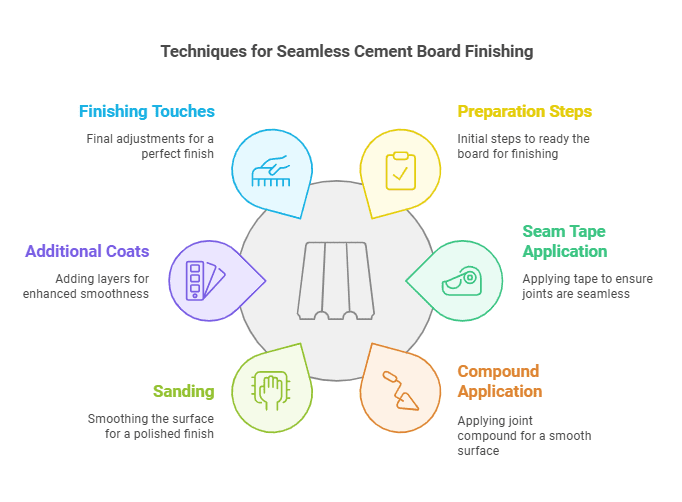

How to Finish Cement Board: Seamless Techniques

To finish cement board, first, apply a thin layer of joint compound using a trowel. Once dry, sand the surface to a smooth finish.

Cement board is a popular choice for tile backers and wet areas like bathrooms. Its moisture resistance makes it ideal for various projects, including flooring and wall installations. Finishing cement board properly ensures a smooth surface that enhances the overall appearance and durability of your tiling work.

Whether you’re a DIY enthusiast or a professional, understanding the right techniques for finishing cement board is crucial. This process not only prepares the surface for tile adhesion but also prevents future issues like cracking or water damage. Learn how to achieve the best results with simple, effective methods.

Introduction To Cement Board Finishing

Cement board finishing is essential for a durable surface. It provides a strong base for tiles and other coverings. Understanding the right techniques helps achieve a polished look. This section covers why cement board is popular and how to choose the right tools.

Why Cement Board?

Cement board offers numerous benefits for construction projects. Here are some key advantages:

- Water Resistance: It does not warp or swell in moisture.

- Durability: Cement board withstands heavy impacts.

- Fire Resistance: It is non-combustible, enhancing safety.

- Easy to Install: It cuts easily to fit any space.

| Feature | Benefit |

|---|---|

| Moisture Resistance | Prevents damage in wet areas. |

| Longevity | Lasts longer than traditional materials. |

| Versatility | Works well with various finishes. |

Choosing The Right Tools

Selecting the right tools is vital for cement board finishing. Here’s a list of essential tools:

- Utility Knife: For cutting the board.

- Drill: For securing the boards to studs.

- Measuring Tape: For accurate measurements.

- Screws: Specific for cement board installation.

- Joint Tape: For reinforcing seams.

Invest in high-quality tools. They make the finishing process easier. Proper tools ensure a clean and professional look.

Preparation Steps

Preparing to finish cement board is crucial for a smooth project. Proper preparation ensures durability and a professional appearance. Follow these steps to achieve the best results.

Measuring And Cutting

Accurate measurements lead to precise cuts. Follow these steps:

- Gather Tools: You need a tape measure, a straight edge, and a utility knife.

- Measure: Measure the area where you will install the cement board.

- Mark the Board: Use a pencil to mark your measurements on the board.

- Cut the Board: Score the marked line with the utility knife. Snap the board along the score line.

Check the fit before securing the boards. Make adjustments if necessary.

Securing The Boards

Secure the cement boards properly to avoid movement. Here’s how:

- Use Screws: Use cement board screws for better grip.

- Spacing: Space screws every 8 inches along the edges.

- Check for Gaps: Ensure there are no gaps between the boards.

Follow the manufacturer’s guidelines for screw depth and spacing. This ensures a strong bond.

Applying Joint Compound

Joint compound helps create a smooth surface. Follow these steps:

- Mix the Compound: Follow the instructions on the packaging.

- Apply the First Coat: Use a taping knife to spread the compound over seams.

- Embed Tape: Press fiberglass tape into the wet compound.

- Apply Second Coat: Once dry, add a second layer of compound. Feather the edges for a smooth finish.

- Sand: Once dry, sand the surface lightly for smoothness.

Ensure the surface is even before moving on. This step is crucial for a quality finish.

Seam Tape Application

Applying seam tape is crucial for a smooth finish on cement board. Proper application prevents cracks and ensures a strong bond. Follow these steps to achieve excellent results.

Types Of Seam Tape

Choosing the right seam tape is essential. Here are the most common types:

| Type of Seam Tape | Description |

|---|---|

| Fiberglass Mesh Tape | Strong and flexible. Ideal for cement board seams. |

| Paper Tape | Used for drywall. Not recommended for cement board. |

| Self-Adhesive Tape | Easy to apply. Great for quick repairs. |

Step-by-step Application

Follow these steps for applying seam tape:

- Gather Materials: Collect seam tape, thin-set mortar, and a taping knife.

- Clean the Surface: Ensure the cement board seams are free of dust.

- Apply Thin-Set Mortar: Spread a thin layer over the seam.

- Press the Tape: Place the tape over the wet mortar. Press it down firmly.

- Cover the Tape: Apply another layer of thin-set over the tape.

- Feather the Edges: Smooth the edges to blend with the board.

- Let it Dry: Allow the thin-set to dry completely before sanding.

Following these steps will ensure a durable and smooth finish on your cement board seams.

Applying The First Coat Of Compound

Applying the first coat of compound on cement board is crucial. It helps create a smooth surface for tiles or paint. Follow these steps for a successful application.

Mixing The Compound

Proper mixing of the compound ensures a smooth finish. Use a pre-mixed compound or mix your own. Here’s how:

- Use a clean bucket for mixing.

- Add water as per the manufacturer’s instructions.

- Gradually add the compound to the water.

- Mix thoroughly using a drill mixer or a hand mixer.

- Avoid lumps for a better application.

Technique For Smooth Application

Employ the right technique for a smooth finish. Follow these steps:

- Use a 12-inch taping knife for application.

- Start at the top and work down.

- Apply a thin layer of compound.

- Hold the knife at a 30-degree angle.

- Feather the edges to blend into the surface.

Check for any missed spots. Fill them before the compound dries. Allow the first coat to dry completely before sanding.

Sanding For Smoothness

Sanding is essential for achieving a smooth finish on cement board. Proper sanding helps to eliminate rough edges and ensures a clean surface for painting or tiling. This process enhances the overall appearance and longevity of your project.

Choosing The Right Sandpaper

Selecting the right sandpaper is crucial for effective sanding. The grit of sandpaper determines how coarse or fine it is. Here’s a quick guide:

| Grit Level | Use Case |

|---|---|

| 60-80 | Initial sanding of rough surfaces |

| 120-150 | Intermediate sanding for a smoother finish |

| 220+ | Final sanding for a polished look |

For cement board, start with a medium grit (120-150). This grit removes imperfections without damaging the surface.

Sanding Techniques

Employing the right techniques ensures a smooth finish. Follow these steps:

- Wear a mask. Cement dust can be harmful.

- Use a sanding block. This helps maintain even pressure.

- Sand in a circular motion. This technique reduces flat spots.

- Check your progress. Periodically wipe off dust to see results.

- Finish with fine grit. Use 220 grit for the final pass.

Remember to keep the sandpaper flat against the surface. Avoid pressing too hard; let the sandpaper do the work.

Applying Additional Coats

Applying additional coats to cement board enhances durability and appearance. This process ensures smooth finishes and protects against moisture. Follow these simple guidelines for the best results.

When To Apply

Timing is crucial for applying additional coats. Wait for the first coat to dry completely before adding more. Here’s a quick guide:

| Coat Number | Drying Time (Hours) | Ideal Conditions |

|---|---|---|

| First Coat | 24 | Room temperature, low humidity |

| Second Coat | 24 | Room temperature, low humidity |

| Third Coat | 24 | Room temperature, low humidity |

Achieving Seamless Surfaces

Seamless surfaces make cement board projects look professional. Follow these tips to achieve this effect:

- Sand Between Coats: Lightly sand each coat after it dries.

- Use a Trowel: Apply coats evenly with a trowel.

- Feather Edges: Blend edges to eliminate visible lines.

- Inspect Thoroughly: Check for imperfections before the final coat.

Finishing Touches

Finishing touches make all the difference in cement board projects. These steps ensure a smooth and professional look. Let’s explore the key steps: final sanding and cleaning and priming.

Final Sanding

Final sanding is crucial for a flawless finish. Follow these steps:

- Choose the Right Sandpaper: Use 120 to 150 grit sandpaper.

- Use a Sander: An electric sander speeds up the process.

- Smooth the Surface: Sand in circular motions to avoid scratches.

- Check for Imperfections: Look for rough spots and sand them down.

After sanding, wipe the surface clean. This removes dust and prepares for the next step.

Cleaning And Priming

Cleaning and priming enhance adhesion. Follow these steps:

- Dust Removal: Use a damp cloth to wipe the surface.

- Inspect for Debris: Ensure no dust or particles remain.

- Choose a Primer: Use a quality primer suitable for cement board.

- Apply Primer: Use a paint roller for an even coat.

Allow the primer to dry completely. This step is essential for durability.

Troubleshooting Common Issues

Finishing cement board can lead to various issues. Identifying these problems early helps prevent costly repairs. Here, we will discuss common issues and how to fix them effectively.

Avoiding And Fixing Bubbles

Bubbles can occur when applying thin-set or mortar. They trap air and affect adhesion. Here are steps to avoid and fix them:

- Proper Mixing: Mix thin-set according to the manufacturer’s instructions.

- Application Technique: Use a notched trowel for even spread.

- Pressing Down: Firmly press the cement board into the mortar.

- Rolling Pin: Use a rolling pin to eliminate air pockets.

If bubbles appear:

- Gently poke the bubble with a sharp tool.

- Squeeze out trapped air.

- Reapply thin-set over the area.

Dealing With Cracks

Cracks can form due to expansion and contraction. Addressing them quickly is crucial. Follow these steps to prevent and fix cracks:

| Prevention Tips | Repair Methods |

|---|---|

| Use a quality cement board. | Fill cracks with a patching compound. |

| Ensure proper installation. | Apply fiberglass tape over the crack. |

| Control moisture levels. | Sand the area smooth after drying. |

Regular inspection helps catch cracks early. Fix them immediately to avoid further damage.

Frequently Asked Questions

How Do You Finish Cement Board Edges?

To finish cement board edges, first, ensure they are clean and dry. Use a thin layer of thin-set mortar to fill any gaps. Once dried, sand the edges lightly for a smooth finish. Finally, apply a waterproofing membrane or tile adhesive before installing tiles.

Can You Paint Cement Board?

Yes, you can paint cement board. However, it’s important to use a suitable primer designed for cement surfaces. This ensures better adhesion and prevents moisture damage. After priming, use exterior latex paint for durability. Always allow sufficient drying time between coats for best results.

What Is The Best Way To Seal Cement Board?

The best way to seal cement board is by applying a waterproofing membrane. This protects it from moisture damage and mold. Use a roller or brush to spread the membrane evenly. Allow it to dry completely before installing tiles or other finishes for optimal protection.

Is Cement Board Necessary Under Tile?

Yes, cement board is necessary under tile in wet areas. It provides a stable, moisture-resistant surface that prevents cracking. Using cement board helps extend the lifespan of your tile installation. Always follow manufacturer guidelines for proper installation to ensure lasting results.

Conclusion

Finishing cement board can transform your space effectively. Follow the steps outlined to ensure a smooth, durable surface. Proper preparation and finishing techniques make a significant difference in the final look. With the right tools and patience, you’ll achieve professional results.

Start your project confidently and enjoy the benefits of your hard work.