Can You Cut Sheetrock With a Circular Saw? Discover the Power Behind This Tool!

Yes, you can cut sheetrock with a circular saw easily and efficiently. Sheet rock, also known as gypsum board or drywall, can be cut using a circular saw equipped with a carbide-tipped blade to quickly trim or shape the material.

This method provides smooth and precise cuts, making it a popular choice for both professionals and DIY enthusiasts. Whether you need to make straight cuts, create openings for outlets or windows, or even perform large-scale sheetrock installations, a circular saw is a handy tool that can get the job done with ease.

Learn more about the process and safety precautions in the following paragraphs.

Understanding Sheetrock

Sheetrock, also known as drywall, is a panel made of gypsum plaster pressed between thick sheets of paper used mainly for interior walls and ceilings construction. It is a cost-effective and durable material that provides a smooth, flat surface for painting or applying wallpaper. Sheetrock comes in different thicknesses, with the most common being 1/2 inch and 5/8 inch.

Sheetrock is extensively used in the construction and renovation of residential and commercial buildings. It provides a quick and efficient way to create smooth, even surfaces for painting and finishing. Common uses include constructing walls, ceilings, and partitions. It is also used for repairing damaged walls or ceilings due to its ease of installation and versatility.

Circular Saw: An Overview

The circular saw offers an effective cutting solution for sheetrock, making it a valuable tool for DIY projects and professional applications. Its versatility and precision make it an ideal choice for cutting through this material with ease.

What Is A Circular Saw?

A circular saw is a versatile power tool that is commonly used in woodworking and construction projects. It is handheld and operates on a circular motion, allowing it to effectively cut through a variety of materials, including wood, plastic, and metal. The circular saw consists of a round blade with sharp teeth that spins at a high speed, enabling precise and efficient cutting.

Features And Types Of Circular Saws

Modern circular saws come with a range of features that make them user-friendly and efficient. Some of the key features to consider when choosing a circular saw include:

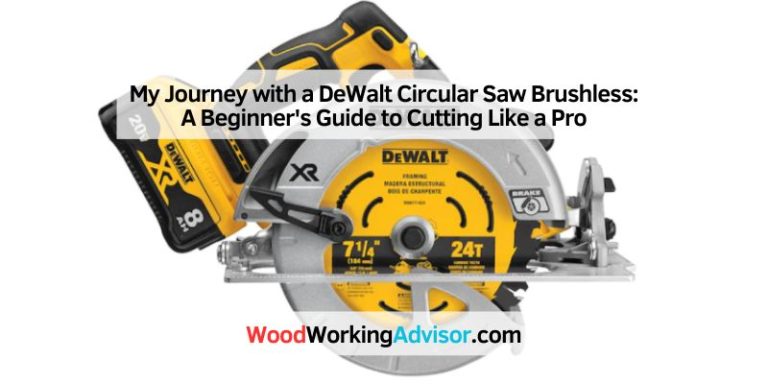

- Blade Size: Circular saws are available in different blade sizes, typically ranging from 4 inches to 12 inches. The size of the blade affects the depth and type of cuts the saw can make.

- Power Source: Circular saws can be powered by electricity or battery. Electric saws are commonly used in professional settings, while battery-powered saws offer portability and convenience for on-the-go projects.

- Depth Adjustment: Adjustable depth settings allow you to control the cutting depth of the blade, making it easier to achieve precise cuts for various applications.

- Safety Features: Look for circular saws that incorporate safety features such as blade guards and electric brakes, which help prevent accidents and improve overall user safety.

- Ergonomics: Consider the weight, grip, and overall ergonomics of the saw. A comfortable and lightweight design will ensure better maneuverability and reduced user fatigue.

There are several types of circular saws available, each designed for specific tasks. The most common types include:

- Standard Circular Saw: This is the most basic type of circular saw, suitable for general-purpose cutting tasks.

- Compact Circular Saw: Compact saws are smaller and lighter, making them ideal for projects that require more flexibility and precision.

- Track Circular Saw: Track saws feature a guide rail system that allows for straight and accurate cuts over long distances.

- Sidewinder Circular Saw: Sidewinder saws have a motor located along the same axis as the blade, providing a more compact and lightweight design.

Before you start using a circular saw, it’s important to familiarize yourself with its features and types. Understanding the capabilities and limitations of your circular saw will help you make the most of this powerful tool in your woodworking and construction endeavors.

Can You Cut Sheetrock With A Circular Saw?

Before you start cutting sheetrock with a circular saw, it’s important to take the necessary safety precautions to ensure your well-being. Here are some key safety measures to follow:

- Wear protective goggles to shield your eyes from any potential flying debris.

- Put on ear protection to minimize the noise produced by the circular saw.

- Use a respiratory mask to avoid inhaling the dust generated while cutting.

- Ensure you have a stable work surface to prevent accidents and injuries.

- Firmly secure the sheetrock to prevent it from moving during the cutting process.

Steps For Cutting Sheetrock With A Circular Saw

Now that you’re aware of the safety precautions, let’s dive into the step-by-step process of cutting sheetrock with a circular saw:

- Start by measuring and marking the area on the sheetrock where you need to make the cut.

- Set the cutting depth on your circular saw to match the thickness of the sheetrock.

- Position the sheetrock on a stable work surface, ensuring it is well-supported.

- Align the circular saw blade with the marked line on the sheetrock.

- Hold the saw firmly, switch it on, and gently guide the blade along the marked line.

- Move at a steady pace to ensure a clean and precise cut.

- Once you’ve completed the cut, switch off the circular saw and carefully remove the sheetrock.

- Inspect the cut edge for any imperfections or rough spots.

- If necessary, use sandpaper to smooth out any rough edges.

By following these steps and taking the necessary safety precautions, you can successfully cut sheetrock with a circular saw.

Benefits Of Using A Circular Saw For Sheetrock Cutting

Cutting sheetrock with a circular saw offers numerous benefits that make the task easier and more efficient. Using a circular saw provides unparalleled time efficiency, precise and clean cuts, and versatile cutting capabilities, making it a valuable tool for any sheetrock cutting project.

Time Efficiency

Circular saws are designed to cut through materials quickly, making them highly time-efficient for sheetrock cutting projects. The powerful motor and efficient blade enable swift cuts, allowing you to complete the task in less time compared to traditional cutting methods.

Precision And Clean Cuts

When it comes to precision, circular saws excel at delivering clean, accurate cuts in sheetrock. The sharp blade and adjustable depth settings ensure that you can achieve the exact cut you need without splintering or damaging the material, resulting in a professional-looking finish.

Versatility

In addition to speed and accuracy, circular saws offer unparalleled versatility for sheetrock cutting. Whether you need to make straight cuts, curved cuts, or intricate shapes, a circular saw provides the flexibility to handle various cutting requirements, making it a valuable asset for any sheetrock installation or renovation project.

Conclusion

In sum, a circular saw is a viable option for cutting sheetrock due to its speed and efficiency. When used properly and with the right blade, it can produce clean and precise cuts. However, it’s crucial to prioritize safety and use the appropriate safety gear to minimize any potential hazards.

Experimenting with scrap pieces and adjusting the saw’s settings can help achieve the desired results. Ultimately, with the proper techniques and precautions, cutting sheetrock with a circular saw can be a convenient and effective choice for many DIY enthusiasts and professionals alike.