How to Remove Stuck Drill Bit: Genius Solution

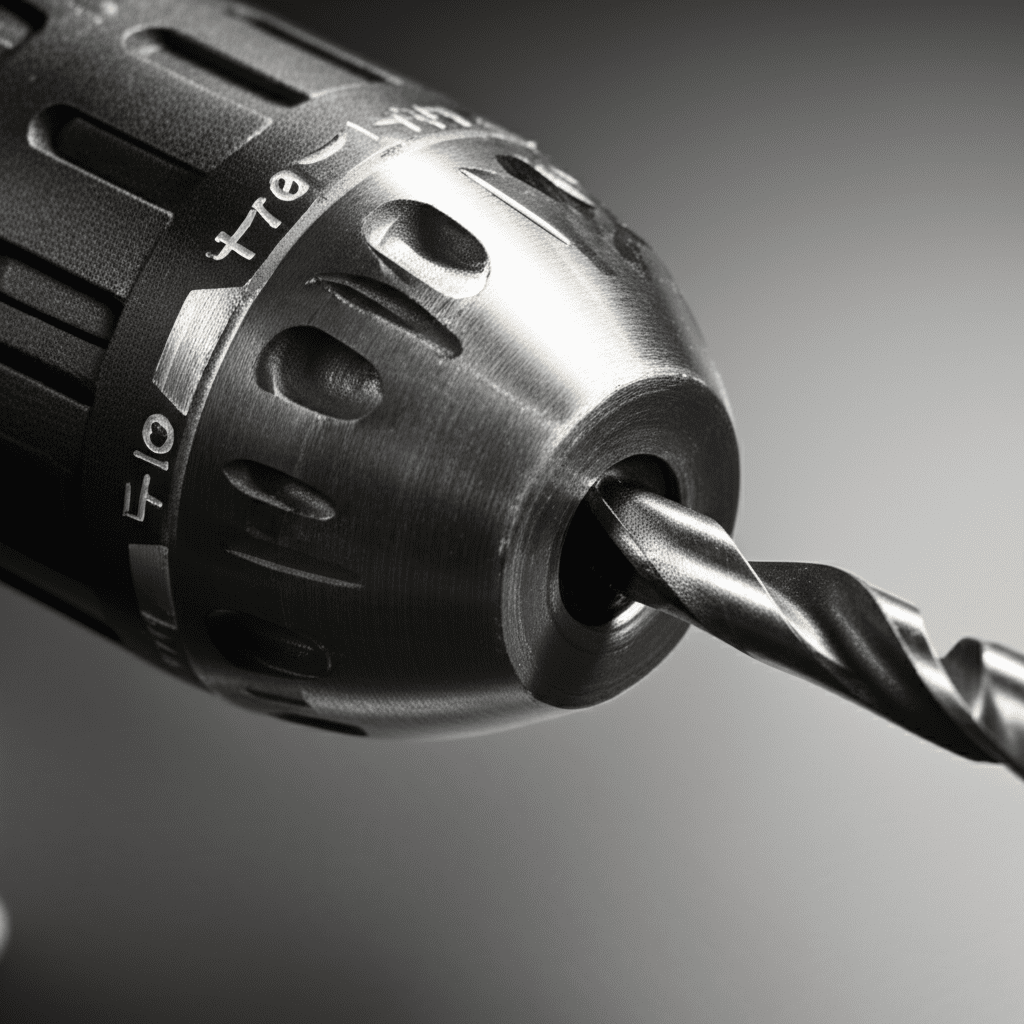

Stuck drill bits in your keyless chuck? Don’t worry! This guide offers a straightforward, genius solution to safely free your drill bit without damaging your tool. You’ll get your drill working like new in no time with simple steps and common household items.

How to Remove a Stuck Drill Bit: Your Genius Solution

We’ve all been there, right? You’re deep into a project, and suddenly, your drill bit refuses to budge from the chuck after you’ve finished drilling. It’s a frustrating moment that can halt your progress and make you question your tools, but I promise, it’s a common issue most woodworkers face. The good news is, you don’t need fancy tools or a trip to the repair shop. With a few simple tricks and a bit of patience, you can easily remove that stubborn drill bit and get back to building.

This guide is all about making woodworking less intimidating. We’ll break down the problem and provide a clear, step-by-step method that’s safe and effective. You’ll learn how to diagnose the issue and apply the right pressure and technique to free your bit. Let’s get your drill chuck working smoothly again!

Why Do Drill Bits Get Stuck in Keyless Chucks?

Keyless chucks are fantastic for quick bit changes, but sometimes, the jaws grip the bit a little too tightly, especially after drilling into tough materials or using a lot of force. This can happen for a few reasons:

- Debris Buildup: Sawdust, metal shavings, or even tiny bits of the material you were drilling can get lodged between the chuck jaws and the bit shank, acting like a wedge.

- Over-tightening: Sometimes, we instinctively tighten the chuck more than necessary to ensure the bit stays put, which can cause the jaws to grip too firmly.

- Heat Expansion: Drilling can generate heat, causing the metal chuck jaws and the bit to expand slightly. When they cool down, they can contract onto the bit, making it harder to release.

- Worn Chuck Jaws: Over time, the jaws themselves can wear down unevenly, leading to a less precise grip that can sometimes hold onto bits too tightly.

- Bent Bits: If a drill bit bends slightly while in use, it can get caught at an angle in the chuck, making it very difficult to release.

Understanding these reasons helps us approach the solution correctly. It’s usually not a sign of a broken tool, just a bit of mechanical stubbornness!

Gather Your Supplies: What You’ll Need

Before we get to work, let’s make sure you have everything ready. You probably have most of these items already in your workshop or home. This method is designed to be accessible and require minimal special tools.

- Safety Glasses: Always protect your eyes!

- Gloves: To protect your hands from sharp edges or grease.

- Rubber Mallet or a Wooden Block: For gentle tapping.

- Penetrating Lubricant (like WD-40 or a graphite-based lubricant): To help loosen seized parts.

- Rag or Paper Towels: For cleaning up.

- Adjustable Wrench or Pliers (optional, for stubborn cases): Use with extreme caution.

- Another Drill (optional, for an assist): Only if the chuck won’t turn at all.

Having these items on hand will make the process smooth and efficient. Remember, the goal is to free the bit without forcing the chuck or the bit itself, which could cause damage.

The Genius Solution: Step-by-Step Guide

This method combines a bit of leverage, lubrication, and gentle persuasion. It’s often the simplest approach that yields the best results. Let’s get that bit out!

Step 1: Assess the Situation

First, take a good look at your drill and the chuck. Is the chuck itself stuck, or just the bit inside? Try turning the chuck collar to loosen it. If it turns freely but the bit doesn’t release, the problem is likely with the bit being held too tightly. If the entire chuck is stiff or won’t turn, there might be more involved, but this method can often help with that too.

Step 2: Apply Penetrating Lubricant

This is where the magic begins. Spray a small amount of penetrating lubricant directly onto the chuck jaws where they grip the drill bit shank. Aim for the gap between the jaws and the bit. Let it sit for 5-10 minutes. This gives the lubricant time to seep in and break down any corrosion or “stickiness” that might be holding the bit.

Why this works: Penetrating lubricants are designed to creep into tight spaces and reduce friction. Think of it like giving the stuck parts a gentle nudge to let go.

Step 3: Gentle Tapping

After the lubricant has had a chance to work, it’s time for some gentle persuasion. Use your rubber mallet or the wooden block to tap lightly around the chuck collar. You’re not trying to bash it; you’re just trying to create small vibrations that can help break the bond. Tap on the sides of the collar, not directly on the jaws or the bit.

Safety First: Always wear your safety glasses during this step. If you’re using the wooden block, ensure it’s large enough to provide a solid surface to tap against. Avoid hitting the drill body itself.

Step 4: Attempt to Loosen the Chuck

Now, try turning the chuck collar counter-clockwise by hand again. With the lubrication and gentle tapping, it should, in theory, be easier to open. If it still feels tight, give it another shot of lubricant and a few more gentle taps.

Step 5: The “Push and Twist” Technique (Chuck Rotates Freely)

If the chuck collar turns but the bit just spins with it, or if the bit is still firmly held, try this: Grip the drill body firmly with one hand. With your other hand, rotate the chuck collar counter-clockwise as you simultaneously try to pull the drill bit straight out of the chuck. Sometimes, a combination of outward pressure and rotational force is needed.

Step 6: The “Impact Assist” (When Chuck is Stubborn)

This is where things get a little more hands-on and is best for those moments when the chuck collar itself seems seized. Grab your rubber mallet or wooden block again.

- Position: Place the drill so the chuck is facing upwards or sideways, making it easy to access.

- Grip: Hold the drill body securely.

- Tap Direction: Aim the mallet at the very edge of the chuck collar, specifically on the forward-rotating part (the part you turn to tighten). Give it a few firm, sharp taps in the direction that would normally loosen the chuck (counter-clockwise). The idea is to shock the mechanism slightly.

- Alternate Grips: Sometimes, applying pressure with a pair of pliers (gently!) on the chuck while tapping can give you a better grip.

After tapping, try turning the chuck collar once more by hand. If it loosens, proceed to pull the bit free.

Step 7: Using a Second Drill (The Last Resort for a Stubborn Chuck)

If you absolutely cannot turn the chuck collar by hand, even after lubrication and tapping, you can carefully use another drill to help turn the chuck collar. This requires a bit of finesse:

- Chuck a Driver Bit: In a second drill, chuck a standard screwdriver bit (preferably one that fits snugly into the slots or grooves of your stuck chuck collar).

- Set Torque: Set your second drill to its lowest torque setting and reverse (unscrew) mode.

- Engage Carefully: Align the screwdriver bit with a groove or slot on the chuck collar of the stuck drill. Gently engage the trigger of the second drill. The goal is to use the second drill to power the rotation of the chuck collar.

- Listen and Feel: Be prepared to stop immediately if you hear any concerning noises or feel excessive resistance. You are trying to persuade, not force.

Once the chuck collar loosens, remove the second drill and try to pull the bit out by hand.

Step 8: Clean and Maintain

Once the bit is out, this is a perfect time to clean your chuck. Use a cotton swab or a small brush to remove any sawdust or debris from inside the chuck jaws. A quick spray of lubricant and working the jaws open and closed can help keep things moving smoothly. Regular cleaning and a light application of grease can prevent future sticking.

For useful tips on maintaining your power tools, the Popular Mechanics guide to tool maintenance is a great resource.

When to Seek Professional Help

While these methods are usually effective, there are rare occasions when a chuck might be genuinely damaged or seized due to extreme force or wear. If, after trying these steps, your chuck remains completely immobile or you hear grinding noises that suggest internal damage, it might be time to consult a professional tool repair service or consider replacing the chuck. However, for most beginners and intermediate users, the above steps are highly effective.

Tips for Preventing Future Stuck Bits

Prevention is always better than cure! Here are some habits to adopt:

- Don’t Over-Tighten: Tighten the chuck just enough to firmly grip the bit. You should feel resistance, but it shouldn’t require Herculean strength.

- Clean After Use: Make it a habit to clear debris from your chuck after each project. A quick blast of compressed air works wonders.

- Use the Right Bits: Ensure you’re using the correct type and size of drill bit for your material.

- Lubricate Regularly: A tiny drop of light machine oil or grease applied sparingly to the chuck mechanism periodically can keep it running smoothly.

- Center Punch for Starting: When starting a hole in metal or hard materials, using a center punch first helps guide the drill bit and reduces the chance of it slipping and binding.

Adopting these simple practices will save you a lot of frustration in the long run and extend the life of your drill and its chuck.

Table: Troubleshooting Common Chuck Issues

Here’s a quick reference for dealing with typical chuck problems:

| Problem | Likely Cause | Solution |

|---|---|---|

| Chuck won’t loosen | Debris, over-tightening, corrosion | Lubricant, gentle tapping with rubber mallet, try using pliers for better grip (carefully!) |

| Bit spins but won’t release | Jaws not opening fully, bit shank burred | Lubricant, “push and twist” technique, inspect bit shank for damage |

| Chuck is stiff/hard to turn | Lack of lubrication, internal debris | Penetrating lubricant, work chuck open/closed, clean thoroughly |

| Chuck jaws are not gripping firmly | Worn jaws, debris preventing full closure | Clean jaws, try lubricating, if persistent consider chuck replacement |

Frequently Asked Questions (FAQ)

Q1: Will using WD-40 damage my drill chuck?

A: In most cases, a small amount of WD-40 used as directed won’t harm your chuck. It’s designed to lubricate and free up metal parts. However, avoid saturating the chuck, and wipe away any excess. For long-term lubrication, a dedicated drill grease might be better, but for an emergency release, WD-40 is effective.

Q2: Is it safe to use a hammer on my drill chuck?

A: You should never use a metal hammer directly on your drill chuck. Always use a rubber mallet or a wooden block to cushion the impact. Excessive force or direct hammer blows can easily damage the chuck mechanism, the drill motor, or even the drill bit itself.

Q3: My drill bit is bent. How do I get it out?

A: A bent drill bit can be extra tricky. Try the lubrication and tapping methods first. If it’s still stuck, you might need more leverage when trying to pull it out. Grip the drill body firmly and use adjustable pliers (wrapped in tape to protect the bit if you plan to reuse it) on the exposed shank of the bit to try and wiggle it free while turning the chuck collar. Be patient, as bent bits are inherently harder to remove.

Q4: Should I try to force the chuck open if it’s really stuck?

A: It’s generally best to avoid forcing things in woodworking. While you want to apply firm pressure, excessive force can strip the threads inside the chuck, break the chuck collar, or even damage the drill’s motor. Stick to the methods of lubrication, gentle tapping, and controlled leverage. If it feels like something is about to break, stop and reassess.

Q5: How often should I clean my drill chuck?

A: A good rule of thumb is to clean your chuck after every significant project, or at least at the end of each workday if you’re using the drill frequently. Remove any visible dust or debris with a brush or compressed air. Performing a quick clean regularly prevents the buildup that leads to stuck bits and extends the life of your chuck.

Q6: Can I use heat to remove a stuck drill bit?

A: While heat can expand metal and sometimes help loosen seized parts, it’s generally not recommended for drill chucks. The heat could damage the internal components of the chuck or the drill motor, and it introduces a fire risk, especially with flammable lubricants present. The methods described above are safer and usually just as effective.

Conclusion

Dealing with a stuck drill bit can seem like a major setback, but as you’ve seen, it’s a problem with straightforward solutions. By using a little penetrating lubricant, some gentle tapping with a rubber mallet, and the right technique, you can free that bit and get back to creating. Remember these steps, keep your tools clean, and don’t be afraid to apply a bit of strategic persuasion. You’ve got this! Happy building!