Can You Stain Edge Banding? Unlock the Secrets!

Yes, you can stain edge banding, but results vary based on the material. Wood veneer edge banding stains well, while plastic or melamine options may not absorb stain effectively.

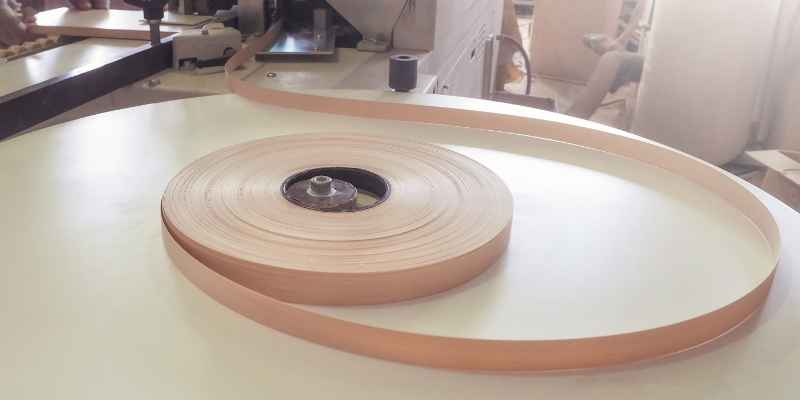

Edge banding is a crucial element in woodworking and cabinetry. It provides a finished look to exposed edges of plywood or particle board. Staining edge banding can enhance its appearance, making it blend seamlessly with your project. Choosing the right type of edge banding is essential for optimal results.

Wood veneer is often preferred for staining due to its natural grain and texture. Understanding how different materials react to stain can help you achieve a polished finish. This guide explores the possibilities and limitations of staining various types of edge banding, ensuring your woodworking projects look professional and visually appealing.

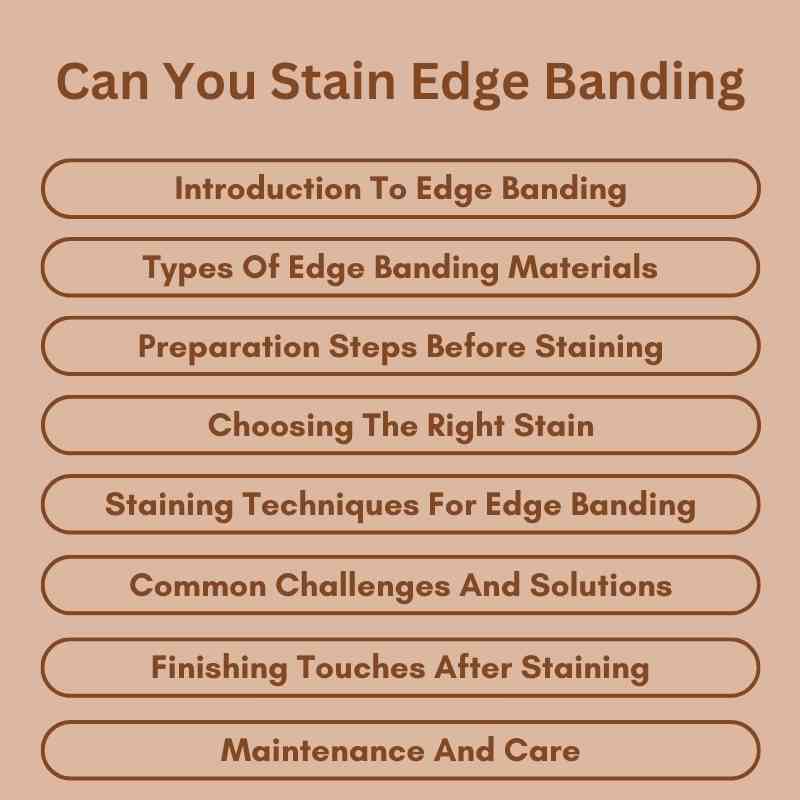

Introduction To Edge Banding

Edge banding is a thin strip of material used to cover the raw edges of plywood or particle board. It provides a finished look and protects the edges from damage. Many materials can be used for edge banding, including wood, plastic, and veneer.

Staining edge banding can enhance its appearance. It helps the banding match the rest of the furniture or cabinet. Proper staining can also add a protective layer, making it last longer.

Before staining, ensure the surface is clean and smooth. Use a suitable stain that works with the edge banding material. Test the stain on a small area first to see how it looks.

Types Of Edge Banding Materials

Wood veneer is a popular choice for edge banding. It comes from real wood, giving a natural look. Staining wood veneer is possible, enhancing its beauty. Choose a compatible stain for best results.

PVC and ABS edge banding are made from plastic materials. These materials are durable and easy to clean. Staining them is not recommended. Instead, they come in many colors and finishes.

Melamine edge banding offers a smooth, glossy finish. It is made from a resin-coated paper. Staining melamine is not effective. Like PVC and ABS, it is available in various colors.

Preparation Steps Before Staining

Cleaning the surface is very important before staining edge banding. Use a damp cloth to remove dust and dirt. Make sure the surface is completely dry before applying any stain. This step helps the stain to stick better.

Sanding is another key step for better adhesion. Use fine-grit sandpaper to smooth the edge banding. Sanding helps to open the wood fibers. This allows the stain to soak in more evenly. Wipe away the dust after sanding to ensure a clean surface.

Choosing The Right Stain

Choosing the right stain for edge banding is crucial. Water-based stains are easy to clean. They dry quickly and offer a low odor. These stains are great for indoor projects.

Oil-based stains provide a rich color and durable finish. They take longer to dry but penetrate deeply. This option is ideal for outdoor furniture or high-traffic areas.

Gel stains are thick and easy to control. They work well on vertical surfaces and do not drip. Gel stains are perfect for achieving a consistent look.

Staining Techniques For Edge Banding

Staining edge banding can enhance the look of your project. Three effective techniques exist: brush application, wiping method, and spray staining.

Brush Application allows for precise control. Use a small brush to apply stain evenly. Make sure to follow the grain of the wood.

The wiping method is quick and easy. Apply stain with a cloth and wipe off the excess. This method provides a softer finish.

Spray staining is fast and covers large areas. Use a spray gun for an even coat. Ensure proper ventilation when spraying.

Common Challenges And Solutions

Staining edge banding can be tricky. Uneven stain occurs when the banding absorbs color differently. To fix this, use a pre-stain conditioner. This helps to create an even base for staining.

Preventing stain bleed is essential. Use painter’s tape to protect areas around the banding. Apply the stain carefully, and avoid over-saturating the edge banding.

Matching the stain to the board can be challenging. Test the stain on scrap pieces first. This ensures the color matches well before applying it to the final project.

Finishing Touches After Staining

After staining, applying a top coat is essential. This helps protect the edge banding. Choose a high-quality finish for the best results.

Sanding between coats is very important. Use fine-grit sandpaper for a smooth surface. Lightly sand after each coat dries.

Achieving a smooth finish requires patience. Apply thin layers of stain and top coat. This prevents runs and drips. Wait for each layer to dry completely. A well-finished edge banding enhances the overall look.

Maintenance And Care

Regular cleaning is important for edge banding. Use a soft cloth with warm water. Avoid harsh chemicals that can damage the finish.

For touching up stains, match the color of the edge banding. Use a small brush or a cotton swab. Apply the stain carefully to avoid mess.

Protecting edge banding from heat and moisture is essential. Always use coasters under hot items. Keep the area dry to prevent warping.

Regular maintenance will help keep your edge banding looking new and lasting longer.

Frequently Asked Questions

Can You Stain Edge Banding?

Yes, you can stain edge banding. However, the results depend on the material. Real wood edge banding absorbs stain well. On the other hand, melamine or plastic banding may not take stain effectively. Always test on a small area first.

What Types Of Edge Banding Can Be Stained?

Wood veneer edge banding is stain-friendly. Solid wood banding also accepts stains easily. However, synthetic materials like PVC or melamine do not. Always check the material type before attempting to stain.

How To Prepare Edge Banding For Staining?

Start by sanding the edge banding lightly. Use fine-grit sandpaper for best results. Clean the surface to remove dust and debris. This preparation ensures better stain absorption and a more uniform finish.

What Stain Works Best On Edge Banding?

Oil-based stains are usually the best choice. They penetrate wood effectively and enhance grain visibility. Water-based stains can also be used but may require more preparation. Always consider the type of edge banding before choosing a stain.

Conclusion

Staining edge banding can enhance the overall look of your projects. It adds depth and color, making your furniture stand out. Always test the stain on a small sample first. This ensures you achieve the desired finish. With the right technique, your edge banding can look as stunning as the rest of your woodwork.