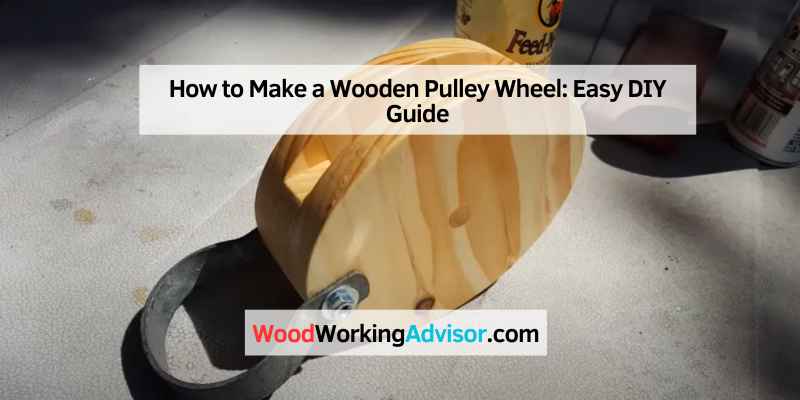

To make a wooden pulley wheel, first, select a sturdy wood like oak or maple. Then, cut the wood to the desired size using a saw.

Next, carve out the wheel shape and drill a hole in the center for the axle. Sand the wheel smooth and add a coat of varnish for protection. Finally, attach the wheel to the axle securely using screws or glue.

With these steps, you can create a functional and durable wooden pulley wheel for various mechanical applications.

Introduction To Wooden Pulley Wheels

Wooden pulley wheels are simple yet ingenious devices that have been used for centuries to lift heavy objects with minimal effort. In this article, we will explore the role of pulleys in mechanics and the advantages of using wooden pulleys in various applications. Whether you are a woodworking enthusiast or simply interested in learning more about the principles of mechanics, understanding how to make and use wooden pulley wheels can be a rewarding experience.

The Role Of Pulleys In Mechanics

Pulleys are essential components in mechanical systems, providing a means of transmitting and modifying forces. By changing the direction of a force or providing a mechanical advantage, pulleys enable the lifting of heavy loads with reduced effort. Whether used in industrial machinery or simple household systems, pulleys play a crucial role in facilitating work and improving efficiency.

Advantages Of Wooden Pulleys

- Natural Flexibility: Wooden pulleys offer a degree of flexibility that allows them to absorb shock and reduce wear on the load-bearing ropes or cables.

- Low Friction: The smooth surface of wooden pulleys minimizes friction, enabling smooth movement and efficient power transmission.

- Lightweight yet Strong: Despite their lightweight nature, wooden pulleys are remarkably strong and durable, making them ideal for various applications.

- Aesthetic Appeal: Wooden pulleys can add a rustic and visually appealing touch to any mechanical system or decorative piece.

Tools And Materials Required

To make a wooden pulley wheel, you will need a variety of tools and materials. Some of the tools you will need include a saw, drill, sandpaper, and a lathe. Materials needed include wood, screws, and a pulley. With these items, you can create a functional and attractive wooden pulley wheel for use in various projects.

When it comes to making a wooden pulley wheel, having the right tools and materials is crucial. Let’s dive into the essential items you’ll need for this woodworking project.

Selecting The Right Wood

To begin, select a durable and sturdy wood for your pulley wheel. Opt for hardwoods like oak, maple, or cherry for their strength and longevity. Softwoods like pine can also be used, but may require reinforcement for heavier loads. Ensure the wood is free from knots and defects, as these can weaken the pulley wheel.

Essential Crafting Tools

| Tools | Materials |

|---|---|

|

|

Moreover, ensure the woodworking tools are in good condition to achieve precise cuts and smooth finishes. The wood lathe will be instrumental in shaping the wheel, while the drill press is crucial for creating the center hole. Utilize quality sandpaper for a refined, polished surface.

In addition, using high-quality wood glue is essential for a sturdy bond between the wooden components. With the right tools and materials, you can embark on crafting a durable and functional wooden pulley wheel.

Designing Your Pulley Wheel

Designing Your Pulley Wheel is a critical step in creating a functional and efficient pulley system.

Determining Dimensions

Measure the required diameter and width for your pulley wheel accurately.

Creating A Blueprint

Sketch a detailed blueprint of the pulley wheel design.

Cutting The Wheel

Making a wooden pulley wheel is a challenging yet rewarding DIY project that can be accomplished with the right tools and techniques. Once you have gathered all the necessary materials and have prepared your wood, it’s time to start cutting the wheel. Here are some important steps to follow:

Marking The Wood

Before you start cutting your wooden pulley wheel, you need to mark the wood to ensure that you make precise cuts. Use a ruler to measure the diameter of your wheel and mark it at the center of your wood. Then, mark the outer edge of the wheel with a compass. This will help you to make accurate cuts and ensure that your wheel is perfectly round.

Using A Saw For Precision

Now that you have marked your wood, it’s time to start cutting your wheel. Use a saw to cut along the outer edge of your marked circle. Make sure that your saw blade is sharp and that you are using the right type of saw for the job. If you want to achieve a precise cut, you can use a jigsaw or a band saw. Remember to take your time and cut slowly to avoid any mistakes.

If you’re not confident with using a saw, you can always use a wood lathe to make your wooden pulley wheel. A lathe will allow you to turn your wood and create a perfectly round wheel with ease.

Once you have cut your wheel, use sandpaper to smooth any rough edges and make sure that your wheel is perfectly round. You can also use a router to create a groove in the center of your wheel to hold your rope or cable.

Cutting your wooden pulley wheel can be a time-consuming process, but with patience and practice, you can create a beautiful and functional wheel that will last for years to come.

Carving The Groove

When it comes to carving the groove on your wooden pulley wheel, precision is key. This step will determine the smoothness of the rotation and the efficiency of the pulley system.

Measuring For The Rope

Before carving the groove, measure the diameter of the rope you will be using. Ensure the groove is slightly wider than the rope to prevent friction.

Techniques For A Smooth Groove

Use a sharp chisel to carve the groove along the circumference of the wooden wheel. Start with shallow cuts and gradually deepen them for a uniform groove.

Assembling The Pulley Components

To assemble the pulley components for making a wooden pulley wheel, start by carefully aligning the wheel and attaching the axle securely. Ensure the wheel turns smoothly before proceeding with the next steps in crafting your functional pulley system.

Attaching The Wheel To The Axle

To attach the wooden pulley wheel to the axle, place the wheel onto the axle and secure it with screws. Ensure that the wheel is centered and level on the axle. Tighten the screws firmly, but not too tight, as this may cause the wheel to crack.

Ensuring Smooth Rotation

To ensure smooth rotation of the pulley wheel, sand the wheel’s edges and surfaces until they are smooth. Use fine-grit sandpaper to avoid creating rough spots or scratches. Additionally, apply a coat of wood sealant to the wheel to protect it from moisture, rot, and wear.

Testing The Pulley System

Once the pulley components are assembled, test the system to ensure that it operates smoothly. Attach a rope or cable to the pulley wheel and pull it up and down to check its movement. If the wheel rotates smoothly and without any wobbling, the pulley is ready for use.

Maintaining The Pulley System

To maintain the pulley system, periodically inspect the wheel, axle, and rope for wear and damage. Replace any worn or damaged components immediately to prevent system failure. Additionally, lubricate the pulley wheel and axle with a light oil to ensure smooth rotation and prevent rust.

Assembling a wooden pulley wheel is a fun and rewarding DIY project that can be completed with basic woodworking skills and tools. By following these simple steps, you can create a functional pulley system that is perfect for lifting and moving heavy objects.

Finishing Touches

Once you have successfully constructed your wooden pulley wheel, it’s time to add the finishing touches to ensure its durability and longevity. This involves sanding the wheel to achieve a smooth surface and sealing the wood to protect it from moisture and other elements.

Sanding The Wheel

Sanding the wheel is an essential step to smoothen the surface and remove any rough edges. Start by using coarse-grit sandpaper to eliminate any imperfections and shape the wheel as desired. Gradually move to finer-grit sandpaper to achieve a polished finish. Remember to sand both the outer and inner surfaces of the wheel, ensuring a uniform texture.

Sealing And Protecting The Wood

Sealing the wood is crucial to protect it from moisture, humidity, and other environmental factors that could lead to damage or deterioration. There are various options for sealing the wood, including using wood sealants, varnishes, or oils. Before applying any sealant, make sure the wheel is clean and free from dust or debris. Apply the chosen sealant following the manufacturer’s instructions, ensuring complete coverage of the wood surface.

One popular option for sealing wooden pulley wheels is using a clear polyurethane sealant. This type of sealant provides a protective layer that enhances the wood’s natural beauty while offering excellent resistance against moisture and UV rays. Apply multiple coats of polyurethane, allowing each coat to dry completely before applying the next.

Alternatively, you can use linseed oil to seal the wood. Linseed oil not only protects the wood but also enhances its natural color and grain. Apply the oil generously using a brush or cloth, ensuring it penetrates into the wood fibers. Allow the oil to soak in for a few minutes, then wipe off any excess. Repeat this process until you achieve the desired level of protection.

By sanding the wheel and sealing the wood, you are not only enhancing its appearance but also ensuring its longevity. These finishing touches will help protect your wooden pulley wheel from wear and tear, allowing it to function smoothly and effectively for years to come.

Installation And Testing

Once you have successfully constructed your wooden pulley wheel, the next step is to install it and test its functionality. Proper installation and thorough testing are essential to ensure the pulley system operates smoothly and safely. In this section, we will cover the steps involved in mounting the pulley system, as well as important safety checks and adjustments.

Mounting The Pulley System

Mounting the pulley system requires careful consideration of the location and proper installation techniques. Follow these steps to mount your wooden pulley wheel:

- Identify a suitable location where the pulley system will be installed. Ensure there is enough space and a sturdy structure to support the weight and movement of the system.

- Attach the pulley wheel to the designated spot using screws or bolts. Make sure it is securely fastened to avoid any accidents during operation.

- Connect the pulley wheel to the desired load or object that needs to be lifted or moved. Use a strong rope or cable that can withstand the weight and tension.

- Double-check all connections and ensure they are tight and properly aligned before proceeding to the testing phase.

Safety Checks And Adjustments

Before testing the pulley system, it is crucial to conduct safety checks and make any necessary adjustments. Follow these guidelines to ensure the safety and effectiveness of your wooden pulley wheel:

- Inspect all components of the pulley system, including the wheel, rope, and attachments, for any signs of damage or wear. Replace any worn-out parts to prevent accidents.

- Ensure there is enough clearance around the pulley system to prevent entanglement with objects or individuals during operation.

- Verify that the load or object being lifted does not exceed the weight capacity of the pulley system. Overloading can lead to equipment failure and potential injuries.

- Perform a test run of the pulley system with a lighter load to check for any abnormal noises, jerky movements, or other signs of malfunction. Make any necessary adjustments to ensure smooth operation.

- Regularly inspect and maintain the pulley system to keep it in optimal condition. Lubricate the wheel and check for any loose or damaged parts.

By following these steps for installation, safety checks, and adjustments, you can ensure that your wooden pulley wheel functions properly and safely. Regular maintenance and periodic inspections will prolong the lifespan of your pulley system and contribute to its efficient operation.

Maintenance Tips

As with any mechanical device, proper maintenance is essential for the longevity and smooth operation of wooden pulley wheels. In this section, we will discuss some essential maintenance tips to help keep your wooden pulleys in top condition.

Regular Inspection

Regular inspection is crucial to identifying any potential problems before they become severe. Inspect your wooden pulleys regularly and look for any signs of wear or damage, such as cracks, warping, or splintering. If you notice any problems, address them immediately to prevent further damage.

Long-term Care For Wooden Pulleys

Wooden pulleys require proper care to ensure their longevity. The following tips will help you take care of your wooden pulleys:

- Keep the pulleys clean and free of dirt, dust, and debris.

- Apply a coating of wax or oil to protect the wood from moisture and prevent cracking.

- Store the pulleys in a dry, cool place away from direct sunlight.

- Inspect the pulleys periodically for signs of damage or wear.

By following these maintenance tips, you can ensure that your wooden pulleys will provide reliable service for years to come. Remember, proper maintenance is essential to the longevity and smooth operation of your wooden pulley wheels.

Applications And Creative Uses

Crafting a wooden pulley wheel can be a creative and practical project for various applications. By following simple steps and using basic tools, you can create a functional and visually appealing wooden pulley wheel for use in lifting systems, mechanical projects, or even decorative purposes.

Practical Applications

Wooden pulley wheels have practical applications in various industries, including agriculture, manufacturing, and transportation. They are commonly used in conveyor systems, lifts, and cranes.

Wooden pulleys are versatile and can be used in a range of applications. They are popular in home improvement projects and can be used to create unique lighting fixtures or hanging planters.

Decorative And Novelty Ideas

Wooden pulley wheels can also be used in decorative and novelty projects. They can be repurposed into rustic chandeliers or used as part of a nautical-themed decor.

In home decor, wooden pulleys can serve as curtain rod holders or as a base for a vintage-inspired table. The possibilities for creative uses are endless.

Wooden pulleys can be painted or stained to match any design aesthetic, making them a versatile and eye-catching addition to any space. They can also be used as a decorative accent in a room or as a statement piece in a gallery wall.

Wooden pulleys can be repurposed into unique pieces of jewelry or key holders. They can also be used in children’s play areas to create interactive and imaginative play spaces.

Frequently Asked Questions

How Do You Make A Wooden Pulley Wheel?

To make a wooden pulley wheel, first, choose a suitable wood material like oak or maple. Then, sketch and cut the wheel shape using a bandsaw. Next, drill a hole in the center for the axle. Sand the edges and apply a protective finish.

Finally, attach the wheel to the pulley system using the axle.

What Tools Are Needed To Make A Wooden Pulley Wheel?

To make a wooden pulley wheel, you will need a bandsaw for cutting the wheel shape, a drill for creating the axle hole, sandpaper for smoothing the edges, and a finish like varnish or oil for protection. Additionally, you may need measuring tools, clamps, and a router for more intricate designs.

What Are The Benefits Of Using A Wooden Pulley Wheel?

Using a wooden pulley wheel offers several benefits. Firstly, wood is lightweight and durable, making it suitable for various applications. Secondly, wood has a natural aesthetic appeal, adding a touch of elegance to the pulley system. Lastly, wooden pulley wheels are quieter compared to metal ones, reducing noise during operation.

Conclusion

In crafting a wooden pulley wheel, patience and precision are key. By following the steps outlined in this guide, you can create a functional and durable pulley wheel for your various projects. Remember to use high-quality wood and tools for the best results.

With practice, you’ll master this essential woodworking skill.