Compared To A Common Drill An Impact Driver Has: Genius Power

Compared to a common drill, an impact driver has genius power for tough tasks. It delivers rotational force combined with concussive blows, making it superior for driving long screws, fasteners into hardwood, or removing stubborn bolts. Impact drivers offer more torque and less user fatigue for repetitive jobs.

Ever found yourself wrestling with a stubborn screw, wondering if your drill is just not cutting it? You’re not alone! Many DIYers and woodworkers face this common frustration. That little screw just won’t go in, or maybe it strips out halfway. It feels like you’re fighting the tool instead of the project. Well, there’s a good reason for that, and it often comes down to choosing the right tool for the job. Today, we’re going to explore a super-powered sibling to your trusty drill: the impact driver. You’ll discover why it’s not just a ‘stronger drill,’ but a different kind of beast that can make tackling those tough fastening jobs feel almost effortless. Get ready to unlock a new level of power and efficiency in your projects!

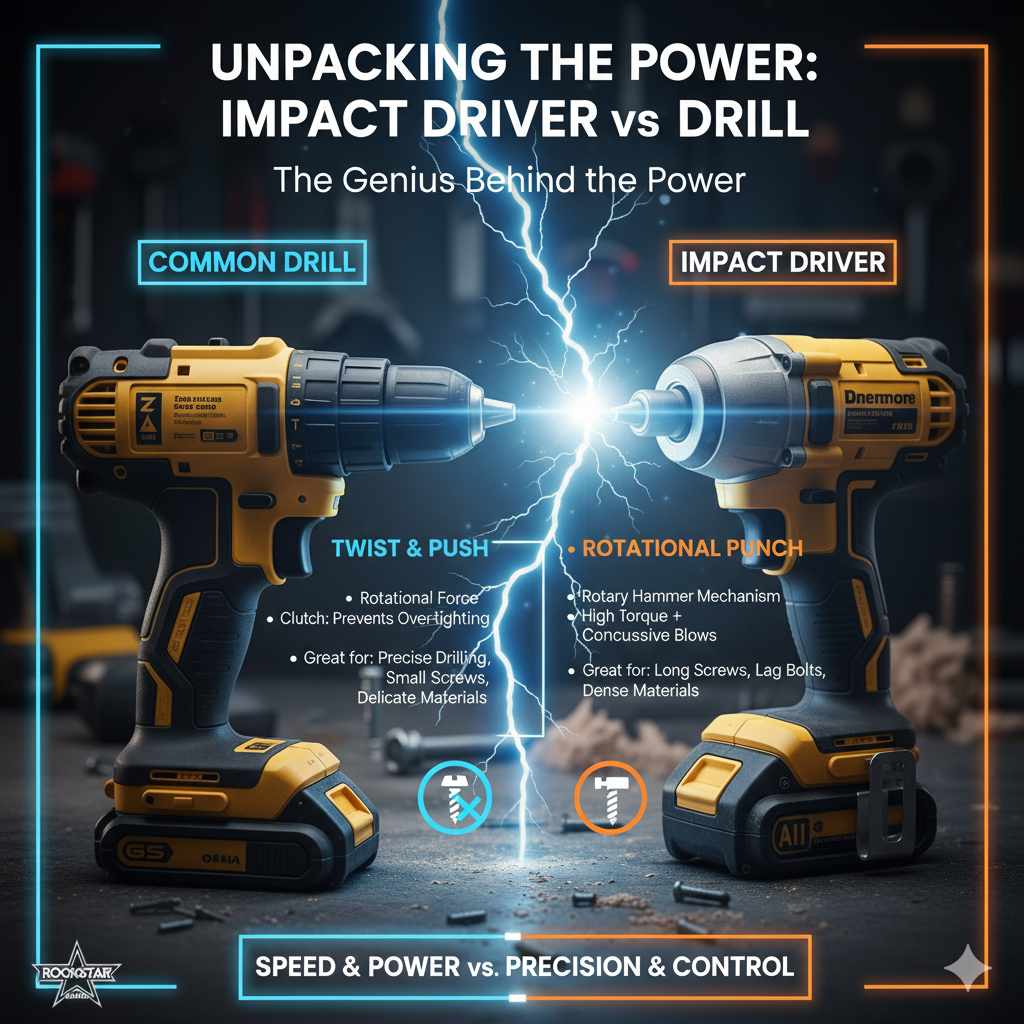

Unpacking the Power: Impact Driver vs. Drill

At first glance, an impact driver and a drill might look quite similar. They both have a trigger, a chuck for holding bits, and they both spin. But dig a little deeper, and you’ll find that the way they apply force is fundamentally different. This difference is what gives an impact driver its “genius power” for specific tasks. Think of it this way: a drill is like a persistent, steady hand trying to twist a screw in. An impact driver is like that same hand, but with a quick, powerful tap every time it twists. This combination of rotational force and hammer-like blows is a game-changer. Let’s break down what makes them distinct.

How a Drill Works: The Twist and Push

Your standard drill, whether corded or cordless, primarily uses rotational force to drill holes and drive screws. When you pull the trigger, a motor spins the chuck. If you’re drilling a hole, this spinning action cuts through the material. When you’re driving screws, the motor’s torque is what turns the screw. Most drills have a clutch system, which is fantastic for preventing you from over-tightening screws and stripping them out. You set a specific torque level, and once the screw reaches that resistance, the clutch disengages, stopping the drill from turning. This is great for delicate work or when you need consistent shallow depth.

How an Impact Driver Works: The Rotational Punch

An impact driver operates on a different principle. It uses a powerful motor to spin a rotary hammer mechanism. When the tool meets resistance, a cam and anvil system engages. This system hammers the rotating bit in short, powerful bursts while simultaneously turning it. It’s this rapid, concussive force, applied thousands of times per minute, that allows an impact driver to sink screws effortlessly. Unlike a drill’s clutch, an impact driver doesn’t have a torque setting to prevent over-tightening in the same gentle way. Its power is focused on rotational torque and the impact action. This is why it excels at tasks where sheer power and speed are needed, like driving long screws into dense materials or removing stubborn fasteners.

Key Differences Explained

To truly appreciate the genius power of an impact driver, let’s compare it directly to a common drill across several key areas. Understanding these differences will help you decide which tool is best suited for your next project.

Power and Torque

This is where the impact driver truly shines. Impact drivers typically deliver significantly more torque (rotational force) than a standard drill. While a good drill might offer anywhere from 300-500 in-lbs of torque, an impact driver can easily push 1,000-1,500 in-lbs or even more. This raw power means it can drive larger screws, longer screws, and fasteners into harder woods with far less effort. A drill will struggle and eventually stop, or the user will feel the torque fighting back, causing wrist strain. An impact driver just keeps going.

Speed and Efficiency

Impact drivers are designed for speed, especially when driving fasteners. The rapid hammering action works with the rotational force to drive screws much faster than a drill. For jobs involving dozens or hundreds of fasteners, this efficiency saves a tremendous amount of time and energy. This is particularly noticeable when working with large construction projects or assembling furniture that requires many screws.

User Fatigue

Because an impact driver delivers rotational force directly to the fastener with its hammering mechanism, it transfers less of that twisting force back to your wrist. When driving a screw with a drill, especially a long one into hard material, your wrist takes the brunt of the torque trying to twist it. An impact driver substantially reduces this torque reaction. This means you can work longer without experiencing hand and wrist fatigue, a significant advantage for prolonged projects.

Bit Engagement and Stripping

Impact drivers use a ¼-inch hex collet for their bits, which is different from a drill’s three-jaw chuck. This hex shank design makes bit changes quick and secure. Crucially, the impact action allows the driver to maintain a strong engagement with the screw head, even if the bit isn’t perfectly seated or the screw head is slightly damaged. While drills can strip screw heads more easily if the bit slips or is over-torqued, the impact driver’s pounding action grips better, reducing the chance of cam-out (stripping the screw head).

Noise Level

It’s important to note that impact drivers are generally louder than standard drills due to their percussive hammering mechanism. You’ll want to wear hearing protection when using one, especially for extended periods. Drills, while not silent, operate with a more consistent motor sound without the sharp percussive bursts.

When to Reach for the Impact Driver (and When to Stick with Your Drill)

Choosing the right tool makes all the difference between a smooth DIY experience and a frustrating one. Here’s a guide to help you decide:

Best Scenarios for an Impact Driver:

- Driving Long Screws: Think 3-inch and longer deck screws, framing screws, or lag bolts.

- Hardwood Projects: Sinking fasteners into dense woods like oak, maple, or hickory is much easier.

- Automotive and Metal Fasteners: Removing stubborn lug nuts, bolts, or working on metal frames.

- Repetitive Fastening Tasks: Assembling multiple pieces of furniture, building decks, or framing walls.

- Drilling Larger Holes (with specific bits): While not their primary function, some impact drivers can drill surprisingly large holes in wood with appropriate hole saws or Forstner bits, especially where depth isn’t a major concern.

Best Scenarios for a Drill/Driver:

- Precision Drilling: When you need to drill perfectly straight holes of a specific size, especially shallow ones.

- Delicate Materials: Working with soft woods, plastics, or thin sheet metal where too much force could cause damage.

- Countersinking: The drill’s clutch is excellent for setting countersinks to a precise depth.

- Mixing Paint or Mud: The consistent, controlled rotation is better for these tasks.

- Driving Small/Medium Screws: For most general-purpose screw-driving tasks where finesse is more important than raw power, a drill with its clutch works wonderfully.

- Using Diamond Core Bits or Hole Saws for Tile/Masonry: These often require a specific RPM and often a hammer drill function, not the impact driver’s rotary hammer action for concrete.

Impact Driver Anatomy: What Makes It Work?

Understanding the parts that contribute to an impact driver’s “genius power” can demystify its operation. While designs vary slightly between brands, the core components are consistent.

1. Motor

This is the heart of the tool. High-powered brushless motors are common in modern impact drivers, offering more power, efficiency, and a longer lifespan compared to brushed motors.

2. Trigger

Controls the speed and power. You’ll find variable speed triggers, allowing for more control at lower speeds and maximum power at higher speeds.

3. Hammer Mechanism

This is the key differentiator! It consists of a rotating hammer (often attached to the motor shaft) and an anvil (a stationary piece with striking surfaces). When resistance is met, the hammer strikes the anvil, which in turn strikes the output shaft, delivering the percussive blow along with the rotation.

4. Output Shaft & Collet

This is where the driver bit attaches. Impact drivers use a ¼-inch hex collet. You simply insert a hex-shank bit and pull back on the collar to release it. This design ensures a very secure connection for high torque applications.

5. Gearbox

Transmits power from the motor to the output shaft. For impact drivers, this gearbox is built to withstand the repeated shocks from the hammer mechanism.

6. Battery

Like most cordless tools, impact drivers rely on battery packs (typically 18V or 20V MAX systems) for power. Higher amperage hour (Ah) batteries will provide longer runtimes.

Choosing the Right Impact Driver for You

When you’re ready to add this powerful tool to your arsenal, consider these factors:

- Power (Torque): Look at the manufacturers’ specifications for torque (measured in in-lbs or Nm). More torque means more power for tough jobs. For most home DIYers, 1,000-1,500 in-lbs is a good range.

- Speed (RPMs): Rotations Per Minute (RPM) indicates how fast the tool spins. Higher RPMs mean faster driving, but sometimes lower RPM settings are needed for control. Many impact drivers have different speed settings.

- Brushless Motor: If your budget allows, opt for a brushless motor. They are more efficient, run cooler, last longer, and offer better power delivery.

- Battery Platform: If you already own cordless tools from a particular brand, it makes sense to buy an impact driver that uses the same battery system. This can save you money.

- Ergonomics and Weight: Hold prospective tools if possible. A comfortable grip and balanced weight are important for reducing fatigue during use.

- Features: Some impact drivers come with helpful features like LED work lights, variable speed trigger sensitivity, and even electronic braking for immediate stops.

Safety First: Using Your Impact Driver Wisely

Despite its power, an impact driver is a safe and manageable tool when used correctly. Here are some essential safety tips:

- Wear Eye Protection: Always wear safety glasses to protect your eyes from flying debris.

- Use Hearing Protection: Impact drivers are loud. Earplugs or earmuffs are crucial to prevent hearing damage.

- Secure Your Workpiece: Always clamp down your material firmly. A spinning workpiece can be dangerous.

- Proper Grip: Hold the impact driver firmly with both hands. Be prepared for the tool’s power when you pull the trigger. Never point it at yourself or others.

- Use the Right Bit: Ensure you are using the correct size and type of driver bit for the fastener. A bit that fits snugly in the screw head will reduce the chance of stripping.

- Be Aware of Kickback: While impact drivers have less wrist-flick kickback than drills, if the driver bit binds unexpectedly, the tool can still twist suddenly. Maintain a strong grip.

- Inspect the Tool: Before each use, check for any damaged cords (if corded), loose parts, or worn bits.

- Read the Manual: Familiarize yourself with your specific model’s features, operation, and safety guidelines. You can often find excellent resources from manufacturers like DEWALT, which provides comprehensive safety information for their tools.

Impact Driver vs. Drill: A Quick Comparison Table

Here’s a handy table summarizing the key differences:

| Feature | Common Drill | Impact Driver |

|---|---|---|

| Primary Action | Rotation | Rotation + Percussive Hammering |

| Torque Output | Moderate (300-500 in-lbs) | High (1,000+ in-lbs) |

| Speed for Fastening | Moderate | Very Fast |

| User Fatigue Reduction | Lower (Torque transfers to wrist) | Higher (Impact action absorbs torque) |

| Screw Head Stripping Risk | Higher (with clutch over-reliance or slippage) | Lower (better bit engagement) |

| Hole Drilling Capability | Primary function, good for precision | Secondary, better for larger holes in wood |

| Chuck Type | 3-Jaw Chuck | 1/4-inch Hex Collet |

| Noise Level | Moderate | High |

| Best For | Drilling holes, delicate fastening, light-duty screws | Driving long/large screws, hard materials, repetitive fastening |

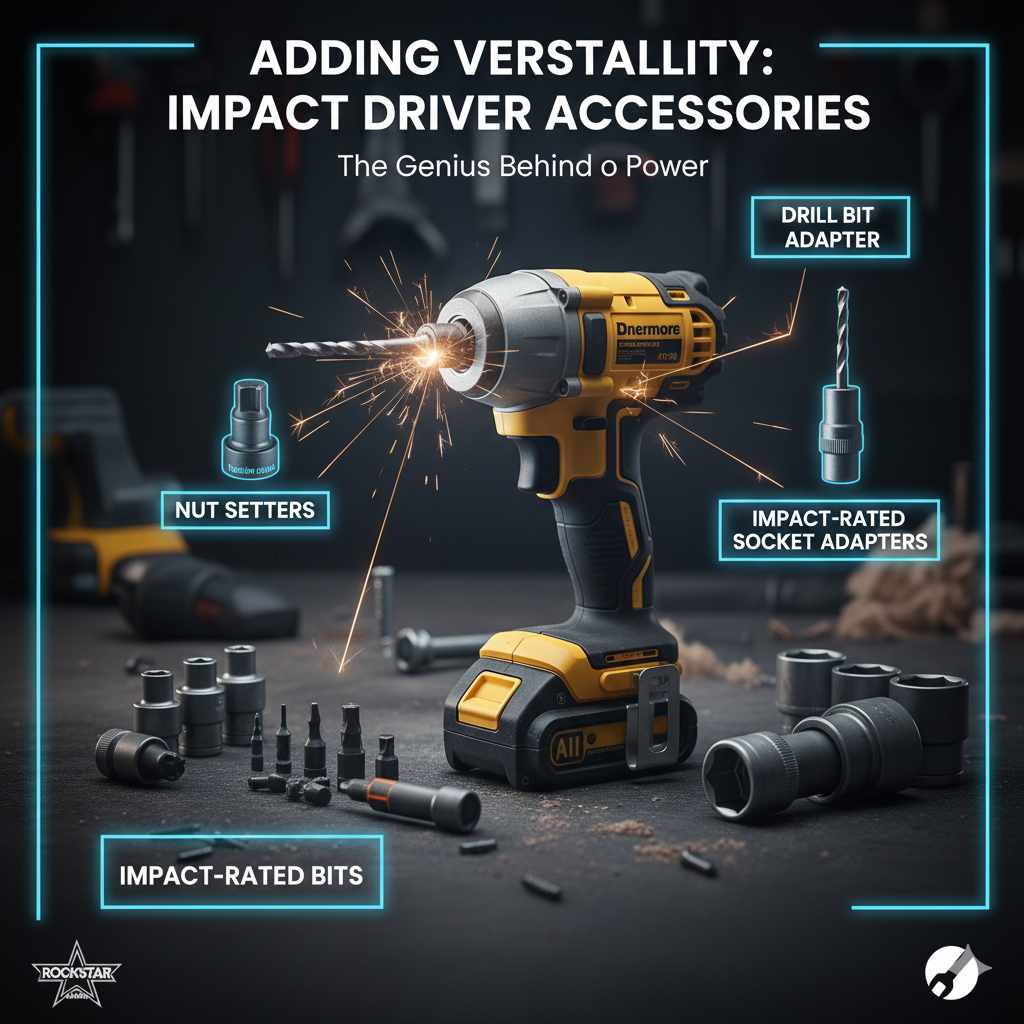

Adding Versatility: Impact Driver Accessories

While the impact driver itself is powerful, the right accessories can unlock even more of its potential. Here are some popular additions:

- Impact-Rated Bits: These are specially hardened bits designed to withstand the shock and torque of an impact driver. Using standard drill bits in an impact driver can quickly damage them and the tool. Look for bits with a torsion zone, which absorbs the shock.

- Nut Setters: These are sockets designed to fit onto the hex shank of an impact driver, allowing you to drive nuts and bolts with ease.

- Impact-Rated Socket Adapters: These adapters allow you to use standard sockets with your impact driver for a wide range of automotive and mechanical tasks.

- Drill Bit Adapters: For tasks where you might need to drill a hole as part of the fastening process and prefer the impact driver’s power, you can find hex-shank adapters for standard drill bits. However, remember the drill’s clutch is better for precise depth-controlled drilling.

Frequently Asked Questions (FAQs)

Q1: Can an impact driver replace my drill?

For many tasks, yes! An impact driver is excellent for driving screws and some drilling applications. However, if you frequently need to drill precise holes, especially shallow ones, or work with delicate materials, a standard drill with a clutch is still invaluable. Many pros carry both.

Q2: Is an impact driver suitable for beginners?

Absolutely! While they are powerful, impact drivers are often easier for beginners to use for driving screws than drills. The reduced cam-out and less torque reaction on the wrist make them more forgiving for straightforward fastening jobs. Always start with safety gear and a clear understanding of the tool.

Q3: Do I need special bits for an impact driver?

Yes, it’s highly recommended to use “impact-rated” bits. These bits are manufactured with stronger materials and often have a flexible torsion zone designed to absorb the shock of the impact mechanism. Using regular drill bits can cause them to break or strip screws quickly.

Q4: Are impact drivers safe for all wood types?

They are fantastic for hardwoods and large screws. For very soft woods (like pine) and small screws, you might need to use a lower speed setting on your impact driver or a drill with a clutch to avoid sinking the screw too deep or damaging the wood.

Q5: How much torque do I really need?

For typical home DIY projects—driving deck screws, assembling furniture, or general repairs—an impact driver with 1,000-1,500 in-lbs of torque is usually more than enough. For heavy-duty construction or automotive work, you might look for models with even higher torque ratings. You can find great guidance on torque ratings and tool specifications from resources like This Old House.

Q6: Can I drill holes with an impact driver?

Yes, you can drill holes, especially in wood, using impact-rated drill bits or spade bits with hex shafts. However, it’s not as precise as a drill, and the impact action can sometimes make it harder to control the start of the hole or achieve very shallow depths. Its real strength is in driving fasteners.

Conclusion: The Impact Driver – Your New Best Friend for Tough Jobs

So, there you have it! When compared to a common drill, an impact driver possesses a “genius power” born from its unique ability to combine rapid rotational force with concussive blows. This makes it an indispensable tool for anyone who regularly drives screws, especially long ones, into challenging materials like hardwood or through multiple pieces of lumber. It saves time, reduces fatigue, and minimizes frustration, turning potentially arduous tasks into quick, satisfying wins. While it won’t replace your drill for every job (precision drilling still calls for a drill!), the impact driver is a powerful ally that will elevate your DIY and woodworking capabilities significantly. Investing in one means investing in efficiency, power, and a much smoother building experience.