How to Join Wood: Expert Techniques for Seamless Joints

Joining wood involves connecting two pieces together to create a solid structure. It’s an essential skill in woodworking, used in making furniture, frames, and other projects.

Woodworking can seem complex, but learning how to join wood is a fundamental step in mastering this craft. Whether you’re a beginner or have some experience, understanding the basics of wood joints is key. Properly joining wood ensures your projects are strong and durable.

Different methods exist, from simple butt joints to more intricate dovetail joints. Each technique has its uses and benefits. This guide will introduce you to the most common methods, helping you choose the right one for your project. Let’s dive in and explore the world of wood joints.

Credit: www.youtube.com

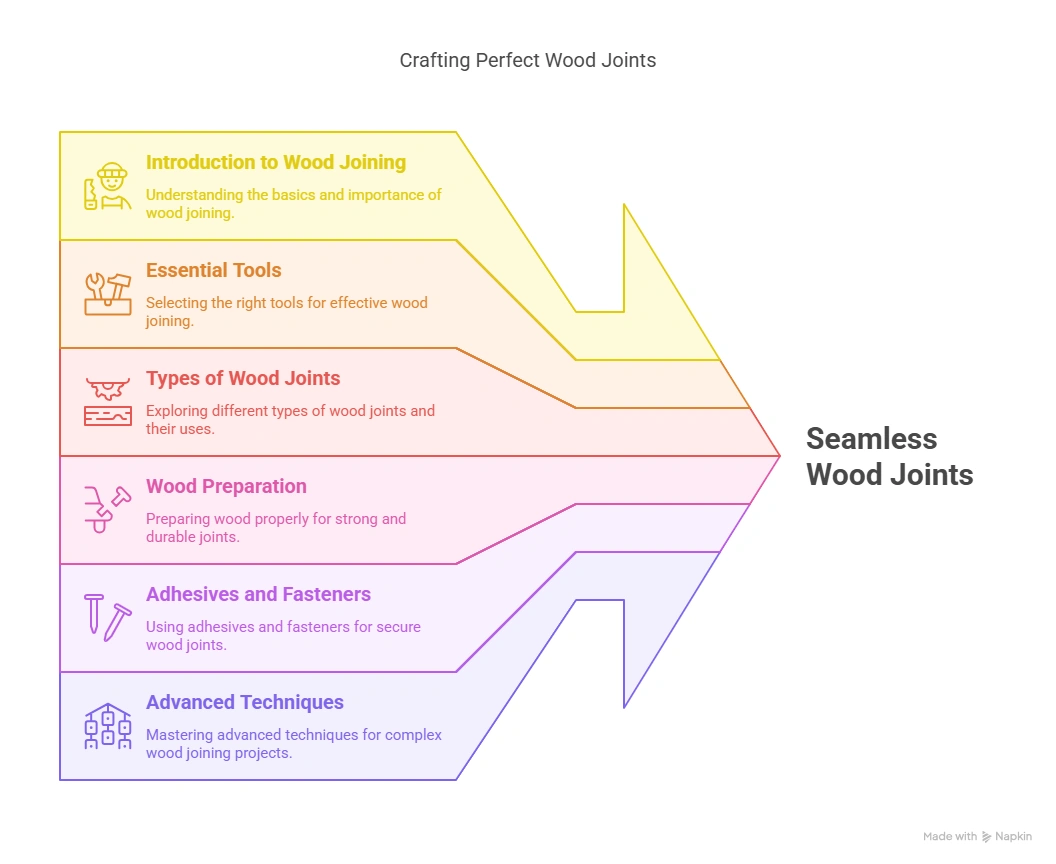

Introduction To Wood Joining

Discover the basics of how to join wood effectively. Learn various techniques to create strong and lasting joints. Enhance your woodworking skills with simple and practical methods.

Importance Of Proper Joints

Proper wood joints are key for strong furniture. They hold pieces together. Poor joints can make furniture weak. Proper joints make items last long. They also look nice. Good joints show skill and care. Always aim for strong and neat joints.

Common Wood Joining Challenges

Joining wood can be tricky. Pieces might not fit well. Gaps can show. Wood can split or crack. Aligning pieces can be hard. Glue might not hold. Screws can strip wood. Joints need to be precise. Practice helps. Good tools are a must. Measure twice, cut once.

:max_bytes(150000):strip_icc()/100869700-799bc53a1d704c4b85cc1308e3cb5200.jpg)

Credit: www.woodmagazine.com

Essential Tools For Wood Joining

Hand tools are important for wood joining. A hammer is needed to drive nails. A chisel helps to carve wood. Clamps hold wood pieces together. A hand saw cuts wood to size. Sandpaper smooths rough edges. A square helps to measure and check angles. Glue is used to bond wood pieces.

Power tools make wood joining easier. A power drill makes holes for screws. A circular saw cuts wood quickly. A power sander smooths large surfaces. An electric screwdriver drives screws fast. A jigsaw cuts curves and shapes. A router creates grooves and edges. A biscuit joiner helps with strong joints.

Types Of Wood Joints

Butt joints are simple and easy to make. Two pieces of wood are joined together end to end. They are often used in basic projects. This joint is not very strong by itself. Adding glue or screws can help make it stronger.

Miter joints are made by cutting wood at an angle. The most common angle is 45 degrees. They are often used for frames and boxes. This joint looks nice and clean. It requires precise cutting to fit well.

Dovetail joints are very strong and durable. Pieces of wood fit together like puzzle pieces. This joint is often used in drawers and furniture. It requires skill to make. The pieces must fit together tightly.

Mortise and tenon joints are used for heavy-duty projects. One piece of wood has a slot (mortise). The other piece has a tongue (tenon) that fits into the slot. This joint is strong and reliable. It is used in tables and chairs.

Preparing Wood For Joints

First, make sure the wood is clean and dry. Use a ruler and pencil to measure the wood pieces. Mark the spots where the cuts will be. Double-check the measurements. Mistakes can ruin the project. A measuring tape can also help. Accuracy is very important.

Choose the right saw for the job. Hand saws are good for small cuts. Use a table saw for bigger pieces. Make sure the saw blade is sharp. Dull blades can make bad cuts. Cut along the marked lines. Keep your hands away from the blade. Safety comes first.

Using Adhesives And Fasteners

Wood glue is popular. It is strong and easy to use. Another choice is epoxy. It works well for big projects. Super glue is fast-drying. It is good for small pieces. Remember to match the glue to the type of wood you have.

Screws hold wood tightly. They are easy to remove. Nails are fast to use. They are good for quick jobs. Use screws for strong joints. Use nails for lighter work. Select the right size for your wood. This stops it from splitting.

Advanced Joining Techniques

Biscuit joints are strong and easy to use. Small, oval-shaped pieces of wood called biscuits are used. These biscuits fit into slots cut into the wood. Glue is then applied to secure the joint. The biscuit expands, making a tight fit. This technique is great for aligning edges. It is often used in table tops and cabinets.

Pocket hole joints are quick and simple. A special jig is used to drill angled holes. Screws are then driven into these holes to join the wood. This method is strong and hides the screws. It is perfect for frames, cabinets, and furniture. No need for clamps while the glue dries. Easy to learn and very versatile.

Finishing And Sanding Joints

Sanding helps make wood smooth. Use a sanding block for flat surfaces. For curves, use sanding sponges. Begin with coarse grit sandpaper. Move to finer grit as the surface gets smoother. Sand in the direction of the grain. This avoids scratches. Check the surface often. Look for rough spots. Sand those areas more.

Clean the wood before applying finishes. Remove dust. Use a clean cloth or a vacuum. Choose your finish. Stain changes wood color. Varnish protects wood. Apply the finish with a brush. Use thin layers. Let it dry. Add more layers if needed. Sand lightly between layers.

:max_bytes(150000):strip_icc()/wood-joinery-types-3536631-v3-5b9827b84cedfd002536486c.png)

Credit: www.thesprucecrafts.com

Troubleshooting Common Issues

Gaps can appear if the wood pieces do not fit well. Check for warped wood. Use clamps to hold pieces tight together. Sand edges to make a smooth fit. Apply more glue to fill small gaps. If gaps are large, use wood filler. Let it dry, then sand it smooth. Always measure twice before cutting.

Weak joints can break under pressure. Ensure the glue covers the entire joint. Use strong clamps to hold pieces while the glue dries. Add screws or nails for extra strength. Check that all pieces fit tightly. A loose fit will weaken the joint. Use corner braces for added support on large projects. Always dry-fit pieces before gluing.

Frequently Asked Questions

What Is The Best Way To Join Two Pieces Of Wood?

Use wood glue and clamps for a strong bond. Reinforce with screws or nails for added stability.

What Is The Strongest Joining Method For Wood?

The strongest joining method for wood is the mortise and tenon joint. It provides durability and a secure fit.

What Is The Simplest Joint In Woodworking?

The butt joint is the simplest joint in woodworking. It involves joining two pieces by simply butting them together.

What Is The Japanese Technique To Join Wood Together?

The Japanese technique for joining wood is called “Kanawa Tsugi. ” It involves intricate, interlocking joints without nails or screws.

Conclusion

Joining wood can be easy with the right tools and techniques. Practice makes perfect. Start with simple projects to gain confidence. Pay attention to detail for strong joints. Always measure twice, cut once. Use clamps to hold pieces in place.

Experiment with different methods to find what works best. Safety is crucial, so wear protective gear. With these tips, you’ll become better at woodworking over time. Happy building!