Baltic Birch Plywood?

Baltic birch plywood can be expensive. It may warp if exposed to moisture. It’s heavier compared to other plywood.

Conclusion

Choosing between BCX and CDX plywood depends on your project’s needs. BCX plywood suits visible projects with its smoother finish. CDX plywood works well for structural needs, offering strength at a lower cost. Both types provide durability and reliability. Always consider the specific requirements of your project.

This ensures the best choice for both quality and budget. Make informed decisions for successful outcomes.