How to Seal Poplar Wood: Best Tips for Durability

To seal poplar wood, clean the surface and sand it lightly. Apply a suitable wood sealant, following the manufacturer’s instructions.

Poplar wood is known for its versatility and attractive grain. It’s often used in furniture, cabinetry, and crafting. However, poplar is susceptible to moisture and wear, making sealing essential for durability. Sealing enhances its natural beauty while providing protection against environmental damage.

Various sealants are available, including oils, varnishes, and polyurethane. Each option has unique benefits, so choosing the right one is crucial. Proper sealing not only extends the life of poplar wood but also makes maintenance easier. Understanding the sealing process can lead to stunning, long-lasting results for your projects. Embrace the beauty of poplar by sealing it effectively.

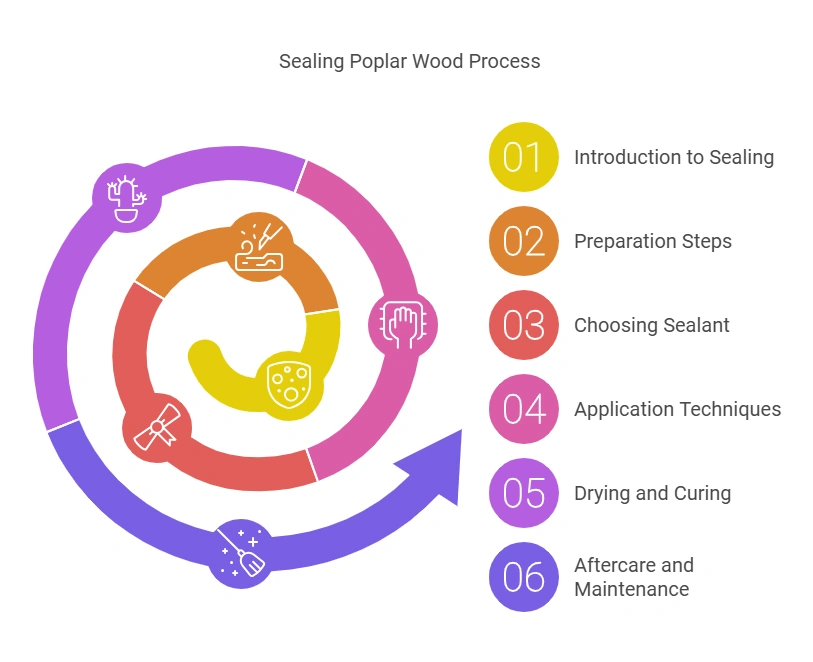

Introduction To Sealing Poplar Wood

Sealing poplar wood is very important. This process protects the wood from moisture and damage. Poplar wood is soft and can get easily scratched. Sealing helps to maintain its appearance and durability.

Another reason to seal poplar wood is to prevent stains. Without a seal, liquids can penetrate the wood. This can cause ugly marks that are hard to remove. Sealing also helps in enhancing the wood’s natural color.

Using a sealant can make the wood easier to clean. Dirt and grime will not stick as easily. A good seal can also make the wood last longer. It keeps the wood looking fresh and new.

Preparation Steps Before Sealing

Start by cleaning the surface of the poplar wood. Use a soft cloth or sponge to remove dust and dirt. A mild soap solution can help, but rinse well afterward. Let the wood dry completely before proceeding.

Next, sanding for smoothness is essential. Use fine-grit sandpaper for a smooth finish. Sand in the direction of the wood grain to avoid scratches. This step helps the sealant adhere better. Wipe away any dust after sanding to ensure a clean surface.

Choosing The Right Sealant

Choosing the right sealant for poplar wood is very important. Various types of sealants are available. Here are some popular options:

| Sealant Type | Features |

|---|---|

| Polyurethane | Durable and water-resistant, ideal for heavy use. |

| Acrylic | Easy to apply, quick-drying, and paintable. |

| Oil-based | Penetrates deeply, enhances natural wood grain. |

| Water-based | Low odor, dries clear, safe for indoor use. |

Choosing the best sealant depends on your project needs. Polyurethane works well for outdoor items. Acrylic is great for quick projects. Oil-based sealants add depth to the wood. Water-based options are perfect for indoor furniture.

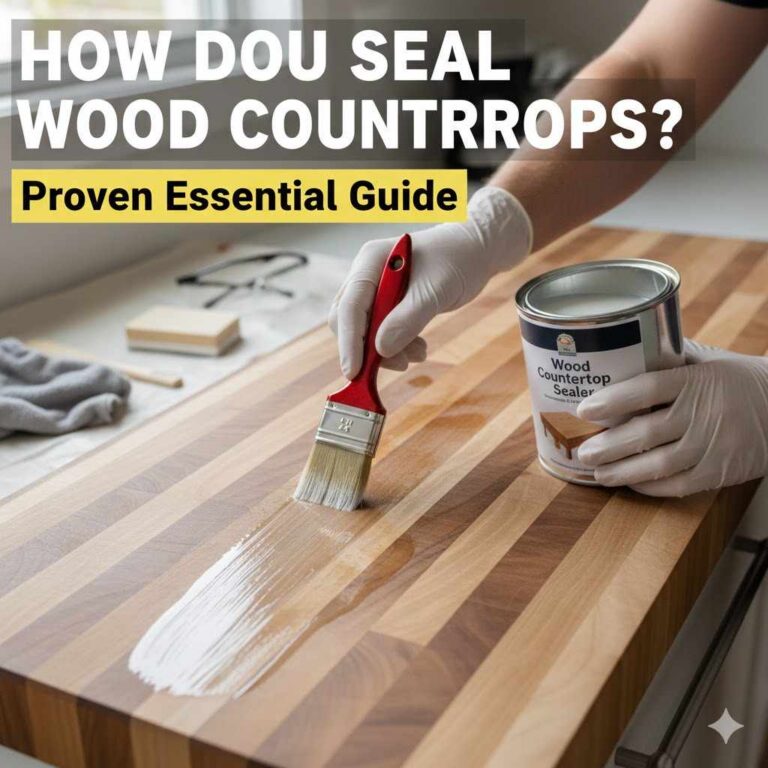

Application Techniques

Choosing between brush and spray techniques can affect your results. A brush allows for better control and is ideal for small areas. It helps to work the sealer into the wood grain. On the other hand, spray techniques cover large areas quickly. This method is great for achieving a smooth finish.

Applying even coats is crucial for a professional look. Always start with a thin layer and let it dry. Apply additional coats as needed. Ensure each coat is completely dry before adding more. This prevents drips and runs. Use a light touch when applying to avoid uneven surfaces.

Drying And Curing Time

Drying and curing poplar wood is important for its quality. Expected timeframes can vary based on conditions. Generally, air drying takes 6 to 12 months. Kiln drying is faster, usually around 1 to 3 weeks.

Several factors affect drying time. Humidity plays a big role. High humidity slows down the process. Temperature also matters; warmer air helps wood dry faster. The thickness of the wood influences drying time, too. Thicker pieces take longer to dry.

| Drying Method | Timeframe |

|---|---|

| Air Drying | 6 to 12 months |

| Kiln Drying | 1 to 3 weeks |

Aftercare And Maintenance

Routine cleaning is essential for maintaining poplar wood. Use a soft cloth to wipe the surface. Avoid harsh chemicals that can damage the wood. Clean spills immediately to prevent stains. Regular dusting will help keep the wood looking fresh.

Reapplication intervals depend on usage and environment. For indoor furniture, reapply every 1-2 years. Outdoor items may need reapplication every 6-12 months. Monitor the wood for signs of wear. If it looks dull, it’s time to reapply.

Common Mistakes To Avoid

Overapplication of sealant can lead to a sticky mess. Always apply in thin layers. This helps the wood breathe and prevents peeling.

Skipping sanding is another common mistake. Sanding creates a smooth surface for better adhesion. It also helps to remove any dirt or old finish.

Always use the right grit sandpaper. Start with a coarser grit and finish with a finer one. This will ensure a perfect finish.

Advanced Tips For Enhanced Durability

Using sealant additives can improve the durability of poplar wood. These additives help protect against moisture and decay. Choose products that are easy to apply and compatible with your sealant.

Applying a protective top coat is essential. It adds an extra layer of defense. Look for options like polyurethane or varnish. These products offer good UV protection and resist scratches. Always follow the manufacturer’s instructions for the best results.

Remember to sand the wood before applying any products. This creates a smooth surface for better adhesion. Apply multiple thin coats for a more durable finish.

Frequently Asked Questions

How Do You Prepare Poplar Wood For Sealing?

To prepare poplar wood for sealing, first sand the surface with fine-grit sandpaper. This removes any imperfections and opens the wood grain. Next, clean the surface using a damp cloth to remove dust and debris. Allow it to dry completely before applying the sealant.

What Type Of Sealant Is Best For Poplar Wood?

The best sealants for poplar wood are polyurethane and water-based finishes. These options provide excellent protection against moisture and wear. Choose a clear sealant to enhance the wood’s natural beauty. Always check the product label to ensure compatibility with poplar wood.

How Many Coats Of Sealant Should I Apply?

It’s recommended to apply at least two to three coats of sealant. Each coat enhances protection and durability. Allow the previous coat to dry completely before applying the next. This ensures even coverage and optimal results for your poplar wood project.

Can I Use Oil-based Sealants On Poplar Wood?

Yes, oil-based sealants can be used on poplar wood. They offer a rich finish and deep penetration. However, they may take longer to dry compared to water-based options. Ensure proper ventilation when using oil-based products for safety and to reduce odors.

Conclusion

Sealing poplar wood enhances its beauty and durability. With the right techniques, you can protect it from moisture and wear. Choose high-quality sealants for the best results. Regular maintenance will keep your projects looking fresh. Embrace these steps to ensure your poplar wood lasts for years to come.

Happy sealing!