Can MDF Hold Weight? Discover Its Strength & Limits

Are you planning a DIY project or looking to build sturdy furniture without breaking the bank? MDF, or Medium Density Fiberboard, might be the material you’re considering.

But before you dive into your project, you might be wondering: can MDF hold weight? You’re not alone in this concern, and the answer might surprise you. Understanding the strength and limitations of MDF is crucial for ensuring your creations are both reliable and durable.

This article will uncover the truth about MDF’s weight-bearing capacity, helping you make informed decisions. By the end, you’ll know exactly how to use MDF to its fullest potential, ensuring your projects are both safe and successful. Stay with us as we explore the ins and outs of MDF’s strength and discover practical tips to maximize its use.

Credit: www.youtube.com

What Is Mdf?

MDF stands for Medium-Density Fiberboard. It’s a type of engineered wood.

People make it from wood fibers and glue. Then, they press it into sheets.

MDF is smooth and easy to cut. It’s used in furniture and cabinets.

MDF is less expensive than solid wood. But it’s not as strong.

It can hold weight, but not too much. Heavy items might make it bend or break.

Always check the thickness before using it. Thicker MDF can hold more weight.

Credit: www.reddit.com

Manufacturing Process

MDF, or Medium Density Fiberboard, is made from wood fibers. These fibers come from both softwood and hardwood. They are broken down into small pieces. A machine mixes them with resin. The resin helps fibers stick together. Then, the mixture gets pressed into sheets. These sheets are very flat and smooth.

The pressing process uses heat and pressure. This makes the board strong and dense. The board’s strength depends on the density. Higher density means stronger MDF. People often use it for furniture. It is also used in cabinets and shelves. MDF can hold weight well, but it must be supported properly.

Finished boards are cut to size. They can be painted or covered with veneer. This makes them look nice and ready to use.

Properties Of Mdf

MDF stands for Medium Density Fiberboard. It is made from wood fibers. These fibers are pressed together. This creates a dense sheet. The density is about 600 to 800 kg/m³. MDF is heavier than plywood. It feels solid and firm. The density helps it hold weight. But not too much weight. It can support shelves and cabinets. Heavy items might need extra support.

The surface of MDF is smooth. It is easy to paint. The finish looks good. Veneers can be added on top. This gives a real wood look. The surface is also easy to cut. You can shape it in many ways. The edges are soft. They do not splinter. It is a popular choice for furniture. The finish makes it look nice.

Weight Capacity Of Mdf

MDF stands for Medium-Density Fiberboard. It is made from wood fibers. These are glued together. The strength of MDF depends on many things. The thickness of the board is very important. Thicker boards hold more weight. The type of glue used also matters. Stronger glue makes stronger boards. Moisture affects MDF too. Wet MDF is weak and can bend. Always keep it dry.

Several factors influence MDF’s strength. The quality of wood fibers is key. Good quality fibers make strong boards. The pressing process is also important. Well-pressed boards hold more weight. Temperature during pressing affects strength. High temperatures make better boards.

Let’s compare MDF with other materials. MDF is cheaper than plywood. But plywood is usually stronger. Solid wood is the strongest. MDF is smoother than both. It paints well. MDF is heavier than plywood. It is more stable than chipboard. Each material has its own use.

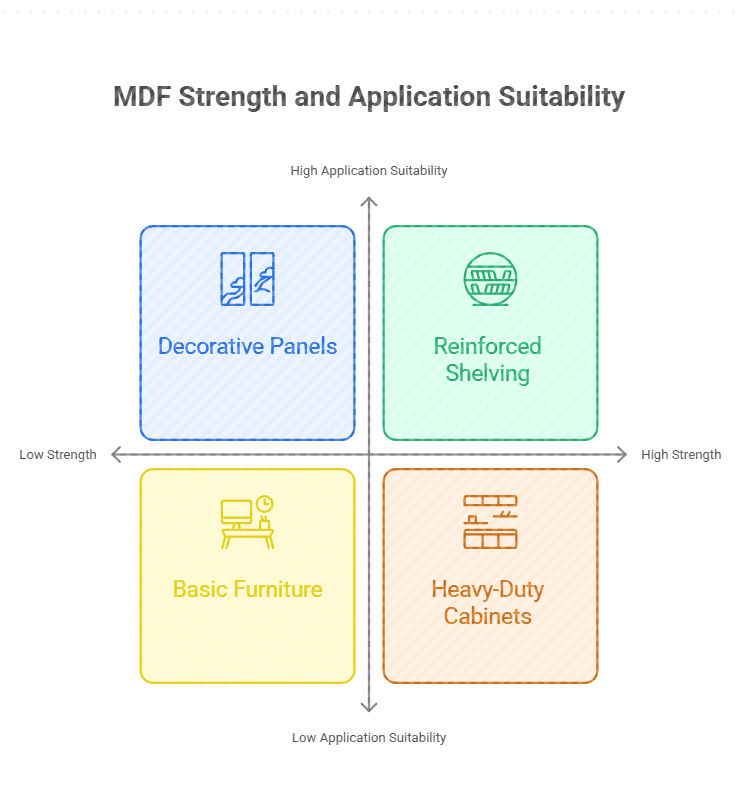

Applications Of Mdf

MDF is used in making furniture like tables and chairs. It is strong and can hold weight well. Many people choose MDF for its smooth surface. This makes it easy to paint and finish. The material is less expensive than solid wood. It’s also easier to cut and shape into various designs. This helps in creating unique furniture pieces.

MDF is used in construction projects for building shelves and cabinets. It is used for wall panels too. MDF is a preferred material due to its durability. It does not warp easily when exposed to changes in temperature. Builders use MDF for its cost-effectiveness. It is also environmentally friendly. MDF is made from recycled wood fibers. This makes it a good choice for sustainable building.

Credit: www.walmart.com

Limitations And Considerations

MDF, or Medium Density Fiberboard, is a wood product. Its creation involves cutting trees. This leads to reduced natural habitats for animals. The production process also uses chemicals. These chemicals can pollute water and air. MDF is not easy to recycle. It may end up in landfills. Over time, it releases gases that can harm the environment. Choosing MDF affects the planet. It is important to consider these impacts.

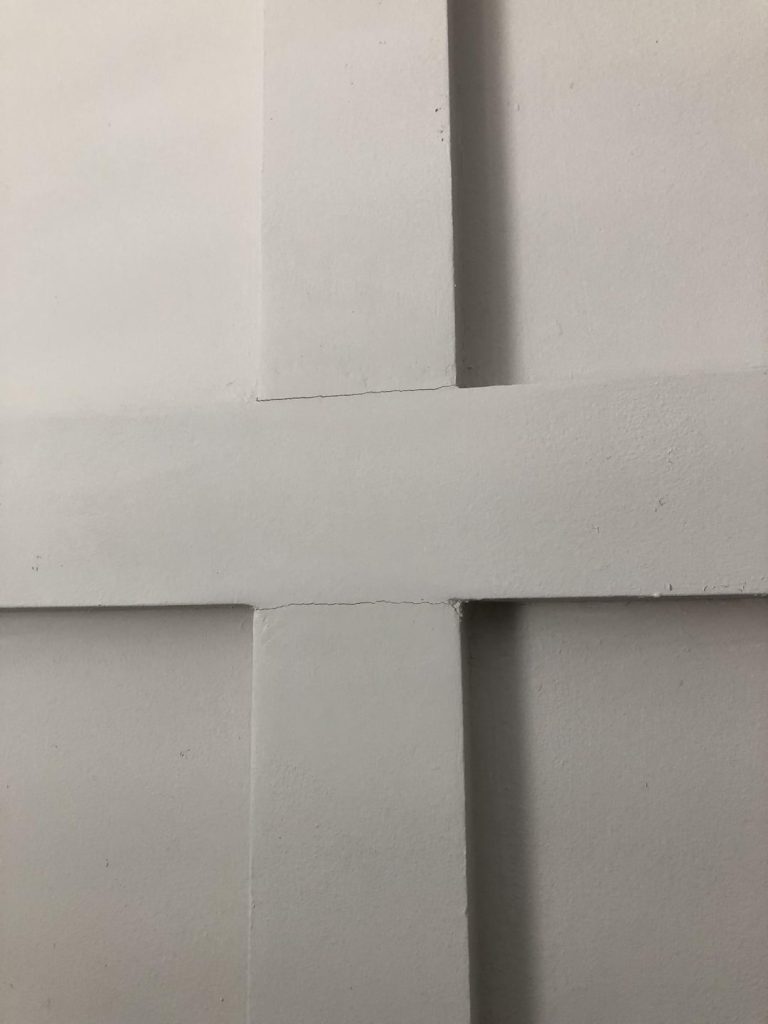

MDF is strong but not as solid as real wood. It can break under heavy weight. Water can damage it easily. Swelling and bending occur when wet. Edges might chip without protection. Screws can loosen over time. This leads to weak joints. MDF does not handle stress well. Regular use can wear it out fast. It’s important to know these durability issues.

Enhancing Mdf Strength

MDF or Medium Density Fiberboard is strong, but it can be even stronger. Builders use smart ways to make it hold more weight. One way is using reinforcement strips. These strips add extra support. Another method is using corner braces. Braces help keep the MDF in shape. Some people also add a layer of laminate. This makes the surface tougher. Special glues can also help. They bond the wood fibers tightly. All these techniques make MDF more reliable. It can then hold heavier items.

Reinforcement Methods

Reinforcement is key for strength. One method is to use metal brackets. They are placed at corners. Another way is adding cross beams. Beams help distribute weight evenly. Screws are better than nails for securing parts. Always choose the right size of screws. Using these methods makes the MDF safer. It becomes more durable and strong.

Frequently Asked Questions

Can Mdf Withstand Weight?

MDF can support considerable weight but is less durable than solid wood. It works well for shelves and furniture. Ensure proper support and thickness for heavier items. Always check manufacturer specifications for weight limits to prevent damage.

Is Mdf Strong Enough To Stand On?

MDF is not designed to bear heavy loads. It may not be strong enough to stand on. For safety, use materials specifically designed for weight-bearing applications. MDF is better suited for furniture, cabinetry, and decorative projects. Always check load-bearing specifications before use.

Is Mdf Strong Enough To Hold A Tv?

MDF can hold a TV if properly supported. Ensure adequate thickness and secure mounting for stability. Use brackets for safety. Check weight limits and manufacturer’s guidelines. Proper installation is crucial for durability and safety. Regularly inspect for any signs of wear or damage.

How Much Can An Mdf Shelf Hold?

An MDF shelf can hold between 20 to 50 pounds, depending on thickness and support. Proper installation is crucial. Consider shelf size, load distribution, and wall anchoring for maximum capacity. Always check manufacturer’s guidelines for specific weight limits to ensure safe use.

Conclusion

MDF can hold weight effectively for many home projects. It offers a sturdy and affordable option for shelves and furniture. Ensure proper support and thickness for heavier loads. Use brackets or reinforcement for extra strength. MDF is sensitive to moisture, so seal it well in damp areas.

It’s a versatile material but has its limits. Choose MDF when weight and cost are factors. Always plan and test for safety. By understanding its properties, you can make informed decisions. MDF is a reliable choice when used correctly.