Drill Versus Electric Screwdriver Choosing the Right Tool

Choosing between a Drill vs Electric Screwdriver: Which Is Right for You? can be tricky when you’re just starting out. Many find it confusing because both tools seem similar. However, their strengths and uses are quite different. This post is designed to simplify the decision-making process. We’ll explore the main differences, so you can confidently pick the right tool for your tasks. Ready to learn more?

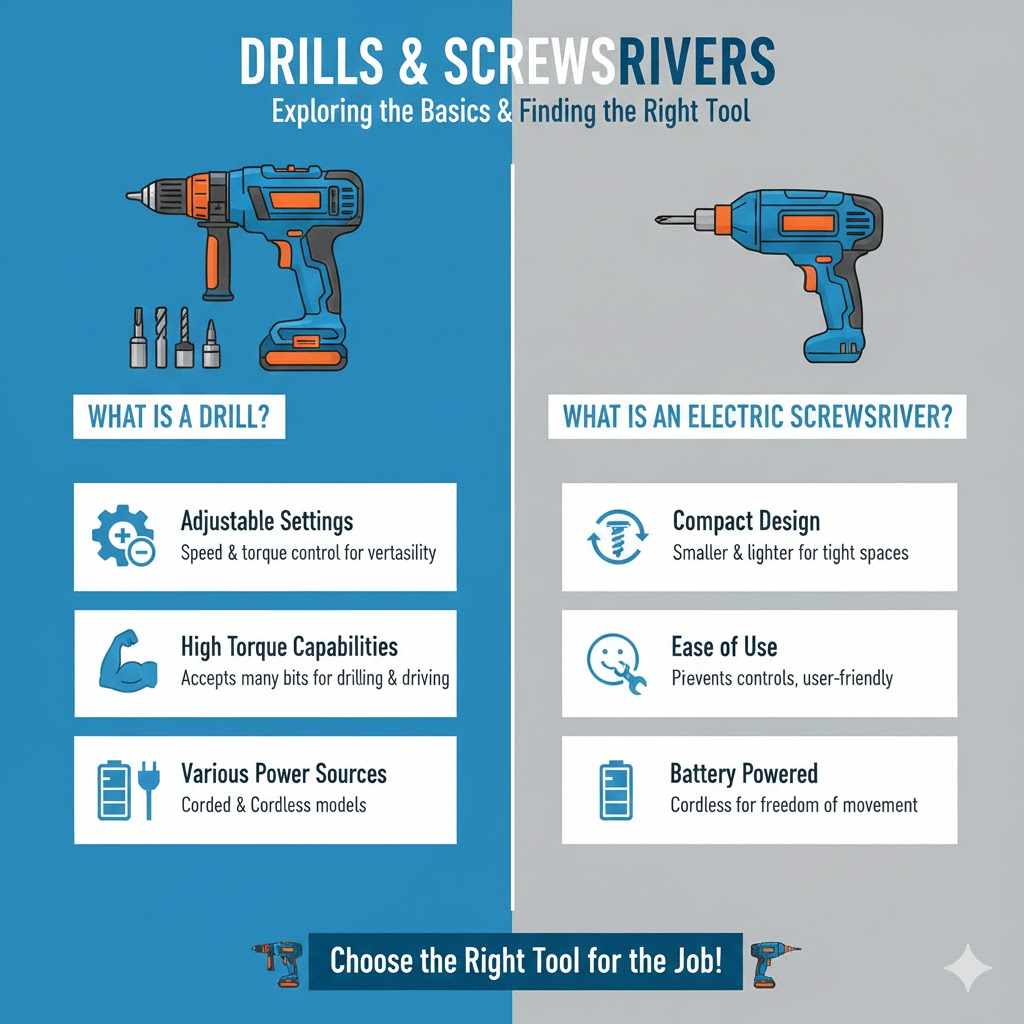

Drills and Screwdrivers Exploring the Basics

Before jumping into a tool comparison, it is beneficial to get a solid grasp of what each tool is. A drill is typically a more powerful tool, created for drilling holes and driving screws into various materials, like wood, metal, and plastic. An electric screwdriver, on the other hand, is generally a lighter-duty tool, primarily intended for driving screws. They are more compact and user-friendly for tasks that require less power. Exploring the basics is an excellent foundation for understanding their differences and finding out the right tool for you.

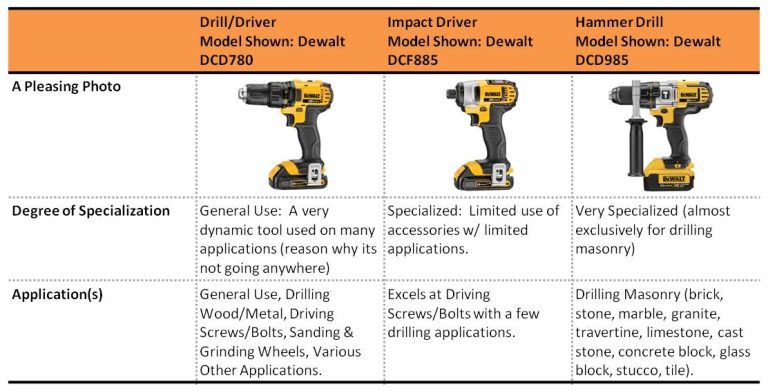

What Is a Drill?

A drill, often called a power drill, is a versatile tool used in numerous projects. It is designed to create holes and drive screws. The key feature of a drill is its rotating drill bit. This bit cuts into the material. The power comes from an electric motor, allowing for significant torque. You can typically adjust the speed and torque settings depending on the task. Drills come in different sizes and power levels. This lets you match the tool to the job. Drills are excellent for working with tougher materials and tasks where more force is required, like creating larger holes or driving screws into dense wood.

- Adjustable Settings: Most drills offer adjustable speed and torque settings. This gives you greater control. Slower speeds are ideal for starting screws, while faster speeds are suitable for drilling.

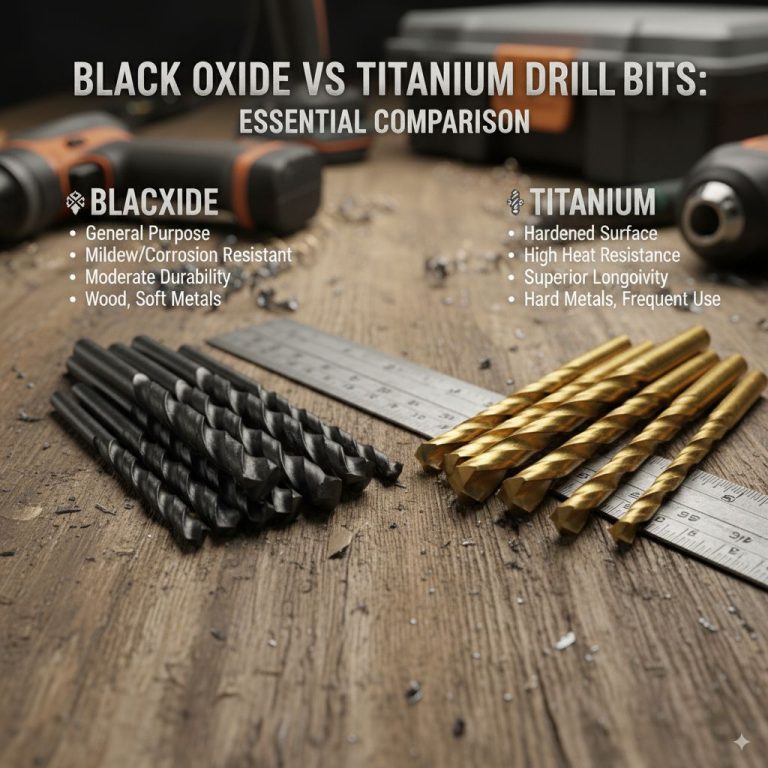

- Interchangeable Bits: Drills accept a wide variety of drill bits, making them useful for many applications. This feature allows for drilling holes of different sizes and shapes, as well as driving screws.

- High Torque Capabilities: Drills deliver high torque. This is beneficial for tasks requiring more power, like drilling through hardwood or driving long screws.

- Various Power Sources: Drills are available in corded and cordless models. Cordless drills offer more portability. Corded drills often provide more power continuously.

What Is an Electric Screwdriver?

An electric screwdriver is a more specialized tool created for driving screws into materials. It is smaller and lighter than a drill. This makes it easier to handle. It is especially useful for tasks with many screws or in tight spaces. Electric screwdrivers typically have a lower torque than drills. This can be beneficial for preventing damage to softer materials. Electric screwdrivers often have built-in clutches. This prevents over-tightening of screws. Their compact design and ease of use make them great for tasks like assembling furniture, installing electrical outlets, and more.

- Compact Design: Electric screwdrivers are usually smaller and lighter than drills. This makes them easier to use in cramped areas. It also reduces fatigue during prolonged use.

- Built-in Clutch: Many models include a clutch. This feature automatically stops the screw when it reaches a certain torque level. This prevents over-tightening.

- Ease of Use: Designed for simplicity, electric screwdrivers are generally user-friendly. They often feature a comfortable grip and straightforward controls.

- Battery Powered: Most electric screwdrivers are cordless. This provides enhanced freedom of movement, and they are usually lightweight to carry.

Drill vs Electric Screwdriver Power and Functionality

The core difference between a drill and an electric screwdriver lies in their power and how they work. Drills have greater torque and speed, making them suitable for a broader range of tasks, including drilling holes and driving screws into tougher materials. Electric screwdrivers, with less power, are best for lighter tasks. Consider what you are looking to do. Choosing the correct tool based on power and performance can make a big difference in both efficiency and the final results.

Power Output Comparison

The power output of a drill is generally higher than that of an electric screwdriver. This is primarily due to its more powerful motor. Drills are made to handle a greater variety of materials. The higher torque of a drill allows it to create larger holes, work with denser materials, and drive longer screws. Electric screwdrivers, while useful, have a lower torque. They are optimized for lighter-duty tasks. Here is a comparison of typical specifications.

| Feature | Drill | Electric Screwdriver |

|---|---|---|

| Torque | High (Adjustable) | Low (Typically Pre-set) |

| Speed | High (Adjustable) | Moderate (Fixed or Low) |

| Materials | Wood, Metal, Plastic | Wood, Plastic |

- Torque Levels: Drills can deliver high torque, especially at lower speeds, which is important for driving screws into tough materials or creating larger holes. Electric screwdrivers have lower torque, so it’s easier to manage.

- Speed Settings: Drills often offer adjustable speed settings. This is useful for various applications. Lower speeds are excellent for driving screws, while higher speeds are good for drilling. Electric screwdrivers usually have a fixed or lower speed.

- Motor Strength: The motor size and power of a drill are typically greater than an electric screwdriver. The bigger motor allows the drill to manage challenging tasks.

- Material Compatibility: The higher power of a drill enables it to work effectively with wood, metal, and plastic. Electric screwdrivers are often better suited for softer materials.

Key Functionality Differences

The functionality of a drill versus an electric screwdriver differs. The drill is versatile, capable of creating holes, driving screws, and performing multiple tasks. Electric screwdrivers focus on driving screws, making them more specialized tools. This is excellent for repetitive tasks or when precision and ease of use are priorities. The correct choice depends on the project’s requirements, and the specific needs will guide your selection.

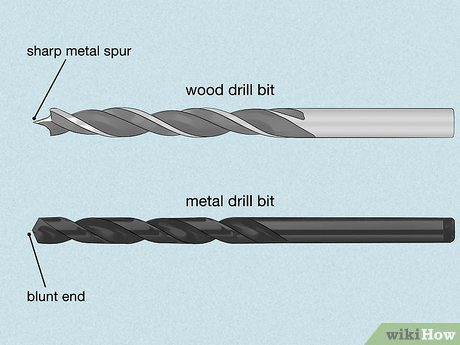

- Drilling Capability: Drills are created for drilling holes of different sizes and into various materials. They use a wide range of drill bits.

- Screw Driving: Both tools can drive screws, but electric screwdrivers are often more convenient for this task. They offer features like built-in clutches that prevent over-tightening.

- Versatility: Drills can perform a wider range of tasks, including mixing paint, sanding, or polishing with the proper attachments. Electric screwdrivers are designed primarily for screw-driving.

- Precision: Electric screwdrivers, with their compact design and ease of use, can provide better control. This is beneficial in tasks where precision is important.

Choosing the Right Tool for the Job

The best tool depends on the specific job. For projects that require drilling holes, a drill is the go-to option. If you are regularly driving screws, an electric screwdriver might be a better choice. Assess the materials you will be working with, the tasks you need to complete, and the frequency of use. Considering these factors ensures you select the most suitable tool.

Tasks Best Suited for a Drill

A drill shines when used for tasks demanding more power, versatility, and precision. It is excellent for drilling holes through tough materials, such as metal or hardwood. A drill’s adjustable settings allow for varied applications. Some tasks, such as creating pilot holes before driving screws, are made easier with a drill. Here are a few key tasks for which a drill is generally the better choice.

- Drilling Holes: The primary use for a drill is creating holes. The ability to use different drill bits makes it easy to work with various sizes and materials.

- Driving Screws in Tough Materials: A drill can drive screws into dense materials where an electric screwdriver might not be powerful enough.

- Mixing and Sanding: With the appropriate attachments, a drill can be used for a wide variety of tasks like mixing paint or sanding surfaces.

- Demanding Projects: When the project calls for power and versatility, such as home renovation or larger building projects, a drill is essential.

For example, imagine you are installing a new deck. You will need to drill holes for the support posts and then drive screws to secure the decking boards. A drill would be the perfect tool for this task because it can handle both actions efficiently.

Tasks Best Suited for an Electric Screwdriver

An electric screwdriver is excellent for tasks involving multiple screws or when precision and ease of use are important. Its compact design and built-in clutch make it convenient for assembling furniture or installing electrical outlets. Consider these scenarios for an electric screwdriver’s advantages.

- Furniture Assembly: Many furniture items require the use of numerous screws. The screwdriver makes the assembly process quicker and simpler.

- Installing Electrical Outlets: Electric screwdrivers are perfect for jobs where precise screw driving is required. This is essential for safety.

- Small Electronics Repair: Due to their size and control, electric screwdrivers are often favored for repairing small electronics.

- Light-Duty Tasks: Tasks requiring a lot of screw driving or that are done in tight spaces are perfect for the screwdriver.

For example, if you are putting together a flat-pack bookcase, an electric screwdriver would be ideal. It makes the task less strenuous and more efficient, allowing you to quickly secure the many screws required for the assembly.

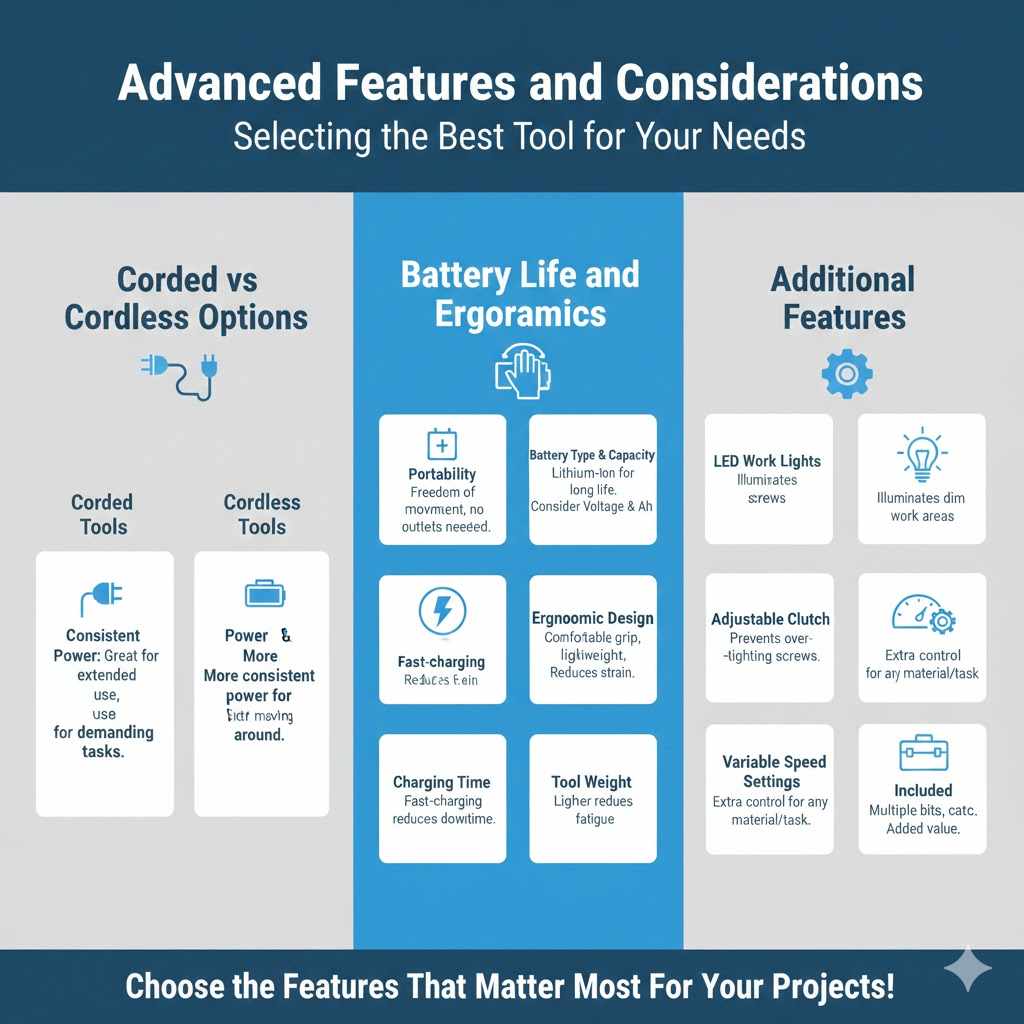

Advanced Features and Considerations

Besides basic functionality, certain features affect how well the drill or electric screwdriver works. You will want to consider the power source (corded versus cordless), battery life, ergonomics, and added features, such as LED lights and adjustable clutches. A closer look at these aspects will help ensure you select the best tool.

Corded vs Cordless Options

Both drills and electric screwdrivers come in corded and cordless versions. Each type offers different advantages. Corded tools provide continuous power, while cordless tools offer enhanced mobility. The power source selection depends on the job’s needs. Understanding the pros and cons of each helps in making an informed decision.

- Corded Tools: Provide a consistent power supply. This is great for tasks that require extended use. No need to worry about the battery running out.

- Cordless Tools: Offer portability and freedom of movement, especially in areas without available power outlets. However, the battery life limits the work duration.

- Power and Performance: Corded drills often provide more consistent power, so they are beneficial for demanding tasks. Cordless tools have improved greatly over time.

- Convenience and Mobility: Cordless tools are better when you need to move around a lot. Corded tools are great for staying in one place.

Battery Life and Ergonomics

With cordless tools, battery life is important, as it affects how long you can work without a break. Ergonomics, including the grip and balance, affect comfort during prolonged use. These features impact your experience when working. Investing in a tool with a good battery life and comfortable design can improve your experience.

- Battery Type and Capacity: Lithium-ion batteries have a long life. They are a good choice. Consider the voltage and amp-hours (Ah) of the battery to determine how long it will last.

- Ergonomic Design: A comfortable grip, balanced design, and lightweight construction reduce strain during use. This is particularly beneficial for projects that take longer.

- Charging Time: A fast-charging feature can greatly reduce downtime. This allows you to quickly get back to work.

- Tool Weight: A lighter tool is less likely to cause fatigue during prolonged use, especially if you need to work overhead or in tight areas.

Additional Features

Many drills and electric screwdrivers have useful features. These include LED lights for illuminating workspaces, adjustable clutches to prevent over-tightening screws, and multiple speed settings for added versatility. Evaluating these features can enhance your experience.

- LED Work Lights: LED lights are valuable because they can illuminate the work area. This is great for working in dim environments.

- Adjustable Clutch: A clutch stops the tool when the screw reaches a certain torque. This prevents over-tightening and protects delicate materials.

- Variable Speed Settings: This provides extra control. It allows you to adjust the speed to the material or task.

- Included Accessories: Some tools come with extra accessories, such as multiple screwdriver bits. This adds value and improves convenience.

Frequently Asked Questions

Question: Can I use a drill as an electric screwdriver?

Answer: Yes, you can use a drill as an electric screwdriver by installing a screwdriver bit. However, a drill may overtighten screws due to higher torque if the settings are not carefully adjusted.

Question: Are electric screwdrivers more portable than drills?

Answer: Electric screwdrivers are generally more portable. They are smaller and lighter than drills, making them easier to handle and move around, especially in tight spaces.

Question: Which tool is better for assembling furniture?

Answer: An electric screwdriver is usually better for furniture assembly because it simplifies the screw-driving process. Electric screwdrivers often have clutches that stop over-tightening.

Question: What’s the main difference in power between a drill and an electric screwdriver?

Answer: A drill has significantly more power. This is due to a more powerful motor and higher torque output, allowing it to work with a broader range of materials and perform a wider range of tasks.

Question: Is an electric screwdriver better for detailed work?

Answer: Yes, because of their smaller size and enhanced control, electric screwdrivers are usually better for tasks involving small components or in environments where precision is important.

Final Thoughts

The choice between a Drill vs Electric Screwdriver: Which Is Right for You? ultimately comes down to your specific project needs. A drill is best when you need power and versatility. If you need to make holes and drive screws in various materials, it is an excellent choice. An electric screwdriver is a good option when you need ease of use and precision. This tool is best for lighter-duty tasks, such as furniture assembly. Assessing the materials, the tasks, and the features of each tool will allow you to make the proper choice. Remember to consider factors such as corded versus cordless options, battery life, and ergonomic design. Selecting the appropriate tool enhances efficiency and results. Get started on your next project today!