How Soon Can You Seal Cedar Wood: Quick Guide

You can seal cedar wood as soon as it is dry to the touch. This usually takes about two to three months.

Cedar wood is a popular choice for outdoor projects due to its natural resistance to decay and insects. Properly sealing cedar wood enhances its durability and appearance. Sealing prevents moisture from penetrating the wood, which helps to maintain its structural integrity.

It also protects against UV damage, which can cause the wood to fade and deteriorate over time. Before sealing, ensure the wood is clean and dry. Choosing the right sealant is crucial for long-lasting protection. Regular maintenance, including re-sealing every few years, will keep your cedar wood looking great and performing well.

Introduction To Cedar Wood Sealing

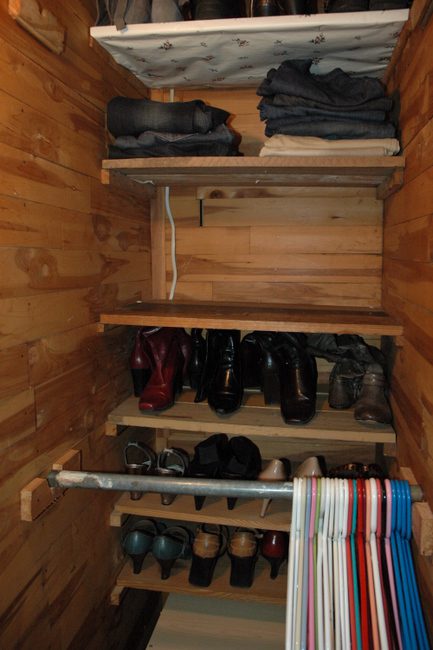

Sealing cedar wood helps protect it from moisture damage. It also prevents the wood from cracking and splitting. A sealed cedar surface resists mold and mildew growth. This keeps the wood looking fresh and clean. Sealed cedar wood lasts longer than untreated wood. It also maintains its color and beauty. Sealing enhances the wood’s natural durability. It makes the cedar easier to clean and maintain.

Many people think cedar wood does not need sealing. This is not true. Even though cedar is naturally durable, sealing adds extra protection. Some believe sealing cedar will change its color. But sealing can actually help keep the wood’s natural color. Another myth is that sealing is hard and time-consuming. Sealing cedar wood is easy and can be done quickly with the right products.

Factors Affecting Sealing Time

Older cedar wood absorbs sealant faster than new wood. New cedar wood needs more time to dry before sealing. Softwood like cedar dries quicker than hardwood. Drying time affects how soon you can seal cedar wood. Untreated cedar may need more time to dry out.

Weather conditions play a big role in sealing time. Humid weather slows down the drying process. Sunny days help the wood to dry faster. Rainy weather can delay sealing by several days. Airflow also helps the wood dry evenly.

Preparation Steps Before Sealing

Cedar wood requires proper preparation before sealing. Ensure the wood is dry, clean, and sanded to perfection for optimal results.

Cleaning The Cedar Surface

Cleaning the cedar surface is very important. Remove all dirt and debris using a soft brush. Use a wood cleaner for tough stains. Rinse the wood with water after cleaning. Let the wood dry completely before the next step. A clean surface ensures better sealant application.

Sanding For Better Adhesion

Sanding smooths the cedar wood surface. Use fine-grit sandpaper for this task. Sand the wood evenly to avoid rough patches. Wipe away the dust with a damp cloth. Sanding helps the sealant stick better to the wood.

Choosing The Right Sealant

There are two main types of cedar sealants. These are water-based and oil-based. Each has its own pros and cons.

| Water-Based Sealants | Oil-Based Sealants |

|---|---|

| Dry quickly | Penetrate deep into wood |

| Easy cleanup | Last longer |

| Less odor | Rich finish |

| Eco-friendly | Repel water well |

The Best Conditions For Sealing

Sealing cedar wood works best in dry weather. Rain can ruin the sealing process. Sunny days are perfect for this task. This helps the sealant dry properly. A dry surface is essential for a good seal.

Temperature and humidity affect the sealing process. The ideal temperature is between 50°F and 90°F. Too hot or too cold can spoil the work. High humidity delays drying. Lower humidity speeds up drying. Check the weather forecast before starting.

Application Techniques For Sealant

Using a brush allows for better control over the sealant. Spraying is faster but may lead to uneven coverage. A brush can reach tight spots and corners. Spraying is ideal for large surfaces. Choose the method based on the area size and detail required. Some people prefer combinations of both methods. This ensures smooth and even sealant application.

Always clean the wood surface first. Apply sealant in thin layers. Work slowly to avoid drips and runs. Overlap strokes to ensure even coverage. Check for missed spots as you go. Use a quality brush or sprayer for best results.

Drying And Curing Time

Drying cedar wood can take between two to twelve weeks. The exact time depends on various factors. A key factor is the wood’s thickness. Thicker wood takes longer to dry. Humidity levels in your area also play a role. High humidity slows down the drying process.

Several factors affect the curing process of cedar wood. The type of cedar wood used is important. Some types dry faster than others. Temperature is another critical factor. Warmer temperatures speed up curing. Proper ventilation helps too. Good airflow around the wood aids in faster curing.

Maintenance After Sealing

Regular inspections of cedar wood are very important. Look for any signs of damage or wear. Pay attention to cracks, discoloration, or water damage. Cleaning the surface every few months helps in keeping the wood in good condition. Use a soft brush and mild detergent for cleaning. Never use harsh chemicals as they can harm the wood.

Reapply sealant when the wood starts to look dull. This usually happens every one to two years. Check the wood by sprinkling water on it. If water soaks in, it’s time to reapply. Follow the manufacturer’s instructions for the best results. Always choose a high-quality sealant.

Troubleshooting Common Issues

Sometimes cedar wood has sticky residue after sealing. This can happen if the wood is not completely dry. Always ensure the wood is dry before sealing. Wipe the sticky residue with a clean cloth. Use a mild soap solution if needed. Let the wood dry properly again before resealing. This prevents sticky spots in the future.

Uneven coating can make cedar wood look bad. Sand the wood lightly with fine-grit sandpaper. This smooths out the uneven areas. Reapply the sealer in thin, even layers. Use a good quality brush or roller. Avoid thick layers of sealer. Thin layers dry faster and more evenly. Let each layer dry completely before adding another. This helps achieve a smooth, even finish.

Frequently Asked Questions

How Long To Wait Before Sealing Cedar?

Wait at least two weeks before sealing cedar. Allow the wood to dry completely. Ensure it’s clean and free of debris.

Can You Seal New Cedar?

Yes, you can seal new cedar. Sealing helps protect cedar from moisture, UV rays, and weathering. Use a high-quality sealer for best results.

Can I Stain Cedar Right Away?

You should wait before staining cedar. Allow it to weather for a few months. This ensures better stain absorption.

What Is The Best Sealant For Cedar Wood?

The best sealant for cedar wood is a high-quality, oil-based stain or sealant. It provides excellent protection and enhances the natural beauty of the wood. Look for products specifically designed for cedar to ensure durability and longevity.

Conclusion

Sealing cedar wood promptly enhances its durability and appearance. Wait until the wood is dry and clean. Proper timing ensures protection from moisture and UV damage. Regular maintenance extends the wood’s life and keeps it looking beautiful. Follow these tips to enjoy the long-lasting benefits of sealed cedar wood.