How Elmer’s Glue Is Made: Essential Secrets Revealed

Elmer’s glue is made primarily from polyvinyl acetate (PVA) and water, with a few additives for stability and performance. The process involves mixing these ingredients under controlled conditions to create the familiar white glue.

Ever looked at that trusty bottle of Elmer’s glue and wondered what’s inside? It’s the go-to for so many projects, from school crafts to quick home repairs. But how does this common household staple actually come to be? It might seem like magic, but the creation of Elmer’s glue is a fascinating blend of science and careful manufacturing. You’re probably thinking, “Is it complicated?” Absolutely not! We’re going to break down the essential secrets of how Elmer’s glue is made, making it super easy to understand, just like fixing a wobbly chair leg. Let’s dive into the workshop of glue-making!

The Simple Magic Behind Elmer’s Glue

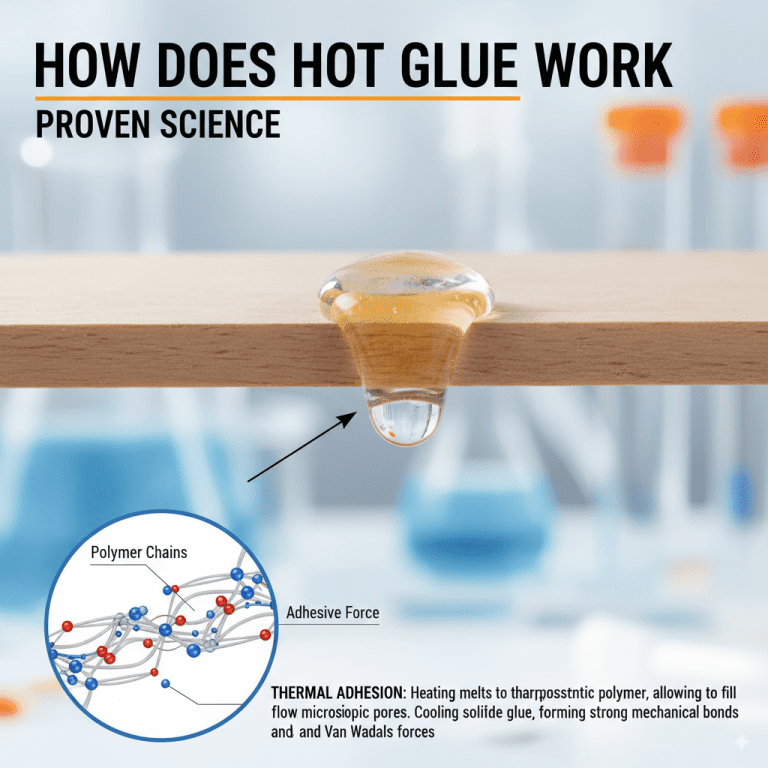

At its heart, Elmer’s glue is a polymer emulsion. Don’t let that fancy term scare you! Think of it like tiny plastic particles (that’s the polymer) mixed into water, with a few extra helpers to make it work just right. The magic happens when the water evaporates, leaving those plastic particles behind to lock together and create a strong bond. It’s this simple concept that makes Elmer’s glue so reliable for a vast range of materials.

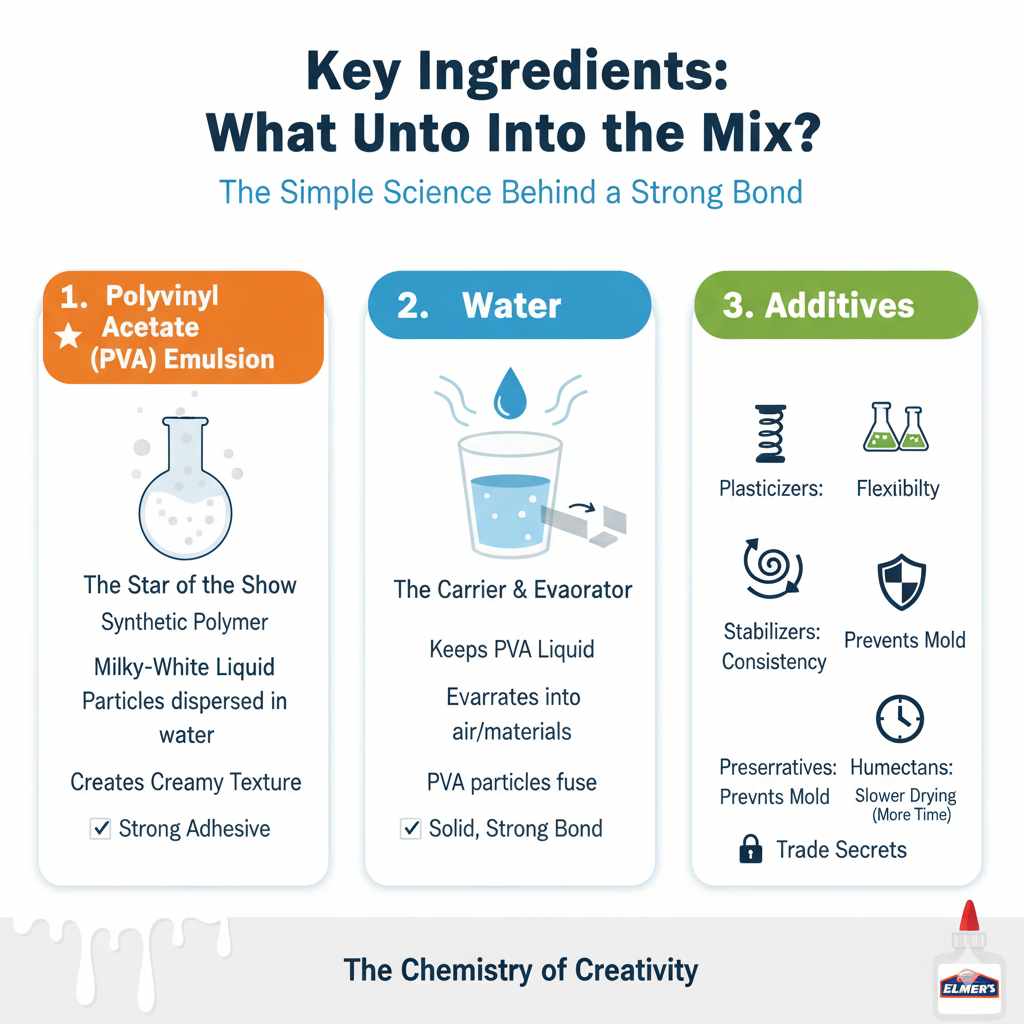

Key Ingredients: What Goes into the Mix?

The main players in Elmer’s glue are surprisingly straightforward. They are chosen for their ability to form a strong adhesive bond when dry and for their safety and ease of use.

1. Polyvinyl Acetate (PVA) Emulsion: The Star of the Show

This is the sticky stuff that does most of the work. Polyvinyl acetate is a synthetic polymer. In Elmer’s glue, it’s not in solid form but as a milky-white liquid called an emulsion. This means the PVA particles are tiny and dispersed evenly throughout water, creating that signature creamy look and feel. PVA is also the main ingredient in many wood glues, showing its strength and versatility.

2. Water: The Carrier and Evaporator

Water is crucial. It keeps the PVA in an easy-to-pour liquid state. When you spread the glue, the water starts to evaporate into the air or soak into the materials you’re joining. As the water leaves, the PVA particles get closer and closer, eventually fusing together to form that solid, strong bond.

3. Additives: The Supporting Cast

While PVA and water make up the bulk of the glue, a few other ingredients are added to improve its performance, shelf life, and safety. These are often kept as trade secrets by manufacturers, but common types include:

- Plasticizers: These make the dried glue film more flexible, so it won’t crack or become brittle over time, especially when used on materials that might bend or shift slightly.

- Stabilizers: These prevent the PVA particles from clumping together in the bottle and ensure the glue remains smooth and consistent.

- Preservatives: A small amount is added to prevent mold or bacteria from growing in the glue, giving it a longer shelf life.

- Humectants: Sometimes included to help the glue dry slower, giving you more time to position your pieces perfectly.

The Manufacturing Process: From Ingredients to Bottle

Making Elmer’s glue isn’t done in a backyard shed; it happens in specialized factories with precise control over the process. Here’s a simplified look at how it’s done:

Step 1: Creating the PVA Emulsion

This is a chemical process. Monomers of vinyl acetate are polymerized in water. Think of it like linking many tiny building blocks (vinyl acetate) together to form long chains (polyvinyl acetate) while they are suspended in water. This creates the stable white liquid we recognize.

Step 2: Mixing the Ingredients

In large, industrial mixers, the PVA emulsion is combined with water and the secret blend of additives. The mixing is done carefully to ensure everything is perfectly blended. Too much or too little of an ingredient, or mixing too fast or too slow, can affect the glue’s final strength and consistency. Imagine making a cake – the order and method of mixing matter!

Step 3: Quality Control

Before the glue is bottled, it goes through rigorous testing. Technicians check for the right consistency, pH level, viscosity (how easily it flows), and adhesive strength. This ensures every bottle meets Elmer’s high standards. If a batch doesn’t pass, it won’t make it to the store shelves.

Step 4: Bottling and Packaging

Once approved, the glue is pumped into bottles, jars, or tubes. The filling process is automated to ensure accuracy and speed. Then, labels are applied, and the glue is ready to be shipped out to homes and schools everywhere.

Elmer’s Glue vs. Other Adhesives: Why Choose PVA?

You might be wondering why Elmer’s glue, a type of PVA, is so popular. It’s all about its fantastic balance of properties, especially for DIYers and crafters.

Pros of Elmer’s PVA Glue:

- Versatile: Works well on paper, cardboard, wood, fabric, and some plastics.

- Non-Toxic: Generally safe for children to use, a big win for craft projects.

- Easy Cleanup: Water-based, so spills and excess glue wipe away with just water when wet.

- Affordable: One of the most budget-friendly adhesives available.

- Strong Bond: Creates a durable bond for many common household materials.

- Dries Clear or White: Depending on the specific formula, it can dry clear or leave a slightly opaque white finish, suitable for many applications.

Cons to Consider:

- Not Waterproof: Traditional Elmer’s glue can break down if exposed to significant moisture or water. For outdoor projects or items that will get wet, a specialized waterproof glue is a better choice.

- Limited Temperature Range: Freezing temperatures can permanently damage the glue, and extreme heat can affect its performance.

- Not Ideal for All Materials: It won’t bond well to very slick surfaces like metal or glass without proper preparation.

A Peek Behind the Curtain: Common Misconceptions

There are a few ideas about glue-making that aren’t quite right. Let’s clear them up!

Is Elmer’s Glue Made from Animal Parts?

No, the most common Elmer’s white glue is made from synthetic polymers (PVA) and water. Older glues, like traditional hide glue, were made from animal collagen, but modern PVA glues are chemical formulations. This makes them more consistent and often safer to use.

Is it Glue or Paste?

This is a great question! Traditional white paste, often used in schools, is typically based on starches (like wheat or corn). Elmer’s white glue is an emulsion, making it stickier and more permanent than starch-based paste. While both are adhesives, glue generally offers a stronger hold.

Comparing Elmer’s Glue Types

Elmer’s has developed different formulations of their glue to suit specific needs. Here’s a quick look at a few common types:

| Glue Type | Primary Use | Key Features |

|---|---|---|

| Elmer’s School Glue (White) | Crafts, paper, school projects | Non-toxic, washable, easy to use, dries clear or white |

| Elmer’s Wood Glue | Woodworking, furniture repair | Stronger bond for wood, dries clear or yellow, often more water-resistant than school glue |

| Elmer’s Craft Bond (Clear) | General crafting, bonding various materials | Dries clear for invisible bonds, good for decorations and DIY |

| Elmer’s Glue-All | Multi-purpose for home, school, and office | Bonds porous to semi-porous surfaces, stronger than school glue |

When to Use What: Choosing the Right Bond

Understanding the basics of how Elmer’s glue is made helps you pick the right one for your task. For most paper crafts and kid-friendly projects, the classic white school glue is perfect. If you’re working with wood for a DIY shelf or a small repair, reach for Elmer’s Wood Glue. Its formulation is optimized for wood fibers, creating a much stronger joint that’s often more durable. For projects where you don’t want a visible glue line, like attaching embellishments or clear plastics, an Elmer’s clear adhesive is the way to go.

For materials that are less forgiving, like certain plastics or fabrics, always check the glue bottle’s label for recommended uses. Sometimes, a little extra preparation, like lightly sanding a plastic surface, can help improve adhesion.

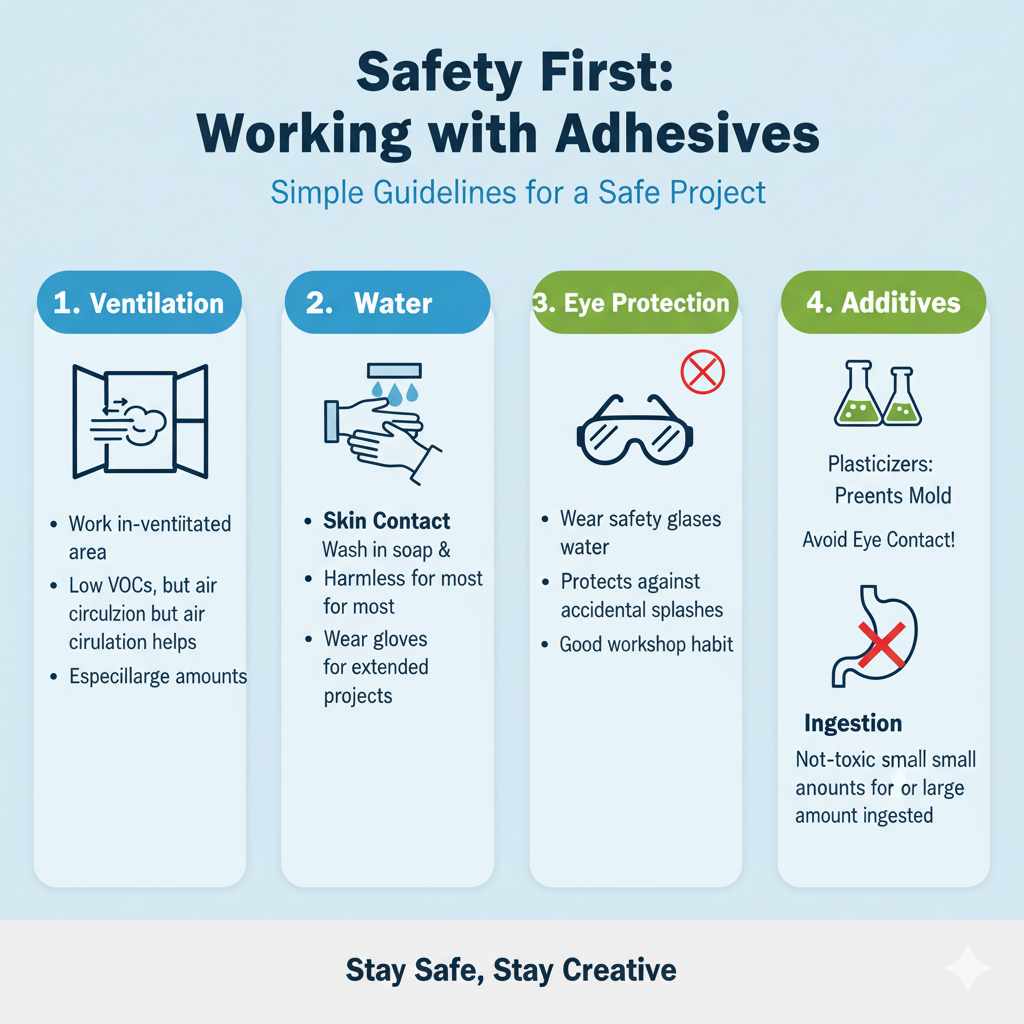

Safety First: Working with Adhesives

Even though Elmer’s glue is generally safe, it’s always good practice to follow some basic safety tips, especially when you’re working on a project.

- Ventilation: While PVA glues have low VOCs (Volatile Organic Compounds), it’s always a good idea to work in a well-ventilated area, especially if you’re using a large amount or working for an extended period.

- Skin Contact: If you get glue on your skin, it’s usually harmless, and you can wash it off with soap and water. However, if you have sensitive skin or notice any irritation, wash it off immediately. Consider wearing gloves for extended projects.

- Eye Protection: Although unlikely, glue can sometimes squirt unexpectedly. Wearing safety glasses is a good habit, especially in a workshop environment. You can learn more about eye safety in DIY projects from resources like the NIOSH Eye Protection page.

- Ingestion: Elmer’s glue is not meant to be eaten. If swallowed, it’s generally non-toxic in small amounts, but can cause stomach upset. If a large amount is ingested, it’s best to consult a medical professional or poison control center.

Frequently Asked Questions About Elmer’s Glue

Q1: Is Elmer’s glue permanent?

A: Traditional Elmer’s School Glue is designed for crafts and is not considered permanent in the way some industrial adhesives are. It provides a strong, durable bond for paper and light materials. For wood, Elmer’s Wood Glue offers a much more permanent and robust bond.

Q2: Can I use Elmer’s glue on fabric?

A: Yes, Elmer’s School Glue and Glue-All can be used on fabric for crafts. It dries flexible enough for most fabric projects. For more demanding fabric applications like durable seams or washable items, a fabric-specific adhesive is recommended.

Q3: Will Elmer’s glue hold metal?

A: Elmer’s glue is not ideal for bonding metal. It works best on porous or semi-porous surfaces. For metal-to-metal bonding, you would need a specialized adhesive like epoxy or a strong cyanoacrylate (super glue).

Q4: How long does it take for Elmer’s glue to dry?

A: Drying time can vary. For Elmer’s School Glue on paper, it might take about 15-30 minutes to set and a few hours to fully cure. For wood glue, it needs at least an hour to set and 24 hours for full strength development. Factors like humidity and temperature also play a role. You can find more about drying and curing times on Elmer’s official website.

Q5: Can I thin Elmer’s glue with water?

A: You can thin Elmer’s School Glue with a small amount of water for certain techniques, like creating glue for paper mache or for easier spreading. However, thinning it too much will weaken the bond. For wood glue, it’s generally not recommended to add water, as it can significantly compromise its strength.

Q6: What is Elmer’s glue made of if it smells sweet?

A: The pleasant smell of some glues comes from the plasticizers or other specific additives used in the formulation. These are carefully selected to be safe and are not related to the primary adhesive properties of the PVA emulsion.

Conclusion: Your Trusted Adhesive, Explained

So, there you have it! The “essential secrets” of how Elmer’s glue is made are really about understanding the simple yet effective combination of polyvinyl acetate emulsion and water, enhanced by a few smart additives. It’s a testament to how basic chemistry can create a product that’s become indispensable in our homes, schools, and workshops. From holding together your child’s masterpiece to reinforcing that DIY furniture project, Elmer’s glue performs reliably because of its carefully crafted formulation and manufacturing process.

Knowing what’s inside and how it works not only demystifies this common product but also empowers you to choose the right adhesive for your next project. Remember, whether it’s for a quick fix or a creative endeavor, Elmer’s glue offers an accessible, safe, and effective solution. Keep that bottle handy – you never know when you’ll need to join two things together!