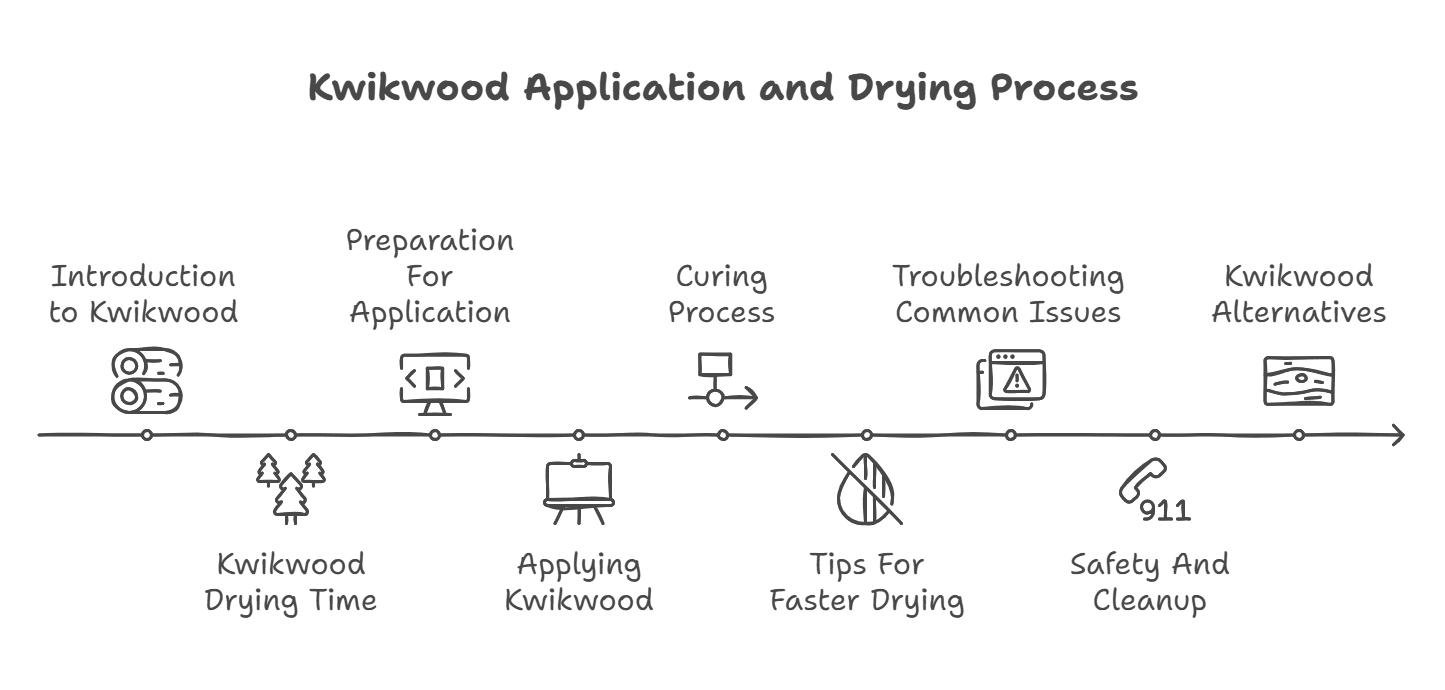

How Long Does Kwikwood Take to Dry? Quick Guide!

KwikWood typically takes about 15 to 30 minutes to set and can fully cure in 24 hours. Drying times may vary based on environmental conditions like temperature and humidity.

KwikWood is a versatile epoxy putty ideal for wood repairs. It bonds well to a variety of surfaces, making it perfect for both indoor and outdoor projects. Users appreciate its quick setting time, allowing for rapid fixes without long waits.

This product is especially handy for filling cracks, gaps, or missing pieces in wood. Whether you’re tackling furniture repairs or home improvement tasks, KwikWood offers a reliable solution. Its easy application and strong adhesion make it a favorite among DIY enthusiasts and professionals alike. Understanding its drying time helps ensure optimal results for your projects.

Introduction To Kwikwood

Kwikwood is a versatile wood repair product. It is designed for easy use. This product is a putty that can fill gaps and cracks.

Common uses of Kwikwood include repairing furniture, doors, and moldings. It works well for both indoor and outdoor projects. Kwikwood can also be used for crafts and DIY repairs.

This product dries quickly, making repairs faster. It can be sanded, painted, or stained after drying. Many people choose Kwikwood for its strong bond and durability.

Kwikwood Drying Time

Kwikwood is a popular wood filler known for its quick drying time. Generally, it takes about 30 minutes to dry to the touch. Full curing may take up to 24 hours. This duration can change based on various factors.

Several factors affect the drying time of Kwikwood:

- Humidity: High humidity can slow down the drying process.

- Temperature: Warmer temperatures speed up drying.

- Thickness: Thicker applications take longer to dry.

- Ventilation: Good airflow helps Kwikwood dry faster.

Preparation For Application

Before applying Kwikwood, ensure the surface is clean and dry. Remove dirt, dust, and grease. Use a sanding block or sandpaper for smooth surfaces.

A clean area helps the adhesive bond better. Remove any old finishes or coatings. This ensures the best results.

| Tools Needed |

|---|

| Sandpaper |

| Sanding Block |

| Putty Knife |

| Clean Cloth |

| Protective Gloves |

Applying Kwikwood

To get the best results with Kwikwood, proper mixing is essential. Start by gathering the two-part product: the resin and the hardener. Use a clean container for mixing. Add equal parts of the resin and hardener. Stir them together thoroughly. Make sure there are no lumps or dry spots.

Mixing should take about 1 to 2 minutes. A consistent texture is key for a successful application. After mixing, you have a limited time to work with the product. Aim to apply it within 15 to 20 minutes for optimal results. Always follow the instructions on the package for best practices.

Curing Process

The curing process of Kwikwood involves several important stages. Each stage plays a role in how well it sets and dries.

The first stage is the initial setting. This occurs within a few minutes after application. The second stage is the hardening phase, where it starts to firm up. This can take a couple of hours.

Lastly, the full cure can take several days. A good way to tell if it’s fully cured is by checking its hardness. If it feels solid and does not leave a mark, it is ready.

| Stage | Time Frame |

|---|---|

| Initial Setting | Minutes |

| Hardening Phase | Hours |

| Full Cure | Days |

Tips For Faster Drying

To speed up the drying of Kwikwood, pay attention to temperature and humidity. Warmer temperatures help the product dry faster. Aim for a room temperature of at least 70°F. Low humidity levels also aid in quicker drying. Ideally, keep humidity below 50%.

Improving ventilation is another effective tip. Open windows to let fresh air in. Use fans to circulate air around the area. Better airflow helps moisture escape more quickly. This can significantly reduce drying time.

Troubleshooting Common Issues

Kwikwood can sometimes feel sticky or tacky after drying. This issue often arises from applying too much product. Make sure to use only the recommended amount for each project.

If the product seems incomplete or not fully dry, check the temperature and humidity. High humidity can slow down the drying time. Always allow enough air circulation around the area.

| Common Issues | Solutions |

|---|---|

| Sticky or Tacky Feel | Use less product and ensure proper air circulation. |

| Incomplete Drying | Check temperature and humidity levels; allow more time to dry. |

Safety And Cleanup

Always wear gloves and a mask when using Kwikwood. This protects your skin and lungs. Avoid contact with your eyes and mouth. Keep the workspace well-ventilated to reduce fumes.

For post-application cleanup, use solvents like mineral spirits. Clean tools immediately after use to avoid hardening. Dispose of any leftover material according to local regulations. Store Kwikwood in a cool, dry place, away from children and pets.

Check the label for specific safety instructions. Following these tips ensures a safe and clean experience while using Kwikwood.

Kwikwood Alternatives

Several wood fillers can serve as great Kwikwood alternatives. Each option has unique features. Here’s a quick comparison:

| Wood Filler | Drying Time | Best Use |

|---|---|---|

| Epoxy Filler | 24 hours | Outdoor projects |

| Polyester Filler | 15 minutes | Large gaps |

| Latex Filler | 1 hour | Indoor repairs |

| Wood Glue | 30 minutes | Wood joints |

Each filler has its strengths. Choose one based on your specific needs. Check drying times before starting your project. This helps ensure the best results.

Final Thoughts

Kwikwood typically dries in about 30 minutes for a firm hold. Full curing takes up to 24 hours. Drying time can vary based on humidity and temperature.

For best results, apply Kwikwood in a well-ventilated area. Ensure surfaces are clean and dry before use. Mixing is important; follow the instructions closely.

Always check the label for specific drying times. Keep in mind that thicker applications will take longer to dry.

| Application Thickness | Drying Time |

|---|---|

| Thin | 30 minutes |

| Medium | 1-2 hours |

| Thick | 24 hours |

Check the manufacturer’s website for more tips and advice. This will help you achieve the best results.

Frequently Asked Questions

How Quickly Does Kwikwood Set?

Kwikwood typically sets within 15 to 30 minutes. However, complete drying may take longer. Factors like temperature and humidity can affect setting time. For best results, allow it to cure for at least 24 hours before sanding or painting. Always check the manufacturer’s instructions for specific guidance.

Can Kwikwood Be Painted After Drying?

Yes, you can paint Kwikwood after it dries completely. Ensure the surface is clean and sanded for better adhesion. Use a compatible paint type for the best finish. Allow sufficient drying time before applying the paint. This will help achieve a smooth and durable surface.

Is Kwikwood Waterproof When Dry?

Kwikwood is water-resistant but not fully waterproof when dry. It can withstand light moisture but may not hold up in constant wet conditions. For outdoor projects or areas exposed to water, consider applying a sealant. This extra layer will enhance its durability against water damage.

How Long Does Kwikwood Take To Cure Fully?

Kwikwood usually takes about 24 hours to cure fully. However, curing times can vary based on environmental factors. Higher humidity or cooler temperatures may prolong the curing process. For optimal results, allow a full 48 hours before subjecting it to stress or heavy use.

Conclusion

Kwikwood typically dries within 15 to 30 minutes. Factors like humidity and temperature can affect this time. For best results, ensure proper application and environment. Understanding these drying times can help you plan your projects effectively. Always check the manufacturer’s guidelines for optimal use and performance.

Happy crafting!