Does Burning Wood Make It Waterproof? A Simple Explanation

If you’re wondering, Does Burning Wood Make It Waterproof?, you’re not alone! It’s a common question, especially for those new to working with wood or involved in camping and survival skills. Figuring out how to protect wood from water can seem tricky. Don’t worry, we’ll break down the science in easy-to-understand terms. We’ll explore the methods used to make wood more water-resistant. This article is all about making things simple, so you can easily learn to preserve your wooden items. Let’s get started!

The Science of Wood and Water

Wood is a natural material that readily absorbs water. This is because of its porous structure, made up of tiny tubes that act like straws, drawing water inside. When wood gets wet, it swells, and dries, it shrinks, this constant expansion and contraction can lead to cracking, warping, and eventually, decay. Different types of wood have different densities and therefore varying levels of water absorption. Hardwoods generally absorb less water than softwoods, but all types are vulnerable. Moisture also encourages the growth of fungi and bacteria, which cause wood rot. Understanding this relationship between wood and water is key to learning how to protect wooden items.

Wood’s Natural Properties

The cellular structure of wood is the main factor determining how it reacts to water. Wood cells, when alive, transport water and nutrients throughout the tree. Even after the tree is cut, these cellular spaces remain. These spaces are what make wood so absorbent. Different wood species have different cell sizes and arrangements, influencing how much water they can take up. Furthermore, the presence of lignin and cellulose within the cell walls influences wood’s interaction with moisture. Lignin is responsible for the rigidity of the cell walls, and it is a relatively water-resistant compound. Cellulose, which provides the structural framework, tends to be more hydrophilic and absorbs water.

- Cellulose: This is a carbohydrate that makes up the bulk of the wood’s structure. It’s strong and gives the wood its shape, but it also readily attracts water molecules.

- Lignin: This acts as a glue, binding the cellulose fibers together. It adds strength and rigidity to wood, but it is also much less absorbent than cellulose.

- Pores: These are the tiny openings within the wood that transport water and nutrients when the tree is alive. After the tree is cut, these pores are what allow water to enter and be absorbed.

- Wood Density: Hardwoods, with their smaller pores and denser structures, tend to be less water-absorbent than softwoods, which have larger pores and are generally less dense.

The Impact of Moisture on Wood

When wood gets wet, the water molecules enter the wood’s cells and bind to the cellulose. This causes the wood to swell. As the wood dries, the water evaporates, and the wood shrinks. This process of swelling and shrinking can lead to a number of problems. The continuous movement of wood due to changes in water content causes stress within the wood structure. This can cause the wood to crack or split, leading to loss of structural integrity. It also can cause the wood to warp, which means it bends or twists out of its intended shape, making it difficult to use for construction or other purposes.

- Rot and Decay: Constant moisture creates the perfect environment for fungi and bacteria to grow. These organisms break down the wood, causing rot and significantly weakening the material.

- Swelling and Warping: When wood absorbs water, it expands. As it dries, it shrinks. This cycle can cause it to warp, twist, and crack.

- Loss of Strength: The constant movement and potential decay weaken the wood, making it less able to bear weight or resist stress.

- Aesthetic Damage: Water can stain wood and lead to the growth of mold and mildew, ruining its appearance.

Burning Wood to Make It Waterproof

The practice of charring or burning the surface of wood is an ancient method of preservation, providing a basic form of water resistance. The process, known as charring, involves burning the surface of the wood. This creates a layer of carbon, which seals the pores and hardens the surface. Charring has been used for various purposes, from creating durable fences and tools to preserving wooden structures. The key to this process is the transformation of the wood’s surface into a layer of charcoal. While charring doesn’t make wood completely waterproof, it does significantly slow down the absorption of water and reduces its impact.

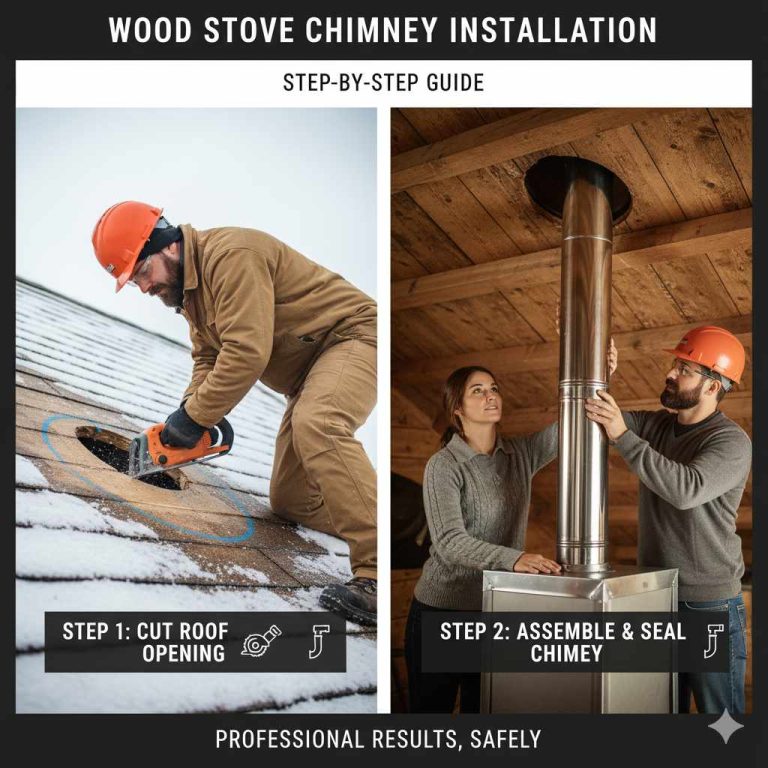

The Process of Charring Wood

Charring wood isn’t just about setting it on fire; it’s a controlled process that turns the outer layer into charcoal. The intensity and duration of the burn affect the final result. If the burn is too intense, the wood will simply be consumed. If it’s not intense enough, the surface won’t be sufficiently altered to provide protection. It involves carefully burning the surface of wood to create a carbon layer. This process alters the wood’s surface, making it less absorbent. The depth of the char is a critical factor, directly influencing the water-resistant properties.

- Preparation: The wood should be clean and dry. Removing any loose debris helps ensure an even burn.

- The Burn: Use a controlled heat source, like a torch or a slow fire. The goal is to create a charred layer without burning the wood completely.

- Cooling: Allow the charred wood to cool slowly. Rapid cooling can cause the wood to crack.

- Finishing: You might choose to apply a natural oil to further protect the wood. This also enhances its appearance.

How Charring Affects Water Absorption

When wood is charred, the heat changes its structure. The surface wood material becomes carbonized, creating a hardened, less porous layer. This layer serves as a barrier, slowing down water’s entry into the wood. The process partially seals the pores, making it more difficult for water to be absorbed. Water finds it more difficult to penetrate the surface due to the altered properties. This charring process does not make the wood fully waterproof but it is a step toward preventing water damage. The thicker the char, the more effective it becomes at repelling water.

- Reduced Porosity: Charring closes up the tiny pores in the wood, making it harder for water to soak in.

- Carbon Barrier: The carbon layer acts as a barrier, preventing water from reaching the untreated wood.

- Slowed Absorption: Even if water gets past the charred layer, it will absorb more slowly.

- Enhanced Durability: The charred surface is more resistant to decay.

Alternative Methods for Wood Preservation

While charring offers a simple method for protection, several other approaches provide even greater water resistance and longevity for wood. From traditional methods like applying natural oils to modern treatments such as chemical preservatives, the best approach depends on the intended use of the wood and the level of protection needed. These methods, when correctly applied, can significantly enhance wood’s resistance to moisture, decay, and damage from the elements. There are various ways to achieve superior results, including a combination of techniques and materials.

Natural Oils and Sealants

Natural oils and sealants work by penetrating the wood and filling its pores, creating a barrier that repels water. They are usually derived from plants and other natural sources, making them a safe and eco-friendly option for wood preservation. Linseed oil, tung oil, and mineral oil are common examples. These oils can be applied repeatedly to maintain protection and enhance the wood’s appearance. Oils are often used to beautify wood, adding a natural shine. Sealants, on the other hand, form a protective coating on the wood’s surface, acting as a physical barrier.

- Linseed Oil: Derived from flax seeds, linseed oil penetrates deeply into the wood. It hardens over time, providing water resistance.

- Tung Oil: This oil creates a durable, water-resistant finish that’s ideal for outdoor items.

- Mineral Oil: A non-drying oil that is safe for food contact. It’s often used for wooden cutting boards.

- Varnish: Forms a hard, clear coating on the wood’s surface that protects from water and wear.

- Sealants: These products create a solid layer on the wood. They are often used for outdoor projects.

Chemical Treatments

Chemical treatments offer a more advanced form of wood preservation. These products often contain active ingredients that are designed to penetrate the wood and prevent decay from moisture, rot, and insects. These treatments are often used in construction and outdoor projects. The chemical treatments can vary in their formulations, depending on the desired level of protection and the environmental conditions they will be exposed to. Some treatments might offer water resistance, while others focus on protecting the wood from termites, fungi, and other threats. When using these methods, it’s crucial to follow the manufacturer’s instructions for safe and effective use.

- Wood Preservatives: These chemicals kill or prevent the growth of fungi and insects.

- Water Repellents: These products make the wood less absorbent.

- Stains with Sealants: Many stains now include sealants, providing both color and protection.

- Pressure-Treated Wood: Wood is treated with preservatives under high pressure, forcing the chemicals deep into the wood’s pores.

Comparison Table: Charring vs. Other Methods

Here’s a simple table to compare charring with other techniques:

| Method | Effectiveness | Application | Pros | Cons |

|---|---|---|---|---|

| Charring | Moderate | Burning the wood’s surface. | Simple, affordable, and requires no special tools. | Offers limited water resistance and can affect appearance. |

| Natural Oils | Good | Applying oils like linseed or tung oil. | Enhances appearance and provides moderate water protection. | Needs reapplication, offers limited protection against decay. |

| Chemical Treatments | Excellent | Applying preservatives or sealants. | Highly effective against water, rot, and insects. | Can involve safety concerns and require special handling. |

| Varnish | Good | Applying varnish. | Forms a strong, protective layer. | Can chip or crack over time and requires preparation. |

Real-Life Examples and Scenarios

Real-world examples can help you see how different approaches work in practice. Let’s look at a few examples where techniques like charring or using other treatments were used.

- Example 1: Charred Fences: Many cultures have used charring to protect fences, posts, and outdoor structures. The burnt layer helps to protect the wood from weathering, decay, and damage. It is a simple and inexpensive method of wood preservation, especially useful in regions with significant weather variation. The charred surface of the posts creates a protective layer that slows down water absorption and extends the fence’s life.

- Example 2: Wooden Boats and the Use of Oils: Historically, wooden boats were treated with natural oils, such as linseed oil, to make them more water-resistant. The oils would penetrate the wood, creating a barrier that prevents water absorption and reduces rot. The use of oils allowed boats to last for years, with regular maintenance and reapplication.

- Example 3: Modern Wood Decks: Today, decks are often built with pressure-treated wood. The wood is treated with chemicals that penetrate deep into the wood, making it resistant to rot, insects, and water damage. This process offers a high level of protection, extending the lifespan of decks and similar outdoor structures.

Here are some examples:

- You’re building a simple birdhouse for your backyard. Charring the outside can help protect it from rain. After charring, applying a clear sealant can increase its lifespan.

- You have an old wooden cutting board that you want to refresh. Cleaning and applying mineral oil can bring back its look while providing protection.

Frequently Asked Questions

Question: Does charring wood make it completely waterproof?

Answer: No, charring wood doesn’t make it entirely waterproof. It makes the surface more water-resistant by partially sealing the pores. However, water can still penetrate, so it’s not a complete barrier.

Question: What type of wood is best for charring?

Answer: Any type of wood can be charred, but dense hardwoods generally char more effectively and offer better protection. However, any type of wood can benefit from this process.

Question: Can I use charring on wood that will be in contact with food?

Answer: Charring can be used on wood that will be in contact with food, but make sure to apply a food-safe oil, like mineral oil, after charring.

Question: How often should I reapply oil to preserve wood?

Answer: The frequency of oil reapplication depends on the type of oil and the weather conditions. As a rule, you might need to reapply oil every few months or annually.

Question: Are chemical treatments safe for use on wood?

Answer: Chemical treatments can be effective, but always read and follow the manufacturer’s instructions. Some chemicals can be harmful if not used correctly, so always wear protective gear and work in a well-ventilated area.

Final Thoughts

So, does burning wood make it waterproof? The simple answer is that it makes it more water-resistant. Charring changes the surface, slowing down water absorption and extending the wood’s life. While it’s a useful technique, other methods like oils and sealants offer even better protection. No single method is perfect, and the best choice depends on what you plan to do with the wood. Whether you’re charring a fence post, applying oil to a cutting board, or building a deck, knowing about wood preservation helps to protect your wooden items. Now that you understand the different methods, go ahead and explore them!