How to Tighten a Chain on a Chainsaw: Quick Fixes

To tighten a chain on a chainsaw, first shut off the engine and release the chain brake. Loosen the wingnut and lift up the guide bar, then turn the adjustment wheel to the desired tension.

Finally, tighten the wingnut and check the chain tension. Most chainsaws come with a tool called a “scwrench” that matches the side plate nut and tension adjustment screw size. Properly tightening a chainsaw chain is crucial for safe and efficient operation.

A loose chain can slip off the guide bar while a tight chain can cause excessive wear on the chain and bar. We will discuss the step-by-step process of tightening a chainsaw chain and provide tips for maintaining proper chain tension. We will also answer common questions about chainsaw chain tension and recommended tension levels.

Safety First: Preparing To Tighten The Chainsaw Chain

Before tightening the chainsaw chain, it’s crucial to prioritize safety. By following the necessary precautions, you can prevent accidents and ensure a smooth and efficient chain tightening process.

Power Off The Chainsaw

Ensure that the chainsaw is completely powered off before attempting to tighten the chain. This involves shutting off the engine to eliminate any potential hazards.

Engage The Chain Brake

Engage the chain brake by pulling the chain brake handle towards you. This action will secure the chain and prevent any unexpected movements during the tightening process.

Gathering The Right Tools

To tighten a chain on a chainsaw, you’ll need the right tools such as a wrench or scrench, which is a screwdriver-wrench combo. After shutting off the engine and releasing the chain brake, loosen the wingnut, lift up the guide bar, turn the adjustment wheel, tighten the wingnut, and check the chain tension.

Always double-check the chain tightness before using the chainsaw.

Identifying Your Chainsaw Model

Before you begin tightening the chain on your chainsaw, it’s important to identify the specific model you have. Each chainsaw model may have different specifications and requirements for chain tightening. Check the user manual or the manufacturer’s website for information on your particular chainsaw model. By knowing your chainsaw model, you can ensure that you gather the appropriate tools for the task.

Selecting The Appropriate Tools

Once you have identified your chainsaw model, it’s time to gather the right tools. Having the correct tools on hand will make the chain tightening process much easier and more efficient. Here are the tools you will need:

- Scwrench: This is a combination tool that serves as a screwdriver and a wrench. Most chainsaws come with a scwrench that matches the side plate nut and the tension adjustment screw size of the chainsaw. If you don’t have a scwrench, you can purchase one separately.

- Flathead screwdriver: In some cases, you may need a flathead screwdriver to adjust the tension of the chain. Check your chainsaw’s user manual to see if a flathead screwdriver is necessary for your specific model.

Having these tools readily available will ensure that you can easily and effectively tighten the chain on your chainsaw.

Loosening The Nuts

To tighten a chain on a chainsaw, you first need to loosen the nuts on the side cover of the bar. Once the cover is removed, you can adjust the tension of the chain by turning the adjustment wheel and then tighten the nuts back in place.

Remember to check the chain tension before use.

Proper Technique For Loosening

When it comes to tightening a chain on a chainsaw, one crucial step is loosening the nuts before making any adjustments. Proper technique for loosening ensures that you can easily adjust the tension and maintain the optimal performance of your chainsaw.

To begin, switch off the tool and shut off the engine. This will ensure your safety during the process. Next, release the chain brake by pulling the chain brake handle towards you. This step is essential as it allows the chain to move freely while making adjustments.

Now, it’s time to loosen the wingnut. Use the appropriate tool, such as a screwdriver or chainsaw scrench, to turn the wingnut counterclockwise. This will loosen the tension and allow you to lift up the guide bar.

With the guide bar lifted, you can now turn the adjustment wheel to adjust the chain tension. Turn the wheel clockwise to tighten the chain or counterclockwise to loosen it. Make sure to adjust the tension according to the manufacturer’s recommendations for your specific chainsaw model.

Once you have achieved the desired tension, tighten the wingnut by turning it clockwise. This will secure the guide bar and prevent any movement during operation. Lastly, let go of the guide bar tip and check the chain tension to ensure it is properly adjusted.

Precautions To Avoid Damage

While loosening the nuts may seem like a straightforward task, it’s essential to take some precautions to avoid any damage to your chainsaw. Here are a few precautions to keep in mind:

1. Use the right tool: Always use the recommended tool, such as a screwdriver or chainsaw scrench, to loosen the nuts. Using the wrong tool can lead to stripped or damaged nuts, making it difficult to tighten the chain properly.

2. Follow the manufacturer’s instructions: Each chainsaw model may have specific instructions for loosening the nuts. It’s important to refer to the manufacturer’s manual to ensure you are following the correct procedure.

3. Avoid over-tightening or over-loosening: Over-tightening the nuts can put excessive pressure on the chain, leading to premature wear and potential damage. On the other hand, over-loosening can cause the chain to slip or derail during operation. It’s crucial to find the right balance and adjust the tension within the recommended range.

4. Check for any wear or damage: Before loosening the nuts, inspect the guide bar, chain, and sprocket for any signs of wear or damage. If you notice any issues, such as a worn-out bar or damaged chain, it’s best to replace them before adjusting the tension.

By following these precautions, you can ensure a smooth and safe process of loosening the nuts and adjusting the chain tension on your chainsaw.

Remember, proper technique and precautions are essential for maintaining the performance and longevity of your chainsaw. With the nuts loosened correctly, you can proceed to make the necessary adjustments to achieve the optimal chain tension for efficient cutting.

Adjusting The Chain Tension

To tighten a chain on a chainsaw, start by switching off the tool and releasing the chain brake. Then, loosen the wingnut and lift up the guide bar before turning the adjustment wheel to achieve the desired tension. Finally, tighten the wingnut and check the chain tension to ensure it’s at the correct tightness.

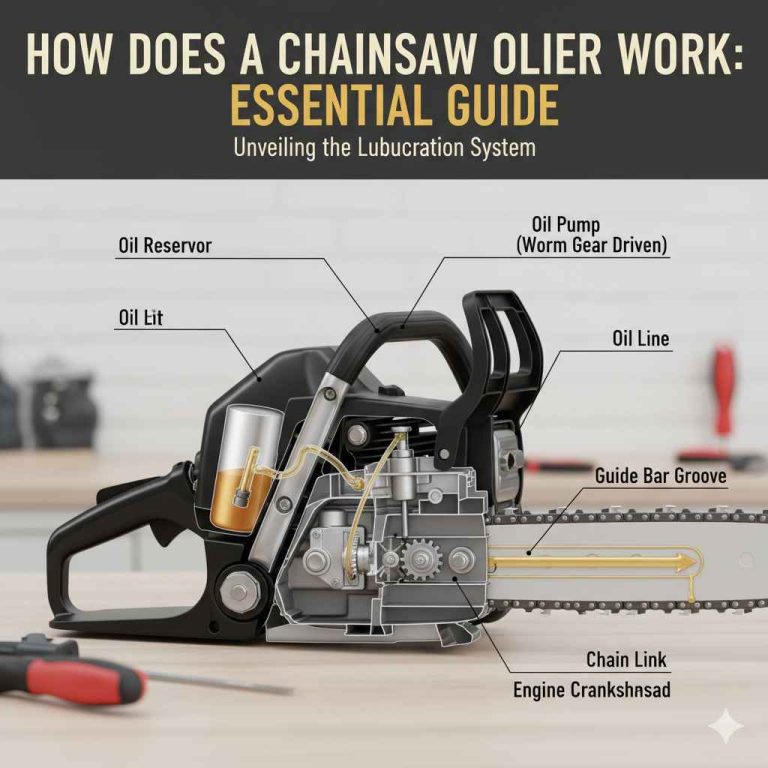

Finding the Tensioning Screw

When it comes to tightening a chainsaw chain, the first step is to locate the tensioning screw. This screw is responsible for adjusting the tension of the chain and ensuring it is neither too loose nor too tight. The tensioning screw is typically located on the side of the chainsaw, near the bar and chain. It can be easily identified by its unique design and may require the use of a specialized tool, such as a screwdriver or a chainsaw scrench.

Turning the Screw: When and How

Once you have located the tensioning screw, it’s time to adjust the chain tension. But when should you turn the screw, and how should you do it? It’s important to note that the chain should not be adjusted while the chainsaw is running or the engine is on. Always remember to shut off the engine and release the chain brake before making any adjustments.

To tighten the chain, you will need to loosen the wingnut that secures the bar cover. Use the appropriate tool, such as a screwdriver or a chainsaw scrench, to lift up the guide bar. Then, turn the adjustment wheel clockwise to move the guide bar forward, tightening the chain. Once you have achieved the desired tension, tighten the wingnut to secure the bar cover in place.

On the other hand, if the chain is too tight and needs to be loosened, follow the same steps of loosening the wingnut and lifting up the guide bar. This time, turn the adjustment wheel counterclockwise to move the guide bar backward, loosening the chain. Once you have achieved the correct tension, tighten the wingnut to secure the bar cover.

Remember to always double-check the chain tension before moving on to ensure it is at the correct tightness. A properly tensioned chain should have a slight amount of slack when pulled away from the guide bar. If the chain is too loose, it may come off during operation, while an overly tight chain can cause excessive wear on the bar and decrease cutting performance.

In conclusion, adjusting the chain tension of a chainsaw is a crucial maintenance task to ensure optimal performance and safety. By locating the tensioning screw and following the correct steps, you can easily tighten or loosen the chain to achieve the desired tension. Remember to always take the necessary precautions and refer to the manufacturer’s instructions for your specific chainsaw model.

Lifting The Guide Bar

To tighten the chain on a chainsaw, start by switching off the tool and releasing the chain brake. Then, loosen the wingnut and lift up the guide bar. Turn the adjustment wheel to achieve the desired tension, and finally, tighten the wingnut.

Check the chain tension before use.

Lifting the Guide Bar is an important step in tightening a chain on a chainsaw. It is crucial to use the Correct Lifting Method to avoid injury and ensure proper tensioning. To do this, start by shutting off the engine and releasing the chain brake by pulling the chain brake handle towards you. Next, loosen the wingnut and lift up the guide bar using the correct lifting technique.

Maintaining Position for Tensioning is the next step. It is important to keep the guide bar in the same position as when it was lifted to avoid the chain becoming too tight or too loose. While holding the guide bar, turn the adjustment wheel to tighten the chain to the appropriate tension. Once the chain is properly tensioned, tighten the wingnut and let go of the guide bar tip. Finally, check the chain tension to ensure it is correct.

Remember to always use caution when tightening a chain on a chainsaw. Shut off the engine, release the chain brake, and use the correct lifting technique to lift the guide bar. Maintain the guide bar position during tensioning and check the chain tension once finished. With these steps, you can tighten a chain on a chainsaw safely and effectively.

Tightening The Chain

To tighten the chain on a chainsaw, start by turning off the tool and releasing the chain brake. Then, use the appropriate tool to loosen the wingnut, lift up the guide bar, turn the adjustment wheel, and tighten the wingnut.

Finally, check the chain tension before using the chainsaw.

When it comes to using a chainsaw, it’s important to ensure that the chain is tightened properly. A loose chain can be dangerous and cause damage to both the chainsaw and the user, while an overly tight chain can cause excessive wear and tear. Achieving optimal tightness is key to ensuring safe and efficient operation. In this article, we’ll explore the steps involved in tightening a chainsaw chain, with a focus on avoiding over-tightening.

Achieving Optimal Tightness

To achieve optimal tightness, start by switching off the chainsaw and shutting off the engine. Release the chain brake by pulling the chain brake handle towards you. Next, loosen the wingnut and lift up the guide bar. Turn the adjustment wheel to increase or decrease the tension until the chain is at the desired tightness. Tighten the wingnut and let go of the guide bar tip. Finally, check the chain tension by pulling down on the chain. The chain should move freely but not sag from the underside of the guide bar.

Avoiding Over-tightening

Over-tightening a chainsaw chain can cause excessive wear and tear, leading to a shorter lifespan for both the chain and the chainsaw. To avoid over-tightening, it’s important to check the chain tension regularly and adjust as needed. It’s also important to use the correct tool for tightening the chain, such as a “scwrench” that matches the side plate nut and tension adjustment screw size. When tightening the chain, remember to double check the tightness before moving on to using the chainsaw.

Securing The Bar And Chain

To tighten a chain on a chainsaw, follow these steps: 1) Switch off the tool and release the chain brake. 2) Loosen the wingnut and lift up the guide bar. 3) Turn the adjustment wheel and tighten the wingnut. 4) Let go of the guide bar tip and check the chain tension.

Use the appropriate tool provided with your chainsaw to make the necessary adjustments.

Re-tightening The Nuts

When it comes to securing the bar and chain on your chainsaw, one important step is re-tightening the nuts. These nuts are responsible for holding the bar and chain in place, ensuring they stay secure during operation. Over time, the vibrations and movements of the chainsaw can cause these nuts to loosen, which can affect the performance and safety of the chainsaw. Therefore, it is crucial to regularly check and re-tighten the nuts to maintain optimal performance.

To re-tighten the nuts, start by locating the bar nuts on the side cover of the chainsaw. Using the appropriate tool, such as a scrench (a combination screwdriver and wrench), loosen the nuts slightly to allow for adjustment. Make sure not to loosen them too much, as this could lead to the bar and chain becoming detached. Once loosened, you can proceed to the next step of ensuring all components are secure.

Ensuring All Components Are Secure

Ensuring that all components of your chainsaw are secure is essential for safe and efficient operation. In addition to re-tightening the nuts, there are a few other components to check and secure.

First, make sure the chain brake is released by pulling the chain brake handle towards you. This will allow for easier adjustment and tightening of the chain.

Next, lift up the guide bar to create some slack in the chain. This will make it easier to adjust the tension and ensure all components are properly aligned.

Then, locate the adjustment wheel or screw, which is used to tighten or loosen the chain. Turn the adjustment wheel clockwise to tighten the chain and counterclockwise to loosen it. Remember to make small adjustments and periodically check the tension to avoid overtightening or loosening the chain.

Once you have achieved the desired tension, tighten the bar nuts using the scrench. Ensure they are securely fastened, but be careful not to overtighten, as this can put unnecessary strain on the chainsaw.

Finally, let go of the guide bar tip and check the chain tension by pulling it away from the guide bar. The chain should have a slight amount of play, allowing it to move freely but without sagging. If the tension is too loose or too tight, repeat the steps above until you achieve the correct tension.

By re-tightening the nuts and ensuring all components are secure, you can maintain the proper tension of the chain on your chainsaw. This will not only improve the performance and efficiency of the chainsaw but also ensure your safety during operation. Regularly checking and securing these components is an important part of chainsaw maintenance and should be done before each use or as needed.

Remember, a properly tightened chain is crucial for safe and effective chainsaw operation. By following these steps and regularly checking and securing the bar and chain, you can ensure your chainsaw is ready to tackle any cutting task with ease and precision.

Final Checks And Maintenance

To tighten a chain on a chainsaw, follow these steps: switch off the tool, release the chain brake, loosen the wingnut, lift up the guide bar, turn the adjustment wheel, tighten the wingnut, and check the chain tension. Make sure to use the correct tool provided by the chainsaw manufacturer for tightening the chain.

Performing The Snap Test

Before you wrap up the process of tightening your chainsaw chain, it’s essential to perform a snap test to ensure proper tension. This test will help you determine if the chain is securely tightened and ready for use. Follow these steps:

- Switch off the chainsaw and allow the engine to shut off completely.

- Release the chain brake by pulling the chain brake handle towards you.

- Loosen the wingnut that you tightened earlier to adjust the tension.

- Lift up the guide bar and turn the adjustment wheel clockwise to tighten the chain.

- Tighten the wingnut firmly to secure the adjustment.

- Let go of the guide bar tip and check the chain tension.

While performing the snap test, the chain should snap back into place without sagging. If the chain remains loose or saggy, repeat the process of tightening until you achieve the correct tension.

Routine Chain Maintenance Tips

In addition to tightening the chain, it’s crucial to perform routine maintenance to ensure the longevity and optimal performance of your chainsaw. Here are some maintenance tips to keep in mind:

- Regularly inspect the chain for signs of wear and damage. Replace the chain if it is excessively worn or damaged.

- Keep the chain clean by removing any debris or sawdust buildup after each use.

- Properly lubricate the chain with chainsaw bar oil to reduce friction and prevent overheating.

- Check the tension of the chain before each use and adjust as necessary.

- Inspect and tighten the guide bar nuts to ensure they are secure.

- Sharpen the chain regularly to maintain its cutting efficiency.

By following these routine maintenance tips, you can ensure that your chainsaw chain remains in optimal condition and performs at its best.

Troubleshooting Common Issues

To tighten a chain on a chainsaw, follow these steps: switch off the tool, release the chain brake, loosen the wingnut, lift up the guide bar, turn the adjustment wheel, tighten the wingnut, and check the chain tension. Use the provided “scwrench” tool or a screwdriver to make the necessary adjustments.

It is important to ensure the chain is properly tightened for safe and efficient operation.

Dealing With A Slipping Chain

If you’re dealing with a slipping chain on your chainsaw, don’t worry, it’s a common issue that can be easily fixed. Here’s what you need to do:

- Switch off the tool and shut off the engine to ensure your safety.

- Release the chain brake by pulling the chain brake handle towards you.

- Loosen the wingnut using a screwdriver or a chainsaw scrench.

- Lift up the guide bar and turn the adjustment wheel to tighten the chain.

- Tighten the wingnut securely to hold the chain in place.

- Let go of the guide bar tip and check the chain tension.

If the chain is still slipping, you may need to repeat the process and tighten the chain even further. Remember to check the manufacturer’s guidelines for the correct chain tension.

Addressing Over-tightened Chains

Over-tightened chains can also cause problems and affect the performance of your chainsaw. Here’s how to address this issue:

- Switch off the tool and shut off the engine.

- Release the chain brake by pulling the chain brake handle towards you.

- Loosen the wingnut using a screwdriver or a chainsaw scrench.

- Insert a screwdriver or chainsaw scrench into the Intenz slot of the guide bar.

- Turn the screwdriver or scrench clockwise to move the guide bar forward and loosen the chain tension.

- Perform a “snap” test by pulling the chain away from the guide bar to ensure the proper tension.

Make sure not to overtighten the chain, as it can put unnecessary strain on the chainsaw and cause damage. Always follow the manufacturer’s guidelines for chain tension.

Understanding Chain Tension Dynamics

How Chain Tension Affects Cutting

Proper chain tension is crucial for the efficient and safe operation of a chainsaw. If the chain is too loose, it can derail or even come off the guide bar during operation, posing a serious safety hazard. On the other hand, an overly tight chain can lead to excessive wear on the bar and the engine, reducing the chainsaw’s overall lifespan.

Reading The Signs Of Incorrect Tension

Signs of incorrect chain tension include excessive vibration, uneven cutting, and visible wear on the guide bar and chain. Additionally, a loose chain may produce a rattling sound during operation, while an overly tight chain can cause the engine to overheat.

When To Replace The Chainsaw Chain

If your chainsaw chain is showing signs of wear and tear, it’s crucial to consider replacing it to ensure safe and efficient operation. Over time, chainsaw chains can become dull, damaged, or stretched, impacting their cutting performance. Regularly inspecting the chain for wear and knowing when to replace it can help maintain the chainsaw’s effectiveness and prevent potential safety hazards.

Signs Of Wear And Tear

Inspect the chainsaw chain for signs of wear and tear, such as dull or damaged cutting teeth, excessive heat discoloration, or elongation of the chain links. If you notice significant wear, including chipped or broken cutting teeth, it’s advisable to replace the chain promptly to avoid compromising cutting efficiency and safety.

Choosing The Right Replacement Chain

When selecting a replacement chain, consider the specific chainsaw model, the bar length, and the chain pitch to ensure compatibility. Opt for a high-quality replacement chain that matches the manufacturer’s specifications to maintain optimal cutting performance and safety. Additionally, follow the manufacturer’s guidelines for proper installation and tensioning of the new chain.

Expert Tips For Optimal Performance

To tighten a chain on a chainsaw, first shut off the tool and release the chain brake. Then, loosen the wingnut and lift up the guide bar before turning the adjustment wheel to increase tension. Finally, tighten the wingnut and check the chain tension with a “snap” test.

Use the included scwrench or screwdriver to make adjustments.

Best Practices From Professionals

When it comes to ensuring optimal performance of your chainsaw, it is crucial to follow the best practices recommended by professionals. Proper chain tension is essential for safe and efficient operation of the chainsaw. Here are some expert tips to help you tighten the chain and maintain your chainsaw for long-term performance.

Long-term Chainsaw Care

Regular maintenance and care are vital for the longevity of your chainsaw. By following these expert tips for optimal performance, you can ensure that your chainsaw operates at its best for a long time.

How To Tighten A Chain On A Chainsaw

When it comes to tightening the chain on a chainsaw, it is important to use the appropriate tools and follow the correct steps. Here’s a simple guide to help you achieve the optimal chain tension for your chainsaw:

- Switch off the tool.

- Release the chain brake by pulling the chain brake handle towards you.

- Loosen the wingnut.

- Lift up the guide bar.

- Turn the adjustment wheel to tighten the chain.

- Tighten the wingnut.

- Let go of the guide bar tip.

- Check the chain tension to ensure it is at the correct tightness.

Most chainsaws come with a “scwrench” (screwdriver/wrench) that matches their side plate nut and tension adjustment screw size. This tool is used to tighten the chain and ensure it is at the correct tension for optimal performance.

What Happens If A Chainsaw Chain Is Too Loose?

If the chainsaw chain is too loose, it can pose a safety hazard and affect the performance of the chainsaw. A loose chain can result in kickback and reduced cutting efficiency. Therefore, it is important to regularly check and adjust the chain tension to prevent these issues.

Proper chain tension is essential for safe and efficient operation of the chainsaw. By following these expert tips and best practices from professionals, you can ensure that your chainsaw operates at its best for a long time.

Frequently Asked Questions

How To Properly Tighten A Chainsaw Chain?

To properly tighten a chainsaw chain, start by switching off the tool and releasing the chain brake. Then, loosen the wingnut and lift up the guide bar. Turn the adjustment wheel until the chain is tight and then tighten the wingnut.

Finally, let go of the guide bar tip and check the chain tension. Use the chainsaw’s provided wrench to adjust the chain tension.

What Tool Do You Use To Tighten The Chain On A Chainsaw?

To tighten the chain on a chainsaw, use the “scwrench” (screwdriver/wrench) that matches the side plate nut and tension adjustment screw size. Insert the scwrench into the tension adjustment screw and turn it clockwise to tighten the chain. Make sure to check the chain tension before moving forward.

What Happens If A Chainsaw Chain Is Too Loose?

If a chainsaw chain is too loose, it can pose several risks and issues. The chain may come off the guide bar, which can result in accidents or damage to the chainsaw. Additionally, a loose chain will not cut efficiently, leading to poor performance and a waste of time and effort.

It is important to regularly check and adjust the chain tension to ensure safe and effective operation of the chainsaw.

How Do You Tighten A Chain On A Stihl Chainsaw?

To tighten a chain on a Stihl chainsaw, follow these steps: 1. Switch off the tool and shut off the engine. 2. Release the chain brake by pulling the chain brake handle towards you. 3. Loosen the wingnut. 4. Lift up the guide bar.

5. Turn the adjustment wheel to tighten the chain. 6. Tighten the wingnut. 7. Let go of the guide bar tip. 8. Check the chain tension. Most chainsaws come with a “scwrench” tool that matches the side plate nut and tension adjustment screw size.

Conclusion

Maintaining the proper tension of your chainsaw chain is crucial for safe and efficient operation. Regularly checking and adjusting the chain tension can prevent accidents and extend the life of your chainsaw. Follow the manufacturer’s guidelines and use the appropriate tools for tightening the chain to ensure optimal performance.