How to Make Wood Ash Soap: A Step-by-Step Guide

Imagine turning something as simple as wood ash into a luxurious bar of soap. It sounds intriguing, doesn’t it?

By learning how to make wood ash soap, you’re not just creating a useful household item; you’re embracing a timeless craft that connects you with nature and history. You might wonder, why wood ash? Well, this humble ingredient has been used for centuries to make soap that cleanses effectively and gently.

Plus, it’s an eco-friendly alternative that reduces waste and promotes sustainability. As you explore the process, you’ll discover how easy it can be to transform ash into soap with just a few basic ingredients and tools. The satisfaction of crafting your own soap is unmatched, and the benefits it brings to your skin and environment make it worthwhile. Are you ready to dive into the world of wood ash soap-making? This guide is designed to walk you through each step, ensuring you feel confident and excited about creating your own natural soap. Let’s get started!

Credit: www.fireplacemall.com

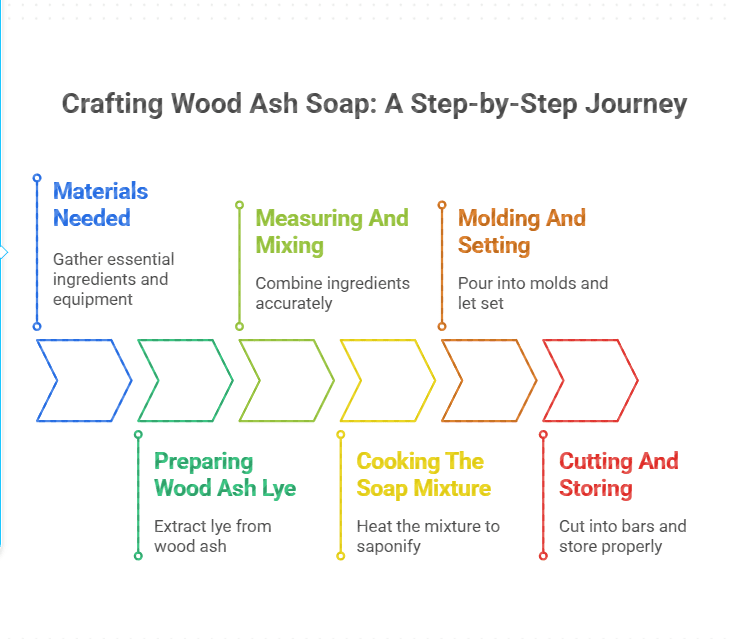

Materials Needed

Wood ash is the star ingredient. It gives the soap its cleaning power. Water helps to mix everything together. Animal fat or vegetable oil is needed. It makes the soap creamy. Salt helps harden the soap. Easy to find ingredients. Simple to use. Make sure everything is clean.

Use a large pot for mixing. A stirring stick helps blend well. A mold shapes the soap. Gloves protect hands while working. Safety goggles keep eyes safe. Measuring cups ensure the right amount. Thermometer checks the temperature. Sieve filters the ash. Scale weighs the ingredients.

Preparing Wood Ash Lye

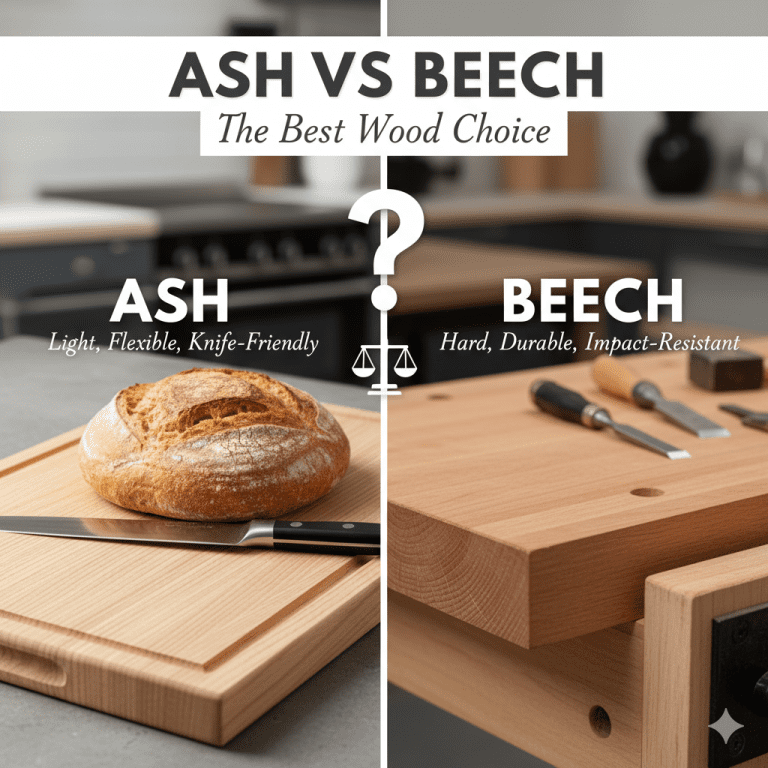

Choose hardwood ash for soap making. Oak, maple, or beech are good choices. They produce a strong and reliable lye. Ensure the ash is clean and dry. Avoid ash with charcoal bits or debris. Store ash in a dry container to keep it ready.

You need a large container for the lye solution. Pour ash into the container until it is half full. Slowly add soft water, like rainwater, to the ash. Stir the mixture gently with a wooden stick. Let the ash and water sit for a few days. The liquid that forms is the lye solution. Strain the liquid to remove ash bits. Your lye is now ready for soap making.

Measuring And Mixing

Lye is a key ingredient in soap. Use caution when handling it. Measure the lye precisely. Wear gloves for safety. Use a scale for accuracy. Fats are needed too. Olive oil is a popular choice. Measure oils carefully. Balance lye and fats. This ensures proper saponification.

Mix lye with water first. Stir it well. It becomes clear when ready. Add oils slowly. Pour them into the lye mixture. Stir gently. Watch the mixture closely. It thickens gradually. Keep stirring until it reaches “trace.” Trace means it’s ready to mold. Pour it into molds quickly. Let it set overnight.

Cooking The Soap Mixture

Start by heating the soap mixture gently. Use a medium-sized pot. Keep the heat low. Stir the mixture slowly. Use a strong wooden spoon to stir. Make sure the mixture does not boil. Boiling can cause problems.

Keep stirring to blend everything well. The mixture should become smooth. Watch for changes. The mixture will thicken. This is called reaching “trace.” Trace means the soap is ready for the next step. You can test by lifting the spoon. If the mixture leaves a mark on the surface, it has reached trace.

Molding And Setting

Picking the right mold is very important. Different shapes can change the soap look. Square molds make neat bars. Round molds make fun shapes. Silicone molds are easy to use. They do not stick. Wooden molds are good too. They must be lined with paper. This keeps soap from sticking. Always check mold size. Big molds need more soap mix. Small molds need less.

Pour the soap mix slowly into the mold. Fill each mold carefully. Make sure it is even. Tap gently to remove bubbles. Let the soap sit and cure. It needs time. Usually, it takes 24 hours. Cover the mold with a towel. This keeps the heat in. Curing makes the soap hard. After curing, remove the soap from the mold. Let it cure more on a rack. This takes 4 weeks. Now, the soap is ready.

Credit: www.youtube.com

Cutting And Storing

Cutting soap into bars and storing it properly is crucial for preserving its quality. Ensure even cuts for uniform size. Store the bars in a cool, dry place to help them cure and harden. This prevents moisture buildup and prolongs the soap’s shelf life.

Cutting Into Bars

After the soap hardens, it’s time to cut it. Use a sharp knife for clean cuts. Aim for even pieces. This will help them dry evenly. Each bar should be the same size. This ensures they look nice and dry well. Be careful while cutting. The soap might be slippery.

Soap is soft at first. Let it sit for a while before cutting. This makes it easier to handle. Patience is key. This way, bars come out smooth and neat.

Proper Storage Techniques

Store the soap in a cool, dry place. This keeps it from melting. Avoid direct sunlight. It can change the soap’s color. Use a shelf or a box with air holes. This helps the soap breathe.

Wrap each bar in paper or cloth. This keeps dust away. Do not use plastic. It traps moisture. Moisture can ruin the soap. Check the bars regularly. Make sure they stay dry. This keeps the soap fresh and long-lasting.

Safety Precautions

Creating wood ash soap demands caution. Wear gloves and goggles to protect skin and eyes from caustic lye. Ensure good ventilation to avoid inhaling fumes during the mixing process.

Handling Lye Safely

Lye is a strong chemical. Always handle it with care. Use it in a well-ventilated area. Keep children and pets away. Never mix lye with water quickly. The mixture can heat up fast.

Protective Gear And Equipment

Wear gloves and goggles. Protect your skin and eyes. Use a mask to avoid inhaling fumes. Keep a first aid kit nearby. In case of spills, have vinegar ready. It neutralizes lye.

Tips For Beginners

Many beginners use too much water. This can make the soap soft. Measure the water carefully. Too much ash can also cause problems. Use a small amount at first. Some people forget to mix the ash well. Mix until there are no lumps. Rushing the process can lead to bad soap. Take your time and be patient.

Adding herbs can make soap smell nice. Lavender is a popular choice. Oils can make soap smooth. Olive oil is a good option. Colors can be added to soap. Use natural colors like beet juice. Essential oils can be used too. They add a fresh scent. Be careful with amounts. Too much can ruin the soap.

Credit: www.youtube.com

Frequently Asked Questions

How Do You Make Wood Ash Soap?

Mix wood ash with water, creating a lye solution. Combine this with animal fat and heat. Stir until it thickens. Pour into molds to cool and solidify. Ensure safety measures are followed throughout the process.

Can Wood Ash Be Used As Soap?

Yes, wood ash can be used to make soap. It contains potassium carbonate, which creates lye when mixed with water. This lye, combined with fat, produces a basic soap. Ensure careful handling, as lye can be caustic. Homemade soap from wood ash is an eco-friendly alternative.

Is Wood Ash Safe For Skin?

Wood ash can be used on the skin but should be handled carefully. It may cause irritation or dryness. Always test a small area first and moisturize afterward. Avoid using on sensitive skin or open wounds. Consult a dermatologist for personalized advice if unsure about its suitability.

How To Make Lye Soap For Beginners?

Begin by gathering lye, water, and oils like olive or coconut. Carefully mix lye with water, then add oils. Stir until thick. Pour into molds and let cure for 4-6 weeks. Always wear safety gear when handling lye. Follow precise measurements for safe and successful soap making.

Conclusion

Making wood ash soap is rewarding. It’s simple and eco-friendly. You create something useful from waste materials. The process connects you to traditional methods. You learn about natural ingredients. Soap made from wood ash cleans well. It feels good on skin.

It’s gentle and effective. Perfect for sustainable living. Share this skill with others. Encourage friends to try it. Experience the joy of homemade soap. Enjoy the benefits of using natural products. It’s a satisfying craft. Plus, you save money and reduce waste.

Embrace this creative journey today.