Can You Drill Through Plastic: Proven Effortless Method

Yes, you absolutely can drill through plastic! With the right drill bit, technique, and a few simple tips, drilling clean, precise holes in almost any plastic is an effortless and satisfying DIY task. This guide will show you exactly how to achieve perfect results every time, no matter your experience level.

Hey there, DIY friends! Md Meraj here. Ever found yourself needing to attach something to a plastic surface, only to hesitate because you’re unsure about drilling? You’re not alone! Many folks worry about cracking, melting, or creating messy holes in plastic. It can seem a bit tricky compared to wood, but I promise you, it’s entirely manageable. The key is using the right approach. Forget those frustrating experiences; this guide is packed with proven, straightforward methods to make drilling through plastic as easy as pie. We’ll go from picking the right tools to handling different plastic types. Get ready to tackle those plastic projects with confidence!

Why Drilling Plastic Can Seem Tricky (And How We’ll Fix It)

Plastic is a wonderfully versatile material, used in everything from home decor and organization to electronics and car parts. But unlike wood, which is more forgiving, plastic can be a bit sensitive. It can melt if you drill too slowly or with too much friction, leading to gummy, messy holes. It can also chip or crack if you apply too much pressure, especially with brittle plastics. The goal is to create a clean, smooth hole without damaging the surrounding material. This might sound daunting, but the solutions are surprisingly simple and rely on a few key principles that we’ll cover in detail.

The good news is that with a little knowledge and the correct technique, drilling plastic becomes a breeze. We’ll cover:

- Choosing the best drill bits for plastic.

- Setting up your drill correctly.

- Essential safety precautions.

- Step-by-step instructions for a perfect hole.

- Tips for different types of plastic.

By the end of this article, you’ll feel completely confident drilling through any plastic project you have in mind. Let’s get started!

Essential Tools and Materials You’ll Need

Before we even think about picking up a drill, let’s gather our supplies. Having the right tools makes the job not only easier but also much safer. We’re aiming for precision and a clean finish, so don’t skip this step!

The Right Drill Bits for Plastic

This is arguably the most crucial element. Using a standard wood or metal drill bit can lead to the issues we discussed earlier – melting and chipping. For plastic, you need bits designed to cut cleanly, removing material efficiently without excessive heat buildup.

- Specialty Plastic Drill Bits: These are ideal. They often have a sharper point (a higher “hook angle”) and wider flutes (the spiral grooves) to help clear out plastic shavings quickly. This reduces friction and heat. You can find sets specifically designed for plastics at most hardware stores.

- Brad-Point Bits: While designed for wood, brad-point bits can work well on plastics. Their sharp center spur helps to accurately locate the hole and prevents the bit from “wandering” across the surface.

- Standard Twist Bits (with caution): If you must use a standard twist drill bit (HSS – High-Speed Steel), choose sharp ones. You might consider using lubricants or reducing your drilling speed. We’ll discuss this more later.

It’s worth investing in a few specific plastic drill bits if you plan on working with plastic frequently. They make a world of difference!

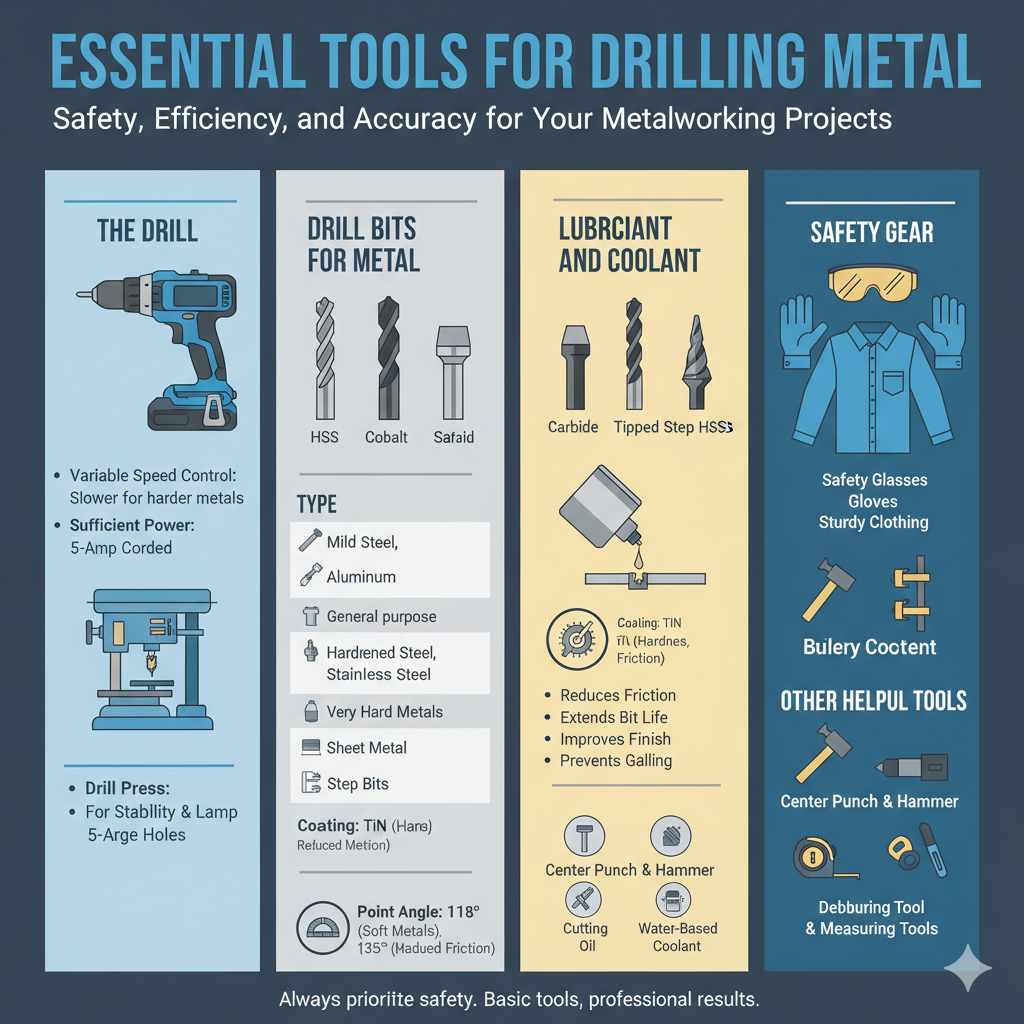

Your Drill

Most common household drills will work. A corded drill offers consistent power, which can be helpful, but a cordless drill offers great mobility. What’s more important is its control—specifically, its variable speed setting.

- Variable Speed Drill: This is essential for controlling the speed at which you drill. We’ll be using lower speeds for plastic.

- Drill Press (Optional but Recommended for Precision): If you need very precise, repeatable holes, especially in a production setting or for critical applications, a drill press offers the most accuracy and stability.

Other Helpful Items

Don’t forget these essentials:

- Safety Glasses: Non-negotiable! Plastic can splinter, and stray bits can fly. Full-coverage safety glasses are a must.

- Gloves: Protect your hands from sharp edges and potential heat.

- Masking Tape: Helps prevent the drill bit from “walking” on smooth plastic surfaces and can reduce minor surface scratching.

- Marker or Pencil: To mark your drilling spot accurately.

- Clamps: To securely hold your plastic piece in place. Never try to drill un-clamped plastic!

- Dustpan and Brush or Vacuum: For easy cleanup of plastic shavings.

- Lubricant (Optional but beneficial): A bit of soapy water, WD-40, or a specialized plastic lubricant can help reduce heat and friction.

- Backer Material: A scrap piece of wood or even another piece of plastic to place behind your workpiece. This prevents “blowout” – where the plastic splinters or cracks as the drill bit exits the other side.

Understanding Different Types of Plastic

Not all plastics are created equal, and some might require slightly different approaches. While our general method will work for most, knowing the type can help you fine-tune your technique.

Here’s a quick look at some common plastics and how they behave:

| Plastic Type | Characteristics | Drilling Considerations |

|---|---|---|

| Acrylic (PMMA) | Clear, rigid, can be brittle. Often used for windows, displays, or crafting. | Prone to cracking. Use sharp bits, slow speed, and a backer board. Keep drilling pressure light. |

| Polycarbonate (PC) | Very strong, impact-resistant, often clear. Used for safety glasses, machine guards. | Tougher than acrylic, less prone to cracking but can still chip. Similar approach to acrylic – slow speed, light pressure. |

| PVC (Polyvinyl Chloride) | Rigid or flexible, widely used in plumbing, pipes, and construction profiles. | Relatively easy to drill. Can melt if too much heat is generated. Keep speeds moderate and use good chip clearance. |

| Polyethylene (PE – HDPE, LDPE) | Tough, flexible, waxy feel. Used for bottles, containers, some pipes. | Can be “gummy.” Sharp bits and a slightly faster speed (but still controlled) can help cut through without melting. Lubrication is often beneficial. |

| ABS (Acrylonitrile Butadiene Styrene) | Tough, impact-resistant, commonly used in LEGO bricks, appliance housings, and automotive parts. | Drills well with standard procedures for plastic. Avoid excessive heat. |

For beginners, the most important takeaway is that heat and excessive pressure are your enemies. Our methods focus on minimizing both.

The Proven Effortless Method: Step-by-Step

Now, let’s get down to business. This method is designed to be simple, effective, and safe for a wide range of plastic projects. Follow these steps carefully, and you’ll be drilling like a pro in no time!

Step 1: Prepare Your Workspace and Plastic

Safety first! Find a well-lit area where you can work comfortably and without distractions. Ensure good ventilation, as some plastics can release fumes when drilled (though less common with basic DIY plastics at moderate speeds). Clear your workspace of clutter.

Next, prepare your plastic piece:

- Clean the Surface: Make sure the area where you’ll be drilling is clean and free of dust, grease, or debris.

- Mark Your Spot: Use a marker or pencil to clearly mark the exact center of where you want the hole.

- Apply Masking Tape: For smoother plastics, applying a piece of masking tape over your marked spot can prevent the drill bit from slipping when you start. It also helps to reduce surface scratches.

- Secure the Workpiece: This is critical for safety and accuracy. Use clamps to firmly attach your plastic material to a workbench or a sturdy surface. Ensure there’s no wobble. If you’re drilling near an edge or through a thin piece, position scrap wood or plastic underneath (your backer material) to support the exit side.

Step 2: Select and Install the Correct Drill Bit

Choose a drill bit that is specifically designed for plastic, or a sharp brad-point bit. Select a bit size that matches the diameter of the hole you need. Ensure your drill bit is sharp. A dull bit will generate more heat and require more force, both bad for plastic.

Install the bit into your drill’s chuck. Make sure it’s seated firmly and centered. If you’re using a cordless drill, ensure it’s fully charged.

Step 3: Set Your Drill Settings

This is where the magic happens for plastic!

- Speed: Slow and Steady Wins the Race. Set your drill to its lowest or second-lowest speed setting. High speeds generate friction heat, which melts plastic. Lower speeds allow the bit to cut cleanly. For example, for a 1/4-inch bit, you might be looking at speeds between 200-500 RPM (Revolutions Per Minute). Check manufacturer recommendations for your specific plastic if available.

- Direction: Standard Drilling. Ensure your drill is set to the normal forward (clockwise) direction for drilling.

- Torque (if applicable): For drills with adjustable torque settings, use a low setting to avoid over-tightening the bit in the chuck or forcing the drill into the material.

If you’re unsure about your drill’s RPM, err on the side of caution and use the absolute slowest setting. You can’t go wrong with being too careful with speed.

Step 4: The Drilling Process

Now, let’s drill the hole:

- Position the Drill: Hold the drill perpendicular (straight up and down) to the surface of the plastic, aligning the tip of the drill bit with your marked spot.

- Start Slowly: Begin drilling at an extremely slow speed. As the bit starts to cut, you can gradually increase the speed slightly, but always keep it within the low range for plastic.

- Apply Gentle, Consistent Pressure: Let the drill bit do the work. Apply light, steady downward pressure. Don’t force the drill. If you feel a lot of resistance or the drill bogs down, you’re likely pressing too hard, the bit is dull, or the speed is too high. Back off slightly.

- Clear the Shavings: As you drill, plastic shavings (chips) will be produced. Allow the wide flutes of your specialized plastic bit to clear these away. If you see shavings building up and the bit seems to be struggling or the plastic is starting to melt, pause drilling. Back the bit out slightly (while it’s still spinning slowly) to clear the flutes, then continue. For very deep holes, you might need to do this multiple times. This is where a lubricant can really help prevent clogging.

- Watch for the Exit: As the drill bit is about to break through the other side of the plastic, ease up on the pressure significantly. This is where blowout is most likely to occur. If you have your backer material in place, this will greatly minimize damage.

- Complete the Hole: Drill completely through the material. Once the bit has fully penetrated, keep the drill spinning on its lowest setting and slowly withdraw the bit from the hole. This helps to smooth the edges as it exits.

Step 5: Finishing Touches

Once the hole is drilled:

- Inspect the Hole: Carefully remove your workpiece from the clamps. Examine the hole. It should be clean, with minimal burrs or melted edges.

- Clean Up: Remove the masking tape (if used). Use a brush or a vacuum to clean away any plastic dust or shavings from your workpiece and the surrounding area.

- Deburr (if necessary): Sometimes, even with the best technique, a tiny burr might remain around the edge of the hole. You can carefully remove this with a small deburring tool, a sharp knife (used with extreme caution), or a bit of fine-grit sandpaper wrapped around your finger. For most applications, this won’t be necessary if you’ve followed the steps correctly.

And voilà! A perfectly drilled hole in plastic. See? Effortless!

Tips for Specific Plastic Challenges

While the general method is robust, here are a few extra pointers for common plastic situations:

Drilling Thin Plastic Sheets (like Plexiglass or Acrylic)

These are the plastics most prone to cracking. Always use a backer board. Start the drill very slowly and apply almost no pressure. The specialty plastic bits are your best friend here. Think of it as guiding the bit rather than forcing it.

Drilling Thick or Hard Plastics

For thicker materials like PVC pipes or polycarbonate sheets, you might need to drill a pilot hole first if you’re using a larger diameter bit. Use a smaller bit to drill the initial hole, then switch to your final size. This makes the job easier and reduces stress on the bit and the plastic. You might also consider using a spray lubricant like WD-40, which is excellent for cutting metal and plastic, helping to keep things cool and lubricated.

Preventing Melting in Soft Plastics (like Polyethylene)

Softer plastics can melt easily. Ensure your bit is very sharp. A slightly faster (but still controlled!) speed can sometimes help the bit cut rather than drag and melt. Frequent backing out of the bit to clear shavings and using a coolant (like soapy water or a specialty plastic lubricant) are key.

Dealing with Curved Surfaces

For curved surfaces, it’s even more critical to use masking tape to establish a stable starting point for the drill bit. A brad-point bit is particularly helpful here as its spur will seat itself more reliably on a curve. Ensure the piece is absolutely secure with clamps, and consider using a drill guide if available for extra stability.

For more detailed information on material handling and safety, the Occupational Safety and Health Administration (OSHA) provides extensive resources, including guidance on power tool safety that can be broadly applied to drilling operations: OSHA Standard 1910.215 – Abrasive wheel and power presses (while specific to grinding, the principles of safe tool operation and material handling are relevant).

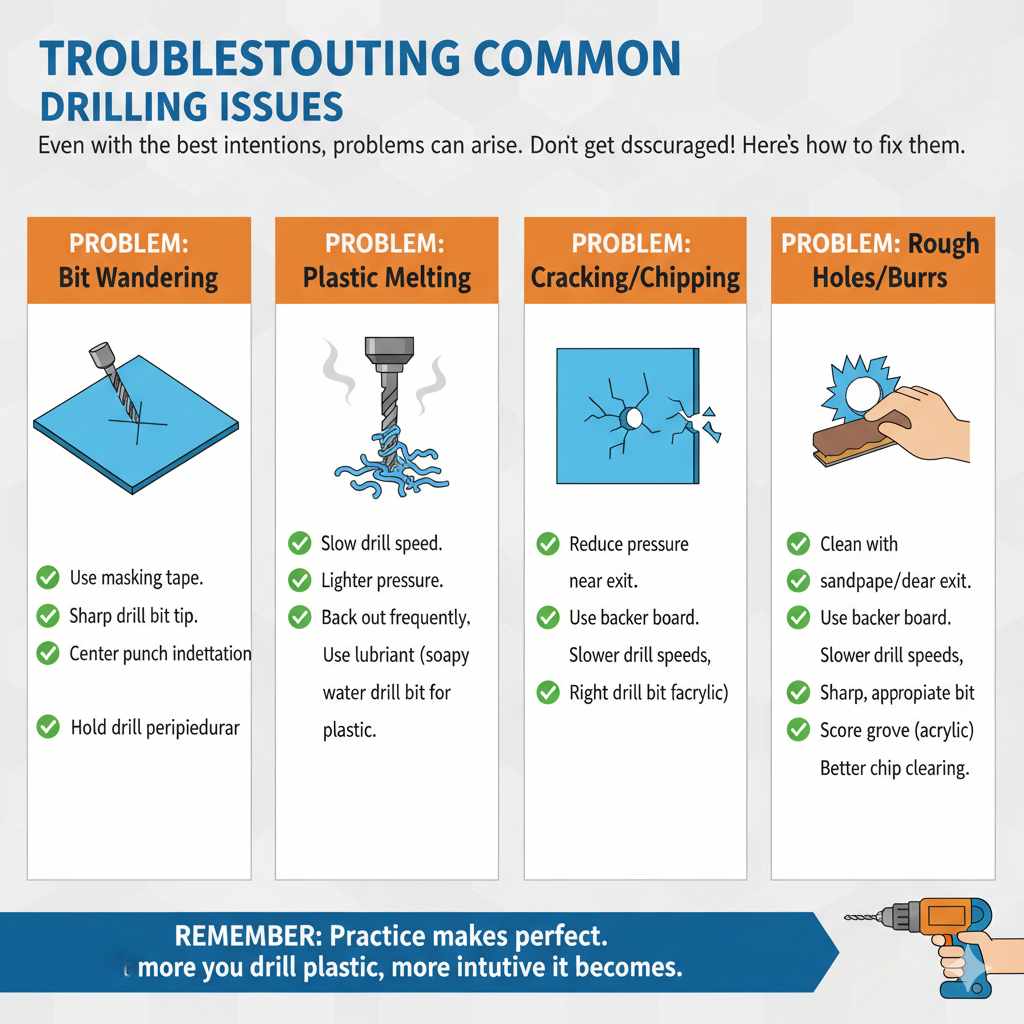

Troubleshooting Common Drilling Issues

Even with the best intentions, problems can arise. Don’t get discouraged! Here’s how to fix them.

Problem: The drill bit is wandering or “walking” on the surface.

- Solution: Use masking tape over the marked spot. Ensure your drill bit tip is sharp. Use a center punch to create a small indentation for the bit to start in (be careful not to crack brittle plastics with a heavy punch). Make sure you’re holding the drill perfectly perpendicular.

Problem: The plastic is melting and gumming up the bit.

- Solution: Your drill speed is too high, or you’re applying too much pressure. Slow down the drill speed significantly. Apply lighter, more consistent pressure. Back the drill bit out frequently to clear shavings. Use a lubricant (soapy water, WD-40). Ensure you’re using the right type of drill bit for plastic.

Problem: The plastic is cracking or chipping, especially upon exit.

- Solution: Reduce drilling pressure dramatically, especially as you near the exit. Use a backer board of scrap wood or plastic behind your workpiece. Use slower drill speeds. Ensure your drill bit is sharp and appropriate for plastic. For brittle plastics like acrylic, consider scoring a groove with a utility knife first to help guide the bit.

Problem: The hole is rough or has a large burr.

- Solution: This usually indicates too much heat or pressure. If it’s a minor burr, you can clean it up with sandpaper or a deburring tool after drilling. For future holes, focus on slower speeds, less pressure, and better chip clearing.

Remember, practice makes perfect. The more you drill plastic, the more intuitive it becomes.

FAQ: Your Plastic Drilling Questions Answered

Can I use a regular drill bit to drill through plastic?

You can, but it’s not ideal. Regular twist bits, especially if dull, tend to generate more heat, leading to melting, or can snag and chip brittle plastics. Specialty plastic drill bits or sharp brad-point bits are highly recommended for cleaner, easier results.